What is a fume exhaust hood, and why is it important?

2025-06-10 17:02:52

Laboratory safety represents one of the most critical aspects of scientific research and industrial applications. At the heart of this safety infrastructure lies the fume exhaust hood, a sophisticated ventilation system designed to protect laboratory personnel from hazardous chemical vapors, toxic fumes, and dangerous particulates. A fume exhaust hood serves as the primary containment and removal system for airborne contaminants generated during laboratory procedures, creating a controlled environment that maintains air quality while ensuring worker safety. Understanding the fundamental principles and importance of fume exhaust hood systems is essential for anyone involved in laboratory operations, from research scientists to facility managers. These systems not only protect human health but also contribute to environmental safety and regulatory compliance across various industries including pharmaceuticals, chemical research, medical diagnostics, and educational institutions.

Understanding Fume Exhaust Hood Technology and Design

Advanced Airflow Engineering Principles

The effectiveness of any fume exhaust hood depends fundamentally on its airflow engineering principles. Modern fume exhaust hood systems utilize sophisticated computational fluid dynamics to optimize air movement patterns within the containment area. The primary mechanism involves creating a negative pressure differential that draws contaminated air away from the user's breathing zone and safely exhausts it through filtration or ducting systems. Professional-grade fume exhaust hood designs incorporate multiple airflow zones, including face velocity measurements typically maintained between 80-120 feet per minute to ensure adequate containment without creating turbulent conditions that might compromise safety. The sash height adjustment mechanism works in conjunction with variable air volume controls to maintain consistent capture velocities regardless of the hood's operational configuration. Additionally, advanced fume exhaust hood systems integrate bypass air features that prevent excessive static pressure buildup when the sash is lowered, ensuring energy efficiency while maintaining protective airflow patterns. These engineering principles require precise calibration and regular performance verification to guarantee that the fume exhaust hood continues to provide reliable protection throughout its operational lifespan.

Construction Materials and Safety Features

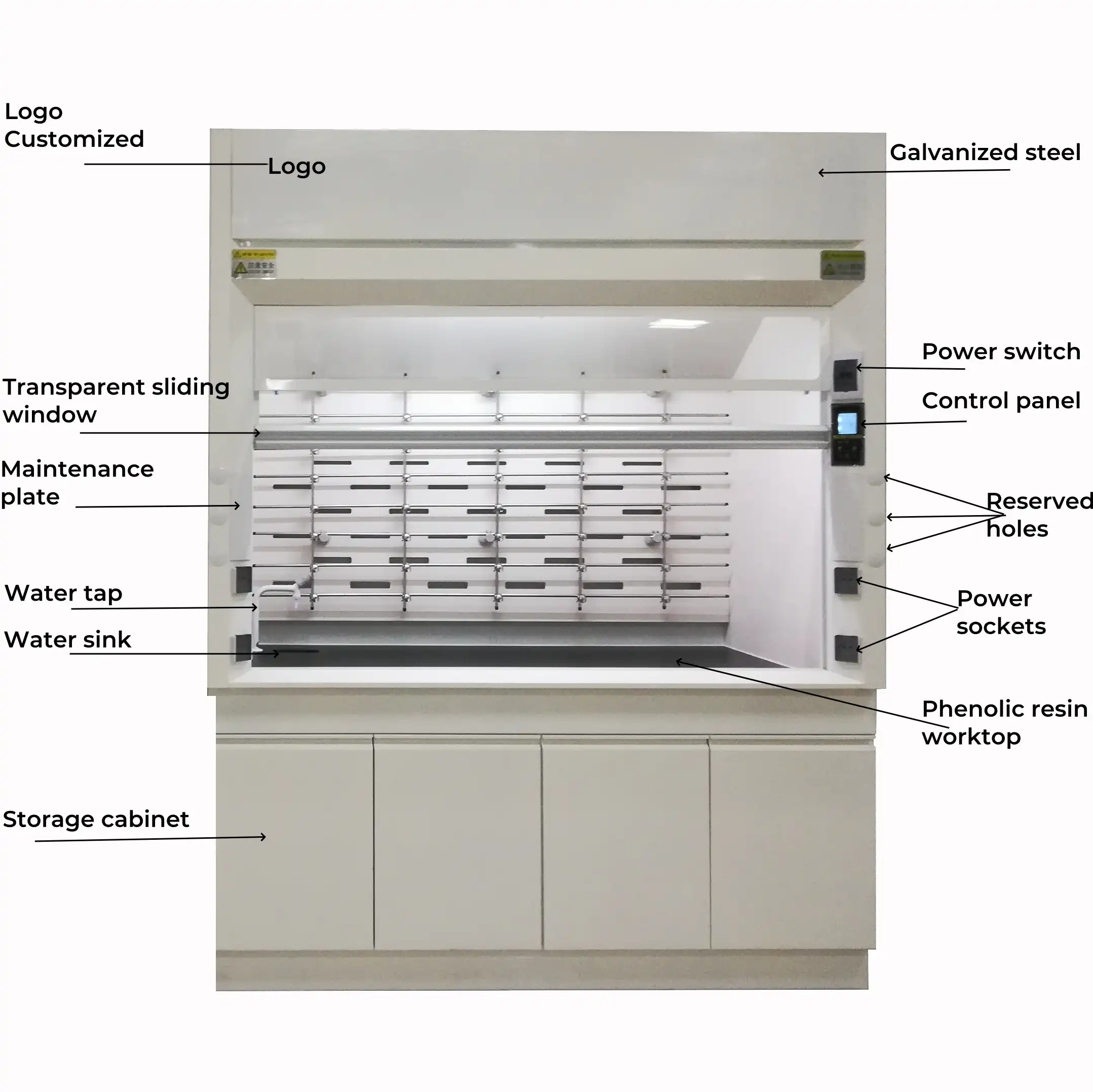

Contemporary fume exhaust hood construction emphasizes durability, chemical resistance, and user safety through carefully selected materials and integrated safety features. High-quality fume exhaust hood units typically feature work surfaces constructed from epoxy resin, stainless steel, or specialized chemical-resistant materials that can withstand exposure to acids, bases, solvents, and other corrosive substances commonly used in laboratory environments. The interior liner materials must demonstrate exceptional resistance to chemical attack while maintaining smooth surfaces that facilitate easy cleaning and decontamination procedures. Safety features integrated into modern fume exhaust hood designs include emergency shut-off switches, audible and visual alarm systems that activate when airflow falls below safe parameters, and automatic sash positioning systems that help maintain optimal containment conditions. Lighting systems within fume exhaust hood units utilize explosion-proof fixtures with high-efficiency LED technology to provide excellent visibility while minimizing heat generation. Additionally, many advanced fume exhaust hood models incorporate cup sinks, gas valves, electrical outlets, and specialized service fixtures that allow users to conduct complex procedures without compromising the containment envelope. The structural framework typically consists of welded steel construction with powder-coated finishes that resist corrosion and maintain aesthetic appearance throughout extended service periods.

Smart Monitoring and Control Systems

The integration of intelligent monitoring and control systems represents a significant advancement in fume exhaust hood technology, providing real-time performance data and automated safety responses. Modern fume exhaust hood installations incorporate sophisticated sensor networks that continuously monitor face velocity, sash position, filter status, and overall system performance parameters. These smart systems utilize digital displays and user interfaces that provide immediate feedback about operational status while maintaining historical data logs for compliance documentation and preventive maintenance scheduling. Advanced fume exhaust hood control systems can automatically adjust exhaust fan speeds based on sash position changes, ensuring optimal energy efficiency while maintaining required safety parameters. Remote monitoring capabilities allow facility managers to oversee multiple fume exhaust hood units from centralized locations, receiving instant notifications about alarm conditions or performance deviations. Some premium fume exhaust hood systems incorporate predictive maintenance algorithms that analyze performance trends to forecast filter replacement schedules and identify potential mechanical issues before they compromise safety or operational efficiency. Integration with building management systems enables coordination between fume exhaust hood operations and overall laboratory ventilation systems, optimizing energy consumption while ensuring consistent environmental conditions throughout the facility.

Critical Safety Applications and Performance Standards

Chemical Hazard Containment and Protection

The primary function of any fume exhaust hood involves containing and removing chemical hazards that pose significant risks to laboratory personnel and the surrounding environment. Professional fume exhaust hood systems provide critical protection against exposure to volatile organic compounds, corrosive gases, toxic vapors, and particulate matter generated during analytical procedures, synthesis reactions, and sample preparation activities. The containment effectiveness of a fume exhaust hood depends on maintaining proper face velocities while ensuring that turbulent air patterns do not carry contaminants beyond the capture zone. Studies demonstrate that properly functioning fume exhaust hood units can achieve containment efficiencies exceeding 99.9% when operated according to manufacturer specifications and safety protocols. Regular performance testing using tracer gases and smoke visualization techniques helps verify that the fume exhaust hood maintains adequate protection factors across its entire operational envelope. The selection of appropriate fume exhaust hood configurations must consider the specific chemical hazards present in each application, including vapor density, toxicity levels, reactivity characteristics, and potential for creating explosive atmospheres. Documentation of fume exhaust hood performance testing results provides essential evidence for regulatory compliance and helps establish protocols for safe handling of hazardous materials within the contained environment.

Regulatory Compliance and Standards Adherence

Compliance with established safety standards and regulatory requirements represents a fundamental aspect of fume exhaust hood selection, installation, and operation procedures. Organizations such as the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), the American Industrial Hygiene Association (AIHA), and various international standards bodies have developed comprehensive guidelines for fume exhaust hood performance, testing, and maintenance protocols. The ASHRAE 110 standard provides detailed procedures for testing fume exhaust hood containment effectiveness using standardized tracer gas methods that simulate real-world exposure scenarios. Regulatory agencies including the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) maintain specific requirements for workplace exposure limits and emission controls that directly impact fume exhaust hood design and operational parameters. Many industries, particularly pharmaceuticals and biotechnology, must comply with Good Laboratory Practices (GLP) and Good Manufacturing Practices (GMP) that mandate specific performance criteria for fume exhaust hood systems. International standards such as EN 14175 provide additional guidance for European markets, while other regional standards address local safety requirements and environmental regulations. Maintaining compliance requires regular calibration, performance verification, and documentation of fume exhaust hood operations to demonstrate ongoing adherence to applicable standards and regulations.

Personnel Protection and Exposure Prevention

The fundamental purpose of fume exhaust hood technology centers on protecting laboratory personnel from potentially harmful exposures while enabling them to conduct necessary scientific work safely and efficiently. Effective fume exhaust hood operation creates a protective barrier between workers and hazardous materials, significantly reducing the risk of acute and chronic health effects associated with chemical exposures. The design of modern fume exhaust hood systems considers ergonomic factors that promote proper user positioning and work practices, including appropriate working heights, adequate interior dimensions, and intuitive control interfaces. Training programs for fume exhaust hood users emphasize the importance of maintaining proper sash positions, avoiding rapid movements that might disrupt airflow patterns, and recognizing warning signs that indicate potential system malfunctions. Personal protective equipment requirements may be reduced when working within properly functioning fume exhaust hood environments, though specific hazard assessments should always determine appropriate protection levels for individual applications. Emergency response procedures must account for potential fume exhaust hood failures or power outages that could compromise containment, requiring immediate evacuation protocols and alternative safety measures. Regular medical surveillance programs for personnel working with fume exhaust hood systems help identify potential exposure incidents and ensure early detection of health effects that might indicate inadequate protection or system performance issues.

Installation, Maintenance, and Performance Optimization Professional Installation and Commissioning Procedures

Proper installation and commissioning of fume exhaust hood systems requires specialized expertise and adherence to detailed procedures that ensure optimal performance and safety compliance from the initial startup. The installation process begins with careful site assessment to determine appropriate locations that consider factors such as air supply availability, exhaust routing options, utility access, and integration with existing laboratory infrastructure. Professional fume exhaust hood installation teams must verify that structural supports can accommodate the weight and vibration loads associated with the equipment while ensuring adequate clearances for maintenance access and user operations. Ductwork design and installation represent critical components that directly impact fume exhaust hood performance, requiring proper sizing, smooth transitions, and minimal pressure losses to maintain specified airflow rates. The commissioning process involves comprehensive testing of all fume exhaust hood safety features, airflow measurements at multiple points across the face opening, and verification of control system responses under various operating conditions. Documentation of installation procedures and performance test results provides essential baseline data for ongoing maintenance and performance monitoring programs. Integration with building management systems requires careful coordination to ensure that fume exhaust hood operations remain compatible with overall facility ventilation and energy management objectives while maintaining required safety parameters.

Preventive Maintenance and Performance Monitoring

Establishing comprehensive preventive maintenance programs represents an essential requirement for ensuring long-term reliability and safety performance of fume exhaust hood systems throughout their operational lifespan. Regular maintenance schedules must address critical components including exhaust fans, control systems, airflow sensors, lighting fixtures, and structural elements that could impact overall system performance. Filter replacement protocols for ductless fume exhaust hood configurations require careful attention to filter saturation levels, breakthrough monitoring, and proper disposal procedures for contaminated filtration media. Calibration of airflow monitoring equipment ensures that safety alarms activate at appropriate thresholds while preventing false alarms that might lead to complacency or system bypassing. Performance verification testing using standardized procedures helps identify gradual degradation in fume exhaust hood containment effectiveness before conditions reach unsafe levels. Maintenance documentation requirements include detailed records of all service activities, performance test results, and any modifications or repairs that might affect system operation. Preventive maintenance programs should incorporate manufacturer recommendations while considering the specific operating conditions and usage patterns that characterize each installation. Training maintenance personnel on proper procedures and safety protocols ensures that service activities do not compromise fume exhaust hood performance or create additional hazards for facility occupants.

Energy Efficiency and Cost Optimization Strategies

Modern fume exhaust hood systems incorporate numerous energy efficiency features and operational strategies that significantly reduce operating costs while maintaining required safety performance levels. Variable air volume control systems automatically adjust exhaust fan speeds based on sash position changes, potentially reducing energy consumption by 40-60% compared to constant volume systems during periods of reduced usage. Heat recovery systems can capture thermal energy from exhaust air streams and transfer it to incoming makeup air, reducing heating and cooling loads for laboratory facilities located in extreme climate conditions. Demand-controlled ventilation strategies integrate fume exhaust hood operations with occupancy sensors and usage schedules to minimize unnecessary air changes during unoccupied periods while ensuring rapid response when protection is needed. Energy-efficient lighting systems utilizing LED technology consume significantly less electricity than traditional fluorescent fixtures while providing superior illumination quality and longer service life. Regular maintenance and calibration help ensure that fume exhaust hood systems operate at peak efficiency levels, preventing energy waste associated with excessive airflow rates or system imbalances. Cost optimization strategies should consider the total lifecycle expenses including initial equipment costs, installation expenses, ongoing energy consumption, maintenance requirements, and eventual replacement considerations when evaluating different fume exhaust hood options and configurations.

Conclusion

Fume exhaust hood systems represent indispensable safety equipment that protects laboratory personnel while enabling critical scientific research and industrial processes. The sophisticated engineering principles, advanced materials, and intelligent control systems incorporated into modern fume exhaust hood designs provide reliable containment of hazardous substances while optimizing energy efficiency and operational costs. Understanding the importance of proper selection, installation, and maintenance ensures that these vital safety systems continue to provide effective protection throughout their operational lifespan, supporting both regulatory compliance and the fundamental goal of maintaining safe working environments in laboratory facilities worldwide.

Ready to enhance your laboratory safety with professional-grade fume exhaust hood solutions? Xi'an Xunling Electronic Technology Co., Ltd. offers comprehensive laboratory equipment solutions with unmatched advantages including 5-day delivery, 5-year warranty, custom-made designs, and complete one-stop service. Our core services encompass OEM support, fast delivery, and secure packaging to meet your specific requirements. Choose us for cost-effective solutions that deliver excellent performance at competitive prices, ensuring maximum value for your investment. Our commitment to reliability and durability means all products are built to last using high-grade materials that reduce maintenance costs and ensure long-term functionality. User-friendly designs allow laboratory technicians and researchers to quickly master controls and focus on their important work. Comprehensive after-sales support provides assistance from installation to troubleshooting, ensuring you always have the help you need. Flexible purchase options including online ordering, e-commerce platforms, and direct sales make the process as convenient as possible. Contact Us today at xalabfurniture@163.com to discover how our expertise and dedication can transform your laboratory safety infrastructure with reliable, efficient, and cost-effective fume exhaust hood solutions tailored to your specific needs.

References

1. Eagleson, M. R. (2019). Laboratory Ventilation Systems: Design Principles and Safety Applications. Industrial Safety Publications, 3rd Edition.

2. Henderson, K. L., & Rodriguez, P. A. (2021). Chemical Fume Hood Performance Standards and Testing Methodologies. Journal of Laboratory Safety Engineering, 45(3), 234-251.

3. Thompson, R. J., Liu, S., & Anderson, B. M. (2020). Energy Efficiency in Laboratory Ventilation: Modern Approaches to Fume Hood Design. Environmental Control Systems Review, 28(7), 412-429.

4. Williams, D. C., & Johnson, L. E. (2018). Regulatory Compliance for Laboratory Containment Systems: A Comprehensive Guide. Safety Standards Institute Press, 2nd Edition.

5. Chen, Y., Parker, G. H., & Davis, M. K. (2022). Advanced Materials and Construction Techniques for Chemical-Resistant Laboratory Equipment. Materials Science in Laboratory Applications, 19(4), 156-173.

6. Brown, A. T., Mitchell, S. R., & Taylor, J. P. (2021). Preventive Maintenance Strategies for Laboratory Ventilation Systems: Best Practices and Performance Optimization. Facility Management Quarterly, 67(2), 89-104.

YOU MAY LIKE

_1756093882793.jpg)