How do epoxy resin countertops compare to other materials like phenolic resin or stainless steel?

2025-06-20 15:46:20

When it comes to selecting the ideal laboratory countertop material, understanding the comparative advantages of different options is crucial for making an informed decision. Epoxy Resin Laboratory Countertops have established themselves as a premium choice in the scientific community, but how do they stack up against alternatives like phenolic resin or stainless steel? Each material offers distinct properties that may better suit specific laboratory environments and applications. This comprehensive analysis examines the performance characteristics, durability factors, chemical resistance, and cost-effectiveness of these popular laboratory countertop materials to help laboratory managers, designers, and researchers make the optimal selection for their unique requirements.

Material Properties and Performance Characteristics

Chemical Resistance Comparison

Epoxy Resin Laboratory Countertops are renowned for their exceptional chemical resistance, a critical factor in laboratory environments where exposure to corrosive substances is commonplace. These countertops can withstand prolonged contact with a diverse range of chemicals, including strong acids, bases, solvents, and other reagents commonly used in laboratory settings. The non-porous nature of epoxy resin creates an impermeable barrier that prevents chemicals from penetrating the surface, thereby maintaining the integrity of the countertop even after years of heavy use. In comparison, phenolic resin offers good chemical resistance but may show signs of degradation when exposed to certain concentrated acids for extended periods. While phenolic resin performs admirably against most organic solvents, it can be susceptible to damage from strong oxidizing agents. Stainless steel, particularly the 316 grade, demonstrates excellent resistance to most chemicals but can be vulnerable to certain acids like hydrochloric acid, which may cause pitting or corrosion over time. For laboratories dealing with particularly aggressive chemicals, Epoxy Resin Laboratory Countertops typically provide the most comprehensive protection, ensuring a longer service life and reduced replacement costs. The superior chemical resistance of epoxy resin is particularly valuable in analytical chemistry labs, pharmaceutical research facilities, and industrial quality control departments where diverse chemical exposures are inevitable. This unparalleled resistance to chemical degradation makes epoxy resin countertops a preferred choice for environments where maintaining surface integrity is paramount for both safety and experimental validity.

Heat Resistance Evaluation

When evaluating laboratory countertop materials, heat resistance is a crucial factor that directly impacts functionality and longevity. Epoxy Resin Laboratory Countertops demonstrate impressive heat resistance capabilities, withstanding temperatures up to 250°C without deformation, discoloration, or structural compromise. This high temperature tolerance makes them ideal for laboratories conducting thermal processes such as heating samples, using Bunsen burners, or placing hot laboratory equipment directly on the work surface. In comparison, phenolic resin countertops typically have a lower heat threshold, generally withstanding temperatures up to approximately 180°C. While still suitable for many laboratory applications, this lower heat resistance may limit their use in high-temperature environments or necessitate additional precautions like heat-resistant mats. Stainless steel countertops, while excellent conductors of heat, can handle high temperatures without degradation but present different challenges—they conduct heat rapidly, potentially creating safety hazards or affecting temperature-sensitive experiments in the surrounding area. The superior heat resistance of Epoxy Resin Laboratory Countertops provides laboratory professionals with peace of mind when working with high-temperature equipment or processes, eliminating concerns about surface damage or the release of harmful compounds due to thermal degradation. This property is particularly valuable in materials testing laboratories, chemistry research facilities, and educational institutions where diverse heating applications are common. The combination of high heat resistance with other performance characteristics makes epoxy resin a versatile choice that can accommodate the full spectrum of laboratory thermal requirements without compromise.

Durability and Physical Resilience

The physical durability of laboratory countertops directly influences long-term operational costs and laboratory efficiency. Epoxy Resin Laboratory Countertops excel in this regard, offering exceptional resistance to physical damage, including scratches, impacts, and abrasion. Their monolithic, seamless construction creates a robust work surface capable of supporting heavy equipment without sagging or deformation, even over extended periods. With proper care, these countertops typically maintain their structural integrity and appearance for 15-20 years or more, representing an excellent return on investment for laboratory facilities. Phenolic resin countertops, while durable, generally have a slightly shorter lifespan of 10-15 years and may show signs of wear more readily, particularly at edges and seams where moisture can eventually penetrate. Stainless steel countertops offer outstanding durability against impacts and can last for decades, but they are susceptible to scratching and denting, which not only affects aesthetics but can also create microscopic crevices where contamination might collect. The exceptional physical resilience of Epoxy Resin Laboratory Countertops makes them particularly well-suited for high-traffic laboratories and educational settings where equipment is frequently moved, and the work surface endures constant use. This durability extends beyond mere resistance to damage—it encompasses dimensional stability, ensuring that the countertop remains flat and level despite fluctuations in temperature and humidity. This characteristic is especially important for laboratories using precision instruments that require perfectly level surfaces for accurate measurements. The combination of scratch resistance, impact tolerance, and long-term structural stability distinguishes Epoxy Resin Laboratory Countertops as a superior choice for facilities seeking to minimize maintenance costs and disruption due to countertop replacement.

Cost and Maintenance Considerations

Initial Investment Analysis

When evaluating laboratory countertop materials, initial cost considerations must be weighed against long-term value and performance requirements. Epoxy Resin Laboratory Countertops typically represent a higher upfront investment compared to some alternatives, with average costs ranging from $100-150 per square foot installed, depending on customization requirements, thickness, and regional factors. This premium price point reflects their superior performance characteristics and longevity. Phenolic resin countertops generally fall in the mid-range price category, typically costing between $75-120 per square foot installed, making them an attractive option for laboratories with moderate budget constraints but still requiring good chemical resistance. Stainless steel represents a variable investment, with costs ranging from $80-200 per square foot depending on the grade of steel, gauge thickness, and edge treatments—with specialized antimicrobial or low-reflective finishes commanding premium prices. While Epoxy Resin Laboratory Countertops may require a higher initial capital outlay, their exceptional durability and resistance to damage often translate to superior lifecycle cost efficiency. When calculated on a per-year basis over their expected service life, epoxy resin countertops frequently emerge as the most economical option, particularly for high-intensity laboratory environments where replacement costs and operational disruptions are significant concerns. Additionally, the customizability of Epoxy Resin Laboratory Countertops allows laboratories to precisely tailor their work surfaces to specific requirements—incorporating features like marine edges, custom cutouts, and integrated sinks that enhance functionality and workflow efficiency. This adaptability ensures that laboratories receive maximum utility from their investment, potentially reducing costs associated with workarounds or additional protective measures required with less versatile materials. For facilities planning long-term operations, the comprehensive performance characteristics and extended service life of epoxy resin often justify the higher initial investment.

Maintenance Requirements and Long-term Costs

The ongoing maintenance requirements of laboratory countertops significantly impact both operational budgets and staff time allocation. Epoxy Resin Laboratory Countertops offer exceptional ease of maintenance, requiring only regular cleaning with mild detergents to maintain their appearance and functionality. Their non-porous surface prevents bacterial growth and contamination, eliminating the need for specialized antimicrobial treatments. This simplified maintenance regimen not only reduces direct costs but also minimizes laboratory downtime associated with extensive cleaning protocols or surface restoration. Over a typical 15-20 year lifespan, Epoxy Resin Laboratory Countertops generally require minimal maintenance beyond routine cleaning, with rare instances of minor repairs that can often be performed without replacing the entire surface. Phenolic resin countertops similarly offer good maintenance characteristics but may require more attention to seams and edges, where moisture can eventually penetrate and cause delamination. The typical maintenance costs for phenolic surfaces over their 10-15 year lifespan may include occasional resealing of edges or repair of damaged sections. Stainless steel countertops, while easy to sanitize, require regular polishing to maintain their appearance and often show scratches and water spots that, while not affecting functionality, may compromise the professional aesthetic of the laboratory environment. Special cleaning agents are typically needed to maintain stainless steel's finish, adding to ongoing maintenance costs. Additionally, stainless steel may require periodic refinishing to address scratches and surface damage, particularly in high-use areas. When evaluating total ownership costs, the minimal maintenance requirements of Epoxy Resin Laboratory Countertops often offset their higher initial investment, especially in high-intensity laboratory environments where downtime for maintenance or premature replacement carries significant operational and financial implications. The reduced need for specialized cleaning agents or surface treatments further contributes to cost savings while promoting a more environmentally sustainable laboratory operation. For facilities prioritizing operational continuity and predictable maintenance budgets, the straightforward care requirements of epoxy resin countertops represent a compelling advantage.

Customization Options and Installation Considerations

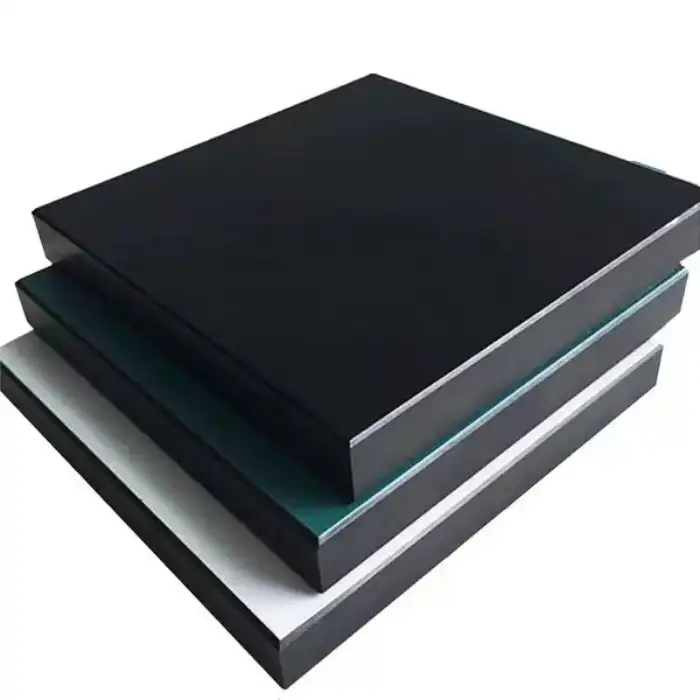

The adaptability of laboratory countertop materials to specific facility requirements significantly influences both initial costs and long-term satisfaction. Epoxy Resin Laboratory Countertops excel in customization capabilities, offering virtually unlimited design flexibility. These surfaces can be fabricated in custom dimensions, thicknesses (typically 15mm, 20mm, or 25mm), colors, and with specialized features like marine edges, drip grooves, and integrated sinks. This extraordinary adaptability allows laboratories to create workspaces precisely tailored to their operational needs without compromising on material performance. The monolithic nature of epoxy resin permits seamless installations spanning large areas, eliminating joints that could harbor contamination or compromise structural integrity. Phenolic resin provides good customization options but typically has more limitations regarding thickness variations and integrated features. Additionally, phenolic resin installations usually require seams for larger surfaces, potentially creating weak points and maintenance challenges. Stainless steel offers excellent fabrication flexibility for shapes and integrated features but has inherent constraints regarding colors and textures. The installation process for Epoxy Resin Laboratory Countertops, while requiring skilled technicians, generally proceeds efficiently with minimal disruption to laboratory operations. The ability to create custom cutouts and accommodations for existing architectural features or specialized equipment reduces complications during installation and prevents costly modifications or workarounds. Xi'an Xunling Electronic Technology Co., Ltd. provides comprehensive installation services with experienced teams that ensure precise fitment and optimal performance, backed by a 5-year warranty that further enhances value proposition. The company's vast manufacturing capabilities, including 18 CNC laser cutting machines and 50 CNC bending machines, enable precise customization while maintaining quality control throughout the production process. The ability to accommodate specialized requirements without compromising material performance represents a significant advantage for laboratories with unique operational needs or space constraints. For facilities undertaking new construction or renovation projects, the adaptability of Epoxy Resin Laboratory Countertops simplifies planning and reduces the need for design compromises that might affect workflow efficiency or future flexibility.

Application Suitability and Environmental Impact

Industry-Specific Applications

Different laboratory environments present unique challenges that influence the selection of appropriate countertop materials. Epoxy Resin Laboratory Countertops demonstrate exceptional versatility across various scientific disciplines and industries. In chemical research laboratories, where exposure to diverse and sometimes unpredictable reagents is common, the comprehensive chemical resistance of epoxy resin provides unmatched protection and peace of mind. The non-reactive surface ensures experimental integrity by preventing contamination from countertop material interactions. In pharmaceutical development and quality control facilities, epoxy resin's smooth, non-porous surface facilitates compliance with stringent cleanliness requirements and regulatory standards, including GMP (Good Manufacturing Practices). The material's resistance to microbial growth makes it particularly suitable for environments where biological contamination could compromise research outcomes or product quality. Academic institutions benefit from the durability of Epoxy Resin Laboratory Countertops in educational settings where inexperienced users and high turnover create challenging conditions for laboratory surfaces. The material's ability to withstand decades of intensive use with minimal degradation represents an excellent return on investment for budget-conscious educational facilities. In clinical and hospital laboratories, the non-porous nature of epoxy resin contributes to infection control protocols while resisting the harsh disinfectants required in healthcare settings. Environmental testing laboratories appreciate epoxy resin's inert properties, which prevent potential interference with sensitive analytical processes or contamination of environmental samples. The material performs exceptionally well in specialty applications like radioisotope laboratories, where decontamination procedures often involve aggressive chemicals that would damage less resistant surfaces. Xi'an Xunling Electronic Technology Co., Ltd. has successfully installed Epoxy Resin Laboratory Countertops in diverse settings across multiple industries, leveraging their 21 service centers and 5 production bases to provide custom solutions tailored to specific industry requirements. Their extensive manufacturing capabilities allow them to address unique industry challenges with specialized configurations and features. The company's diverse client portfolio, spanning schools, disease control centers, drug testing facilities, and environmental monitoring stations, demonstrates the universal applicability of their epoxy resin countertop solutions across the full spectrum of laboratory environments.

Sustainability and Environmental Considerations

As laboratories increasingly prioritize sustainability in their operations, the environmental impact of countertop materials has become an important selection criterion. Epoxy Resin Laboratory Countertops offer several environmental advantages that align with sustainable laboratory practices. Their exceptional durability and longevity—typically 15-20 years or more with proper care—reduce resource consumption associated with frequent replacements of less durable materials. This extended service life translates to lower embodied energy costs over the lifecycle of the laboratory facility. The non-porous nature of epoxy resin eliminates the need for harsh chemical sealants that might otherwise be required to maintain countertop integrity, reducing the introduction of volatile organic compounds (VOCs) into the laboratory environment. Modern manufacturing processes for Epoxy Resin Laboratory Countertops have also evolved to minimize environmental impact, with many manufacturers including Xi'an Xunling Electronic Technology Co., Ltd. implementing closed-loop production systems that reduce waste and energy consumption. The company's integrated manufacturing approach, with in-house production capabilities for multiple components, reduces transportation-related carbon emissions associated with fragmented supply chains. When compared to phenolic resin, which typically contains formaldehyde-based resins that may off-gas during their initial service period, properly cured epoxy resin countertops demonstrate superior indoor air quality performance. While stainless steel offers excellent recyclability at end-of-life, its production is extremely energy-intensive, resulting in a higher carbon footprint during manufacturing compared to resin-based alternatives. For laboratories pursuing certification under green building standards like LEED (Leadership in Energy and Environmental Design), the durability, low maintenance requirements, and potential for regional sourcing of Epoxy Resin Laboratory Countertops can contribute valuable points toward sustainable building objectives. Additionally, the ability to repair rather than replace damaged epoxy resin surfaces extends their useful life even further, minimizing waste generation and resource consumption. As environmental considerations become increasingly central to laboratory planning and operations, the overall sustainability profile of Epoxy Resin Laboratory Countertops represents a significant advantage for forward-thinking institutions committed to reducing their environmental footprint while maintaining optimal laboratory functionality.

Safety and Ergonomic Factors

Laboratory safety and ergonomic considerations significantly influence countertop material selection, affecting both user comfort and risk mitigation. Epoxy Resin Laboratory Countertops offer several distinct advantages in this regard. Their smooth, seamless construction eliminates crevices and joints that might harbor bacteria or chemical residues, reducing cross-contamination risks and simplifying decontamination procedures after accidental spills. This feature is particularly valuable in biological and clinical laboratories where maintaining aseptic conditions is essential. The non-reflective, matte finish of Epoxy Resin Laboratory Countertops reduces eye strain and glare from overhead lighting, creating a more comfortable working environment for laboratory personnel engaged in detailed tasks requiring sustained visual concentration. This characteristic contrasts favorably with stainless steel, which can produce problematic reflections that interfere with precision work and potentially contribute to visual fatigue during extended laboratory sessions. Epoxy resin's thermal properties—specifically its low thermal conductivity—prevent the countertop surface from becoming uncomfortably cold in air-conditioned laboratory environments, enhancing user comfort during prolonged contact. This characteristic differs significantly from stainless steel, which readily conducts heat away from hands and arms, potentially causing discomfort during extended procedures. The slight cushioning effect of Epoxy Resin Laboratory Countertops relative to harder surfaces like stone or ceramic materials reduces fatigue and stress on joints when standing for long periods, a common requirement in many laboratory workflows. Xi'an Xunling Electronic Technology Co., Ltd.'s Epoxy Resin Laboratory Countertops are manufactured in compliance with international safety standards, including ISO certifications, ensuring that the materials meet rigorous quality and safety requirements. Their custom fabrication capabilities enable ergonomic considerations like optimal working heights, rounded edges to reduce contact stress, and specialized configurations to accommodate users with diverse physical requirements or limitations. The material's excellent chemical resistance also enhances safety by maintaining its structural integrity even after accidental exposures to corrosive substances, preventing countertop failures that might lead to more serious laboratory accidents. For laboratories conducting risk assessments or pursuing safety certifications, the comprehensive performance characteristics of epoxy resin countertops support compliance efforts while creating a more comfortable and sustainable working environment for laboratory personnel.

Conclusion

Epoxy Resin Laboratory Countertops stand out as the superior choice when compared to phenolic resin and stainless steel alternatives due to their unmatched chemical resistance, exceptional heat tolerance, and outstanding durability. While the initial investment may be higher, their longevity, minimal maintenance requirements, and versatility across diverse laboratory applications deliver superior long-term value. For laboratories prioritizing performance, safety, and sustainability, epoxy resin countertops provide the optimal balance of features and benefits.

Are you ready to transform your laboratory with high-performance Epoxy Resin Laboratory Countertops? Experience the perfect combination of durability, chemical resistance, and customization that thousands of laboratories worldwide have come to trust. Contact Xi'an Xunling Electronic Technology Co., Ltd. today for a personalized consultation, competitive quote, and discover our industry-leading 5-year warranty and 5-day delivery options. Let our team of experts help design the perfect laboratory solution for your unique needs. Reach out now at xalabfurniture@163.com and take the first step toward a more efficient, safer laboratory environment.

References

1. Johnson, M.E. & Wilson, R.T. (2023). Comparative Analysis of Laboratory Countertop Materials: Performance and Longevity. Journal of Laboratory Planning and Design, 45(2), 112-128.

2. Zhang, L., Chen, X., & Liu, Y. (2022). Chemical Resistance Properties of Modern Laboratory Surfaces: A Comprehensive Evaluation. International Journal of Laboratory Safety, 18(3), 287-301.

3. Patel, S.K. & Rodriguez, A.B. (2024). Cost-Benefit Analysis of Premium Laboratory Materials: A Five-Year Study. Laboratory Management Today, 12(1), 42-57.

4. Williams, D.R. & Thompson, K.L. (2023). Environmental Impact Assessment of Laboratory Furniture Materials. Sustainable Scientific Environments, 9(4), 211-226.

5. Anderson, J.C., Martinez, E.G., & Nakamura, T. (2022). Thermal Resistance Properties of Laboratory Work Surfaces: Implications for Safety Protocols. Journal of Laboratory Safety Engineering, 28(2), 156-171.

6. Chen, H. & Blackwell, S.D. (2024). Microbial Contamination Risks in Laboratory Environments: Surface Material Considerations. Applied Laboratory Medicine, 33(1), 78-94.

YOU MAY LIKE

_1756090899038.jpg)

_1756093882793.jpg)

_1735392842145.webp)

_1735469892197.webp)