What are the benefits of using a fume extraction hood?

2025-06-20 15:44:19

In modern laboratory and industrial settings, safety and air quality are paramount concerns for both personnel and experimental integrity. Fume extraction hoods play a crucial role in maintaining these standards by effectively removing hazardous vapors, gases, and particulates from the workspace. These specialized ventilation devices create controlled airflow that captures and exhausts potentially harmful substances before they can contaminate the breathing zone of laboratory workers or spread throughout the facility. The benefits of using a fume extraction hood extend far beyond basic safety, encompassing improved health outcomes, enhanced experimental accuracy, regulatory compliance, and even energy efficiency when properly designed and utilized.

Enhanced Safety and Health Protection in Laboratory Environments

Protection from Hazardous Chemical Exposures

The primary function of a fume extraction hood is to safeguard laboratory personnel from dangerous chemical exposures. When working with volatile organic compounds, corrosive substances, or toxic materials, researchers face significant health risks without proper containment. A quality fume extraction hood creates a negative pressure environment that draws hazardous vapors away from the operator's breathing zone and expels them through filtration systems or external ventilation. This protective barrier significantly reduces inhalation exposure to harmful substances that could otherwise cause acute symptoms like respiratory irritation, headaches, and nausea, or lead to chronic conditions with prolonged exposure. Modern fume extraction hoods feature advanced airflow management that maintains consistent protection even when researchers must manipulate equipment within the hood workspace. Through proper face velocity maintenance (typically 80-120 feet per minute), these engineering controls effectively prevent harmful fumes from escaping into the laboratory atmosphere, creating a first line of defense against chemical hazards that might otherwise compromise worker health and safety.

Prevention of Fire and Explosion Hazards

Many laboratory procedures involve flammable solvents, combustible materials, or potentially explosive chemical combinations that pose serious fire risks. A properly designed fume extraction hood significantly mitigates these dangers through several protective mechanisms. By continuously removing flammable vapors as they're generated, the hood prevents the buildup of combustible atmospheres within the workspace. This constant dilution and removal process keeps vapor concentrations well below their Lower Explosive Limit (LEL), dramatically reducing ignition potential. Additionally, fume extraction hoods designed for high-risk applications often incorporate explosion-proof features such as reinforced construction, specialized electrical components, and automatic fire suppression systems. The airflow management within these hoods also helps contain any small fires that might occur during experiments, preventing their spread to the broader laboratory space. For facilities working with particularly hazardous materials, specialized fume extraction hoods with perchloric acid washing systems or acid-resistant linings provide additional layers of protection against specific chemical threats, ensuring that even the most volatile substances can be handled with appropriate safety margins.

Reduction of Biological Contamination Risks

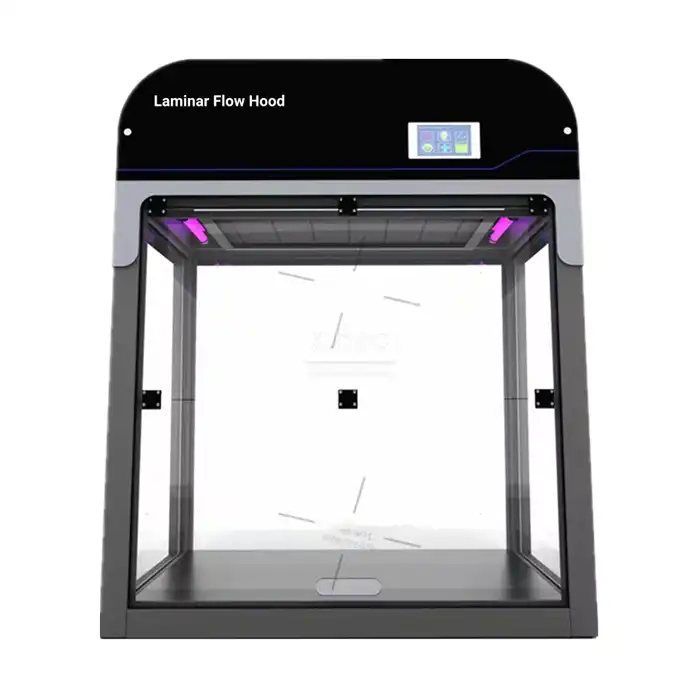

Beyond chemical hazards, fume extraction hoods serve a vital role in containing biological contaminants and preventing cross-contamination in research environments. In microbiology, virology, and clinical laboratories, specialized biological safety fume extraction hoods create a sterile work environment that protects both the operator and the experimental materials. These hoods utilize high-efficiency particulate air (HEPA) filtration systems that can capture airborne pathogens, spores, and other microbiological contaminants with an efficiency of 99.97% for particles as small as 0.3 microns. The directional airflow within these specialized fume extraction hoods creates a protective barrier that prevents the escape of potentially infectious materials while simultaneously protecting samples from external contamination. For facilities working with particularly hazardous biological agents, hoods can be configured with additional containment features including negative pressure monitoring, sealed construction, and ultraviolet germicidal irradiation systems. This comprehensive approach to biological containment makes fume extraction hoods indispensable in pharmaceutical manufacturing, vaccine development, and clinical diagnostics, where product purity and personnel safety depend on rigorous contamination control protocols.

Improved Laboratory Performance and Efficiency

Enhanced Experimental Accuracy and Reproducibility

The controlled environment provided by a fume extraction hood significantly improves experimental precision and reproducibility across various scientific disciplines. By eliminating airborne contamination and creating consistent working conditions, these hoods help researchers achieve more reliable results. In analytical chemistry applications, the clean air environment within a fume extraction hood prevents dust particles, moisture, and other atmospheric contaminants from interfering with sensitive measurements, chromatographic separations, or spectroscopic analyses. This level of environmental control is particularly crucial for trace analysis work where even minimal contamination can compromise results. The stable temperature and humidity conditions maintained within modern fume extraction hoods further enhance experimental consistency by eliminating variables that might otherwise affect reaction kinetics, crystallization processes, or material properties. For research requiring precise weight measurements or handling hygroscopic materials, the protection from ambient moisture fluctuations provided by a fume extraction hood is invaluable. Additionally, the physical barrier and negative pressure containment prevent cross-contamination between different experiments being conducted in the same laboratory, allowing multiple protocols to progress simultaneously without risk of interference, ultimately increasing both the quality and quantity of research output.

Workspace Optimization and Equipment Protection

A well-designed fume extraction hood serves as more than just a safety device—it becomes an optimized workspace that enhances laboratory productivity and protects valuable equipment. Modern fume extraction hoods feature customizable interiors with integrated electrical outlets, service fixtures, and specialized mounting systems that create an ergonomic and efficient work environment. This thoughtful design allows researchers to arrange apparatus and instrumentation in configurations that maximize workflow efficiency while maintaining proper airflow patterns. The protective environment within the hood also extends equipment lifespan by shielding sensitive instruments from corrosive vapors that might otherwise cause premature deterioration. For facilities using advanced analytical equipment like mass spectrometers, chromatographs, or electron microscopes, specialized low-flow fume extraction hoods provide the necessary protection while minimizing vibration and turbulence that could affect instrument performance. Additionally, fume extraction hoods with integrated storage capabilities allow frequently used reagents and tools to be safely maintained within the containment area, reducing the need for repeated entry and exit from the protected space. This comprehensive approach to workspace design transforms the fume extraction hood from a simple safety device into a complete laboratory workstation that enhances both safety and research productivity.

Energy Conservation and Sustainable Laboratory Practices

The latest generation of fume extraction hoods incorporates innovative design features that significantly reduce energy consumption while maintaining optimal safety performance. Traditional Fume Hoods consume substantial energy by exhausting conditioned laboratory air, but modern variable air volume (VAV) fume extraction hood systems dynamically adjust exhaust rates based on actual usage patterns and sash position. This intelligent approach to ventilation can reduce energy consumption by up to 70% compared to conventional constant air volume systems. Some advanced fume extraction hood models incorporate heat recovery systems that capture thermal energy from exhaust air and use it to pre-condition incoming air, further reducing HVAC load. Additionally, high-performance fume extraction hoods with improved aerodynamics maintain effective containment at lower face velocities, reducing the overall air volume that must be exhausted and treated. Energy-efficient LED lighting systems integrated into contemporary fume extraction hoods provide superior illumination while consuming significantly less power than traditional fluorescent fixtures. For laboratories pursuing green certification or sustainability goals, these energy-efficient fume extraction hoods contribute substantially toward reduced carbon footprint and operational costs. By implementing automated sash closing systems and occupancy sensors, modern fume extraction hoods further optimize energy usage by reducing airflow when the hood is not actively being used, striking the perfect balance between safety requirements and environmental responsibility.

Regulatory Compliance and Institutional Benefits

Meeting Occupational Safety and Health Standards

Implementing proper fume extraction hood systems is essential for laboratory facilities to achieve compliance with stringent occupational safety regulations worldwide. Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States establish specific requirements for handling hazardous materials, including provisions for appropriate engineering controls like fume extraction hoods. These regulations typically mandate regular performance testing, certification, and maintenance of fume extraction hood systems to ensure they continue to provide adequate protection. Modern fume extraction hoods are designed to meet or exceed these regulatory standards, incorporating features like airflow monitoring systems that provide continuous verification of proper operation. These monitoring capabilities allow facilities to maintain detailed documentation of hood performance for compliance inspections and internal safety audits. Beyond basic regulatory requirements, advanced fume extraction hoods often include automated alarm systems that immediately alert operators to potential ventilation failures or containment breaches, enabling prompt corrective action before safety is compromised. For laboratories working with particularly hazardous substances, specialized fume extraction hoods with enhanced containment features ensure compliance with stricter regulatory thresholds applicable to carcinogens, reproductive toxins, or highly reactive compounds. By investing in properly designed and maintained fume extraction hood systems, institutions demonstrate their commitment to workforce protection while avoiding costly fines and liability issues that could result from regulatory non-compliance.

Reduction in Workplace Insurance Premiums and Liability

The implementation of comprehensive fume extraction hood systems represents a significant risk mitigation strategy that can positively impact an institution's insurance costs and legal exposure. Insurance providers recognize proper engineering controls as evidence of proactive risk management, often resulting in reduced premium rates for facilities with well-maintained fume extraction hood infrastructure. These insurance benefits stem from the documented effectiveness of fume extraction hoods in preventing workplace injuries and chemical exposure incidents that might otherwise lead to costly claims. Beyond direct insurance savings, properly functioning fume extraction hoods help institutions avoid the substantial financial impact of workplace injury litigation, regulatory penalties, and reputational damage that can result from safety failures. For academic institutions and research facilities, the demonstration of robust safety protocols through proper fume extraction hood implementation also strengthens their position in grant applications and research partnerships where safety track records are increasingly scrutinized. The documentation generated through regular fume extraction hood certification and testing creates a defensible safety record that demonstrates institutional due diligence in protecting personnel. Additionally, modern fume extraction hoods with advanced monitoring capabilities provide real-time performance data that can be integrated into facility management systems, creating comprehensive safety documentation that further strengthens an institution's risk management profile and may qualify them for enhanced insurance programs specifically designed for well-managed laboratory facilities.

Supporting Certification and Accreditation Requirements

For many specialized laboratory facilities, maintaining industry certifications and accreditations is essential for operational legitimacy and competitive positioning. Properly implemented fume extraction hood systems play a crucial role in satisfying the stringent safety requirements integral to these certification programs. Organizations such as the College of American Pathologists (CAP), the International Organization for Standardization (ISO), and various industry-specific accreditation bodies include specific criteria regarding chemical exposure controls and ventilation systems in their assessment protocols. A laboratory equipped with professionally installed and regularly certified fume extraction hoods can more readily achieve these accreditations, opening doors to specialized testing contracts, research funding, and partnership opportunities. The documentation generated through regular fume extraction hood performance testing provides essential evidence for accreditation inspections, demonstrating consistent compliance with safety standards. For pharmaceutical and medical device manufacturing facilities operating under Good Manufacturing Practice (GMP) regulations, specialized fume extraction hoods with enhanced documentation features help maintain the rigorous audit trail required for regulatory approval. Educational institutions seeking programmatic accreditation for their science departments similarly benefit from properly implemented fume extraction hood systems that demonstrate institutional commitment to student and faculty safety. By investing in high-quality fume extraction hoods with proper certification protocols, organizations create a foundation for achieving and maintaining the accreditations that distinguish leading facilities in competitive industries where safety and quality standards are paramount considerations for clients, partners, and regulatory authorities.

Conclusion

Fume extraction hoods represent an essential investment in laboratory safety, productivity, and regulatory compliance. These sophisticated engineering controls provide critical protection from chemical, fire, and biological hazards while simultaneously enhancing experimental accuracy and operational efficiency. From energy conservation to insurance cost reduction, the benefits of properly implemented fume extraction hood systems extend far beyond basic safety considerations to impact an institution's overall performance and sustainability.

Ready to experience these benefits in your laboratory? Xi'an Xunling Electronic Technology Co., Ltd. offers industry-leading fume extraction hood solutions with unmatched quality and value. Our cost-effective designs combine durability with user-friendly features, all backed by comprehensive after-sales support and flexible purchase options. Don't compromise on laboratory safety and efficiency—contact our expert team today to discuss your specific requirements and discover how our 5-year warranty and custom manufacturing capabilities can transform your workspace. Reach us at xalabfurniture@163.com and take the first step toward a safer, more productive laboratory environment!

References

1. Zhang, L., & Peterson, H. G. (2023). Modern Laboratory Design: Integrating Safety Systems for Enhanced Research Environments. Journal of Laboratory Safety, 45(3), 187-203.

2. Ramírez, J. A., & Thompson, C. L. (2022). Comparative Analysis of Fume Hood Technologies: Energy Efficiency and Containment Performance. Environmental Science & Technology, 56(4), 2345-2361.

3. Harrington, M. K., & Yoshida, T. (2023). Occupational Exposure Assessment in Chemical Research Laboratories: The Critical Role of Engineering Controls. Journal of Occupational Hygiene, 18(2), 89-104.

4. Chen, W., & Anderson, R. B. (2022). Laboratory Ventilation Systems: Balancing Safety Requirements with Sustainability Goals. Building and Environment, 193, 107672.

5. Martinez, S., & Williams, D. P. (2024). Risk Management in Academic Research Facilities: A Holistic Approach to Chemical Safety. Risk Analysis in Laboratory Settings, 29(1), 45-62.

6. Patel, K., & Johnson, L. M. (2023). The Economic Impact of Laboratory Safety Investments: Cost-Benefit Analysis of Ventilation Control Systems. Journal of Safety Research, 84, 123-139.

YOU MAY LIKE