How Do I Choose the Right Size and Type of Lab Vent Hood?

2025-06-11 17:28:37

Selecting the appropriate lab vent hood is a critical decision that directly impacts laboratory safety, operational efficiency, and experiment integrity. Lab vent hoods serve as the primary defense against hazardous fumes, vapors, and particulates generated during scientific procedures. This comprehensive guide will help laboratory managers, researchers, and facility planners navigate the complex considerations involved in choosing the right size and type of lab vent hood. From understanding workflow requirements to assessing spatial constraints and compliance standards, we'll explore the essential factors that should inform your decision-making process.

Understanding Lab Vent Hood Fundamentals

Types of Lab Vent Hoods Available

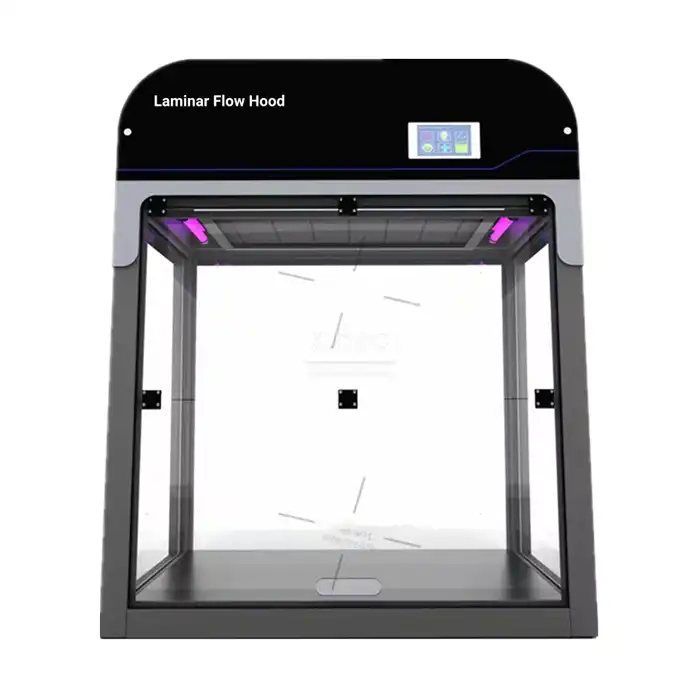

Lab vent hoods come in various configurations designed to address specific laboratory needs. The conventional Ducted Fume Hood remains the most widely used option, directing contaminated air through ductwork to be exhausted outside the building. These systems provide exceptional protection for handling volatile or hazardous substances but require permanent installation and connection to building ventilation systems. Alternatively, ductless or recirculating lab vent hoods utilize advanced filtration technology to purify air before returning it to the laboratory environment. Xi'an Xunling Electronic Technology Co., Ltd. offers both variants with their modular design philosophy, allowing laboratories to select the most appropriate system based on their specific requirements. Our XL-PH series includes both ducted and ductless models, featuring intelligent airflow control systems that maintain surface wind speeds between 0.3-0.6 m/s, ensuring optimal containment while maximizing energy efficiency. Each type serves distinct purposes – while ducted systems are ideal for high-volume or particularly hazardous applications, ductless models provide greater flexibility for laboratory spaces where external ventilation installation is impractical or cost-prohibitive.

Key Safety Features to Consider

When selecting a lab vent hood, safety features should be your paramount concern. Modern lab vent hoods incorporate multiple safety elements designed to protect users from chemical exposure and potential accidents. Xi'an Xunling's Laboratory Fume Hoods feature 5mm tempered glass windows with angle limiters that optimize both visibility and containment. This thoughtful design allows researchers to maintain clear sightlines while ensuring proper airflow dynamics. Our models comply with international standards including EN 14175 and ASHRAE 110, guaranteeing performance that meets or exceeds global safety benchmarks. The corrosion-resistant materials used in construction—including epoxy resin and stainless steel linings—can withstand exposure to strong acids, alkalis, and elevated temperatures, ensuring long-term durability even in demanding research environments. Additionally, real-time airflow monitoring systems provide continuous feedback on containment conditions, with alarm systems that alert users to potential ventilation failures or unsafe operating conditions. Xi'an Xunling's commitment to safety extends to design elements like airfoil sills that minimize turbulence and optimize airflow patterns, further enhancing the protective capabilities of our lab vent hood systems while reducing energy consumption.

Material and Construction Quality

The materials used in lab vent hood construction significantly impact both performance and longevity. Xi'an Xunling's commitment to quality is evident in our material selection process, with each component chosen for specific performance characteristics. Our XL-PH series features polypropylene construction, known for its exceptional chemical resistance and mechanical durability. This material withstands continuous exposure to acids, bases, solvents, and other corrosive substances commonly used in laboratory settings. The inner work surfaces and linings utilize specialized materials including epoxy resin and stainless steel options that provide superior resistance to chemical damage, heat, and physical wear. These materials also facilitate easy cleaning and decontamination procedures, essential for maintaining laboratory hygiene standards. The structural framework employs robust engineering principles to ensure stability during operation, minimizing vibration that could disrupt sensitive procedures. All glass components are laboratory-grade tempered safety glass, providing optimal clarity while maintaining containment integrity. Xi'an Xunling's manufacturing process incorporates rigorous quality control measures, including specialized CNC machinery and automated production lines, ensuring dimensional precision and consistent performance across all our lab vent hood models. With 18 CNC laser cutting machines, 50 CNC bending machines, and fully automated spraying lines, we maintain exceptional manufacturing standards that translate to superior product reliability in laboratory settings.

Determining the Correct Size and Capacity

Laboratory Space Assessment

Before selecting a lab vent hood, conducting a comprehensive laboratory space assessment is essential. This process involves evaluating the available floor space, ceiling height, existing infrastructure, and workflow patterns. Xi'an Xunling's technical team recommends allocating adequate clearance around the hood—typically a minimum of 3 feet on all sides—to ensure proper air circulation and ergonomic operation. Consider vertical clearance requirements as well, particularly for our XL-PH series which stands at 2350mm in height. Laboratory layout efficiency directly impacts research productivity; therefore, the placement of your lab vent hood should minimize foot traffic disruptions while remaining accessible to related equipment and storage areas. Our technical consultants can provide detailed spatial planning assistance to optimize your laboratory configuration. Additionally, consideration should be given to future expansion needs, as retrofitting ventilation systems can be costly and disruptive. Xi'an Xunling's modular design approach facilitates easier modifications should laboratory requirements change over time. The assessment should also evaluate structural support capabilities, especially for larger units like our XL-PH1800 model, which may require reinforced flooring or additional structural considerations. Electrical supply capacity and positioning of utility connections (water, gas, vacuum) must also be factored into your space assessment to ensure seamless integration of your new lab vent hood within the existing laboratory infrastructure.

Workload Volume and Experiment Type

The nature and volume of work conducted within your lab vent hood should directly inform your size selection. For high-throughput laboratories processing numerous samples simultaneously, larger models like Xi'an Xunling's XL-PH1800, with interior dimensions of 1560x630x1180mm, provide the necessary workspace to accommodate multiple experiments or equipment setups. Conversely, laboratories with space constraints or lower processing volumes may find the XL-PH1200 model, with interior dimensions of 960x630x1180mm, more appropriate. The type of experiments performed significantly influences hood selection—procedures generating large volumes of particulates or vapors require greater air handling capacity and more sophisticated filtration systems. Chemical synthesis operations involving volatile organic compounds benefit from Xi'an Xunling's advanced airflow management systems, which maintain optimal face velocities between 0.3-0.6 m/s to ensure complete containment. Biological experiments involving pathogenic materials may require additional containment features or specialized configurations. Pharmaceutical preparation work demands exceptionally clean environments with minimal turbulence. Xi'an Xunling's technical team can provide customized solutions for each application type, ensuring that your lab vent hood specifications align perfectly with your experimental requirements, providing optimal protection while maximizing workflow efficiency and research productivity.

Future Expansion Considerations

Investing in laboratory infrastructure requires forward-thinking strategy, particularly regarding future research directions and expansion possibilities. Xi'an Xunling advises clients to consider potential changes in research focus, anticipated growth in personnel, and evolving regulatory requirements when selecting lab vent hood systems. Our modular design philosophy facilitates adaptation to changing needs—components can be reconfigured, upgraded, or expanded as requirements evolve. The standardized dimensions across our XL-PH series (1200mm, 1500mm, and 1800mm widths) allow for consistent integration within laboratory facilities, simplifying future additions or replacements. Additionally, Xi'an Xunling offers customization options beyond standard dimensions, accommodating unique spatial constraints or specialized research requirements. When planning for future expansion, consider ventilation system capacity—ensuring that building HVAC systems can accommodate additional air handling requirements if more lab vent hoods will be installed later. Our engineering team can provide comprehensive assessment of existing infrastructure capabilities and develop phased implementation plans that align with your organizational growth trajectory. Energy efficiency features in our current models also anticipate future sustainability requirements, with intelligent airflow management systems that minimize operational costs while maintaining optimal containment performance. By selecting Xi'an Xunling lab vent hoods with expansion flexibility in mind, laboratories can avoid costly retrofitting projects and ensure seamless scaling of research capabilities as organizational needs evolve over time.

Making the Final Selection Compliance with Safety Standards

Adherence to industry safety standards is non-negotiable when selecting lab vent hood systems. Xi'an Xunling's commitment to compliance is demonstrated through comprehensive certification of our products according to multiple international standards. Our lab vent hoods meet stringent requirements outlined in EN 14175 European standards for fume cupboards, as well as ASHRAE 110 containment performance testing parameters. These certifications verify that our equipment provides consistent protection against hazardous fumes under various operating conditions. Beyond these primary standards, Xi'an Xunling's products also comply with ISO quality management systems, CE safety directives, and specialized requirements for particular applications or regions. The certification process involves rigorous third-party testing of airflow characteristics, containment efficiency, and structural integrity. Our manufacturing facilities maintain strict quality control protocols with advanced testing equipment to ensure consistent compliance across all production units. Regular performance verification using ASHRAE 110 testing methodology confirms that face velocities remain within optimal ranges (0.3-0.6 m/s) throughout the hood's operational lifespan. When selecting a lab vent hood, facility managers should verify that the manufacturer provides comprehensive documentation of compliance testing and certification. Xi'an Xunling supplies detailed performance data and certification documentation with each unit, allowing laboratories to maintain accurate records for regulatory inspections and institutional safety audits, ensuring continuous compliance with evolving laboratory safety standards.

Budget and Long-term Value Assessment

While initial acquisition costs represent an important consideration, evaluating the total cost of ownership provides a more accurate assessment of lab vent hood value. Xi'an Xunling's products are engineered for operational efficiency and durability, translating to significant long-term savings. Energy consumption constitutes a major operational expense for ventilation systems; our intelligent airflow management technology optimizes air handling requirements while maintaining safety parameters, reducing utility costs throughout the equipment lifecycle. The robust construction materials—including polypropylene structures and corrosion-resistant linings—extend service life even in demanding research environments, minimizing replacement frequency. Maintenance requirements also impact total ownership costs; Xi'an Xunling's quick-release baffle design and accessible components simplify routine maintenance procedures, reducing service expenses and minimizing downtime. When conducting budget assessment, consider potential productivity improvements afforded by properly sized and configured lab vent hoods—enhanced workflow efficiency can significantly offset initial investment costs. Xi'an Xunling offers flexible procurement options, including customized payment terms for institutional clients. Additionally, our comprehensive 5-year warranty program provides financial protection against unexpected repair costs, further enhancing the value proposition. When comparing competitive offerings, evaluate not just the purchase price but also energy efficiency ratings, warranty coverage, expected service life, and included support services to determine the most cost-effective solution for your laboratory's specific requirements and operational budget constraints.

Installation and Support Services

The transition from selection to implementation represents a critical phase in lab vent hood acquisition. Xi'an Xunling provides comprehensive support throughout this process, beginning with detailed site assessment and installation planning. Our technical team coordinates with facility management to ensure proper integration with existing building systems, including HVAC connections, utility services, and structural considerations. Installation procedures follow industry best practices, with certified technicians verifying proper assembly, connection, and initial performance testing. Post-installation commissioning includes comprehensive performance verification according to applicable standards, ensuring that the lab vent hood operates at optimal efficiency from day one. Xi'an Xunling's commitment to customer support extends well beyond installation, with accessible technical assistance available for troubleshooting, performance optimization, and maintenance guidance. Our service network includes 21 service centers strategically located across major regions, providing prompt response to support requests. Training programs for laboratory personnel ensure proper operation and maintenance procedures, maximizing equipment performance and longevity. The preventative maintenance agreements available from Xi'an Xunling include scheduled inspections, filter replacements, airflow certification, and system optimization services. With 1,100+ employees and extensive manufacturing capabilities across five production bases, Xi'an Xunling maintains comprehensive spare parts inventory and rapid fulfillment capabilities, minimizing potential downtime. This integrated approach to installation and ongoing support ensures that your lab vent hood investment delivers maximum value throughout its operational lifespan.

Conclusion

Selecting the right size and type of lab vent hood requires careful consideration of laboratory needs, spatial constraints, safety requirements, and future expandability. By understanding the key factors outlined in this guide, laboratory managers can make informed decisions that enhance safety, improve workflow efficiency, and provide long-term value. Xi'an Xunling Electronic Technology Co., Ltd. stands ready to partner with you in this important selection process.

Ready to find the perfect lab vent hood solution for your laboratory? Contact our expert team today to discuss your specific requirements and discover how our customizable, high-performance products can transform your laboratory operations. With our 5-day delivery, 5-year warranty, and comprehensive after-sales support, we're committed to your complete satisfaction. Reach out now at xalabfurniture@163.com and take the first step toward a safer, more efficient laboratory environment!

References

1. American Conference of Governmental Industrial Hygienists. (2022). Industrial Ventilation: A Manual of Recommended Practice for Design, 30th Edition. ACGIH.

2. National Research Council. (2021). Prudent Practices in the Laboratory: Handling and Management of Chemical Hazards. National Academies Press.

3. Scientific Equipment and Furniture Association. (2023). SEFA 1-2010: Laboratory Fume Hoods Recommended Practices. SEFA Press.

4. International Organization for Standardization. (2022). ISO 14175:2022 - Safety and performance requirements for laboratory fume cupboards. ISO.

5. Occupational Safety and Health Administration. (2023). Laboratory Safety Guidance. U.S. Department of Labor.

6. Mills, J.C. & Robinson, T.E. (2024). Contemporary Laboratory Design: Safety, Efficiency, and Sustainability. Academic Laboratory Press.

YOU MAY LIKE

_1735284212689.webp)