What maintenance practices are essential for fume hoods?

2025-06-12 11:14:03

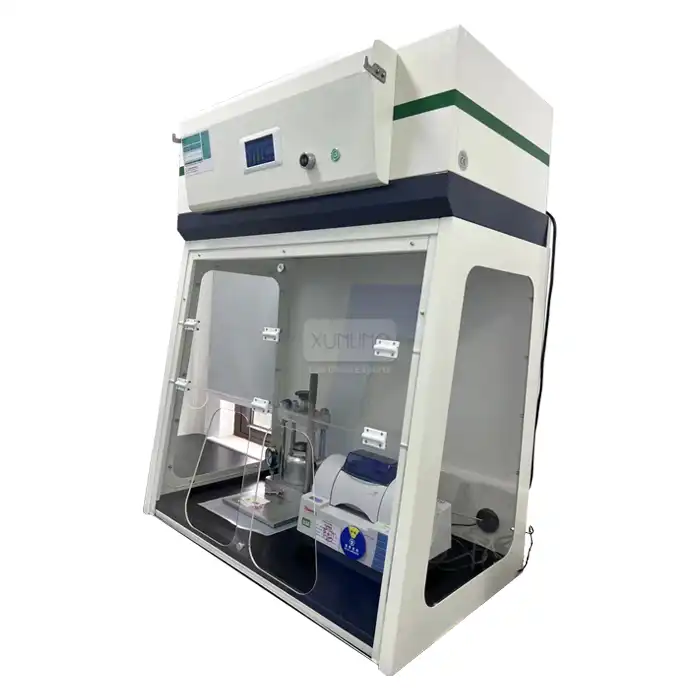

Laboratory safety depends heavily on the proper functioning of ventilation systems, with Fume Hoods serving as the first line of defense against hazardous chemical vapors and contaminants. Understanding and implementing essential maintenance practices for these critical safety devices is paramount for laboratory personnel, facility managers, and safety officers. This comprehensive guide explores the fundamental maintenance requirements that ensure optimal performance, regulatory compliance, and long-term reliability of laboratory fume exhaust hood systems.

Maintaining a fume exhaust hood requires systematic attention to multiple components and operational parameters to guarantee consistent protective performance. Regular maintenance practices encompass daily operational checks, periodic mechanical inspections, filter replacements, airflow calibrations, and comprehensive safety certifications. These essential practices not only ensure compliance with occupational safety standards but also extend equipment lifespan, reduce operational costs, and maintain the integrity of laboratory research environments. Proper maintenance scheduling prevents unexpected failures, minimizes downtime, and protects both personnel and valuable research from potential contamination or exposure incidents.

Regular Inspection and Testing Protocols

Daily Operational Assessments

Establishing comprehensive daily operational assessments forms the foundation of effective fume exhaust hood maintenance programs. Laboratory personnel must conduct systematic visual inspections before each use, checking for obvious signs of damage, unusual sounds, or visible obstructions within the hood chamber. The sash operation should be evaluated for smooth movement, proper positioning, and secure locking mechanisms, while airflow indicators must be verified to confirm adequate ventilation performance. Daily assessments should include verification of lighting functionality, electrical connections, and emergency shutdown systems to ensure immediate response capabilities during critical situations. These routine checks extend beyond simple visual confirmations to include documentation of operational parameters such as face velocity measurements, temperature readings, and any unusual vibrations or noise patterns that might indicate developing mechanical problems. Laboratory staff should maintain detailed logbooks recording daily observations, noting any deviations from normal operating conditions, and immediately reporting concerns to maintenance personnel. The consistency of daily assessments creates a baseline for performance comparison and enables early detection of potential issues before they compromise safety or require expensive emergency repairs.

Weekly Performance Monitoring

Weekly performance monitoring involves more detailed evaluations of fume exhaust hood systems, focusing on quantitative measurements and systematic component assessments. Trained technicians should conduct airflow velocity measurements at multiple points across the hood face using calibrated anemometers or digital flow meters, ensuring readings remain within specified parameters established during initial commissioning. These measurements must be documented and compared against previous readings to identify gradual performance degradation that might not be apparent during daily visual inspections. The weekly monitoring protocol should include thorough examination of ventilation ducts, exhaust fans, and filtration systems for signs of wear, corrosion, or accumulation of chemical residues that could impact performance. Electrical systems require inspection for loose connections, damaged wiring, or signs of overheating that could pose fire hazards or operational failures. Control systems, including variable air volume controls, alarm systems, and monitoring devices, must be tested for proper functionality and calibration accuracy to ensure reliable safety responses during emergency situations.

Monthly Comprehensive Evaluations

Monthly comprehensive evaluations represent the most thorough level of routine maintenance assessment, involving detailed inspection of all fume exhaust hood components and systems. Professional maintenance technicians should conduct extensive airflow pattern analysis using smoke testing or other visualization methods to identify dead zones, turbulence, or reverse flow conditions that could compromise containment effectiveness. These evaluations include complete documentation of all measurable parameters, comparison with manufacturer specifications, and assessment of overall system performance relative to safety standards and regulatory requirements. During monthly evaluations, technicians must examine mechanical components including fan assemblies, drive belts, motor bearings, and shaft alignments for signs of wear or potential failure. Filter systems require detailed inspection for loading, damage, or bypass conditions that could reduce filtration efficiency or create safety hazards. The evaluation process should include review of maintenance records, identification of recurring issues, and development of corrective action plans to address any deficiencies discovered during the comprehensive assessment process.

Cleaning and Filter Management

Surface Cleaning Procedures

Proper surface cleaning procedures for fume exhaust hood systems require specialized approaches that address both cleanliness requirements and material compatibility considerations. Interior surfaces must be cleaned using appropriate solvents and cleaning agents that effectively remove chemical residues without damaging hood materials or creating harmful reaction products. The cleaning process should begin with complete shutdown of the ventilation system, followed by systematic removal of any equipment or materials from the hood chamber to provide unrestricted access to all surfaces requiring attention. Cleaning procedures must account for the specific types of chemicals and processes conducted within each fume exhaust hood, as different contaminants require different removal strategies and safety precautions. Acidic residues demand neutralization procedures before cleaning, while organic solvents may require specialized disposal methods and ventilation considerations during the cleaning process. All cleaning activities should be conducted by trained personnel wearing appropriate personal protective equipment and following established safety protocols to prevent exposure to concentrated contaminants or cleaning agent vapors. Documentation of cleaning procedures includes recording the types of cleaning agents used, areas addressed, and any unusual conditions discovered during the process. This information provides valuable insights into usage patterns, contamination levels, and potential maintenance requirements that might not be apparent through routine operational assessments. Regular surface cleaning not only maintains hygiene standards but also prevents accumulation of corrosive materials that could damage hood components or create safety hazards over time.

Filter Replacement Strategies

Effective filter replacement strategies for fume exhaust hood systems require understanding of different filter types, replacement intervals, and performance criteria that determine optimal maintenance timing. Pre-filters, HEPA filters, and specialized chemical filtration media each have distinct replacement requirements based on loading capacity, efficiency ratings, and contamination levels encountered during normal operation. Replacement scheduling should be based on actual performance measurements rather than arbitrary time intervals, ensuring filters are changed when efficiency drops below acceptable levels or pressure differentials exceed design parameters. The filter replacement process requires proper handling procedures to prevent cross-contamination, exposure to concentrated contaminants, and damage to replacement filters during installation. Used filters must be properly disposed of according to hazardous waste regulations, with particular attention to filters containing radioactive materials, carcinogens, or other regulated substances. Replacement filters should be inspected upon receipt to verify correct specifications, damage-free condition, and proper packaging that prevents contamination before installation. Filter management systems should include inventory tracking to ensure adequate supplies are maintained, documentation of replacement dates and filter specifications, and performance monitoring to verify proper installation and initial operation. Quality assurance procedures must confirm that replacement filters meet or exceed original equipment specifications and that installation procedures maintain system integrity and performance capabilities.

Chemical Residue Management

Chemical residue management within fume exhaust hood systems requires comprehensive understanding of the specific materials and processes conducted in each unit, along with appropriate removal and disposal procedures for accumulated contaminants. Different chemical families create distinct residue patterns and require specialized cleaning approaches that effectively remove contaminants without creating additional hazards or damaging hood components. Acidic materials may cause corrosion if not properly neutralized, while organic compounds might require solvent-based removal procedures with appropriate ventilation and safety measures. The residue management process should include systematic identification of contamination sources, assessment of accumulation patterns, and development of targeted removal strategies that address specific chemical properties and safety requirements. Personnel conducting residue removal must be trained in proper handling procedures, emergency response protocols, and disposal requirements for the specific materials encountered. Documentation of residue management activities provides valuable information for optimizing laboratory procedures and maintenance schedules to minimize future accumulation. Long-term residue management strategies should consider the cumulative effects of different chemicals on hood materials and components, identifying potential degradation patterns that might require component replacement or system modifications. Regular analysis of residue composition can reveal changes in laboratory usage patterns, identify potential safety concerns, and guide decisions regarding maintenance procedures and replacement schedules for critical components.

Ventilation System Optimization

Airflow Calibration Methods

Airflow calibration methods for fume exhaust hood systems require precise measurement techniques and standardized procedures to ensure consistent protective performance across varying operational conditions. Professional calibration involves multiple measurement points across the hood face, using calibrated instrumentation to document velocity profiles and identify any irregularities in airflow patterns that could compromise containment effectiveness. The calibration process must account for sash position variations, environmental conditions, and building pressure relationships that influence overall system performance. Calibration procedures should follow established industry standards and manufacturer specifications, with measurements conducted under conditions that represent typical operational scenarios. Variable air volume systems require calibration across the full range of sash positions and airflow settings to ensure proper response characteristics and maintain appropriate face velocities throughout the operating range. Documentation of calibration results provides baseline data for future comparisons and helps identify gradual performance changes that might indicate developing maintenance requirements. Advanced calibration methods may include computational fluid dynamics analysis or tracer gas studies to evaluate containment effectiveness and identify potential improvements to airflow patterns. These sophisticated techniques provide detailed understanding of air movement within and around the fume exhaust hood, enabling optimization of performance parameters and identification of design modifications that could enhance safety or efficiency. Regular calibration ensures that ventilation systems continue to provide adequate protection as building conditions, usage patterns, and equipment configurations change over time.

Energy Efficiency Improvements

Energy efficiency improvements for fume exhaust hood systems offer significant opportunities to reduce operational costs while maintaining or enhancing safety performance. Variable air volume controls can substantially reduce energy consumption by automatically adjusting airflow rates based on sash position and occupancy sensors, eliminating unnecessary ventilation during unoccupied periods. Heat recovery systems can capture thermal energy from exhaust air streams, reducing heating and cooling costs for replacement air while maintaining proper ventilation rates. Implementing energy efficiency measures requires careful analysis of usage patterns, operational requirements, and safety considerations to ensure that cost-saving modifications do not compromise protective performance. Modern control systems can integrate multiple efficiency strategies, including demand-based ventilation, occupancy sensing, and predictive maintenance scheduling to optimize energy usage while maintaining regulatory compliance. These systems can also provide detailed energy usage data that supports facility management decisions and identifies additional improvement opportunities. The economic benefits of energy efficiency improvements often justify initial investment costs through reduced utility bills, lower maintenance requirements, and extended equipment lifespans. Facilities should consider lifecycle cost analysis when evaluating efficiency upgrades, accounting for energy savings, maintenance reductions, and potential incentives or rebates available for energy-efficient laboratory equipment. Documentation of energy performance before and after improvements provides valuable data for assessing return on investment and planning future efficiency projects.

Control System Maintenance

Control system maintenance for fume exhaust hood installations requires specialized knowledge of electronic components, software systems, and integration protocols that govern automated ventilation responses. Modern control systems incorporate sophisticated sensors, actuators, and processing units that require regular calibration, software updates, and component testing to ensure reliable operation. Maintenance procedures should include verification of sensor accuracy, actuator response times, and alarm system functionality to prevent safety system failures during critical operational periods. The maintenance program for control systems should address both hardware and software components, including regular backup of system configurations, verification of communication protocols, and testing of emergency response procedures. Preventive maintenance schedules should account for environmental conditions that may affect electronic components, including temperature variations, humidity levels, and chemical exposure that could cause corrosion or degradation of sensitive equipment. Documentation of control system performance provides valuable troubleshooting information and helps identify patterns that might indicate developing problems. Advanced control systems may include remote monitoring capabilities, predictive maintenance features, and integration with building management systems that require specialized maintenance approaches. These sophisticated systems offer enhanced safety and efficiency capabilities but require ongoing attention to cybersecurity considerations, software updates, and system integration issues that could affect performance. Regular training for maintenance personnel ensures that they remain current with evolving technology and can effectively support increasingly complex control system requirements.

Conclusion

Implementing comprehensive maintenance practices for fume exhaust hood systems represents a critical investment in laboratory safety, operational efficiency, and regulatory compliance. The systematic approach outlined through regular inspections, proper cleaning procedures, and ventilation system optimization ensures reliable protective performance while minimizing operational costs and extending equipment lifespans. These essential maintenance practices create a foundation for safe laboratory operations, protecting personnel, research integrity, and institutional investments in sophisticated laboratory infrastructure. Success requires commitment to consistent implementation, ongoing training, and continuous improvement of maintenance procedures as technology and regulatory requirements evolve.

Ready to ensure your laboratory maintains the highest safety standards with professional-grade fume exhaust hood systems? Xi'an Xunling Electronic Technology Co., Ltd. offers comprehensive solutions including custom-designed fume hoods, complete maintenance support, and expert technical guidance to optimize your laboratory ventilation systems. With our 5-day delivery guarantee, 5-year warranty coverage, and one-stop service approach, we provide cost-effective solutions that combine reliability, durability, and user-friendly operation. Our dedicated team offers comprehensive after-sales support, flexible purchasing options, and OEM services tailored to your specific requirements. Contact Us today at xalabfurniture@163.com to discover how our expertise can enhance your laboratory safety and operational efficiency.

References

1. American Conference of Governmental Industrial Hygienists. "Industrial Ventilation: A Manual of Recommended Practice for Design." 30th Edition, ACGIH Publications, 2019.

2. National Institute for Occupational Safety and Health. "Criteria for a Recommended Standard: Occupational Exposure to Chemical Fume Hoods in Laboratories." DHHS Publication No. 2018-106, Centers for Disease Control and Prevention, 2018.

3. ASHRAE Standard Committee. "Method of Testing Performance of Laboratory Fume Hoods." ANSI/ASHRAE Standard 110-2016, American Society of Heating, Refrigerating and Air-Conditioning Engineers, 2016.

4. Laboratory Equipment Manufacturers Association. "Best Practices for Laboratory Ventilation System Maintenance and Operation." LEMA Technical Publication LV-2020-03, 2020.

5. International Organization for Standardization. "Laboratory Equipment - Fume Cupboards - Part 1: Vocabulary and General Requirements." ISO 14175-1:2019, International Standards Organization, 2019.

6. Occupational Safety and Health Administration. "Laboratory Safety Guidance for Compliance with the OSHA Laboratory Standard." OSHA Publication 3404-10R, U.S. Department of Labor, 2021.

YOU MAY LIKE