How Does a Lab Ventilation Hood Protect Operators from Harmful Chemicals?

2025-06-23 14:50:28

In laboratory environments where hazardous chemicals, toxic vapors, and dangerous fumes are commonplace, ensuring operator safety remains paramount. A lab ventilation hood serves as the primary barrier between researchers and potentially life-threatening substances, creating a controlled environment that effectively captures, contains, and eliminates harmful contaminants before they can pose risks to human health. These sophisticated engineering systems combine advanced airflow dynamics, robust construction materials, and intelligent monitoring technologies to provide comprehensive protection against chemical exposure, making them indispensable components in modern laboratory safety protocols. The fundamental principle behind lab ventilation hood protection lies in creating a negative pressure environment that draws contaminated air away from the operator's breathing zone. Through carefully engineered airflow patterns, these systems establish a protective barrier that prevents hazardous substances from escaping into the laboratory atmosphere. This critical safety measure not only protects individual researchers but also maintains overall laboratory air quality, ensuring compliance with stringent occupational health and safety standards while enabling scientific work to proceed safely and efficiently.

Physical Barrier and Containment Systems

Sash Design and Protective Barriers

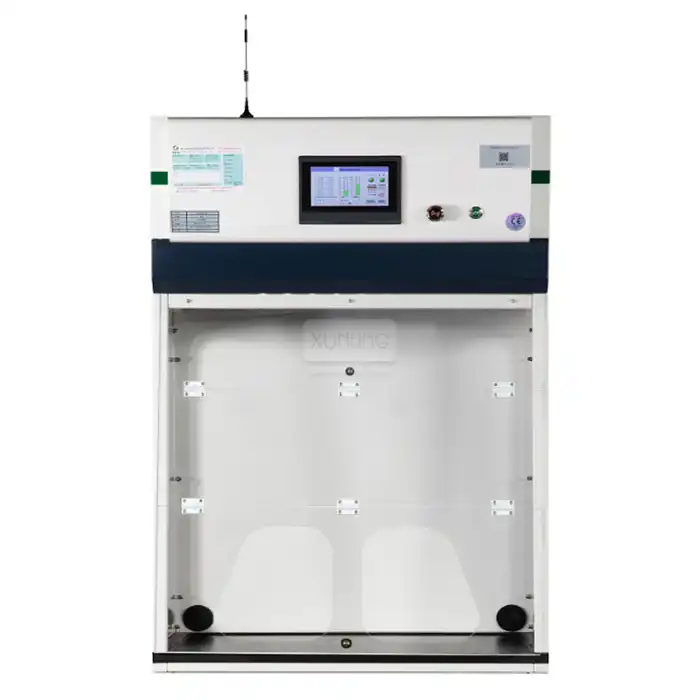

The sash system represents the primary physical interface between operators and hazardous materials within a lab ventilation hood. Modern Laboratory Fume Hoods incorporate 5mm tempered glass windows with precision-engineered angle limiters that provide optimal visibility while maintaining critical airtight protection. This design allows researchers to observe their work clearly while ensuring that harmful vapors, gases, and particulates remain contained within the hood's controlled environment. The tempered glass construction offers superior durability and safety, capable of withstanding chemical splashes and potential impacts that might occur during routine laboratory operations. The sash mechanism operates on sophisticated counterbalancing systems that enable smooth vertical movement while maintaining consistent airflow characteristics throughout the operational range. When properly positioned, the sash creates an effective barrier that minimizes turbulence and prevents the escape of hazardous materials. The angle limiter feature ensures that the sash cannot be raised beyond safe operational parameters, maintaining the integrity of the containment system even during intensive laboratory procedures. This intelligent design consideration reflects the critical importance of maintaining proper airflow dynamics while providing researchers with adequate workspace access for their experimental procedures. Advanced lab ventilation hood designs incorporate automated sash controls that adjust airflow rates in real-time based on sash position, ensuring optimal containment performance regardless of the working height. These systems integrate with laboratory management systems to provide continuous monitoring and documentation of safety parameters, creating comprehensive records for regulatory compliance and safety auditing purposes.

Internal Chamber Construction and Materials

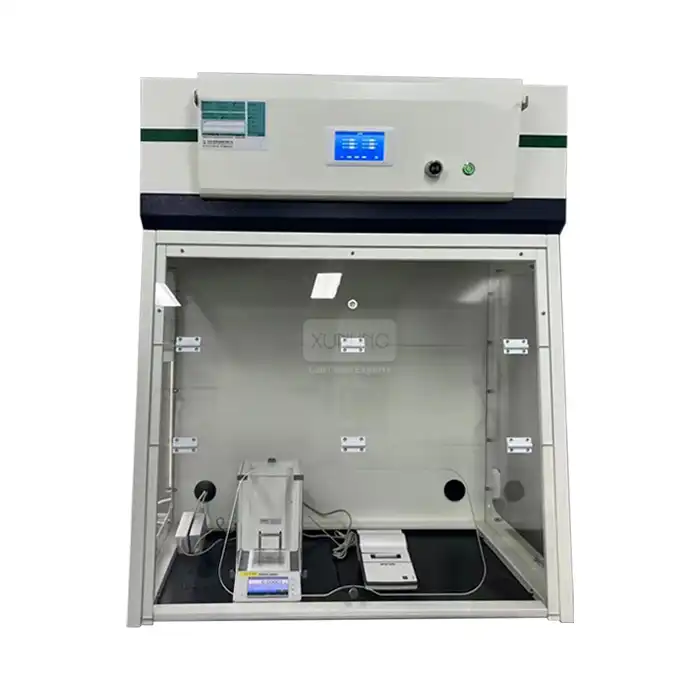

The internal chamber construction of a lab ventilation hood represents a critical engineering challenge, requiring materials that can withstand aggressive chemical environments while maintaining structural integrity over extended operational periods. Xi'an Xunling's laboratory fume hoods feature interior linings constructed from high-grade epoxy resin and stainless steel compositions, specifically selected for their exceptional resistance to strong acids, alkalis, and high-temperature conditions commonly encountered in laboratory applications. Epoxy resin linings provide seamless, non-porous surfaces that prevent chemical absorption and facilitate thorough decontamination procedures. The smooth surface finish eliminates crevices where hazardous residues might accumulate, ensuring that cleanup procedures can effectively remove all traces of dangerous substances. This material selection also provides excellent chemical compatibility across a broad spectrum of laboratory reagents, from concentrated mineral acids to organic solvents and biological materials. The structural framework supporting the internal chamber utilizes corrosion-resistant materials engineered to maintain dimensional stability under varying thermal and chemical stress conditions. Work surfaces within the lab ventilation hood feature chemical-resistant materials that can withstand spills, heat exposure, and aggressive cleaning protocols without degradation. These construction standards ensure that the protective barrier remains intact throughout the hood's operational lifetime, providing consistent safety performance for laboratory personnel working with hazardous materials.

Modular Design and Adaptability Features

Modern lab ventilation hood systems embrace modular design principles that allow for customization based on specific laboratory requirements and safety protocols. The modular approach enables laboratories to select appropriate configurations, including ducted systems that connect to central exhaust systems or ductless filter-type structures that provide self-contained filtration and air purification capabilities. Ducted configurations connect to building ventilation systems, providing maximum contaminant removal capacity for high-volume or highly toxic applications. These systems can handle substantial airflow volumes while maintaining precise control over containment parameters. The ducted approach proves particularly effective in laboratories conducting extensive chemical synthesis work or handling large quantities of volatile substances. Ductless lab ventilation hood configurations offer flexibility for laboratories with limited infrastructure or specific installation constraints. These systems incorporate multi-stage filtration technologies that capture and neutralize airborne contaminants before recirculating cleaned air back into the laboratory environment. Advanced filtration systems combine pre-filters, activated carbon adsorption, and HEPA filtration to address diverse contaminant types effectively.

Airflow Control and Ventilation Mechanisms

Negative Pressure Creation and Maintenance

The cornerstone of lab ventilation hood protection lies in the establishment and maintenance of negative pressure conditions that ensure contaminated air flows consistently away from the operator's breathing zone. This negative pressure environment is created through precisely controlled exhaust systems that remove air from within the hood chamber at rates exceeding the natural air infiltration from the surrounding laboratory space. Xi'an Xunling's intelligent airflow control systems maintain surface wind speeds adjustable from 0.3 to 0.6 meters per second, providing optimal containment performance across diverse operational scenarios. These systems incorporate real-time monitoring capabilities that continuously assess airflow parameters and automatically adjust fan speeds to maintain stable negative pressure conditions regardless of external factors such as laboratory door openings, HVAC system fluctuations, or thermal variations. The negative pressure differential prevents the escape of hazardous vapors even when laboratory personnel are actively working within the hood space. This protection mechanism remains effective during routine operations such as equipment manipulation, sample transfers, and cleaning procedures. Advanced lab ventilation hood systems integrate pressure monitoring with laboratory management systems, providing continuous documentation of safety parameters and immediate alerts when conditions deviate from established safety thresholds. Sophisticated control algorithms analyze multiple parameters simultaneously, including ambient temperature, humidity levels, and external pressure variations, to maintain optimal airflow characteristics. These systems demonstrate remarkable stability and responsiveness, ensuring that protective airflow patterns remain consistent even during dynamic laboratory conditions.

Air Velocity Optimization and Distribution

Effective contamination control within a lab ventilation hood requires carefully optimized air velocity distribution that creates uniform capture zones throughout the working area. The airflow velocity must be sufficient to capture and contain hazardous materials while avoiding excessive turbulence that might disrupt experimental procedures or create areas of inadequate protection. The 0.3 to 0.6 m/s velocity range represents an optimal balance between safety performance and operational practicality. Lower velocities ensure that lightweight materials and delicate procedures are not disrupted by excessive air movement, while higher velocities provide robust containment for more challenging applications involving volatile substances or thermal processes. This adjustable range allows laboratory personnel to optimize conditions for specific experimental requirements while maintaining comprehensive safety protection. Advanced lab ventilation hood designs incorporate computational fluid dynamics modeling to optimize internal airflow patterns, eliminating dead zones where contaminants might accumulate and ensuring uniform capture efficiency across the entire work surface. Strategically positioned airflow straighteners and distribution elements create laminar flow characteristics that enhance containment performance while minimizing energy consumption. The airflow distribution system within Xi'an Xunling's laboratory fume hoods utilizes precision-engineered baffle systems that direct air movement in optimal patterns for maximum safety effectiveness. These baffle designs can be quickly adjusted or removed for cleaning and maintenance procedures, ensuring that the lab ventilation hood maintains peak performance throughout its operational lifetime.

Filtration and Air Treatment Technologies

Comprehensive air treatment within lab ventilation hood systems requires sophisticated filtration technologies capable of addressing diverse contaminant types encountered in modern laboratory applications. Multi-stage filtration approaches combine mechanical filtration, chemical adsorption, and specialized treatment processes to ensure complete removal of hazardous substances before air discharge or recirculation. Primary filtration stages typically employ high-efficiency particulate air (HEPA) filters that capture microscopic particles, biological agents, and solid contaminants with exceptional efficiency. These filters provide protection against airborne pathogens, chemical dusts, and fine particulates that might pose inhalation hazards to laboratory personnel. Regular filter monitoring and replacement schedules ensure consistent performance and prevent filter breakthrough that could compromise safety protection. Chemical adsorption systems utilize activated carbon and specialized sorbent materials to remove volatile organic compounds, acid vapors, and other gaseous contaminants from the airstream. Advanced lab ventilation hood systems may incorporate multiple adsorption stages optimized for different chemical families, ensuring comprehensive removal of diverse contaminant types. These systems prove particularly effective for laboratories working with organic solvents, acid solutions, and other volatile chemicals. Specialized treatment technologies, including ultraviolet sterilization and catalytic oxidation, may be integrated into lab ventilation hood systems for applications requiring additional safety measures. These advanced treatment methods provide enhanced protection against biological agents and complete destruction of organic contaminants, ensuring that discharged air meets the most stringent safety and environmental standards.

Safety Features and Compliance Standards

Real-Time Monitoring and Alarm Systems

Modern lab ventilation hood systems incorporate comprehensive monitoring technologies that provide continuous assessment of safety parameters and immediate notification of any conditions that might compromise operator protection. These sophisticated monitoring systems track multiple variables simultaneously, including airflow velocity, pressure differentials, filter performance, and system operational status. Real-time airflow monitoring utilizes precision sensors strategically positioned throughout the lab ventilation hood to ensure accurate measurement of air velocity and distribution patterns. These sensors provide continuous feedback to control systems that automatically adjust fan speeds and airflow distribution to maintain optimal safety conditions. Digital displays provide laboratory personnel with immediate visual confirmation of system performance, enabling quick assessment of operational status during routine work activities. Advanced alarm systems provide multiple levels of notification for different types of safety concerns. Visual and audible alarms alert laboratory personnel to immediate safety issues requiring prompt attention, while remote notification systems can alert facility management and safety personnel to system malfunctions or maintenance requirements. These comprehensive notification systems ensure that safety issues are addressed promptly, minimizing risks to laboratory personnel and maintaining continuous protection. Integration with laboratory information management systems enables comprehensive documentation of safety parameters, providing detailed records for regulatory compliance and safety auditing purposes. These systems maintain historical data on system performance, filter replacement schedules, and maintenance activities, supporting comprehensive safety management programs and regulatory reporting requirements.

International Compliance and Certification Standards

Xi'an Xunling's lab ventilation hood systems demonstrate comprehensive compliance with international safety and performance standards, including EN 14175 and ASHRAE 110 specifications that establish rigorous requirements for laboratory ventilation equipment. These standards address critical safety parameters such as containment performance, airflow characteristics, and operational reliability under diverse laboratory conditions. EN 14175 compliance ensures that lab ventilation hood systems meet European safety requirements for laboratory ventilation equipment, addressing comprehensive performance criteria including airflow stability, containment effectiveness, and energy efficiency. This certification demonstrates that the equipment provides reliable protection across the full range of operational conditions encountered in modern laboratory environments. ASHRAE 110 certification validates containment performance through standardized testing procedures that simulate real-world laboratory conditions. These tests evaluate the ability of lab ventilation hood systems to contain tracer gases under various operational scenarios, providing quantitative measures of safety performance that ensure adequate protection for laboratory personnel working with hazardous materials. Additional certifications including ISO 9001:2015 quality management system compliance, CE marking for European market acceptance, and RoHS compliance for environmental protection demonstrate comprehensive commitment to quality, safety, and environmental responsibility. These certifications provide assurance that lab ventilation hood systems meet the highest international standards for performance, reliability, and safety.

Maintenance and Operational Safety Protocols

Effective safety protection from lab ventilation hood systems requires comprehensive maintenance programs that ensure consistent performance throughout the equipment's operational lifetime. Regular maintenance procedures include filter replacement schedules, airflow calibration, and comprehensive system inspections that identify potential issues before they compromise safety performance. Quick-release baffle structures and LED shadowless lighting systems in Xi'an Xunling's designs facilitate efficient maintenance procedures while minimizing downtime and operational disruption. These design features enable maintenance personnel to access critical components quickly and safely, ensuring that routine maintenance activities can be completed efficiently without compromising laboratory productivity. Comprehensive maintenance documentation systems track filter replacement schedules, calibration records, and performance verification tests, providing detailed records for regulatory compliance and safety auditing purposes. These systems ensure that maintenance activities are completed on schedule and that equipment performance remains within specified safety parameters throughout the operational period. Training programs for laboratory personnel ensure proper operational procedures and safety protocols are followed consistently. These programs address proper sash positioning, appropriate work practices within the hood, and emergency procedures for system failures or safety incidents. Comprehensive training ensures that lab ventilation hood systems provide maximum protection when operated according to established safety protocols.

Conclusion

Lab ventilation hood systems represent critical safety infrastructure that provides comprehensive protection against hazardous chemical exposure through sophisticated engineering solutions combining physical barriers, controlled airflow dynamics, and advanced monitoring technologies. Xi'an Xunling's laboratory fume hoods demonstrate exceptional performance through corrosion-resistant construction, intelligent airflow control, and comprehensive compliance with international safety standards. These systems ensure reliable protection for laboratory personnel while maintaining the flexibility and performance characteristics required for diverse scientific applications, making them essential components in modern laboratory safety programs. Ready to enhance your laboratory safety with professional-grade ventilation solutions? Xi'an Xunling Electronic Technology Co., Ltd. offers comprehensive laboratory equipment solutions with 5-day delivery, 5-year warranty, and custom-made options tailored to your specific requirements. Our one-stop service approach includes OEM support, fast delivery, and reliable packaging to ensure your laboratory receives the highest quality equipment with minimal downtime. Why choose our lab ventilation hood solutions? We provide cost-effective solutions that balance budget considerations with uncompromising quality standards. Our products offer exceptional reliability and durability through high-grade materials and precision manufacturing processes that reduce maintenance costs while ensuring long-term functionality. User-friendly designs enable laboratory technicians to master operational controls quickly, focusing on their research rather than equipment management. Our comprehensive after-sales support covers everything from installation guidance to troubleshooting assistance, ensuring that your laboratory maintains optimal safety performance throughout the equipment's operational lifetime. With flexible purchase options including online ordering, e-commerce platforms, and direct sales channels, we make acquiring professional laboratory equipment as convenient as possible. Contact Us today to discuss your laboratory ventilation requirements and discover how our expertise can enhance your research environment's safety and efficiency. Email us at: xalabfurniture@163.com

References

1. American Conference of Governmental Industrial Hygienists. (2019). Industrial Ventilation: A Manual of Recommended Practice for Design, 30th Edition. ACGIH Publications.

2. Eagleson, M.D., & Johnston, R.K. (2018). Laboratory Fume Hood Performance: Design Principles and Safety Considerations. Journal of Chemical Health and Safety, 25(3), 15-28.

3. International Organization for Standardization. (2020). Laboratory Equipment - Fume Cupboards - Part 1: Vocabulary. ISO 14175-1:2020. ISO Publications.

4. National Institute for Occupational Safety and Health. (2017). Criteria for a Recommended Standard: Occupational Exposure to Chemical Fume Hoods in Laboratory Settings. NIOSH Publication No. 2017-106.

YOU MAY LIKE

_1743667274497.webp)