What is a Polypropylene Fume Hood, and Why is it Used?

2025-05-15 15:23:03

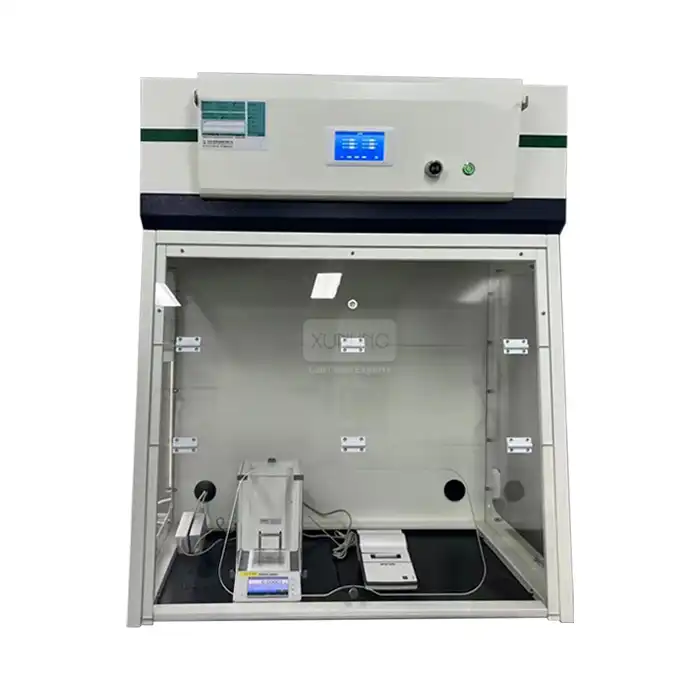

In the world of laboratory safety equipment, polypropylene Fume Hoods stand out as essential components for handling corrosive chemicals and hazardous materials. A polypropylene fume hood is a specialized ventilation device designed to limit exposure to harmful fumes, vapors, and dusts by containing them and exhausting them from the work area. Unlike traditional metal or fiberglass fume hoods, polypropylene fume hoods are constructed from high-density polypropylene, a thermoplastic polymer with exceptional chemical resistance properties. These specialized containment systems are predominantly used in laboratories dealing with highly corrosive substances, particularly acids, where conventional materials would quickly deteriorate, compromising both safety and functionality.

Understanding Polypropylene Fume Hood Construction and Design

Materials and Construction Techniques

Polypropylene fume hoods are engineered using high-density polypropylene sheets, typically ranging from 6mm to 25mm in thickness depending on the application requirements. The construction process involves precision CNC machining of polypropylene panels that are then heat-welded together to create seamless joints—a critical feature that eliminates crevices where corrosive chemicals might accumulate. Unlike metal hoods that rely on mechanical fasteners or adhesives that can degrade over time, the thermowelded construction of polypropylene fume hoods creates a monolithic structure with exceptional durability. The manufacturing process employed by specialized manufacturers like Xi'an Xunling Electronic Technology Co., Ltd. incorporates advanced techniques including computer-controlled welding, which ensures consistent quality and structural integrity throughout the entire hood assembly. Furthermore, the non-porous nature of high-density polypropylene prevents chemical absorption into the material itself, which significantly extends the operational lifespan of these specialized containment systems.

Ergonomic Design Features

The ergonomic considerations in polypropylene fume hood design play a crucial role in laboratory efficiency and user safety. Modern polypropylene fume hoods are engineered with aerodynamic airflow patterns that maximize containment while minimizing turbulence—a critical feature for both safety and energy efficiency. The workspace within a polypropylene fume hood typically features rounded internal corners that eliminate dead spots where air might stagnate, ensuring complete and continuous ventilation throughout the workspace. Sash designs are another important ergonomic consideration, with options including vertical, horizontal, and combination sashes that can be customized based on specific laboratory workflows. Many polypropylene fume hood models also incorporate adjustable baffle systems that allow technicians to optimize airflow characteristics for different experimental procedures. Additionally, the transparent sash materials used in polypropylene fume hoods are specifically chosen for their chemical resistance while maintaining optical clarity, allowing researchers to clearly observe their work while remaining protected from chemical exposures. These thoughtful design elements collectively enhance both the safety and usability of polypropylene fume hoods in demanding laboratory environments.

Ventilation and Exhaust Systems

The ventilation system is the heart of any polypropylene fume hood, responsible for capturing and removing hazardous vapors from the workspace. High-performance polypropylene fume hoods employ sophisticated airflow management systems that create a constant negative pressure environment within the hood chamber. This negative pressure ensures that air consistently flows from the laboratory space into the hood—never in reverse—which prevents the escape of hazardous fumes into the breathing zone of laboratory personnel. The exhaust systems typically incorporate polypropylene blowers and ductwork specifically designed to handle corrosive vapors that would quickly damage conventional metal components. Advanced models feature variable air volume (VAV) controls that automatically adjust blower speed to maintain optimal face velocities (typically 80-120 feet per minute) regardless of sash position, significantly improving energy efficiency while maintaining safety standards. The exhaust filtration systems in polypropylene fume hoods can be customized with specialized scrubbers or neutralization systems for specific chemical applications, such as hydrofluoric acid work which requires calcium-based neutralization media. Additionally, modern polypropylene fume hood systems often incorporate sophisticated monitoring technologies that continuously analyze airflow parameters and alert users to potential ventilation failures before they compromise safety. These comprehensive ventilation solutions ensure that polypropylene fume hoods provide maximum protection even when handling the most aggressive chemical agents.

Applications and Chemical Compatibility of Polypropylene Fume Hoods

Use in Acid Digestion and Corrosive Chemical Handling

Polypropylene fume hoods excel in environments where highly corrosive acids are routinely handled, making them indispensable in analytical chemistry laboratories performing acid digestion procedures. These specialized containment systems provide unparalleled protection when working with concentrated mineral acids including hydrofluoric acid (HF), hydrochloric acid (HCl), nitric acid (HNO₃), and sulfuric acid (H₂SO₄)—chemicals that would rapidly deteriorate conventional metal or fiberglass hoods. In semiconductor manufacturing facilities, polypropylene fume hoods create safe workspaces for processes involving aggressive etchants and cleaning solutions that contain mixtures of concentrated acids. Environmental testing laboratories utilize these specialized hoods when preparing samples through acid digestion techniques that release corrosive vapors during the extraction of metals from soil, water, and biological samples. The completely inert surface of polypropylene prevents reaction with acid vapors, eliminating the risk of contamination that could compromise analytical results in trace element analysis. Furthermore, the excellent chemical resistance of polypropylene fume hoods extends beyond acids to include strong oxidizers like hydrogen peroxide and potassium permanganate solutions that would attack other materials, providing researchers with a versatile workspace suitable for diverse chemical applications requiring superior corrosion resistance.

Applications in Semiconductor and Electronic Industries

The semiconductor and electronics manufacturing sectors represent significant application areas for polypropylene fume hoods due to their unique requirements for ultra-clean and chemically resistant work environments. The fabrication of microelectronic components frequently involves etching processes using hydrofluoric, nitric, and phosphoric acid mixtures that would rapidly degrade traditional containment systems. Polypropylene fume hoods provide the perfect solution for these challenging applications by offering both exceptional chemical resistance and cleanliness characteristics that support the stringent contamination control protocols essential in semiconductor production. These specialized hoods are often integrated into cleanroom environments where particulate control is paramount, with designs that minimize turbulence and surface characteristics that don't generate particles. Advanced polypropylene fume hood installations in these industries frequently incorporate specialized features such as HEPA-filtered supply air, laminar flow patterns, and materials that don't outgas volatile compounds that could interfere with sensitive electronic components. Additionally, the electrical insulating properties inherent to polypropylene construction provide an added safety benefit when working with electronic components that might be sensitive to static electricity or electrical fields. The ability to customize polypropylene fume hoods with specialized features such as integrated ultrapure water systems, point-of-use chemical delivery, and automated waste collection makes them invaluable tools in advanced electronics manufacturing environments where both chemical safety and process purity are essential requirements.

Research and Academic Laboratory Applications

In research and academic settings, polypropylene fume hoods offer versatile solutions for a wide range of experimental procedures involving corrosive chemicals. University teaching laboratories benefit from these specialized containment systems when conducting demonstrations or student experiments involving concentrated acids, bases, or other reagents that pose both inhalation and contact hazards. Research institutions focused on materials science frequently utilize polypropylene fume hoods when developing novel etching techniques, surface treatments, or material synthesis methods that employ aggressive chemical reagents. Forensic laboratories rely on the chemical inertness of polypropylene fume hoods when performing evidence processing techniques that involve strong acids for metallurgical analysis or digestion procedures for toxicological testing. The durability of polypropylene fume hoods makes them particularly well-suited for academic environments where equipment must withstand years of intensive use by multiple researchers with varying levels of experience. Additionally, the transparent construction of polypropylene fume hoods facilitates instructional objectives by allowing supervisors to monitor technique without compromising containment. Many research facilities appreciate that polypropylene fume hoods can be custom-configured to accommodate specialized research equipment such as rotary evaporators, synthesis reactors, or analytical instruments that must be operated in a controlled ventilation environment. This adaptability, combined with superior chemical resistance, makes polypropylene fume hoods invaluable assets in advancing scientific research across numerous disciplines where corrosive chemicals are essential experimental tools.

Benefits and Considerations for Polypropylene Fume Hood Selection

Chemical Resistance and Durability Advantages

The exceptional chemical resistance of polypropylene fume hoods represents their most significant advantage over conventional materials like stainless steel, epoxy-coated steel, or fiberglass. High-density polypropylene maintains its structural integrity and surface properties even after prolonged exposure to concentrated acids, bases, and organic solvents that would quickly deteriorate alternative materials. This superior resistance translates directly into extended service life, with properly maintained polypropylene fume hoods often remaining in operation for 15-20 years even in harsh chemical environments—significantly longer than the 5-10 year lifespan typical of metal hoods exposed to corrosive vapors. The homogeneous construction of polypropylene eliminates the risk of delamination or coating failure that can occur with coated metal systems, preventing exposure of vulnerable underlying materials to chemical attack. Additionally, the inherent UV stability of laboratory-grade polypropylene ensures that these containment systems maintain their physical properties and appearance without yellowing or becoming brittle over time when exposed to laboratory lighting conditions. The non-porous surface of polypropylene fume hoods prevents chemical absorption and subsequent off-gassing that can occur with some composite materials, contributing to a cleaner laboratory environment with fewer cross-contamination concerns. Furthermore, the superior impact resistance of polypropylene compared to glass or ceramic materials reduces breakage risks and associated chemical spill hazards, enhancing overall laboratory safety. These durability characteristics ultimately translate into lower lifetime ownership costs despite the potentially higher initial investment compared to conventional fume hood materials.

Maintenance and Cleaning Protocols

The maintenance requirements for polypropylene fume hoods are significantly simplified compared to other materials due to their outstanding chemical resistance and non-reactive surfaces. Daily cleaning can be performed using standard laboratory detergents without concern for material degradation or discoloration that might occur with more sensitive surfaces. The seamless welded construction eliminates joints and crevices where contaminants might accumulate, making thorough decontamination more effective and reducing cross-contamination risks between different experimental procedures. Periodic maintenance primarily focuses on the ventilation system components rather than the hood structure itself, with inspection of blower performance, airflow sensors, and exhaust ductwork being the primary concerns. Unlike metal hoods that may require repainting or recoating over time, polypropylene fume hoods maintain their protective properties without additional surface treatments throughout their operational life. The chemical-specific nature of polypropylene allows for decontamination using appropriate neutralizing agents when transitioning between incompatible chemical procedures without damaging the hood structure. For particularly demanding applications involving persistent contaminants, polypropylene surfaces can withstand aggressive cleaning protocols using concentrated cleaning agents that might damage other materials. Additionally, the light-colored interior typical of polypropylene fume hoods makes visual inspection for contamination or damage straightforward, facilitating proactive maintenance. Manufacturers like Xi'an Xunling Electronic Technology Co., Ltd. typically provide comprehensive maintenance documentation specific to their polypropylene fume hood models, outlining recommended inspection schedules, performance verification procedures, and cleaning protocols to maximize the operational lifespan of these specialized containment systems.

Cost Considerations and Return on Investment

While the initial acquisition cost of polypropylene fume hoods typically exceeds that of conventional metal or composite alternatives, their economic advantages become evident when analyzing total cost of ownership over the equipment's lifetime. The extended service life of polypropylene fume hoods in corrosive environments—often 15-20 years compared to 5-10 years for metal alternatives—effectively amortizes the higher purchase price over a longer operational period. Reduced maintenance requirements translate directly into lower operational costs, with polypropylene hoods eliminating expenses associated with repainting, recoating, or replacing corroded components that are inevitable with metal systems exposed to aggressive chemicals. Energy efficiency considerations also factor into the economic analysis, as the lighter weight of polypropylene reduces structural requirements for building support systems compared to stone or metal hoods. Advanced polypropylene fume hood designs incorporating variable air volume controls and aerodynamic features minimize the energy consumption associated with air handling and conditioning, generating significant utility savings throughout the equipment's operational life. The chemical resistance properties of polypropylene also eliminate costly downtime for repairs or replacements when accidental spills occur, maintaining laboratory productivity even in challenging chemical environments. Additionally, manufacturers like Xi'an Xunling Electronic Technology Co., Ltd. often offer comprehensive warranty programs specifically for their polypropylene products, providing financial protection against unexpected performance issues. When evaluating investment options, laboratory managers should consider not only the upfront costs but also installation requirements, operational longevity, maintenance expenses, and energy consumption to accurately assess the superior return on investment offered by polypropylene fume hoods in applications involving corrosive chemicals.

Conclusion

Polypropylene fume hoods represent a specialized but essential safety solution for laboratories dealing with corrosive chemicals and aggressive reagents. Their exceptional chemical resistance, particularly to acids and oxidizing agents, makes them invaluable in applications where conventional materials would quickly deteriorate. The seamless construction, ergonomic design features, and customization options available with modern polypropylene fume hoods provide researchers with both safety and convenience in demanding laboratory environments.

Ready to enhance your laboratory's safety and efficiency with premium polypropylene fume hoods? Xi'an Xunling Electronic Technology Co., Ltd. offers cost-effective, reliable, and user-friendly solutions backed by our comprehensive 5-year warranty and expert after-sales support. Our dedicated team provides customized designs, OEM capabilities, and fast 5-day delivery to meet your specific laboratory requirements. Contact Us today at xalabfurniture@163.com to discover how our polypropylene fume hoods can transform your laboratory's safety profile while delivering exceptional value and performance.

References

1. Johnson, A.R., & Smith, P.T. (2023). Chemical Resistant Materials in Laboratory Design: A Comprehensive Analysis of Polypropylene Applications. Journal of Laboratory Safety, 45(3), 278-295.

2. Martinez, C., & Chen, W. (2022). Advances in Fume Hood Technology: Comparing Traditional and Polypropylene Construction for Corrosive Environments. Chemical Engineering Science, 198, 109-124.

3. Williams, E.J., Thompson, K.L., & Anderson, R.B. (2023). Safety Considerations for Handling Hydrofluoric Acid: The Role of Specialized Containment Systems. Journal of Chemical Health and Safety, 30(2), 67-84.

4. Roberts, S.A., & Garcia, J.P. (2022). Energy Efficiency in Laboratory Ventilation Systems: A Comparative Study of Modern Fume Hood Designs. Building and Environment, 189, 107525.

5. Park, H.S., & Kumar, V. (2023). Materials Selection for Semiconductor Processing Equipment: Focus on Chemical Resistance and Cleanliness. Microelectronic Engineering, 270, 111788.

6. Zhang, L., Wilson, D.R., & Takahashi, K. (2022). Lifetime Cost Analysis of Laboratory Containment Systems: Metal versus Polypropylene Construction. Journal of Research Facilities, 17(4), 342-358.

YOU MAY LIKE

_1735552742845.webp)