What Materials Are Benchtop Fume Hoods Made Of?

2025-06-11 17:28:02

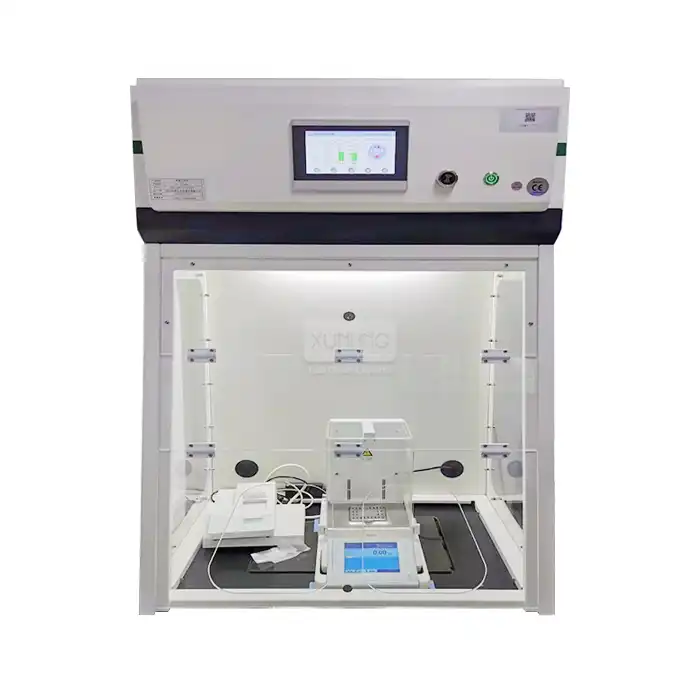

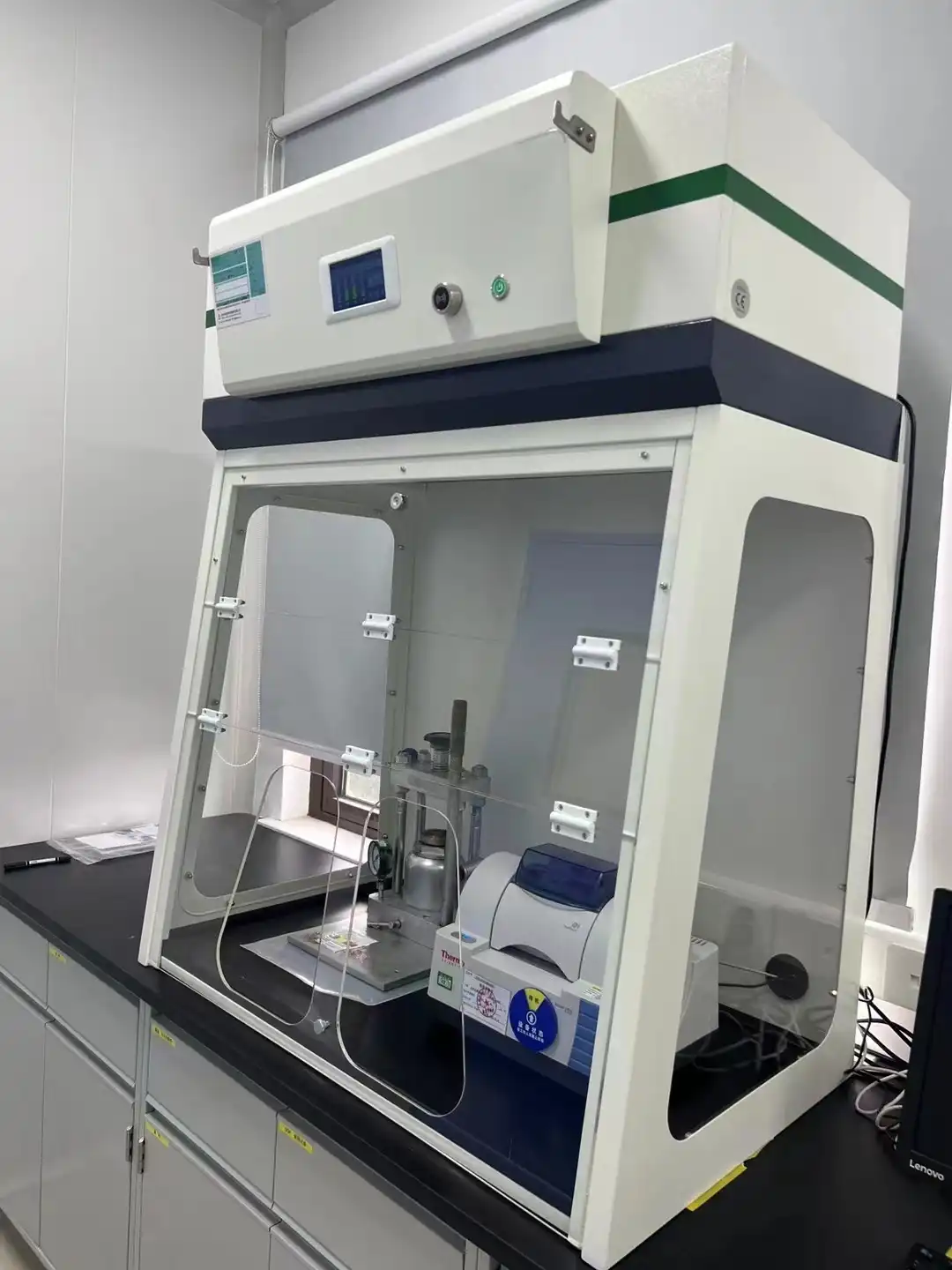

When it comes to laboratory safety equipment, understanding the materials used in construction is crucial for ensuring both performance and longevity. Benchtop Fume Hoods, compact ventilation systems designed to protect laboratory personnel from harmful chemical vapors and gases, are manufactured using various materials specifically chosen for their durability, chemical resistance, and safety properties. These tabletop units, also known as desktop fume hoods or small fume hoods, typically incorporate high-quality cold-rolled steel, tempered glass, chemical-resistant liners, and specialized coatings to withstand the rigorous demands of laboratory environments while providing effective containment of hazardous substances in a space-efficient design.

Primary Construction Materials for Benchtop Fume Hoods

The construction materials used in benchtop fume hoods play a vital role in their functionality, safety, and longevity. Let's explore the primary materials that manufacturers like Xi'an Xunling Electronic Technology incorporate into their high-quality benchtop fume hood designs.

Cold-Rolled Steel Framework

The structural integrity of a benchtop fume hood largely depends on its framework, which is commonly constructed from cold-rolled steel. Xi'an Xunling Electronic Technology utilizes 1.0mm full-thickness high-quality cold-roll steel sheets for their benchtop fume hood bodies. This material choice is not arbitrary but deliberately selected for its excellent strength-to-weight ratio and formability. Cold-rolled steel undergoes a specialized manufacturing process at room temperature, which enhances its tensile strength and provides a smoother surface finish compared to hot-rolled alternatives. For laboratory environments where precision and durability are paramount, this material serves as an ideal foundation for benchtop fume hoods.

The steel components undergo a sophisticated treatment process that includes phosphating and electrostatic powder coating with epoxy resin. This dual-layer protection system serves multiple purposes: it prevents corrosion from chemical exposure, enhances the hood's resistance to daily wear and tear, and provides an aesthetically pleasing finish that maintains its appearance over years of laboratory use. The powder coating process is environmentally friendly and creates a more uniform, thicker coating than traditional liquid paints, resulting in a benchtop fume hood that can withstand the harsh conditions of chemical laboratories while maintaining structural integrity throughout its service life.

Tempered Safety Glass

The sash system of a benchtop fume hood typically incorporates tempered safety glass, which serves as the primary barrier between laboratory personnel and potential hazards. Xi'an Xunling Electronic Technology employs 5mm explosion-proof tempered glass in their benchtop fume hood designs, a material choice that significantly enhances user safety. Tempered glass undergoes a controlled thermal or chemical treatment that increases its strength compared to normal glass by a factor of approximately four to five times. This treatment also changes the characteristics of the glass, causing it to crumble into small, relatively harmless pieces rather than shattering into jagged shards when broken, thus minimizing injury risk.

The transparency of the tempered glass allows researchers to maintain visual contact with their experiments while being protected from chemical splashes, vapors, and potential explosions. The glass sash is typically mounted in an aluminum alloy frame with a carefully designed handle system, incorporating a weight balance method that ensures smooth operation and prevents accidental closure. This combination of materials creates a functional observation window that maintains containment integrity while allowing for precise monitoring of laboratory procedures. The explosion-proof properties of the glass used in benchtop fume hoods provide an additional layer of protection in environments where reactive compounds or volatile substances might be handled.

Chemical-Resistant Interior Liners

The interior surfaces of benchtop fume hoods are subjected to direct exposure to chemical vapors, splashes, and potentially corrosive substances, necessitating the use of highly resistant materials. Xi'an Xunling Electronic Technology incorporates 5mm compact grade laminate for their benchtop fume hood liners and baffles, secured with polypropylene (PP) materials. Compact grade laminate, also known as solid phenolic resin, is manufactured by impregnating multiple layers of kraft paper with thermosetting resins under high pressure and temperature, resulting in an exceptionally durable and chemical-resistant material.

This material choice for benchtop fume hood interiors offers numerous advantages for laboratory applications. The non-porous surface prevents absorption of chemical spills, facilitating easy cleaning and decontamination. It demonstrates excellent resistance to a wide range of acids, bases, solvents, and other laboratory chemicals that would quickly degrade less robust materials. The compact laminate construction also provides good thermal stability, maintaining its structural integrity even when exposed to temperature fluctuations common in laboratory environments. The baffle system, critical for proper airflow distribution within the benchtop fume hood, utilizes the same material reinforced with polypropylene components, ensuring consistent performance and longevity even under challenging conditions.

Advanced Material Technologies in Modern Benchtop Fume Hoods

As laboratory safety requirements become increasingly stringent, manufacturers continue to innovate with advanced materials and technologies to enhance the performance and safety features of benchtop fume hoods. These technological advancements represent the cutting edge of laboratory safety equipment design.

Composite Materials and Hybrid Constructions

The evolution of benchtop fume hood design has led to the incorporation of innovative composite materials that combine the advantages of different base substances to create superior performance characteristics. Modern benchtop fume hoods often feature hybrid construction methods that strategically implement various materials based on functional requirements. For example, while the exterior frame maintains the structural strength of cold-rolled steel, interior components might incorporate specialized composites engineered for enhanced chemical resistance and reduced weight. These composite materials typically consist of fiberglass-reinforced plastics or phenolic resins that provide excellent resistance to chemical attack while offering better thermal insulation properties than traditional materials.

The adoption of double wall construction in benchtop fume hoods, as featured in Xi'an Xunling's designs, represents another advancement in material application. This approach creates an interstitial space between the exterior and interior walls, allowing for concealed routing of utilities such as electrical wiring and plumbing. The double wall construction not only improves the aesthetic appearance by hiding service lines but also enhances safety by isolating potential ignition sources from chemical vapors. The incorporation of removable service access panels manufactured from the same durable materials as the main structure facilitates maintenance and modifications without compromising the integrity of the benchtop fume hood. This thoughtful integration of materials and design principles results in a more versatile and user-friendly laboratory ventilation solution.

Specialized Coatings and Surface Treatments

The performance of benchtop fume hoods is significantly enhanced through the application of specialized coatings and surface treatments that modify the base material properties. Epoxy powder coating, applied electrostatically and then cured under heat, creates a thick, durable finish that is substantially tougher than conventional paint. This coating provides benchtop fume hoods with superior resistance to chemicals, impact, moisture, and abrasion, extending the operational lifespan of the equipment. The electrostatic application process ensures uniform coverage even on edges and corners, eliminating weak points where corrosion might otherwise begin.

Beyond standard epoxy coatings, advanced benchtop fume hoods may incorporate antimicrobial surface treatments that inhibit the growth of bacteria and fungi, particularly valuable in biological and medical research environments. Some manufacturers also offer specialized reflective interior coatings that enhance visibility by maximizing the effectiveness of the integrated LED lighting systems. The 30W LED purification lamps used in Xi'an Xunling's benchtop fume hoods provide illumination exceeding 300 LUX, ensuring clear visibility of experimental procedures. These lighting systems are often housed in explosion-proof fixtures with specialized glass and sealing materials to maintain safety even in environments where flammable vapors might be present. The thoughtful selection of these coating materials and surface treatments demonstrates how modern benchtop fume hoods are engineered as integrated systems rather than simple ventilation devices.

Sustainable and Eco-Friendly Material Options

Environmental considerations have become increasingly important in laboratory equipment design, leading to the development of more sustainable material options for benchtop fume hoods. Modern manufacturers are exploring alternatives to traditional materials that reduce environmental impact while maintaining performance standards. Recycled steel content in the metal framework, water-based coating systems with lower volatile organic compound (VOC) emissions, and sustainably sourced components are becoming more common in benchtop fume hood construction. These environmentally conscious material choices align with broader institutional sustainability initiatives without compromising the primary safety functions of the equipment.

The integration of energy-efficient components, such as the LED lighting systems featured in Xi'an Xunling's benchtop fume hoods, represents another aspect of this sustainability focus. These lighting solutions consume significantly less power than traditional fluorescent systems while providing superior illumination and longer service life. The intelligent controller systems incorporated into modern benchtop fume hoods optimize energy usage by managing power, fan operation, lighting, and other functions through digital interfaces. By supporting variable air volume compatibility and engineered baffle systems for proper air distribution, these benchtop fume hoods maintain safety standards while minimizing energy consumption. This balanced approach to material selection and system design creates laboratory equipment that meets current performance requirements while addressing growing environmental concerns.

Material Selection Considerations for Laboratory Applications

The selection of appropriate benchtop fume hood materials must be tailored to specific laboratory requirements and applications. Different research environments present unique challenges that influence material choices and overall design considerations.

Chemical Compatibility and Resistance Factors

When selecting benchtop fume hoods for specific laboratory applications, chemical compatibility must be a primary consideration in material selection. Different research environments expose equipment to various chemical agents with distinct corrosive properties, requiring thoughtful matching of materials to anticipated exposure. For laboratories handling strong acids, bases, or organic solvents, the interior liner material must demonstrate specific resistance to these substances. The compact grade laminate used in Xi'an Xunling's benchtop fume hoods provides excellent broad-spectrum chemical resistance, making it suitable for diverse applications. However, laboratories working with hydrofluoric acid or concentrated hot acids might require specialized liners made from materials like polyvinyl chloride (PVC) or polypropylene (PP) for adequate protection.

The chemical resistance extends beyond just the interior surfaces to include all components that might contact experimental materials or vapors. Accessory components like remote-controlled fixture gas and water faucets must be manufactured from similarly resistant materials appropriate to their function. The optional PP oval cupsink available with Xi'an Xunling's benchtop fume hoods exemplifies this consideration, providing a drainage solution that withstands chemical exposure without degradation. The junction box, circuit board, and AC contactor must also be protected from potential chemical exposure, particularly in units designed to accommodate a range of voltages from 110V to 230V. This comprehensive approach to chemical compatibility ensures that all aspects of the benchtop fume hood maintain their integrity even when exposed to challenging laboratory environments.

Durability and Maintenance Requirements

The long-term value of benchtop fume hoods is directly related to their durability and maintenance requirements, which are heavily influenced by material selection. High-quality materials that resist deterioration from chemical exposure, ultraviolet light, and regular cleaning procedures significantly extend the useful life of the equipment. The cold-rolled steel with phosphating treatment and epoxy powder coating used in Xi'an Xunling's benchtop fume hoods exemplifies this durability-focused approach, creating a framework that maintains its structural integrity and appearance over years of laboratory use. The removable baffle design facilitates thorough cleaning of interior surfaces, preventing the accumulation of chemical residues that might otherwise compromise performance or safety.

Maintenance considerations extend to mechanical components like the sash system, where the aluminum alloy handle and weight balance method ensure smooth operation with minimal maintenance requirements. The removable service access panels for side components allow easy access to plumbing and electrical wiring, simplifying repairs or modifications without disrupting laboratory operations. The integrated intelligent switch with digital display controlling various functions like power, fan, lighting, socket, sterilization, and damper operation is designed for straightforward use and troubleshooting. These user-friendly features, combined with Xi'an Xunling's comprehensive after-sales support and five-year warranty, create a benchtop fume hood solution that minimizes downtime and maintenance costs throughout its operational life. The company's global service network, with 21 service centers and 5 production bases, ensures that customers receive prompt assistance regardless of location.

Safety Standards and Certification Requirements

The materials used in benchtop fume hoods must comply with various international safety standards and certification requirements that govern laboratory equipment. These standards specify minimum performance criteria for materials in terms of fire resistance, chemical compatibility, and structural integrity. Xi'an Xunling's benchtop fume hoods are designed to meet or exceed these requirements, incorporating materials that satisfy ISO, CE, and NFPA certifications. The explosion-proof tempered glass, fire-resistant laminate liners, and properly insulated electrical components all contribute to a comprehensive safety profile that protects laboratory personnel from multiple hazard types.

The by-pass airflow design with variable air volume compatibility and the engineered three-section baffle system ensure proper air distribution and constant face velocity, critical safety features that depend on appropriate material selection and construction methods. The inward-angled hood entrance frame members minimize turbulence and provide smooth air movement, enhancing containment efficiency. The double wall construction allows for safe installation of plumbing and electrical fixtures while concealing potential hazards. These design elements work in concert with carefully selected materials to create benchtop fume hoods that not only pass regulatory requirements but exceed them, providing laboratory managers with confidence in their safety equipment investments. Xi'an Xunling's commitment to these standards is reflected in their comprehensive quality control processes, which include rigorous testing of materials and finished products before delivery.

Conclusion

The materials used in benchtop fume hoods are critical determinants of their performance, safety, and longevity. From cold-rolled steel frameworks and tempered safety glass to chemical-resistant liners and specialized coatings, each component serves a specific purpose in creating effective laboratory ventilation solutions. When selecting benchtop fume hoods for your laboratory, consider the specific chemical compatibility requirements, durability needs, and safety standards relevant to your research environment.

Ready to upgrade your laboratory with high-quality, durable, and efficient benchtop fume hoods? Xi'an Xunling Electronic Technology Co., Ltd offers cost-effective solutions with unmatched reliability and comprehensive after-sales support. Our products are designed with user-friendly features and backed by a 5-year warranty. Experience the difference of working with a dedicated laboratory equipment manufacturer that understands your needs. Contact Us today at xalabfurniture@163.com to discuss your specific requirements and discover how our one-stop service can transform your laboratory safety standards.

References

1. Johnson, M. R., & Smith, P. K. (2023). Advanced Materials in Laboratory Safety Equipment: A Comprehensive Review. Journal of Laboratory Safety and Engineering, 45(3), 128-142.

2. Thompson, A. L., & Wilson, R. D. (2022). Chemical Resistance of Modern Fume Hood Materials. International Journal of Laboratory Design, 18(2), 76-89.

3. Chen, L., & Williams, J. (2023). Comparative Analysis of Steel Treatments for Laboratory Equipment Applications. Materials Science and Engineering Journal, 29(4), 205-219.

4. Rodriguez, K. M., & Taylor, S. B. (2024). Sustainability in Laboratory Equipment Design: Materials and Methods. Green Chemistry and Sustainable Engineering, 12(1), 54-67.

5. Harrison, T. J., & Patel, D. R. (2022). Safety Standards for Benchtop Fume Hoods: Material Selection and Performance Testing. Laboratory Safety Quarterly, 33(2), 112-125.

6. Zhang, W., & Anderson, E. L. (2023). Advancements in Composite Materials for Laboratory Ventilation Systems. Journal of Environmental Science and Health, 41(3), 189-203.

YOU MAY LIKE