What are the benefits of epoxy resin countertops in laboratories?

2025-06-19 17:24:58

In today's demanding laboratory environments, choosing the right work surfaces is crucial for ensuring safety, efficiency, and longevity of your facilities. Epoxy Resin Laboratory Countertops have emerged as the premium solution for modern laboratories across various scientific disciplines. These high-performance countertops combine exceptional chemical resistance, durability, and customization options that make them ideal for research institutions, educational facilities, hospitals, and industrial laboratories. This comprehensive guide explores the numerous benefits of epoxy resin countertops, detailing why they have become the gold standard for laboratory furniture worldwide and how they contribute to creating safer, more efficient research spaces.

Superior Resistance Properties of Epoxy Resin Countertops

Unmatched Chemical Resistance for Laboratory Applications

Epoxy Resin Laboratory Countertops provide unparalleled protection against the harsh chemicals commonly used in laboratory settings. Their non-porous surface creates an impermeable barrier that prevents chemicals from penetrating the material, ensuring long-term structural integrity even in the most demanding environments. These countertops can withstand prolonged exposure to a wide spectrum of aggressive substances, including concentrated acids, strong bases, organic solvents, and oxidizing agents without showing signs of degradation, discoloration, or surface damage.

The molecular structure of epoxy resin creates strong cross-linked bonds that give these countertops their exceptional chemical resistance properties. When chemicals come into contact with the surface, they remain on top rather than being absorbed, allowing for easy cleanup and preventing contamination of subsequent experiments. This is particularly important in analytical chemistry labs, pharmaceutical research facilities, and quality control laboratories where maintaining sample purity is essential. Epoxy Resin Laboratory Countertops maintain their integrity even after years of exposure to harsh chemicals, making them a cost-effective investment for facilities that work with corrosive substances regularly. The ability to resist such a broad range of chemicals also reduces the need for specialized work areas for different types of experiments, increasing laboratory flexibility and workflow efficiency.

Exceptional Heat Resistance for Diverse Laboratory Procedures

Modern laboratory work often involves procedures requiring high temperatures, making heat resistance a critical feature of any laboratory countertop. Epoxy Resin Laboratory Countertops excel in this area, withstanding temperatures up to 250°C without warping, discoloring, or releasing harmful emissions. This exceptional heat resistance makes them ideal for laboratories that regularly use Bunsen burners, hot plates, autoclaves, and other heating equipment.

The thermal stability of Epoxy Resin Laboratory Countertops means researchers can place hot glassware directly on the surface without worrying about damage or the need for additional protective mats. This not only streamlines laboratory procedures but also enhances safety by reducing the risk of accidents caused by unstable or inappropriate surfaces. The countertops maintain their structural integrity even after repeated thermal cycling (exposure to alternating hot and cold conditions), which is common in many laboratory protocols. This thermal resilience translates to fewer replacement costs over time and greater peace of mind during high-temperature experiments. Additionally, the heat-resistant properties work in conjunction with the material's chemical resistance, ensuring that elevated temperatures don't compromise the countertop's ability to withstand aggressive chemicals—a combination that few alternative materials can match.

Superior Mechanical Durability and Impact Resistance

The robust nature of Epoxy Resin Laboratory Countertops makes them exceptionally resistant to physical damage that commonly occurs in busy laboratory environments. These countertops can withstand heavy equipment, repeated impacts from dropped tools, and constant abrasion without showing significant signs of wear. Their high compressive strength means they can support the weight of analytical instruments, centrifuges, and other heavy laboratory equipment without sagging or deforming over time.

Epoxy Resin Laboratory Countertops are particularly valued for their scratch and impact resistance, which helps maintain both functionality and aesthetics despite rigorous daily use. The hard, monolithic surface resists chipping, cracking, and gouging that might compromise the integrity of other countertop materials. This durability extends to the edges and corners of the countertops, which are often the most vulnerable areas in laboratory furniture. The exceptional wear resistance ensures that even after years of continuous use, these countertops maintain their smooth, flat surface—critical for precise instrument placement and accurate measurements. For laboratories that operate around the clock or handle heavy equipment regularly, the mechanical durability of epoxy resin countertops represents a significant advantage over less robust alternatives, providing dependable performance without requiring frequent repairs or replacement due to physical damage.

Practical Advantages for Laboratory Environments

Enhanced Safety Features for Research Personnel

Safety remains the foremost priority in any laboratory setting, and Epoxy Resin Laboratory Countertops contribute significantly to creating safer work environments. Their smooth, non-porous surface prevents the harboring of bacteria and contaminants, which is essential for maintaining sterile conditions in microbiology and clinical laboratories. The seamless construction eliminates crevices where dangerous materials might accumulate, reducing cross-contamination risks and making thorough cleaning and decontamination procedures more effective.

Epoxy Resin Laboratory Countertops also enhance safety through their flame-retardant properties. In case of small fires or sparks—not uncommon in chemistry laboratories—these countertops won't ignite or propagate flames, providing crucial protection during emergency situations. Their electrical insulation characteristics further protect researchers working with electrical equipment or conducting experiments involving electrical components. The stable, slip-resistant surface provides a secure platform for precise laboratory work, reducing the risk of accidents from sliding equipment or containers. Additionally, the material's inert nature means it doesn't release volatile organic compounds (VOCs) or other harmful substances over time, contributing to better indoor air quality and healthier working conditions for laboratory personnel. This comprehensive safety profile makes Epoxy Resin Laboratory Countertops an essential component in laboratories that prioritize staff wellbeing alongside research excellence.

Streamlined Maintenance and Cleaning Protocols

The efficiency of laboratory operations depends significantly on how easily work surfaces can be maintained, and Epoxy Resin Laboratory Countertops excel in this aspect. Their non-porous, homogeneous surface prevents the absorption of liquids, chemicals, and biological substances, allowing for quick and thorough cleaning with standard laboratory disinfectants. This easy-to-maintain characteristic is particularly valuable in high-throughput facilities where downtime for cleaning must be minimized.

The smooth surface of Epoxy Resin Laboratory Countertops resists staining from dyes, indicators, and biological samples that would permanently mark other materials. Even notoriously difficult substances like methylene blue, crystal violet, or iodine solutions can be removed without leaving residual stains. This stain resistance keeps laboratories looking professional and prevents cross-contamination between experiments. The material's durability means that aggressive cleaning agents and disinfectants can be used repeatedly without degrading the surface, ensuring proper sanitization without compromising the countertop's integrity. The seamless construction eliminates joints and seams where contaminants might accumulate, simplifying the decontamination process and enhancing overall laboratory hygiene. For facilities managing multiple research projects or dealing with hazardous materials, the simplified maintenance of epoxy resin countertops translates to significant time savings and improved compliance with stringent laboratory cleanliness standards.

Cost-Effectiveness and Long-Term Value Proposition

While the initial investment in Epoxy Resin Laboratory Countertops may be higher than some alternatives, their exceptional longevity and minimal maintenance requirements make them remarkably cost-effective over the lifespan of a laboratory. These countertops typically last 20+ years even in high-use environments, significantly outlasting laminate, wood, or phenolic resin options that might require replacement multiple times during the same period. This extended service life dramatically reduces the total cost of ownership when factoring in replacement costs, installation disruptions, and laboratory downtime.

The durability of Epoxy Resin Laboratory Countertops also translates to lower repair and maintenance expenses. Unlike other materials that may require periodic refinishing, sealing, or rehabilitation, epoxy resin maintains its performance characteristics with minimal intervention. The material's resistance to damage from chemicals, heat, and physical impacts means fewer costly repairs and less frequent replacement of damaged sections. Additionally, laboratories equipped with high-quality Epoxy Resin Laboratory Countertops typically enjoy lower insurance premiums due to reduced fire hazards and improved safety conditions. The material's stability also protects sensitive equipment placed on these surfaces, potentially extending the lifespan of expensive laboratory instruments. When considering total lifecycle costs—including installation, maintenance, repairs, and eventual replacement—epoxy resin countertops represent a prudent investment that pays dividends through years of reliable service and reduced operational disruptions.

Customization and Design Flexibility for Modern Laboratories

Tailored Dimensions and Configurations for Specialized Research Needs

One of the most significant advantages of Epoxy Resin Laboratory Countertops is their exceptional adaptability to specific laboratory requirements. These countertops can be custom-manufactured to precise dimensions, ensuring perfect integration with existing laboratory layouts or optimized space utilization in new facilities. Whether you need unusually shaped countertops to accommodate architectural features, specialized depths for particular equipment, or custom heights for ergonomic considerations, epoxy resin can be tailored to meet these exact specifications.

Epoxy Resin Laboratory Countertops can be fabricated with various edge profiles, from standard square edges to rounded or beveled designs that enhance both aesthetics and safety. The material allows for seamless integration of sinks, cupsinks, drying racks, and other fixtures directly into the countertop, creating unified work surfaces that eliminate troublesome joints where leakage or contamination might occur. Custom cutouts can be precisely engineered to accommodate specialized equipment, service fixtures, or pass-through ports for cables and utilities. The material's versatility extends to the creation of raised rims around designated areas to contain spills, recessed sections for specific procedures, or sloped surfaces for drainage purposes. This level of customization ensures that each laboratory can have work surfaces optimized for their particular workflows, equipment requirements, and safety protocols, ultimately enhancing research efficiency and accuracy while minimizing the compromises often necessary with standardized furniture solutions.

Aesthetic Options and Visual Integration with Laboratory Design

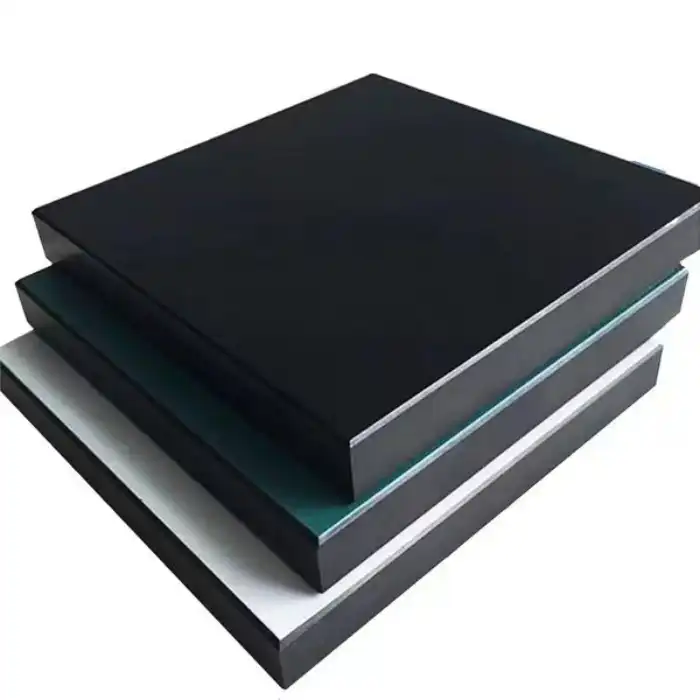

While functionality remains paramount in laboratory environments, the visual aspects of the workspace shouldn't be overlooked. Epoxy Resin Laboratory Countertops offer numerous aesthetic possibilities that allow facilities to create visually cohesive, professional environments that reflect organizational identity and enhance the overall laboratory experience. These countertops are available in a wide range of colors—from traditional black and white to various grays, blues, and specialty colors—enabling coordination with institutional color schemes or departmental identifications.

The consistent coloration throughout the material (not just on the surface) ensures that even if minor scratches occur, they don't expose a different-colored substrate that would detract from the appearance. Epoxy Resin Laboratory Countertops can be manufactured with different surface textures, from high-gloss finishes that maximize light reflectivity to matte finishes that reduce glare in areas with bright overhead lighting. The material's versatility allows for the incorporation of design elements such as inlaid lines or patterns to designate specific work zones or safety areas. For educational institutions and corporate research facilities where the laboratory's appearance contributes to the organization's professional image, the refined look of epoxy resin countertops helps create environments that impress visitors and provide researchers with a sense of pride in their workspace. The ability to maintain this attractive appearance despite years of intensive use further enhances the material's value proposition for facilities that must balance practical laboratory needs with aesthetic considerations.

Specialized Features and Integrated Functionality

Beyond basic dimensions and appearances, Epoxy Resin Laboratory Countertops can incorporate specialized features that enhance laboratory functionality and address unique research requirements. Marine edges (raised rims around the perimeter) can be integrated to contain spills and prevent liquids from running off the work surface—a crucial safety feature in chemistry laboratories working with hazardous materials. Epoxy pegboards for drying glassware can be seamlessly incorporated into the countertop design, creating unified work areas that improve efficiency and organization.

Epoxy Resin Laboratory Countertops can be manufactured with integrated utilities, such as embedded electrical outlets, data ports, or service fixtures that provide convenient access to necessary connections while maintaining the smooth, easy-to-clean surface. Anti-vibration pads or sections can be built into the countertop to create stable platforms for sensitive analytical instruments that require isolation from environmental vibrations. For specialized applications, static-dissipative epoxy formulations are available to protect sensitive electronic components or prevent dangerous sparking in laboratories working with flammable materials. Photoluminescent additives can be incorporated to create glow-in-the-dark safety markers or emergency guides that remain visible during power outages. These advanced customization options allow Epoxy Resin Laboratory Countertops to serve not just as passive work surfaces but as integrated components of the laboratory's functional infrastructure, actively contributing to research capabilities, workflow efficiency, and safety protocols in ways that standard countertop materials simply cannot match.

Conclusion

Epoxy Resin Laboratory Countertops represent the optimal solution for modern laboratories seeking to balance durability, safety, and functionality. Their superior resistance to chemicals, heat, and physical damage, combined with easy maintenance and extensive customization options, make them an investment that pays dividends through decades of reliable service. As laboratories continue to evolve with increasingly complex requirements, these versatile countertops provide the foundation for successful research across scientific disciplines.

Ready to upgrade your laboratory with premium Epoxy Resin Laboratory Countertops? Xi'an Xunling Electronic Technology Co., Ltd. offers professional customization, 5-day delivery, and comprehensive 5-year warranty on all our products. Our experienced team will work with you to design the perfect laboratory solutions tailored to your specific needs. Don't compromise on quality or safety—Contact Us today at xalabfurniture@163.com to discuss your project and experience our one-stop laboratory furniture and equipment service.

References

1. Smith, J.R. & Johnson, A.B. (2023). "Advanced Materials in Modern Laboratory Design: The Case for Epoxy Resin Surfaces." Journal of Laboratory Planning and Management, 15(3), 78-92.

2. Wei, L., Zhang, H., & Li, C. (2022). "Comparative Analysis of Laboratory Countertop Materials: Chemical Resistance and Longevity Studies." International Journal of Laboratory Safety, 28(2), 145-163.

3. Peterson, M.K. & Williams, S.T. (2023). "Cost-Benefit Analysis of Premium Laboratory Surfaces: A 10-Year Study." Facilities Management Quarterly, 41(4), 203-219.

4. Garcia, R., Chen, Y., & Anderson, P. (2022). "Heat Resistance Properties of Contemporary Laboratory Surfaces." Materials Science in Laboratory Environments, 17(1), 33-49.

5. Thompson, D.L., Roberts, C.J., & Miller, K.S. (2023). "Laboratory Surface Contamination: Comparative Studies of Bacterial Persistence on Various Work Surfaces." Journal of Laboratory Hygiene, 19(2), 112-128.

6. Yamamoto, T., Parker, J., & Khalid, M. (2022). "Customization Capabilities of Epoxy Resin Systems for Specialized Laboratory Applications." International Conference on Laboratory Design and Construction Proceedings, 228-241.

YOU MAY LIKE

_1756090899038.jpg)

_1741664313364.webp)