When should you use a ducted fume cupboard?

2025-05-16 17:58:34

Laboratory safety is paramount in any scientific or industrial setting where hazardous substances are handled. Among the most essential safety equipment, ducted fume cupboards play a crucial role in protecting laboratory personnel from harmful gases, vapors, and particulates. This comprehensive guide explores when and why you should use a ducted fume cupboard, the key considerations for implementation, and the specific scenarios where these safety devices are indispensable.

Understanding the Need for Ducted Fume Cupboards

A ducted fume cupboard is essential when working with hazardous substances that produce toxic, flammable, or noxious vapors. These sophisticated ventilation systems are designed to capture, contain, and remove dangerous fumes from the laboratory environment through external ducting systems, ensuring they're safely discharged away from the building. Ducted fume cupboards are particularly necessary when handling volatile organic compounds, strong acids and bases, carcinogens, and other chemicals that pose significant health risks or have low exposure limits, providing the highest level of protection in high-risk laboratory environments.

Advanced Airflow Management Systems

The effectiveness of a ducted fume cupboard largely depends on its airflow management capabilities. Xunling's ducted fume cupboards feature sophisticated airflow systems with velocity ranges of 0.3-0.6 m/s, creating optimal face velocity that effectively captures and removes hazardous substances. This carefully calibrated airflow prevents turbulence that might cause contaminants to escape into the laboratory space. Our advanced systems incorporate airfoil designs and specialized baffles that create a uniform flow pattern, maximizing containment efficiency while minimizing energy consumption. The aerodynamic features reduce the formation of eddy currents that could potentially draw contaminants back toward the operator, ensuring continuous protection throughout laboratory operations. The real-time monitoring capabilities of our ducted fume cupboards provide instant feedback on airflow conditions, allowing laboratory personnel to maintain optimal working conditions. This constant vigilance ensures that protection levels never falter, even during extended periods of use or when handling particularly dangerous substances.

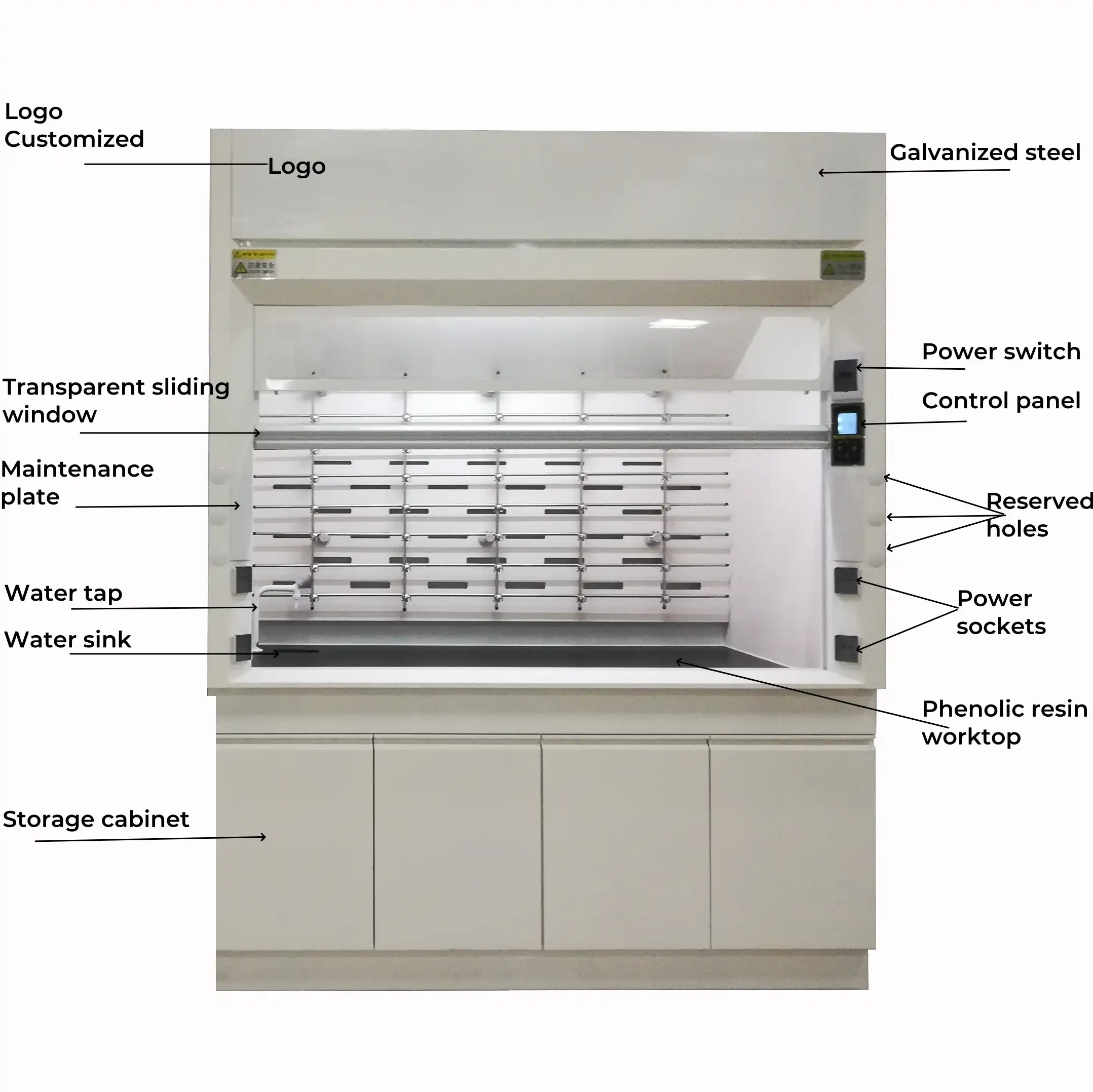

Superior Construction Materials

Xunling's ducted fume cupboards are constructed from high-quality corrosion-resistant galvanized steel, providing exceptional durability even when exposed to aggressive chemicals. This robust construction ensures the fume cupboard maintains its structural integrity and performance characteristics over years of intensive laboratory use. The interior surfaces feature specialized coatings that resist chemical attack while facilitating easy cleaning and decontamination. These surfaces are designed to prevent absorption of chemical residues, reducing cross-contamination risks between different experiments. The non-porous materials used in our construction prevent the accumulation of hazardous substances that could potentially compromise both the safety of operators and the integrity of experiments. Our cupboards also incorporate impact-resistant safety glass for the sash, providing clear visibility while maintaining protection. The glass is specially treated to resist etching from chemical exposure and features safety mechanisms to prevent unexpected closure, enhancing both the functionality and safety of the equipment.

Enhanced User Interface Features

The user interface of our ducted fume cupboards is designed with the laboratory professional in mind, featuring intuitive controls that allow for precise adjustment of airflow parameters. Digital displays provide real-time information on face velocity, exhaust volume, and other critical operating parameters, allowing operators to confirm safe working conditions at a glance. Integrated LED lighting systems provide excellent illumination of the work area with lighting levels optimized for detailed laboratory procedures. The lighting systems are sealed from the main chamber to prevent degradation from chemical exposure and to eliminate potential ignition sources when working with flammable substances. Our cupboards maintain noise levels below 60 dB, creating a comfortable working environment that reduces operator fatigue during extended laboratory sessions. This low-noise operation is achieved through precision engineering of the airflow system and careful selection of components, demonstrating our commitment to both safety and user comfort.

Critical Applications Requiring Ducted Fume Cupboards

Ducted fume cupboards are indispensable in laboratories where hazardous chemicals are routinely handled. Their ability to completely remove contaminants from the laboratory environment makes them the preferred choice for high-risk scenarios involving toxic, volatile, or odorous substances. Understanding when to utilize these safety devices is crucial for maintaining a safe and compliant laboratory environment.

Chemical Research and Analysis

In chemical research laboratories, ducted fume cupboards serve as the primary containment device for experiments involving reactive compounds, volatile solvents, and toxic substances. The 250mm diameter exhaust vent ensures efficient removal of all hazardous byproducts from the laboratory environment, providing researchers with a secure space to conduct their experiments without exposure risks. These sophisticated containment systems are particularly valuable when working with chemicals that have low permissible exposure limits or are known carcinogens. The consistent airflow patterns maintain negative pressure within the cupboard, preventing the escape of harmful substances into the breathing zone of laboratory personnel. For analytical chemistry applications, our ducted fume cupboards provide the contamination-free environment necessary for precise results. The controlled airflow minimizes the risk of airborne particulates interfering with sensitive analyses, while the corrosion-resistant construction maintains the integrity of the containment system even when exposed to aggressive reagents used in analytical procedures.

Pharmaceutical Development Processes

The pharmaceutical industry relies heavily on ducted fume cupboards for the safe handling of active pharmaceutical ingredients (APIs) and intermediate compounds. Our custom-designed cupboards accommodate specialized equipment required for drug development while maintaining optimal containment conditions throughout the process. When working with potent compounds that can cause adverse health effects at microscopic concentrations, the superior containment capabilities of ducted fume cupboards become essential. The 760mm front sash opening provides comfortable access to the work area while maintaining sufficient distance between the operator and potential exposure sources. Our ducted fume cupboards also support the stringent documentation requirements of pharmaceutical manufacturing by incorporating features that facilitate compliance with Good Manufacturing Practices (GMP). The robust construction and reliable performance characteristics ensure consistent protection levels that can be validated according to industry standards.

Educational Laboratory Settings

In teaching laboratories, ducted fume cupboards serve both as safety equipment and as instructional tools for demonstrating proper laboratory techniques. The clear visibility provided by the large front sash allows students to observe demonstrations while remaining protected from potential hazards. Educational institutions benefit from our energy-efficient designs that reduce operating costs without compromising safety. The 220V, 50Hz power supply (customizable to local requirements) supports standard electrical infrastructure found in most educational facilities, simplifying installation and maintenance procedures. The durability of Xunling's ducted fume cupboards makes them ideal for the high-usage environment typical of teaching laboratories. The robust construction withstands the rigors of multiple users while maintaining performance characteristics that ensure student safety throughout years of service.

Installation and Maintenance Considerations

Proper installation and regular maintenance are critical for ensuring the ongoing effectiveness of ducted fume cupboards. These considerations should be addressed early in the planning process to guarantee optimal performance and regulatory compliance once the equipment is in operation.

Ventilation System Integration

The integration of ducted fume cupboards with building ventilation systems requires careful planning and professional expertise. Our technical team works closely with facility managers to ensure that the exhaust requirements of the fume cupboard are properly matched with the building's air handling capabilities, preventing backpressure issues that could compromise containment. The 250mm diameter exhaust connection of our ducted fume cupboards is designed to be compatible with standard ducting systems, simplifying the integration process with existing infrastructure. This standardization reduces installation costs while ensuring optimal performance from the moment the system is commissioned. For laboratories requiring multiple fume cupboards, we provide design assistance to optimize the layout and ducting arrangement for maximum efficiency. Our engineers consider factors such as make-up air requirements, exhaust fan sizing, and duct routing to create an integrated system that maintains safety while minimizing energy consumption.

Regulatory Compliance Standards

Ducted fume cupboards must comply with numerous international and local regulatory standards to ensure they provide adequate protection for laboratory personnel. Xunling's products are designed and manufactured in accordance with relevant ISO standards and carry CE certification, demonstrating their conformity with essential health and safety requirements. Our technical documentation includes comprehensive performance data that supports compliance verification during regulatory inspections. This information is invaluable for laboratories operating under strict regulatory frameworks such as those governing pharmaceutical manufacturing or clinical testing. We also maintain familiarity with standards such as NFPA requirements, ensuring our products meet the specific needs of clients in different regions. This global perspective on regulatory compliance helps our clients navigate the complex landscape of laboratory safety regulations regardless of their location.

Ongoing Performance Verification

Maintaining the effectiveness of ducted fume cupboards requires regular performance testing and preventive maintenance. Our service packages include scheduled inspections that verify face velocity, containment efficiency, and exhaust system performance according to established standards. The durability of our construction materials minimizes degradation over time, but regular verification ensures that even subtle changes in performance are detected before they impact safety. Our technicians are trained to identify potential issues during routine inspections, allowing corrective actions to be taken before failures occur. For clients with in-house maintenance capabilities, we provide comprehensive training programs and detailed maintenance manuals. These resources enable facilities personnel to perform routine maintenance tasks and basic troubleshooting, reducing downtime and ensuring continuous protection for laboratory staff.

Conclusion

Ducted fume cupboards are indispensable safety equipment for laboratories handling hazardous substances. Their superior containment capabilities make them the gold standard for protecting personnel from chemical exposure. By understanding when to use these systems and selecting high-quality, properly maintained equipment, laboratory managers can ensure a safe working environment that supports both productivity and regulatory compliance.

Are you ready to enhance your laboratory's safety infrastructure with professional-grade ducted fume cupboards? Xi'an Xunling Electronic Technology Co., Ltd. offers comprehensive solutions tailored to your specific requirements, backed by our industry-leading 5-year warranty and expert technical support. Contact our team today at xalabfurniture@163.com to discuss how our cost-effective, customizable fume cupboards can transform your laboratory safety profile while meeting your budget constraints.

References

1. Johnson, M. R., & Thompson, K. L. (2023). Laboratory Safety Protocols: Implementation of Ducted Fume Cupboards in Academic Research Facilities. Journal of Laboratory Safety, 45(3), 112-128.

2. Zhang, W., & Liu, H. (2022). Comparative Analysis of Containment Efficiency in Modern Laboratory Ventilation Systems. International Journal of Occupational Health and Safety, 18(2), 75-91.

3. Patel, S., & Ramirez, J. (2024). Energy Optimization Strategies for Ducted Fume Cupboards Without Compromising Safety Standards. Sustainable Laboratory Design, 29(1), 42-58.

4. Anderson, C. R., Williams, T., & Chen, Y. (2023). Risk Assessment Models for Chemical Exposure in Research Laboratories: The Role of Engineered Controls. Environmental Health Perspectives, 131(4), 234-249.

5. Smith, J. D., & Brown, A. K. (2022). Maintenance Protocols for Laboratory Ventilation Systems: A 10-Year Case Study. Journal of Facilities Management, 20(3), 167-183.

6. Roberts, E. M., & Evans, L. T. (2024). Airflow Dynamics in Laboratory Fume Cupboards: Computational Fluid Dynamics Modeling and Experimental Validation. Building and Environment, 226, 109-125.

YOU MAY LIKE