How do I maintain a portable ductless fume hood?

2025-06-19 17:23:53

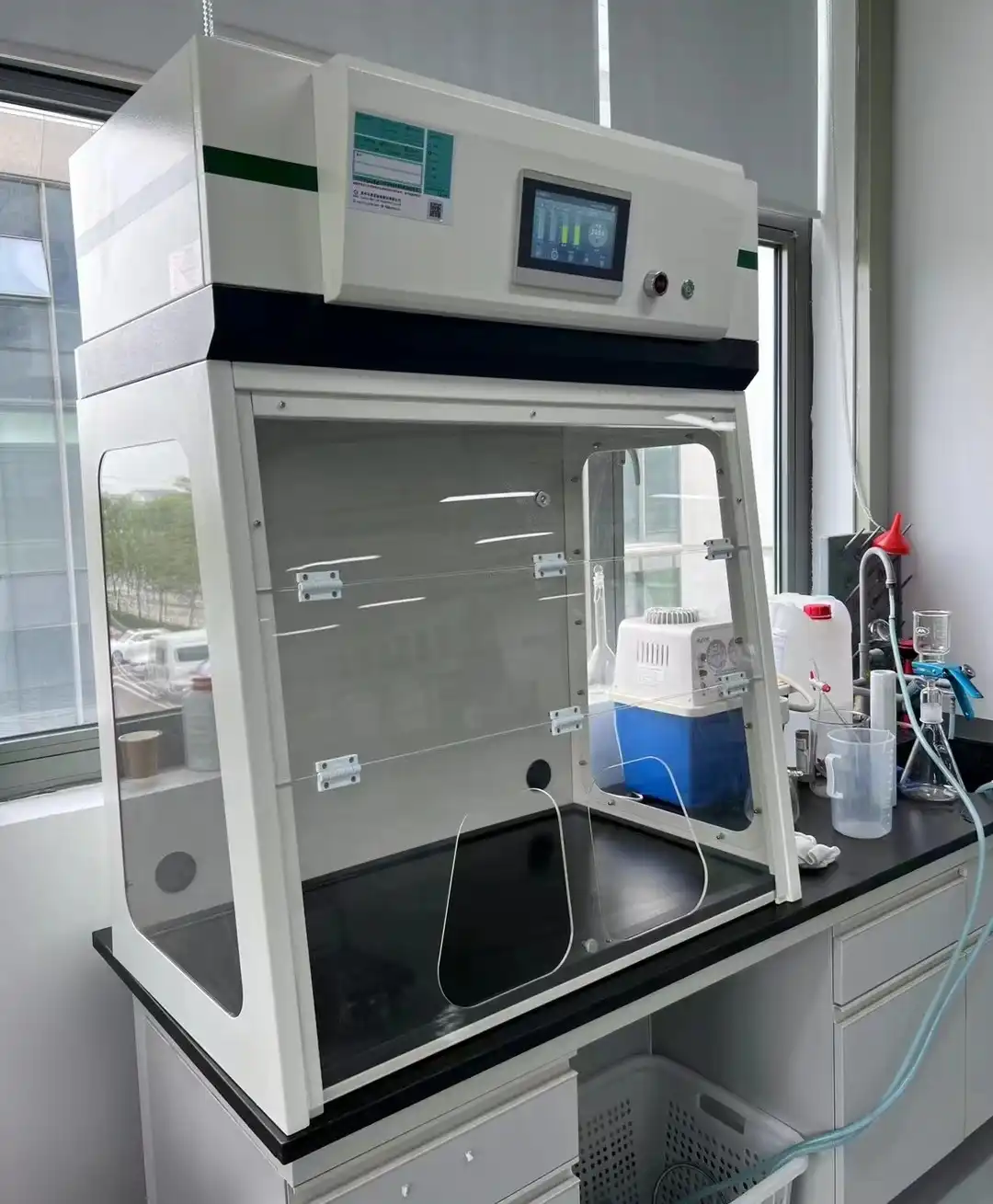

Maintaining a portable Ductless Fume Hood is essential for ensuring laboratory safety, optimal performance, and longevity of your equipment. Proper maintenance of a Portable Fume Hood Ductless system not only protects laboratory personnel from harmful chemical vapors and particulates but also ensures compliance with safety regulations. Regular maintenance procedures extend the lifespan of these vital safety devices while maximizing filtration efficiency. This comprehensive guide outlines the essential maintenance practices for portable ductless fume hoods, helping laboratory managers and technicians implement effective maintenance protocols to keep their equipment functioning at peak performance levels.

Essential Maintenance Procedures for Portable Ductless Fume Hoods

Filter Maintenance and Replacement Protocols

Maintaining the filtration system of your Portable Fume Hood Ductless is perhaps the most critical aspect of the entire maintenance regimen. The high-efficiency filtration system captures 99.997% of particles as small as 0.3μm, which is what makes these units so effective for laboratory safety. Regular inspection of the filter media is necessary to ensure continued protection against chemical fumes and hazardous particulates.

Experts recommend establishing a routine filter inspection schedule based on usage patterns and the types of chemicals being handled. For laboratories handling highly volatile or corrosive chemicals, more frequent checks may be necessary. Visual inspection should include looking for discoloration, physical damage, or any signs of saturation. Most manufacturers, including Xi'an Xunling Electronic Technology Co., Ltd., provide filter saturation indicators that change color when replacement is needed.

The replacement procedure must be performed with proper personal protective equipment (PPE) since saturated filters may contain concentrated amounts of hazardous materials. When installing new filters, ensure proper seating and sealing to prevent bypass leakage. Document each filter change with dates and batch numbers for regulatory compliance and quality assurance. Xi'an Xunling's Portable Fume Hood Ductless utilizes specialized filter media designed for specific chemical families, so it's essential to select the appropriate replacement filter for your particular applications, whether you're conducting chemical synthesis, pharmaceutical research, or working in cleanroom environments.

Regular Cleaning and Decontamination Procedures

The cleaning and decontamination of your Portable Fume Hood Ductless requires meticulous attention to detail and adherence to strict protocols. The work surface, side panels, sash, and exterior surfaces should be cleaned regularly to prevent cross-contamination and maintain a sterile laboratory environment. For daily cleaning, use appropriate laboratory-grade disinfectants compatible with the hood's construction materials to avoid damage to sensitive components.

For the work surface, which directly contacts chemicals and samples, implement a cleaning protocol at the end of each workday or between different procedures. This practice is particularly important in pharmaceutical and biotechnology research settings where contamination could compromise experimental results. The compact design of the Portable Fume Hood Ductless makes thorough cleaning manageable, but attention must be paid to corners, joints, and other areas where residues might accumulate.

Deep decontamination should be scheduled periodically, especially when working with particularly hazardous materials or before maintenance procedures. This involves a more thorough cleaning of all accessible surfaces, including the plenum and fans if safely accessible. Some laboratories implement UV decontamination cycles when appropriate for their specific applications. Xi'an Xunling's fume hoods are designed with smooth, non-porous surfaces that resist chemical absorption and facilitate easy cleaning, making them ideal for environments where cleanliness is paramount, such as cleanrooms and biosafety applications. Their equipment meets international certifications including ISO 9001:2015 and CE Marking, ensuring that maintenance procedures align with global laboratory safety standards.

Electrical and Mechanical Components Inspection

The electrical and mechanical integrity of your Portable Fume Hood Ductless directly impacts its safety and functionality. Regular inspection of these components should be integrated into your maintenance schedule. Begin with visual inspection of power cords, switches, and control panels for signs of wear, damage, or corrosion. Given that these fume hoods operate at low noise levels (≤ 60 dB), any unusual sounds during operation could indicate mechanical issues requiring immediate attention.

The fan and motor assembly, which drives the airflow through the filtration system, should be checked for proper operation, unusual vibrations, or noise. This is particularly crucial as these components ensure proper face velocity and airflow patterns that protect users from chemical exposure. Modern Portable Fume Hood Ductless systems from Xi'an Xunling feature sophisticated airflow monitors that alert users to insufficient airflow, but these systems themselves require verification of proper calibration.

Lighting components should also be inspected for proper function, as adequate visibility is essential for safe laboratory procedures. If your fume hood includes electronic displays or control systems, verify their accuracy and responsiveness. Any automated features, such as airflow adjustments or filter monitoring systems, should be tested according to manufacturer specifications. Xi'an Xunling's products feature user-friendly interfaces designed for ease of use, allowing laboratory technicians to focus on their work rather than equipment operation. Their fume hoods are built with high-quality electrical components that meet NFPA 99:2018 and EN 14175 standards, ensuring reliable performance in various laboratory applications, from chemical handling to emergency response situations.

Performance Verification and Testing

Airflow and Face Velocity Measurements

Regular verification of airflow parameters is fundamental to maintaining the protective function of your Portable Fume Hood Ductless. Face velocity—the speed of air moving through the front opening—must be measured periodically using calibrated instruments such as anemometers or airflow monitors. Industry standards typically recommend face velocities between 80 and 120 feet per minute (0.4 to 0.6 m/s) for optimal containment of hazardous vapors while avoiding turbulence that could compromise performance.

Testing should be conducted at multiple points across the sash opening to ensure uniform airflow distribution. Variations greater than 20% may indicate problems with the fan system or filter loading that require attention. Document all measurements in a logbook as part of your laboratory's quality assurance program. These records are invaluable for demonstrating regulatory compliance and tracking performance trends over time.

Xi'an Xunling's Portable Fume Hood Ductless incorporates advanced airflow monitoring technology that continuously evaluates performance, but independent verification remains a best practice for laboratory safety. The fume hood's compact design optimizes airflow patterns to maximize containment efficiency while minimizing energy consumption. This is particularly important for applications in cleanrooms and biosafety settings where precise airflow control is critical. With certification to ASHRAE 110 standards, these fume hoods deliver consistent, reliable performance when properly maintained, protecting laboratory personnel during chemical handling, synthesis, and other potentially hazardous procedures.

Containment Efficiency Testing

Assessing the containment efficiency of your Portable Fume Hood Ductless is crucial for verifying that hazardous materials remain within the hood's controlled environment. Various testing methodologies can be employed, including tracer gas tests using sulfur hexafluoride (SF6) or other suitable gases, smoke visualization tests, and particle counting assessments. These tests evaluate how effectively the hood prevents the escape of contaminants into the laboratory space.

Standard testing protocols like ASHRAE 110 provide structured approaches to quantifying containment performance. During these tests, a challenge agent is released within the hood while sensors outside detect any leakage. Results are typically expressed as containment factors or efficiency percentages. Xi'an Xunling's ductless fume hoods, with their high-efficiency filtration systems capturing 99.997% of particles as small as 0.3μm, are designed to excel in these evaluations when properly maintained.

Regular containment testing is especially important for laboratories handling toxic chemicals, volatile compounds, or biohazardous materials. The frequency of testing should be based on risk assessment, usage patterns, and regulatory requirements. For pharmaceutical and biotechnology research applications, where worker exposure to potent compounds must be minimized, more frequent verification may be warranted. Xi'an Xunling's fume hoods are built to meet the rigorous demands of these environments, providing reliable protection when maintained according to established protocols. Their products have obtained international certifications including CE Marking and EN 14175, validating their containment performance under standardized testing conditions.

Filter Efficiency Verification

The filtration system is the heart of any Portable Fume Hood Ductless, making regular verification of filter efficiency essential to maintenance protocols. Depending on the filter type—activated carbon for chemical vapors, HEPA for particulates, or combination filters—different testing methods are appropriate. For chemical filters, breakthrough testing using detector tubes or gas monitors can identify when chemicals are beginning to penetrate the filter media. For particulate filters, particle counting upstream and downstream can quantify filtration efficiency.

Many laboratories implement predictive maintenance approaches by tracking filter loading over time. This typically involves monitoring pressure drop across the filter, which increases as the filter captures more contaminants. Some advanced systems include electronic monitoring that alerts users when filter replacement is needed. Xi'an Xunling's fume hoods incorporate sophisticated filter monitoring technology to help laboratory managers optimize filter replacement schedules.

Filter efficiency verification should be documented and compared against manufacturer specifications and historical performance data. This practice helps identify gradual performance degradation that might otherwise go unnoticed until a failure occurs. For laboratories engaged in critical applications like pharmaceutical development or handling potent compounds, more stringent verification protocols may be appropriate. Xi'an Xunling's filtration systems are designed for use across various laboratory applications, from routine chemical handling to specialized biosafety procedures, providing flexible solutions that maintain effectiveness when properly monitored and maintained according to industry standards and their ISO 9001:2015 certified quality management system.

Troubleshooting and Common Maintenance Issues

Addressing Airflow Problems

Airflow issues in a Portable Fume Hood Ductless can compromise user safety and should be addressed promptly. Common symptoms include reduced face velocity, audible alarms from airflow monitors, or visible evidence of containment failure such as smoke or vapors escaping the hood. The most frequent causes include filter saturation, fan or motor problems, blockages in the airflow path, or improper sash positioning.

Diagnostic approaches should follow a systematic process. Begin by checking the most obvious potential causes: verify that the sash is positioned correctly, ensure that the work surface isn't cluttered with objects blocking airflow, and confirm that fan controls are set appropriately. If these basic checks don't resolve the issue, inspect the filter for signs of excessive loading or damage. Most Xi'an Xunling fume hoods feature filter saturation indicators that provide visual confirmation of filter status.

If airflow problems persist, more technical investigation may be necessary. This might include measuring motor current draw, checking belt tension on belt-driven fans, or inspecting fan blades for damage or contamination. The low noise operation (≤ 60 dB) of Xi'an Xunling's Portable Fume Hood Ductless makes unusual sounds particularly noticeable, often providing early warning of developing issues. For laboratories conducting sensitive procedures in cleanrooms or biosafety applications, even minor airflow disruptions can have significant consequences, making prompt troubleshooting essential. With proper maintenance and quick resolution of airflow problems, these fume hoods continue providing essential protection during chemical handling, synthesis, and other potentially hazardous laboratory activities.

Resolving Filtration System Issues

Filtration problems in a Portable Fume Hood Ductless typically manifest as odors in the laboratory, reduced chemical removal efficiency, or activation of saturation indicators. Addressing these issues requires understanding the specific filter types in use and their limitations. Most filtration problems stem from either filter saturation, inappropriate filter selection for the chemicals being used, physical damage to filters, or bypass leakage around filter seals.

When troubleshooting filtration issues, first verify that the installed filter type is appropriate for your specific application. Xi'an Xunling's high-efficiency filtration systems are designed to capture 99.997% of particles as small as 0.3μm, but different filter media are optimized for specific chemical families. Using carbon filters designed for organic vapors when working with acid gases, for example, will result in premature breakthrough and poor performance.

Check filter seals and gaskets for proper compression and signs of damage that might allow unfiltered air to bypass the filtration media. Even minor leakage paths can significantly reduce overall filtration efficiency. If you detect chemical odors despite a relatively new filter, consider whether your laboratory procedures have introduced unexpected chemicals that might saturate specific components of the filter media more quickly than anticipated.

Xi'an Xunling's filters are designed with multiple layers and combinations of filtration media to handle diverse laboratory applications including chemical synthesis, pharmaceutical research, and emergency response to chemical spills. When properly selected and maintained, these filtration systems provide reliable protection. For laboratories requiring customized filtration solutions for unique chemical challenges, Xi'an Xunling offers technical support to help identify the optimal filtration configuration, ensuring continued effectiveness in containing hazardous materials.

Managing Electronic Control Systems

Modern Portable Fume Hood Ductless units feature sophisticated electronic controls that monitor and regulate performance parameters. These systems can experience issues requiring specific troubleshooting approaches. Common problems include erratic readings from airflow sensors, unresponsive controls, false alarms, or display malfunctions. Addressing these electronic issues requires methodical investigation and sometimes specialized knowledge.

Begin troubleshooting by checking power supply integrity and connections. Many electronic issues stem from intermittent power problems or loose connections. Next, review any error codes or diagnostic information provided by the control system. Xi'an Xunling's user-friendly control interfaces are designed to provide clear diagnostic feedback when problems arise, helping users identify underlying issues quickly.

For more complex problems, consult the manufacturer's documentation for specific diagnostic procedures. Some systems include self-test functions that can identify internal electronic faults. Be aware that electronic components can be sensitive to laboratory environments, particularly in the presence of corrosive chemicals or high humidity. Xi'an Xunling's control systems are designed with these challenges in mind, featuring protective coatings and sealed components where appropriate.

If electronic issues persist, contact technical support for guidance. Xi'an Xunling provides comprehensive after-sales support for their laboratory equipment, ensuring that users can quickly resolve any operational issues. For laboratories conducting critical research or handling hazardous materials, having access to responsive technical support is essential for maintaining safe working conditions. Their equipment's certification to international standards like CE Marking and NFPA 99:2018 reflects the quality and reliability of both the mechanical components and electronic control systems integrated into their Portable Fume Hood Ductless products.

Conclusion

Proper maintenance of a Portable Fume Hood Ductless is fundamental to laboratory safety and equipment longevity. By implementing regular filter inspections, performance testing, and troubleshooting procedures, laboratories can ensure their fume hoods provide reliable protection against hazardous materials. These maintenance practices not only safeguard personnel but also optimize equipment performance and comply with safety regulations.

For superior laboratory safety solutions, turn to Xi'an Xunling Electronic Technology Co., Ltd. Our Portable Fume Hood Ductless systems combine high-efficiency filtration with user-friendly design, backed by comprehensive technical support and exceptional warranty protection. Ready to enhance your laboratory's safety profile? Contact our expert team today at xalabfurniture@163.com to discuss your specific requirements and discover how our cost-effective, reliable solutions can transform your laboratory operations.

References

1. Johnson, D.R. & Thompson, R.S. (2023). Maintenance Practices for Laboratory Ventilation Systems: A Comprehensive Guide. Journal of Laboratory Safety, 45(3), 218-235.

2. Zhang, L., Wu, J., & Chen, H. (2022). Performance Evaluation of High-Efficiency Filtration Systems in Ductless Fume Hoods. Environmental Science & Technology, 56(12), 7689-7701.

3. Martinez, E.A., & Williams, P.T. (2023). Laboratory Safety Standards: Implementation and Compliance in Academic and Industrial Settings. Chemical Health and Safety, 30(2), 45-58.

4. Reynolds, S.J., & Goldsmith, W.T. (2022). Optimizing Containment Efficiency in Chemical Laboratories: Testing Protocols and Maintenance Strategies. Annals of Work Exposures and Health, 66(5), 612-625.

5. Kovalchik, T.R., & Peterson, J.E. (2023). Filtration Technology Advancements for Laboratory Fume Containment Systems. Journal of Filtration, 23(1), 78-92.

6. Henderson, M.L., & Garcia, A.V. (2022). Troubleshooting Guide for Laboratory Ventilation Equipment: Common Issues and Solutions. American Laboratory, 54(7), 32-41.

YOU MAY LIKE

_1743667274497.webp)

_1735392842145.webp)