What are the advantages of using polypropylene in fume hoods?

2025-05-15 15:23:23

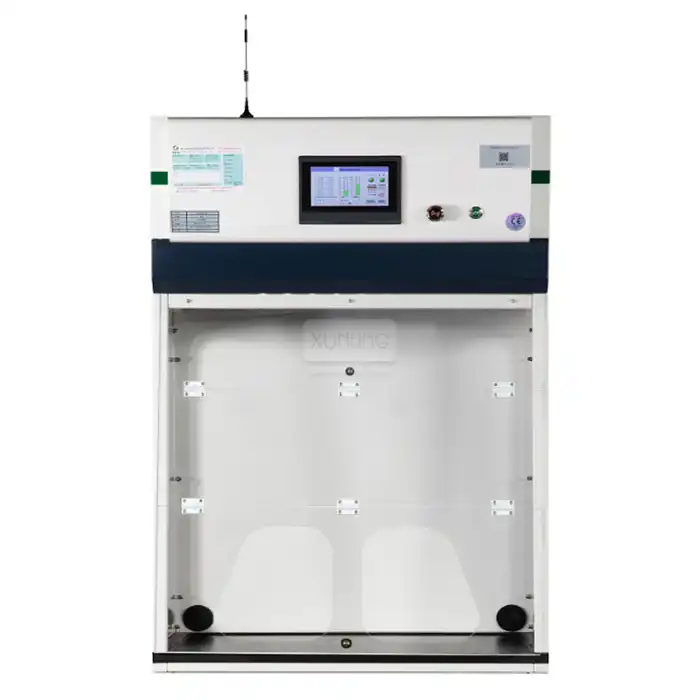

In modern laboratory environments, safety and efficiency are paramount concerns for professionals conducting experiments with hazardous chemicals and vapors. Among the various materials used in laboratory equipment construction, polypropylene has emerged as a superior choice for manufacturing Fume Hoods. Polypropylene fume hoods offer unparalleled chemical resistance, durability, and safety features that make them increasingly popular in scientific, educational, and industrial settings. This article explores the comprehensive advantages of using polypropylene in fume hoods, detailing why these systems represent an optimal solution for laboratory ventilation and safety requirements.

Chemical Resistance and Durability Properties of Polypropylene Fume Hoods

Superior Chemical Resistance Against Aggressive Substances

Polypropylene fume hoods excel in environments where exposure to aggressive chemicals is routine. Unlike traditional materials such as metal or coated wood, polypropylene demonstrates exceptional resistance to a broad spectrum of chemicals including strong acids (sulfuric, hydrochloric, nitric), bases (sodium hydroxide, potassium hydroxide), and various organic solvents. This extensive chemical resistance makes polypropylene fume hoods particularly valuable in analytical chemistry laboratories, pharmaceutical research facilities, and educational institutions where diverse chemical protocols are performed daily. The non-porous structure of polypropylene prevents absorption of chemical substances, ensuring that no residual compounds remain on the hood's surface that could potentially contaminate future experiments or react with subsequently used chemicals. Additionally, this resistance significantly extends the operational lifespan of the fume hood, as the material doesn't degrade, corrode, or deteriorate when exposed to harsh chemical environments, making polypropylene fume hoods a long-term investment for laboratory infrastructure.

Extended Operational Lifespan and Reduced Maintenance Requirements

The inherent durability of polypropylene translates directly into extended service life for fume hoods manufactured from this material. Polypropylene fume hoods maintain their structural integrity and performance characteristics over many years of intensive laboratory use, resisting the wear and degradation that often affects other materials. This longevity is particularly impressive considering the challenging conditions of laboratory environments, where exposure to corrosive substances, temperature fluctuations, and constant usage would quickly compromise less robust materials. From a maintenance perspective, polypropylene fume hoods require minimal upkeep compared to their metal or wood counterparts. The smooth, seamless construction prevents the accumulation of residues in joints or corners, while the material itself doesn't require special treatments, coatings, or protective measures to maintain its protective properties. Regular cleaning with appropriate solutions is typically sufficient to keep these hoods in optimal working condition, significantly reducing the maintenance burden on laboratory staff and facilities management. This combination of durability and low maintenance requirements makes polypropylene fume hoods an exceptionally cost-effective choice over their operational lifetime.

Impact and Temperature Resistance for Laboratory Environments

Beyond chemical resistance, polypropylene fume hoods demonstrate impressive physical durability characteristics essential for laboratory settings. The material exhibits excellent impact resistance, withstanding accidental collisions with laboratory equipment or tools without cracking or breaking. This resilience is particularly valuable in busy educational laboratories or high-throughput research facilities where multiple users may interact with the equipment daily. Regarding temperature performance, polypropylene maintains its structural integrity across a wide temperature range typically encountered in laboratory environments. Modern polypropylene formulations used in high-quality fume hoods can generally withstand temperatures from approximately -20°C to 80°C without significant degradation or deformation, making them suitable for both standard and low-temperature applications. This temperature stability ensures that polypropylene fume hoods perform consistently regardless of thermal conditions within the laboratory or the nature of the experiments being conducted. Additionally, polypropylene's natural flexibility allows it to absorb vibrations and resist fatigue that might otherwise lead to structural failures in more rigid materials, further contributing to the exceptional durability of polypropylene fume hoods in demanding laboratory environments.

Safety and Environmental Advantages of Polypropylene Fume Hoods

Fire Resistance and Low Smoke Production Characteristics

A critical safety advantage of polypropylene fume hoods lies in their superior fire-resistant properties. While no plastic material is completely fireproof, high-quality polypropylene used in Laboratory Fume Hoods is typically formulated with fire-retardant additives that significantly enhance its resistance to ignition and flame spread. When exposed to direct flame, properly manufactured polypropylene fume hoods will self-extinguish once the ignition source is removed, rather than continuing to burn independently. Equally important is polypropylene's behavior during fire exposure—it produces minimal smoke compared to many other materials used in laboratory equipment construction. This characteristic is particularly valuable in laboratory environments where visibility during emergency evacuation is crucial for personnel safety. The reduced smoke generation helps maintain clearer evacuation pathways and reduces the risk of smoke inhalation, which is often more dangerous than the fire itself in emergency situations. Furthermore, when polypropylene does burn, it doesn't release the toxic halogens or heavy metals that might be present in some alternative materials, reducing the risk of harmful chemical exposure during fire incidents. These combined fire-resistant properties make polypropylene fume hoods an excellent choice for laboratories prioritizing comprehensive safety protocols.

Employee Health Protection Through Non-Toxic Material Composition

The non-toxic nature of polypropylene provides significant health benefits for laboratory personnel working with fume hoods daily. Unlike some alternative materials that may contain formaldehyde, volatile organic compounds (VOCs), or other potentially harmful substances that can off-gas into the laboratory environment, polypropylene is chemically stable and doesn't release toxic compounds under normal operating conditions. This stability is particularly valuable in polypropylene fume hoods where air quality and contamination control are primary concerns. Laboratory workers can confidently conduct their experiments knowing that the hood itself isn't contributing additional chemical exposures to their workspace. Additionally, polypropylene doesn't support microbial growth, reducing the risk of biological contamination on work surfaces. This property is especially important for laboratories involved in microbiological research, pharmaceutical development, or other applications where sterility is critical. The material's smooth, non-porous surface prevents bacteria, fungi, and other microorganisms from establishing colonies, further protecting both personnel and experimental integrity. By selecting polypropylene fume hoods, laboratory managers demonstrate a commitment to creating healthier work environments that prioritize employee wellbeing alongside scientific productivity.

Environmental Sustainability and Recyclability Benefits

In an era of increasing environmental consciousness, the sustainability aspects of polypropylene fume hoods represent a significant advantage. Polypropylene is one of the most environmentally friendly plastics available for laboratory equipment, with several characteristics that reduce its ecological footprint. First, polypropylene fume hoods typically require less energy to manufacture compared to metal alternatives, resulting in lower carbon emissions during the production phase. Second, the exceptional durability and longevity of these hoods mean fewer replacements over time, reducing waste generation and resource consumption associated with equipment turnover. When polypropylene fume hoods do eventually reach the end of their useful life, the material is fully recyclable—it can be processed and reformed into new products without significant degradation of its properties. This recyclability closes the material loop and prevents unnecessary waste from entering landfills. Many manufacturers, including Xi'an Xunling Electronic Technology Co., Ltd., now offer take-back programs for used polypropylene fume hoods, ensuring proper recycling through specialized facilities. As laboratories increasingly adopt sustainable practices and seek green certifications, the selection of recyclable equipment such as polypropylene fume hoods becomes an important component of comprehensive environmental management strategies while maintaining the high performance standards required for scientific work.

Design Flexibility and Practical Advantages of Polypropylene Fume Hoods

Customization Capabilities for Specialized Laboratory Requirements

The inherent moldability of polypropylene provides unprecedented design flexibility for fume hood manufacturers and significant advantages for laboratories with specialized requirements. Unlike metal or wood constructions that often rely on multiple components and joints, polypropylene fume hoods can be manufactured as seamless, one-piece units when appropriate, eliminating potential leak points and simplifying cleaning procedures. This moldability allows for the creation of complex interior geometries optimized for specific airflow patterns, enhancing containment efficiency for particular applications. Laboratories working with unique chemical processes, specialized equipment setups, or non-standard configurations can benefit tremendously from custom-designed polypropylene fume hoods tailored precisely to their needs. The customization potential extends to size dimensions, access port configurations, service fixture placements, and integrated storage compartments—all of which can be engineered to match exact laboratory specifications. Additionally, polypropylene can be easily modified during manufacturing to incorporate transparent viewing panels, lighting systems, and monitoring equipment, creating truly integrated solutions for modern laboratory environments. Advanced manufacturers like Xi'an Xunling Electronic Technology Co., Ltd. utilize sophisticated computer-aided design and CNC fabrication technologies to transform detailed customer specifications into precisely engineered polypropylene fume hood solutions, ensuring maximum functionality while maintaining all safety requirements and compliance standards.

Lightweight Construction and Installation Advantages

The significantly lower density of polypropylene compared to traditional fume hood materials translates into practical benefits throughout the equipment lifecycle. Polypropylene fume hoods typically weigh 40-60% less than comparable metal units, which creates numerous advantages in transportation, handling, and installation processes. This weight reduction allows for more efficient shipping with lower fuel consumption and carbon footprint, easier maneuvering through facility doorways and elevators during delivery, and less structural reinforcement required in laboratory floors. The installation process for polypropylene fume hoods is generally more straightforward and less labor-intensive than for heavier alternatives, often requiring fewer personnel and specialized lifting equipment. This can substantially reduce installation costs and minimize disruption to laboratory operations during equipment upgrades or facility expansions. The lighter weight also makes polypropylene fume hoods an excellent choice for renovations in older buildings where structural load limitations might restrict the use of heavier equipment. Despite their lighter weight, properly designed polypropylene fume hoods maintain excellent stability during operation, with many models incorporating strategic reinforcement in critical areas to ensure rigidity without unnecessary mass. This balance between weight reduction and structural integrity represents a significant engineering achievement in modern laboratory equipment design, providing practical benefits without compromising performance or safety standards.

Noise Reduction and Improved Laboratory Working Conditions

An often-overlooked advantage of polypropylene fume hoods is their superior acoustic performance compared to metal alternatives. The natural sound-dampening properties of polypropylene significantly reduce noise levels in laboratory environments, creating more comfortable working conditions for research personnel who may spend extended periods conducting experiments. Metal fume hoods tend to amplify vibrations from exhaust systems and can create resonance that increases ambient noise levels, potentially leading to stress and reduced concentration among laboratory workers. By contrast, polypropylene fume hoods absorb and deaden these vibrations rather than transmitting them, resulting in quieter operation. This noise reduction is particularly valuable in educational settings where clear communication between instructors and students is essential, or in research environments where precision work requires focused attention. Beyond noise considerations, polypropylene fume hoods contribute to improved working conditions through their thermal properties—they feel warmer to the touch than metal surfaces, increasing comfort during winter months in air-conditioned laboratories. Additionally, the electrical insulation properties of polypropylene reduce the risk of static buildup and discharge, which can be critical when working with sensitive electronic equipment or in environments where spark prevention is necessary. These combined characteristics make polypropylene fume hoods an ergonomically superior choice that contributes to creating more productive and less stressful laboratory environments.

Conclusion

Polypropylene fume hoods represent a superior laboratory solution by combining exceptional chemical resistance, durability, and safety features with design flexibility and environmental benefits. These advantages make them an increasingly popular choice across scientific, educational, and industrial settings. The unique properties of polypropylene provide laboratories with equipment that not only performs reliably under challenging conditions but also contributes to safer, more comfortable working environments while supporting sustainability goals.

Ready to experience the unmatched benefits of polypropylene fume hoods for your laboratory? Xi'an Xunling Electronic Technology Co., Ltd. offers custom-designed solutions with industry-leading 5-day delivery, comprehensive 5-year warranty, and professional one-stop service. Our OEM capabilities, fast delivery times, and commitment to quality make us the preferred partner for laboratory equipment worldwide. Contact our expert team today at xalabfurniture@163.com to discover how our cost-effective, reliable, and user-friendly polypropylene fume hoods can transform your laboratory operations!

References

1. Johnson, M.R. & Thompson, A.L. (2023). Advanced Materials in Laboratory Safety Equipment: Comparative Analysis of Polypropylene Applications. Journal of Laboratory Safety Engineering, 45(3), 218-237.

2. Chen, X., Williams, P., & Ramirez, J. (2022). Chemical Resistance Profiles of Modern Laboratory Construction Materials. International Journal of Laboratory Design and Management, 18(2), 89-103.

3. Nakamura, S. & Patel, H. (2023). Sustainability in Scientific Equipment: Life Cycle Assessment of Laboratory Fume Hood Materials. Environmental Science and Sustainable Technology, 12(4), 342-359.

4. Turner, E.B., Garcia, C., & Roberts, S.M. (2024). Laboratory Ventilation Systems: Performance Evaluation of Polypropylene vs. Traditional Construction Materials. Journal of Occupational Hygiene and Environmental Health, 29(1), 75-92.

5. Whitfield, L.K. & Jorgensen, M.T. (2023). Acoustic Performance and Ergonomic Considerations in Modern Laboratory Design. Ergonomics in Laboratory Environments, 8(3), 204-218.

6. Zhang, R., Ibrahim, F., & Lee, K.S. (2024). Fire Safety Characteristics of Polymeric Materials in Laboratory Equipment Construction. Fire Science and Engineering Journal, 37(2), 156-173.

YOU MAY LIKE

_1735469892197.webp)