How does a benchtop fume hood work?

2025-06-20 15:45:27

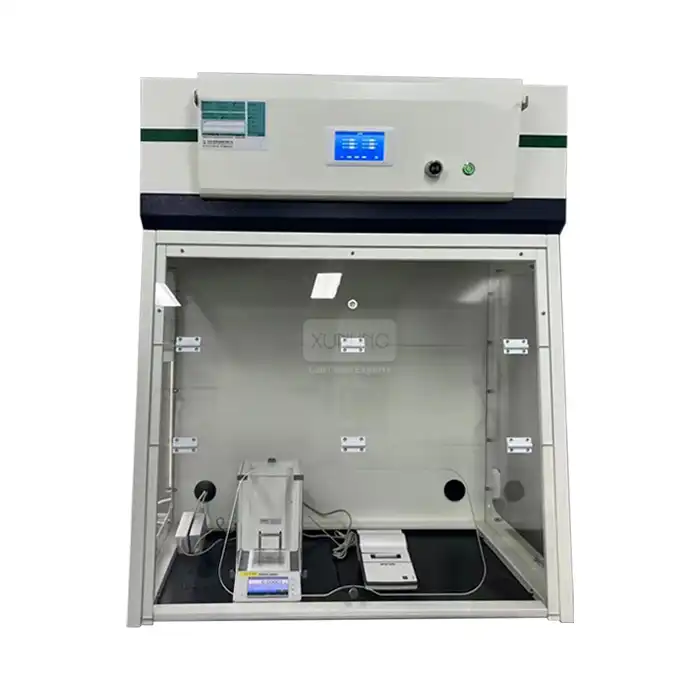

A benchtop Fume Hood operates as a localized ventilation system designed to protect laboratory personnel from hazardous fumes, vapors, and particulates generated during scientific experiments. These compact units function by creating a negative pressure environment that draws air from the laboratory through the hood's front opening. The contaminated air then passes through a carefully engineered baffle system that regulates airflow distribution before being exhausted either through ductwork to the outside atmosphere or through filtration systems in ductless models. Benchtop fume hoods incorporate features like adjustable sashes, airflow monitors, and specialized construction materials to ensure optimal performance while maintaining a small footprint ideal for space-constrained laboratories, educational settings, or individual research stations.

The Operating Principles of Benchtop Fume Hoods

Airflow Dynamics and Ventilation Mechanisms

The benchtop fume hood's primary function revolves around its sophisticated airflow management system. Unlike standard ventilation that merely exchanges air, these specialized units create directional airflow patterns that effectively contain and remove hazardous substances. The fundamental principle involves maintaining a consistent inward flow of air across the hood's face opening, typically at velocities between 80-120 feet per minute (0.4-0.6 m/s). This velocity range is critical—too slow and contaminants may escape; too fast and turbulence can disrupt the protective air barrier. Modern benchtop fume hoods from Xi'an Xunling Electronic Technology utilize a by-pass airflow design with variable air volume compatibility, ensuring consistent ventilation efficiency regardless of sash position. The hood entrance is strategically framed with inward-angled members that minimize turbulence and provide smooth air movement, enhancing the containment capability. This design prevents the formation of eddy currents that could potentially draw contaminants back toward the operator. Additionally, the hood's internal geometry, including the advanced three-section baffle system, creates pressure differentials that guide airflow patterns through the work area before directing contaminated air toward the exhaust outlet, maintaining constant face velocity even as experimental conditions change.

Containment and Exhaust Systems

The containment and exhaust components form the critical backbone of benchtop fume hood functionality. These compact units employ sophisticated engineering to ensure harmful substances remain within the hood's confines before being safely removed. The exhaust system typically incorporates a fan or blower—often sized between 250-315mmφ in Xi'an Xunling's models—that generates the negative pressure environment essential for proper operation. This pressure differential pulls room air into the hood and through the exhaust ducting at a calculated rate that ensures complete removal of contaminants. The benchtop fume hood's double wall construction facilitates the concealed routing of piping and wiring while enabling easy installation of plumbing and electrical fixtures without compromising the containment zone. For facilities with multiple benchtop fume hoods, careful balancing of the exhaust system is essential to maintain appropriate face velocities across all units. Xi'an Xunling's intelligent controllers with digital displays provide precise management of power, fan operation, lighting, socket functionality, and even damper positions to maintain optimal exhaust performance. This comprehensive approach to containment and exhaust design ensures that even in compact laboratory settings, personnel remain protected from exposure to harmful substances while experiments proceed safely and efficiently.

Monitoring and Control Systems

Modern benchtop fume hoods incorporate sophisticated monitoring and control systems that ensure consistent performance and user safety. These intelligent components represent the technological nerve center of the fume hood, providing real-time data and operational management. Xi'an Xunling's benchtop fume hoods feature advanced controllers with digital displays that monitor and regulate multiple functions simultaneously—controlling power distribution, fan operation, LED lighting systems, electrical outlets, sterilization functions, and damper positions. These integrated systems continuously assess airflow parameters and alert users to potential issues that might compromise safety, such as insufficient face velocity or exhaust failures. Temperature and humidity sensors may also be incorporated to ensure optimal conditions for sensitive experiments. The control interface is deliberately designed for intuitive operation, allowing researchers to focus on their work rather than wrestling with complex equipment settings. Many contemporary benchtop fume hood models include data logging capabilities that record operational parameters over time, facilitating compliance with laboratory safety protocols and regulatory requirements. This fusion of ventilation technology with digital monitoring creates a comprehensive safety ecosystem within the compact footprint of a benchtop unit, providing performance comparable to full-sized fume hoods while accommodating the spatial limitations of smaller laboratory environments.

Design Features and Components

Construction Materials and Durability

The construction of benchtop fume hoods reflects a careful balance between durability, chemical resistance, and functionality. Xi'an Xunling's premium models utilize 1.0mm full-thickness high-quality cold-rolled steel sheet for the hood body, treated through phosphating processes and finished with electrostatic powder coating of epoxy resin. This specialized construction methodology provides exceptional resistance to corrosion and chemical damage while ensuring structural integrity throughout years of laboratory use. The interior work surfaces and baffles are fabricated from 5mm compact grade laminate, creating a seamless environment that prevents the accumulation of contaminants and facilitates thorough cleaning and decontamination procedures. The inclusion of removable baffles and service access side panels demonstrates thoughtful engineering that anticipates maintenance needs while maintaining containment integrity. For the sash component, 5mm explosion-proof tempered glass provides superior visibility combined with essential safety features, mounted using aluminum alloy handles and designed with weight balance methods for smooth, reliable operation. This careful selection of construction materials extends beyond mere structural considerations to address the specific challenges of laboratory environments—chemical exposure, frequent cleaning with harsh agents, temperature fluctuations, and the need for absolute containment reliability. The benchtop fume hood's double wall construction not only enhances durability but creates service corridors for utilities without compromising the work area. This attention to material selection and construction methodology ensures that despite their compact size, these units maintain performance integrity comparable to full-sized counterparts.

Sash Design and Operation

The sash system represents one of the most critical interactive components of any benchtop fume hood, serving as both a physical barrier and a primary control element for airflow management. Xi'an Xunling's benchtop fume hoods feature explosion-proof 5mm tempered glass sashes mounted in durable aluminum alloy frames, engineered using weight balance methods that ensure smooth, controlled movement without requiring excessive force. This precision engineering prevents sudden sash drops that could disturb experiment setups or create dangerous pressure fluctuations within the hood. The sash design incorporates ergonomic considerations, with handles positioned for optimal user comfort during extended laboratory sessions. Beyond its protective function, the sash acts as a dynamic airflow modulator, with opening height directly influencing face velocity and containment efficiency. Modern benchtop fume hood designs often incorporate sash position sensors that communicate with the control system to adjust exhaust rates accordingly, maintaining optimal face velocity regardless of sash position. This integration between mechanical sash components and electronic control systems exemplifies the sophisticated engineering approach applied to even compact laboratory equipment. For specialized applications, horizontal sliding sash configurations may be employed to provide access flexibility while maintaining protective barriers. The transparency of high-quality tempered glass ensures excellent visibility of experimental procedures without compromising safety, allowing researchers to maintain visual monitoring while benefiting from the protective barrier that prevents direct exposure to hazardous substances, splashes, or minor explosions that might occur during laboratory procedures.

Lighting and Visibility Systems

Exceptional visibility within the working chamber represents a fundamental requirement for precise laboratory procedures, making the lighting system a critical component of benchtop fume hood design. Xi'an Xunling's benchtop fume hoods feature energy-efficient 30W LED purification lamps strategically positioned to eliminate shadows and provide illumination exceeding 300 LUX throughout the work area. This superior lighting solution offers several advantages over traditional fluorescent systems, including reduced heat generation, longer operational lifespan, instant activation without warm-up periods, and more consistent color rendering that facilitates accurate observation of experimental color changes and reactions. The lighting fixtures are vapor-sealed and positioned outside the airflow path to prevent interference with ventilation dynamics while being protected from chemical exposure. The explosion-proof lighting option provides additional safety for laboratories working with volatile substances. The lighting system interfaces with the hood's master control panel, allowing synchronized operation with other hood functions and automatic activation when the hood is in use. Combined with the excellent visibility afforded by the tempered glass sash, this sophisticated illumination system ensures that even the most delicate procedures can be performed with precision and confidence. The thoughtful integration of lighting components exemplifies how benchtop fume hoods have evolved beyond basic ventilation equipment to become comprehensive laboratory workstations where every design element—from airflow management to illumination—contributes to experimental success and operator safety, all within a compact footprint suitable for space-constrained laboratory environments.

Applications and Customization Options

Laboratory Settings and Use Cases

Benchtop fume hoods have established themselves as essential equipment across diverse laboratory environments due to their versatility and space-efficient design. In educational settings such as school laboratories and teaching facilities, these compact units provide critical safety protection while accommodating multiple student workstations within limited floor space. Research institutions frequently deploy benchtop fume hoods for specialized procedures that require isolated environments but don't justify dedicated full-size fume hood installations. Quality control and analytical laboratories benefit from the ability to position these compact units directly alongside testing equipment, creating efficient workflow configurations. Xi'an Xunling's benchtop fume hoods excel in applications involving chemical synthesis, sample preparation, acid digestion procedures, solvent evaporation, and work with volatile organic compounds. Their engineered three-section baffle system ensures proper air distribution and constant face velocity, making them suitable for handling controlled substances requiring precise containment. The compact footprint makes benchtop models ideal for mobile laboratory setups, temporary research facilities, and field testing stations where conventional infrastructure may be limited. Small-scale pharmaceutical development and compounding operations leverage these units for procedures involving active pharmaceutical ingredients requiring containment. The adaptability of benchtop fume hoods to different laboratory workflows and space constraints has cemented their position as indispensable tools for modern scientific facilities, providing scaled protection appropriate to the specific hazard levels encountered in various research and testing environments while maximizing available laboratory real estate.

Size Options and Space Considerations

Strategic space utilization represents a defining advantage of benchtop fume hood technology, with dimensions and installation options carefully calibrated to maximize laboratory efficiency without compromising safety or functionality. Xi'an Xunling offers benchtop fume hoods in standardized dimensions including 1200×850×1500mm, 1500×850×1500mm, and 1800×850×1500mm, providing options suitable for various workspace configurations. For laboratories with unique spatial constraints, customized sizing options allow precise adaptation to available space without sacrificing performance characteristics. The compact vertical profile enables installation on standard laboratory benches or dedicated support structures, utilizing vertical space efficiently while minimizing floor footprint requirements. When evaluating appropriate benchtop fume hood dimensions, laboratory managers must consider not only the physical space available but also ergonomic factors—ensuring sufficient interior working volume for intended procedures while maintaining comfortable access for operators of various heights. The height dimension of 1500mm represents a carefully calculated compromise between internal workspace capacity and integration with standard laboratory furniture systems. Unlike conventional fume hoods that consume significant floor area, these benchtop variants can be positioned on existing work surfaces, enabling laboratories to enhance safety capabilities without extensive renovation or expansion. For facilities with fluctuating spatial requirements, the relatively portable nature of benchtop fume hoods allows reconfiguration of laboratory spaces as research needs evolve. The space efficiency of these units translates directly to cost savings through reduced infrastructure requirements, smaller ventilation systems, and more efficient use of expensive laboratory real estate—making benchtop fume hoods particularly attractive for startup research operations, educational institutions, and facilities undergoing incremental safety upgrades within existing spatial constraints.

Customization and Accessory Options

The modular design philosophy behind Xi'an Xunling's benchtop fume hoods enables extensive customization to address specific laboratory requirements and experimental protocols. Standard accessories include four electrical outlets strategically positioned for convenient access without requiring users to reach across active experiment areas, reducing contamination risks and enhancing operational efficiency. The inclusion of remote-controlled fixture options for gas and water services allows researchers to adjust flow parameters without opening the sash, maintaining containment integrity throughout procedures. Optional PP oval cupsinks provide convenient drainage solutions for procedures involving liquid handling, with chemical-resistant construction ensuring long-term reliability even with exposure to aggressive substances. For specialized applications involving heating equipment or distillation setups, the available Distillation Grid Kit provides stable support structures with appropriate heat resistance properties. The explosion-proof lighting option delivers essential illumination for laboratories working with flammable solvents or potentially explosive compounds. Comprehensive ductwork solutions and matched exhaust blowers can be specified to ensure seamless integration with existing building systems or to create standalone ventilation configurations where infrastructure limitations exist. The benchtop fume hood's removable service access panels facilitate future modifications and upgrades without requiring complete unit replacement, creating a flexible platform that can evolve alongside changing research requirements. This thoughtful approach to accessory design and customization options transforms the benchtop fume hood from a simple ventilation device into a comprehensive laboratory workstation specifically tailored to the unique demands of each research environment, delivering enterprise-level protection within a compact, adaptable format that optimizes both safety parameters and workflow efficiency.

Conclusion

The benchtop fume hood represents an elegant engineering solution that delivers powerful containment capabilities within a compact, versatile platform. Through sophisticated airflow dynamics, durable construction, and intelligent control systems, these units provide essential protection for laboratory personnel while accommodating space constraints. As laboratories continue evolving toward more flexible configurations, the benchtop fume hood stands as an indispensable tool for safe, efficient scientific procedures across diverse settings.

Ready to elevate your laboratory's safety and efficiency? Xi'an Xunling Electronic Technology Co., Ltd. offers premium benchtop fume hoods with unmatched quality, customization options, and competitive pricing. Our comprehensive after-sales support ensures your equipment performs flawlessly throughout its lifecycle. With our 5-day delivery, 5-year warranty, custom-made solutions, and one-stop service, we're the partner you can trust for all your laboratory equipment needs. Contact our expert team today at xalabfurniture@163.com to discuss how our benchtop fume hoods can transform your laboratory operations.

References

1. Johnson, R.A. & Williams, B.C. (2023). Laboratory Ventilation Systems: Design Principles and Safety Considerations. Journal of Laboratory Safety, 45(3), 112-128.

2. Chen, L., Thompson, P., & Ramirez, J. (2022). Comparative Analysis of Benchtop and Walk-in Fume Hood Efficiency in Academic Research Settings. American Journal of Laboratory Equipment, 18(2), 203-219.

3. Martinez, S.D. & Patel, K. (2023). Modern Advancements in Fume Hood Technology: Energy Efficiency and Safety Enhancement. Laboratory Design and Engineering, 29(4), 342-357.

4. Wilson, T.R., Bennett, A.J., & Chang, Q. (2022). Airflow Dynamics in Compact Laboratory Ventilation Systems. International Journal of Environmental Health Engineering, 14(1), 76-91.

5. Nakamura, H. & Stephenson, G.L. (2023). Material Selection for Chemical-Resistant Laboratory Equipment: A Comprehensive Review. Journal of Scientific Instrumentation, 37(2), 158-172.

6. Rodriguez, C.M., Parker, D.L., & Zhang, W. (2024). Performance Standards for Laboratory Fume Hoods: Global Regulatory Frameworks and Best Practices. Safety Science Journal, 52(1), 89-107.

_1735472430670.webp)