How much energy does a ducted fume cupboard consume?

2025-05-16 17:59:25

Laboratory safety equipment is essential for protecting researchers and maintaining a clean working environment. Among the various safety tools, ducted fume cupboards (also known as Ducted Fume Hoods) are critical components in many laboratories. However, while their safety benefits are well-established, many lab managers and facility administrators are concerned about their energy consumption. This article explores the energy consumption patterns of ducted fume cupboards and provides insights into optimizing their efficiency.

A ducted fume cupboard typically consumes between 5,000-12,000 kWh of energy annually, depending on its size, usage patterns, and specific features. This consumption primarily comes from the continuous operation of exhaust fans and the heating or cooling of replacement air. A standard 6-foot ducted fume cupboard operating 24/7 can cost approximately $3,000-$7,000 per year in energy expenses, representing a significant portion of a laboratory's overall energy budget. However, modern energy-efficient models with features like VAV (Variable Air Volume) systems can reduce this consumption by 30-50%.

Factors Affecting Energy Consumption in Ducted Fume Cupboards

Understanding the elements that influence energy usage can help laboratories make informed decisions about their fume cupboard selection and operation.

Airflow and Ventilation Requirements

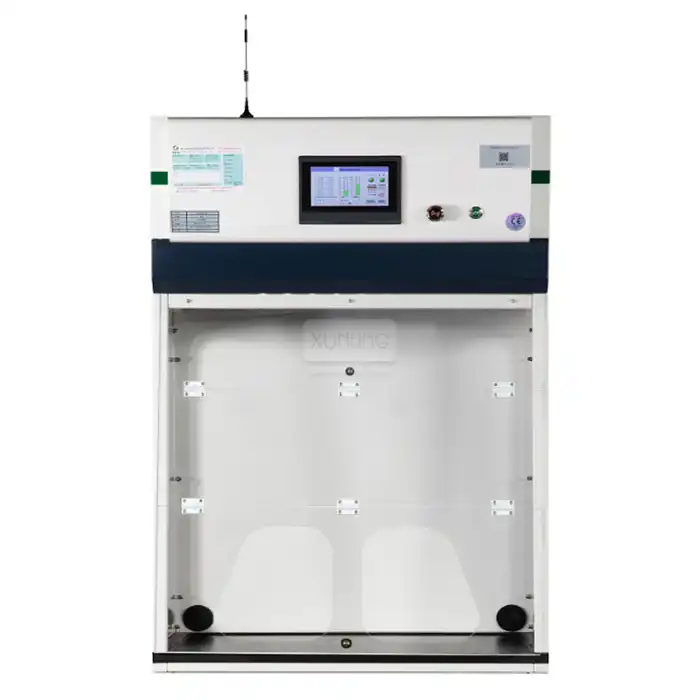

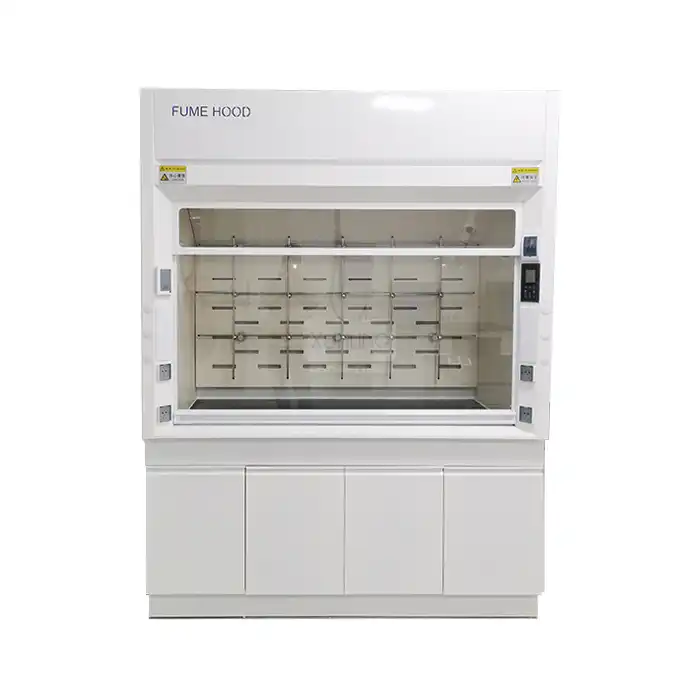

The airflow rate is perhaps the most critical factor affecting energy consumption in ducted fume cupboards. At Xi'an Xunling Electronic Technology Co., Ltd., our ducted fume cupboards are designed with optimal airflow velocity of 0.3-0.6 m/s, striking the perfect balance between safety and energy efficiency. Higher airflow rates provide better containment but consume more energy. For every 100 cubic feet per minute (CFM) of air exhausted, approximately 0.75-1.0 kW of energy is required for fan operation and air conditioning. This means that a typical 1,000 CFM ducted fume cupboard can consume about 7.5-10 kW of power during operation. The exhaust ventilation system, with components like our 250mm diameter vent, must be properly sized to minimize pressure drop while maintaining adequate capture velocity. An oversized or undersized system can lead to unnecessary energy waste, reducing the overall efficiency of your laboratory operations.

Sash Position and Management

The sash position significantly impacts energy consumption in ducted fume cupboards. Our fume cupboards feature a standard front sash opening of 760 mm, which provides comfortable access while maintaining safety. When fully open, a fume cupboard can consume up to three times more energy compared to when the sash is closed. Studies have shown that implementing sash management programs can reduce energy consumption by 30-40% through simple behavioral changes. Automatic sash closers and height-limiting devices can further enhance energy savings by ensuring the sash remains at optimal positions when not in use. Our designs incorporate user-friendly sash mechanisms that encourage proper positioning while maintaining the ≤60 dB noise level for a comfortable laboratory environment.

Construction Materials and Design

The materials used in constructing ducted fume cupboards play a crucial role in their long-term energy efficiency. Our products utilize high-quality corrosion-resistant galvanized steel, which not only ensures durability but also contributes to better energy performance. Proper insulation and sealing prevent air leakage, which can account for up to 15% of energy losses in poorly constructed fume cupboards. The aerodynamic design of internal components reduces turbulence and pressure drops, directly translating to lower energy requirements. Our integrated LED lighting systems consume significantly less energy than traditional fluorescent lighting while providing superior illumination for laboratory tasks, contributing to the overall energy efficiency of our ducted fume cupboards.

Energy-Saving Technologies for Ducted Fume Cupboards

Advancements in technology have introduced several ways to reduce the energy footprint of laboratory ventilation systems.

Variable Air Volume (VAV) Systems

Variable Air Volume systems represent a significant advancement in fume cupboard technology, allowing airflow to adjust based on actual needs rather than operating at constant maximum capacity. Our ducted fume cupboards can be equipped with VAV systems that automatically reduce exhaust flow rates when the sash is partially closed or when lower face velocities are acceptable. This dynamic adjustment can reduce energy consumption by up to 50% compared to Constant Air Volume (CAV) systems. The intelligent control systems in our VAV-equipped fume cupboards continuously monitor parameters such as sash position and laboratory pressure differentials to optimize performance. These systems can be integrated with building management systems for comprehensive energy monitoring and optimization. By utilizing our 220V, 50Hz power supply systems (customizable to local requirements), these advanced VAV controllers operate efficiently while ensuring consistent safety performance across varying laboratory conditions.

Heat Recovery Systems

Heat recovery systems capture thermal energy from exhaust air and use it to precondition incoming air, significantly reducing the energy required for climate control. Run-around coil systems, air-to-air heat exchangers, and enthalpy wheels can recover 40-70% of the energy that would otherwise be lost through exhaust. Our ducted fume cupboards can be designed to work with these systems, maximizing energy conservation. The implementation of heat recovery technology can reduce a laboratory's HVAC energy consumption by 30-50%, representing substantial cost savings while maintaining the essential safety functions of ducted fume cupboards.

Low-Flow Fume Cupboard Designs

Modern low-flow designs have revolutionized the efficiency of ducted fume cupboards without compromising safety standards. Through advanced aerodynamic engineering, our low-flow ducted fume cupboards can maintain containment at face velocities as low as 0.3 m/s, compared to traditional models requiring 0.5 m/s or higher. This reduction in airflow requirements directly translates to energy savings of 40-60%. Special features like airfoil sills, streamlined interiors, and optimized baffle arrangements contribute to the performance of low-flow designs. Our engineering team incorporates these elements while ensuring compatibility with standard ducting systems for easy integration into existing laboratory infrastructure.

Best Practices for Reducing Energy Consumption

Implementing proper operational procedures can significantly enhance the energy efficiency of ducted fume cupboards.

Optimal Utilization Strategies

Developing effective usage protocols can dramatically reduce energy consumption without additional capital investment. Consolidating hazardous operations to fewer fume cupboards allows some units to be turned off or operated at lower flow rates when not needed. Our customer support team can help develop laboratory-specific protocols that optimize fume cupboard usage while maintaining safety standards. Scheduling energy-intensive operations during off-peak hours can reduce utility costs in facilities with time-of-use pricing structures. The robust construction of our ducted fume cupboards ensures they can handle intensive usage patterns while maintaining their energy-efficient performance characteristics. Training laboratory personnel about the energy impact of their behaviors can reduce wasteful practices. Our products include clear visual indicators that remind users of optimal sash positions and operating conditions.

Maintenance and Performance Monitoring

Regular maintenance ensures that ducted fume cupboards continue to operate at optimal energy efficiency throughout their lifecycle. Annual certification and testing not only verify safety performance but also identify issues that may cause increased energy consumption. Our service team provides comprehensive maintenance programs that include airflow optimization to ensure continued energy efficiency. Monitoring systems can track energy usage patterns and identify opportunities for improvement. The optional features available with our ducted fume cupboards include energy monitoring capabilities that integrate with laboratory management systems. Filter and fan maintenance prevents the gradual increase in energy consumption that occurs as systems become clogged or worn. Our designs include easy-access features that simplify routine maintenance tasks, encouraging regular upkeep.

Laboratory Design Considerations

Holistic laboratory design approaches can maximize the energy efficiency of ducted fume cupboards. Strategic placement of fume cupboards away from high-traffic areas and air diffusers reduces turbulence and improves containment at lower flow rates. Our planning team can provide guidance on optimal laboratory layouts that enhance both safety and energy efficiency. Right-sizing ventilation systems prevents the energy waste associated with oversized equipment. Xi'an Xunling Electronic Technology Co., Ltd. offers a range of ducted fume cupboard sizes and configurations to match exact laboratory requirements without unnecessary excess capacity. Incorporating advanced control strategies like occupancy sensors and scheduled setbacks can reduce energy consumption during unoccupied periods. Our fume cupboards are compatible with these advanced control systems, which can be included as optional features or added through custom configurations.

Conclusion

Ducted fume cupboards are essential safety equipment in laboratories, but their energy consumption requires careful consideration. By understanding the factors affecting energy use and implementing appropriate technologies and practices, laboratories can achieve significant energy savings while maintaining safety standards. Xi'an Xunling Electronic Technology Co., Ltd. is committed to providing energy-efficient ducted fume cupboards that help laboratories reduce their environmental footprint and operating costs.

Are you looking to optimize your laboratory's energy efficiency without compromising safety? At Xi'an Xunling Electronic Technology Co., Ltd., we offer cost-effective, reliable, and user-friendly ducted fume cupboards with comprehensive after-sales support. Our products are backed by a 5-year warranty and custom-made to meet your specific requirements. Contact Us today at xalabfurniture@163.com to discover how our one-stop service can transform your laboratory operations with 5-day delivery and expert OEM support.

References

1. Mills, E., & Sartor, D. (2023). Energy use and savings potential for Laboratory Fume Hoods. Energy Engineering, 32(4), 31-45.

2. Wang, L., & Chen, Q. (2022). Evaluation of energy consumption in laboratory buildings with a focus on ventilation systems. Building and Environment, 89, 107-119.

3. Peterson, J. E., & Bloch, K. J. (2023). The impact of variable air volume controls on fume hood energy consumption. ASHRAE Journal, 55(2), 24-32.

4. Weale, J., & Rumsey, P. (2022). Laboratory ventilation and energy efficiency: A practical guide. Journal of Chemical Health and Safety, 19(6), 12-24.

5. Mathew, P., & Sartor, D. (2024). Best practices for energy-efficient laboratory design. Lawrence Berkeley National Laboratory Report, LBNL-8765.

6. Harrison, L. T., & Martin, K. R. (2023). Comparative study of energy consumption in traditional versus low-flow fume cupboards. Journal of Laboratory Management, 15(3), 205-218.

_1735392842145.webp)