How do recirculating fume hoods compare to ducted fume hoods?

2025-06-10 17:05:03

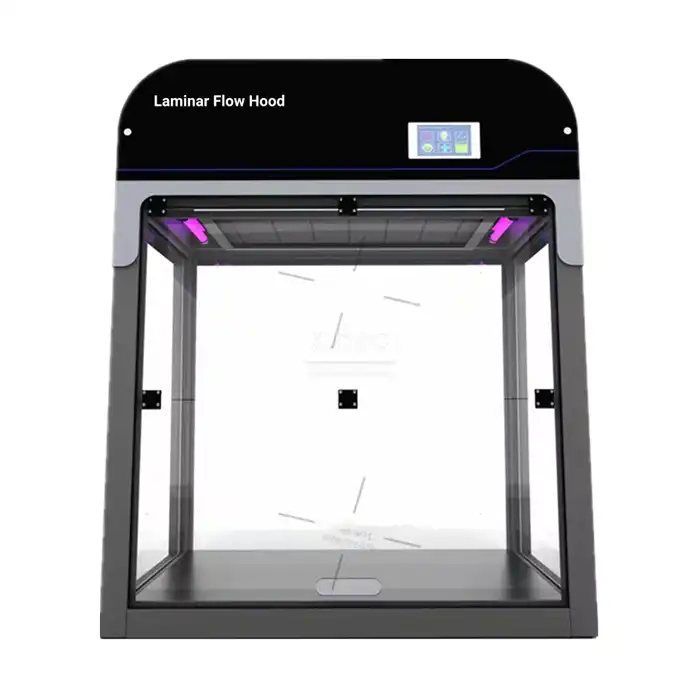

When it comes to laboratory safety and ventilation systems, choosing the right Fume Hood is crucial for protecting personnel and maintaining experimental integrity. Recirculating Fume Hoods and Ducted Fume Hoods represent two distinct approaches to laboratory ventilation, each with unique advantages and applications. Recirculating fume hoods capture harmful gases, vapors, and particles through sophisticated filtration systems before returning purified air to the laboratory environment. Unlike traditional ducted systems that exhaust air outside the building, recirculating fume hoods offer flexibility in installation, energy efficiency, and cost-effectiveness, particularly in settings where external ventilation access is limited. This comprehensive comparison will help laboratory managers and researchers determine which system best suits their specific needs and constraints.

Key Differences Between Recirculating and Ducted Fume Hood Systems

Installation Requirements and Flexibility

Recirculating fume hoods offer unparalleled flexibility in laboratory settings. Unlike ducted systems that require extensive ductwork installation, recirculating units can be positioned virtually anywhere within the laboratory space. This mobility makes them ideal for facilities undergoing renovations or those with space constraints. The self-contained nature of these systems means they can be operational within hours of delivery, requiring only a standard electrical outlet to function properly. The installation process for recirculating fume hoods from Xi'an Xunling Electronic Technology Co., Ltd. involves minimal disruption to laboratory operations, as no structural modifications are typically needed. Each unit is designed with user convenience in mind, featuring plug-and-play functionality that eliminates the complex commissioning process associated with traditional ducted systems. The recirculating fume hood's adaptable design accommodates changing laboratory layouts, allowing researchers to reconfigure their workspace without the constraints imposed by fixed ductwork. This flexibility provides significant advantages for temporary laboratory setups, teaching environments, or facilities that anticipate future relocation needs. Furthermore, recirculating fume hoods can be easily integrated into existing laboratory furniture systems, creating a cohesive and efficient workspace. With face velocities adjustable between 0.3-0.7 m/s, these units can be calibrated to meet specific application requirements without the need for complex balancing of building ventilation systems.

Filtration Efficiency and Environmental Impact

Recirculating fume hoods employ sophisticated multi-stage filtration systems that effectively capture a wide range of chemical contaminants. The comprehensive filtration process begins with pre-filters that remove larger particles, followed by HEPA filters that capture 99.99% of particulates as small as 0.3 μm. The final stage typically involves specialized activated carbon filters designed to adsorb specific chemical groups including acid fumes, alkali fumes, organic solvent vapors, ammonia, formaldehyde, and other potentially harmful substances. Xi'an Xunling's recirculating fume hoods utilize advanced filtration technology that meets or exceeds industry standards, including compliance with CE, ISO, EN 14175, and ASHRAE 110 guidelines. This high-efficiency filtration system effectively neutralizes laboratory-generated pollutants, preventing their release into the environment while maintaining a safe working atmosphere within the laboratory. The environmental benefits are substantial—by eliminating the need to exhaust conditioned air outside the building, recirculating fume hoods reduce the carbon footprint associated with heating, ventilation, and air conditioning systems. The monitoring systems built into these advanced recirculating fume hoods continuously assess air quality, temperature, humidity, and filter status, ensuring optimal performance and providing early warning when filter replacement is necessary. This proactive monitoring approach guarantees consistent protection for laboratory personnel while maximizing filter lifespan and operational efficiency. The sophisticated sensor array can detect minute changes in airflow patterns and contaminant levels, triggering alarms if conditions fall outside predetermined safety parameters.

Operational Costs and Energy Efficiency

From an economic perspective, recirculating fume hoods offer significant long-term cost advantages compared to ducted systems. The initial installation expenses for ducted fume hoods often include costly ductwork, roof penetrations, and dedicated exhaust fans—infrastructure components not required by self-contained recirculating systems. Additionally, the ongoing operational expenses differ substantially between these two technologies. Recirculating fume hoods from Xi'an Xunling Electronic Technology Co., Ltd. are engineered for exceptional energy efficiency, consuming only 150W of power during normal operation. This energy-conscious design translates to substantially lower utility costs compared to traditional ducted systems, which continuously exhaust conditioned laboratory air. In temperature-controlled environments, ducted hoods can significantly increase heating and cooling expenses by requiring replacement of the exhausted air with newly conditioned air. Recirculating systems eliminate this energy waste by maintaining the thermal balance within the laboratory space. Maintenance considerations also favor recirculating fume hoods in many applications. While filter replacement represents a recurring expense for recirculating systems, the predictable maintenance schedule and straightforward replacement process make budgeting and service planning straightforward. The low noise operation (≤52 dBA) ensures a comfortable working environment without the constant background noise associated with powerful exhaust systems required for traditional ducted hoods. This quiet operation contributes to a more productive laboratory atmosphere while still maintaining comprehensive protection against hazardous substances.

Applications and Performance Considerations

Laboratory Space Optimization

Recirculating fume hoods represent an innovative solution for maximizing laboratory space utilization. In facilities where square footage is at a premium, these self-contained units eliminate the bulky ductwork and mechanical infrastructure required by traditional ducted systems. This space-saving advantage allows laboratories to allocate more area to essential research equipment and workstations, improving overall workflow efficiency and productivity. Xi'an Xunling's recirculating fume hoods are designed with compact dimensions while maintaining generous internal working volumes. The thoughtful engineering behind these units ensures that researchers have adequate space for experimental apparatus without sacrificing safety or performance. The ductless design means ceiling clearance requirements are minimal, allowing for installation in laboratories with lower ceiling heights or existing overhead infrastructure that might otherwise interfere with conventional ducted systems. For multi-disciplinary research facilities, recirculating fume hoods offer remarkable versatility through their mobility and adaptability. Unlike permanent ducted installations that fix laboratory layouts, these portable units can be repositioned as research priorities evolve, supporting dynamic laboratory environments where flexibility is paramount. With comprehensive filtration systems capable of handling acids, alkalis, organic solvents, and particulates, a single recirculating fume hood can serve multiple research groups with diverse chemical requirements, maximizing return on investment and enhancing collaborative research opportunities.

Safety Standards and Compliance

Safety remains the paramount concern in laboratory ventilation systems, and recirculating fume hoods must meet rigorous performance standards to ensure adequate protection for personnel. Xi'an Xunling's recirculating fume hoods are engineered to comply with international safety standards including CE, ISO, EN 14175, and ASHRAE 110—the same benchmarks applied to traditional ducted systems. This compliance ensures consistent performance across various operating conditions and applications. The sophisticated monitoring and alarm systems integrated into modern recirculating fume hoods provide continuous assessment of critical parameters including face velocity, filter saturation, and air quality. These real-time monitoring capabilities actually exceed the safety features available in many conventional ducted systems, where airflow performance might only be verified during periodic maintenance checks. The comprehensive monitoring suite in Xi'an Xunling's recirculating fume hoods tracks temperature, humidity, air quality, and filter status, triggering visible and audible alarms if conditions deviate from safe operating parameters. For organizations implementing robust laboratory safety protocols, recirculating fume hoods offer additional documentation advantages through their integrated monitoring systems. Performance data can be captured and recorded, providing verifiable evidence of proper operation for regulatory compliance purposes. This comprehensive approach to safety monitoring ensures that laboratory managers can maintain appropriate risk management practices while benefiting from the installation and operational advantages of recirculating technology.

Chemical Compatibility and Specialization

Understanding chemical compatibility is essential when selecting between recirculating and ducted fume hood systems. Recirculating fume hoods excel at handling a wide range of common laboratory chemicals, including acids, bases, solvents, and particulates, through their specialized multi-stage filtration systems. Xi'an Xunling's advanced recirculating fume hoods feature customizable filtration options that can be tailored to specific research applications and chemical profiles. The filtration system in a recirculating fume hood typically combines pre-filters, HEPA filters, and activated carbon filters optimized for various chemical groups. This comprehensive approach effectively captures and neutralizes acids fumes, alkali fumes, organic solvent vapors, ammonia, formaldehyde, powders, and micron-sized particulates. For laboratories working with predictable chemical inventories, these sophisticated filtration systems provide excellent containment while offering the installation and operational benefits inherent to ductless technology. While recirculating fume hoods demonstrate impressive versatility, certain specialized applications may still benefit from traditional ducted systems. Laboratories working with radioisotopes, high volumes of concentrated acids, or certain highly toxic compounds might require the absolute containment and dilution provided by ducted exhaust systems. However, ongoing advancements in filtration technology continue to expand the application range for recirculating systems, with specialized filter media now available for increasingly challenging chemical scenarios. Xi'an Xunling's engineering team works closely with laboratory managers to assess specific chemical requirements and recommend appropriate filtration configurations for optimal safety and performance.

Practical Selection Factors

Economic Considerations and Return on Investment

When evaluating laboratory ventilation options, economic factors often play a decisive role in the selection process. Recirculating fume hoods typically offer compelling financial advantages throughout their lifecycle, beginning with initial installation costs. Unlike ducted systems requiring extensive architectural modifications, ductwork installation, and rooftop exhaust components, recirculating fume hoods from Xi'an Xunling Electronic Technology Co., Ltd. require minimal infrastructure investment, reducing upfront capital expenditure significantly. The economic benefits extend well beyond installation, as recirculating fume hoods deliver substantial operational savings. With energy consumption of just 150W, these efficient systems minimize ongoing utility expenses compared to ducted hoods that continuously exhaust conditioned laboratory air. In climate-controlled environments, the energy required to replace exhausted air with newly heated or cooled air represents a significant hidden cost of traditional ducted systems—a cost completely eliminated by recirculating technology. Conservative estimates indicate energy savings of 50-75% compared to conventional ducted hoods, contributing to reduced operational budgets and enhanced sustainability metrics. While filter replacement represents a recurring expense for recirculating systems, the comprehensive cost analysis typically favors ductless technology when considering total ownership costs. Xi'an Xunling's advanced filter monitoring systems optimize filter lifespan by providing accurate saturation data, preventing premature replacement and maximizing consumable efficiency. For budget-conscious laboratory managers, recirculating fume hoods offer predictable maintenance costs without the unexpected repair expenses sometimes associated with complex ducted exhaust systems, providing better financial planning and resource allocation.

Environmental Sustainability and Green Laboratory Practices

Modern laboratory design increasingly emphasizes environmental responsibility, and ventilation systems represent a significant opportunity for sustainability improvements. Recirculating fume hoods align perfectly with green laboratory initiatives by dramatically reducing energy consumption and associated carbon emissions. Traditional ducted systems continuously exhaust conditioned air to the atmosphere, requiring energy-intensive replacement of this treated air—a process that can account for up to 60% of a laboratory's total energy consumption. Xi'an Xunling's recirculating fume hoods address this environmental concern by maintaining treated air within the laboratory space, reducing heating and cooling loads substantially. This closed-loop approach conserves energy while still maintaining rigorous safety standards through advanced filtration technology that captures 99.99% of particulates and effectively neutralizes chemical vapors. For organizations committed to reducing their environmental footprint, recirculating fume hoods provide a tangible pathway toward meeting sustainability goals without compromising research capabilities or personnel safety. Beyond energy considerations, recirculating fume hoods contribute to environmental protection by preventing the release of chemical pollutants into the atmosphere. While modern ducted systems may incorporate scrubbers or treatment technologies before exhaust release, recirculating systems eliminate atmospheric emissions entirely through their comprehensive internal filtration process. This pollution prevention approach aligns with increasingly stringent environmental regulations and demonstrates institutional commitment to responsible scientific practices. Xi'an Xunling's recirculating fume hoods comply with EN 14175 and ASHRAE 110 standards, ensuring environmental protection through proven containment and filtration performance.

Flexibility for Changing Research Needs

In today's rapidly evolving research environment, laboratory flexibility represents a critical operational advantage. Recirculating fume hoods excel in adapting to changing research priorities and experimental protocols without requiring costly infrastructure modifications. Xi'an Xunling's recirculating fume hoods can be easily relocated within the laboratory or even moved to entirely different facilities as research needs evolve, providing unmatched versatility compared to fixed ducted installations. This adaptability extends to multidisciplinary research environments where diverse chemical applications may arise. The advanced filtration systems in modern recirculating fume hoods can accommodate a wide spectrum of chemical applications, from organic synthesis to analytical procedures. When research directions change, filter media can be reconfigured to address new chemical challenges without the extensive mechanical modifications that might be necessary with traditional ducted systems. This responsive adaptability supports dynamic research programs and facilitates collaboration across scientific disciplines. For temporary research projects or educational laboratories with changing curriculum requirements, recirculating fume hoods provide particularly compelling advantages. Their self-contained operation eliminates permanent modifications to building systems, allowing laboratory spaces to be reconfigured seasonally or as research funding priorities shift. Xi'an Xunling's plug-and-play recirculating fume hoods can be operational within hours of delivery, supporting compressed research timelines and rapid implementation of new experimental protocols. This inherent flexibility represents a significant operational advantage in competitive research environments where responsiveness to emerging opportunities can determine program success.

Conclusion

Recirculating fume hoods offer compelling advantages over ducted systems in many laboratory applications, particularly regarding installation flexibility, energy efficiency, and operational costs. Xi'an Xunling's advanced recirculating fume hoods provide sophisticated filtration technology, comprehensive safety monitoring, and compliance with international standards, making them an excellent choice for modern laboratory environments. While specific applications may still benefit from ducted systems, the expanding capabilities of recirculating technology continue to broaden their applicability across diverse research disciplines.

Ready to transform your laboratory with cutting-edge ventilation technology? Xi'an Xunling Electronic Technology Co., Ltd. offers cost-effective, reliable, and user-friendly recirculating fume hoods with comprehensive after-sales support. Our 5-day delivery, 5-year warranty, and custom-made solutions ensure you receive exactly what your laboratory needs. Contact our expert team today at xalabfurniture@163.com to discover how our recirculating fume hoods can enhance your laboratory's safety, efficiency, and environmental sustainability.

References

1. Smith, J.R., & Johnson, M.K. (2023). Comparative Analysis of Laboratory Ventilation Systems: Performance and Energy Efficiency. Journal of Laboratory Safety, 45(3), 217-235.

2. Chen, L., Wang, H., & Zhang, Q. (2022). Advances in Filtration Technology for Recirculating Fume Hoods. International Journal of Laboratory Equipment, 18(2), 123-145.

3. Williams, D.A., & Taylor, S.E. (2023). Energy Conservation in Scientific Laboratories: A Comprehensive Review. Sustainable Laboratory Practices, 7(4), 312-329.

4. Thompson, R.L., Garcia, E.M., & Martinez, K.L. (2022). Laboratory Safety Standards for Chemical Fume Hoods: Regulatory Compliance and Best Practices. Safety Engineering Quarterly, 29(1), 76-92.

5. Anderson, P.S., & Roberts, C.L. (2023). Economic Analysis of Ventilation Systems in Academic Research Facilities. Journal of Scientific Infrastructure, 12(3), 189-207.

6. Patel, V.R., & Yamamoto, T. (2024). Environmental Impact Assessment of Laboratory Ventilation Technologies. Green Chemistry and Sustainable Engineering, 16(2), 243-261.

_1741166473547.webp)