What are the advantages of epoxy resin laboratory countertops?

2025-06-10 17:06:45

Epoxy Resin Laboratory Countertops have become the gold standard for laboratory environments worldwide due to their exceptional performance characteristics. These high-performance surfaces offer an unmatched combination of durability, chemical resistance, and customization options that make them ideal for scientific and research facilities. When selecting laboratory countertops, professionals must consider factors such as resistance to chemicals, heat tolerance, and long-term durability—all areas where Epoxy Resin Laboratory Countertops excel. Their non-porous surface prevents bacterial growth and chemical absorption, while their robust construction withstands the daily rigors of laboratory work. This comprehensive overview explores the numerous advantages that have made epoxy resin the preferred countertop material for modern laboratories.

Superior Material Properties of Epoxy Resin Countertops

Exceptional Chemical Resistance

Epoxy Resin Laboratory Countertops are renowned for their outstanding chemical resistance, which is perhaps their most valuable characteristic in laboratory settings. The molecular structure of epoxy resin creates a non-porous, highly stable surface that can withstand exposure to a vast array of chemical substances without degradation. This includes strong acids such as sulfuric and hydrochloric acid, potent bases like sodium hydroxide, and various organic solvents including acetone and methanol. Unlike other countertop materials that may stain, etch, or deteriorate when exposed to harsh chemicals, Epoxy Resin Laboratory Countertops maintain their integrity even after prolonged contact with these substances. The seamless construction eliminates joints where chemicals might penetrate, providing uniform protection across the entire work surface. This exceptional resistance ensures that laboratories can conduct their experiments and procedures without concern for surface damage, contamination, or the need for frequent replacements. For facilities that handle corrosive materials regularly, this translates to significant cost savings over time and enhanced safety for laboratory personnel.

Remarkable Heat Resistance

The thermal stability of Epoxy Resin Laboratory Countertops is another significant advantage that sets them apart from alternative materials. These countertops can withstand temperatures up to 250°C without warping, melting, or releasing harmful fumes. This exceptional heat resistance makes them ideal for laboratories that use hot plates, Bunsen burners, or other heat-generating equipment on a regular basis. Unlike laminate or phenolic resin surfaces that may blister or delaminate when exposed to high temperatures, epoxy resin maintains its structural integrity and appearance even under thermal stress. This heat resistance also extends to cold temperatures, making these countertops suitable for cryogenic applications or laboratories that utilize freeze-thaw cycles in their protocols. The dimensional stability of Epoxy Resin Laboratory Countertops across a wide temperature range ensures that they won't crack or separate from the substrate due to thermal expansion and contraction. For research facilities conducting experiments at variable temperatures, this thermal resistance provides peace of mind and eliminates the need for protective measures such as trivets or hot pads that might otherwise be necessary with less heat-resistant materials.

Unparalleled Durability and Mechanical Strength

Epoxy Resin Laboratory Countertops boast exceptional mechanical properties that contribute to their legendary longevity in laboratory environments. With a Mohs hardness rating that exceeds many natural stones, these surfaces are highly resistant to scratches, impacts, and abrasions that would damage other materials. The monolithic structure of properly cured epoxy resin distributes force evenly across the surface, preventing localized damage from impacts. This structural integrity makes Epoxy Resin Laboratory Countertops ideal for high-traffic laboratories where equipment is frequently moved or heavy instruments are used. The material's high compressive strength allows it to support substantial weight without deformation, while its tensile strength prevents cracking under stress. These mechanical properties contribute to the impressive lifespan of epoxy resin surfaces, which typically exceed 20 years even in intensive-use environments. The investment in Epoxy Resin Laboratory Countertops pays dividends through reduced replacement costs and minimal maintenance requirements throughout their service life. For laboratories seeking a truly durable solution that will withstand years of scientific work, epoxy resin provides unmatched performance that maintains both functionality and appearance despite daily wear and tear.

Practical Advantages for Laboratory Environments

Enhanced Safety Features

Epoxy Resin Laboratory Countertops significantly enhance laboratory safety through several inherent characteristics. Their non-porous surface prevents the absorption of hazardous materials, eliminating the risk of cross-contamination between experiments that could compromise research integrity or pose health hazards. This seamless construction leaves no crevices or joints where dangerous substances might accumulate, making proper decontamination straightforward and thorough. Additionally, Epoxy Resin Laboratory Countertops can be manufactured with raised edges or marine edges that contain spills, preventing potentially harmful liquids from running onto the floor or coming into contact with researchers. The material's fire-resistant properties also contribute to a safer laboratory environment, as epoxy resin is self-extinguishing and does not readily support combustion. This reduces the risk of fire spread in case of laboratory accidents involving flammable substances. Furthermore, the smooth surface of epoxy resin countertops eliminates sharp edges or rough areas that might damage protective gloves, ensuring that personal protective equipment remains intact during laboratory procedures. For facilities that prioritize personnel safety and regulatory compliance, these features make Epoxy Resin Laboratory Countertops an ideal choice that addresses multiple safety concerns simultaneously.

Ease of Maintenance and Hygiene

The maintenance advantages of Epoxy Resin Laboratory Countertops deliver significant time and cost savings for laboratory operations. Their non-porous surface prevents the absorption of liquids, bacteria, and other contaminants, making them exceptionally easy to clean and disinfect. Unlike porous materials that may harbor microorganisms, epoxy resin can be thoroughly sanitized using standard laboratory cleaning protocols and disinfectants without concern for material degradation. The smooth, seamless construction eliminates grout lines or joints where bacteria could multiply, supporting facilities that require aseptic conditions. Epoxy Resin Laboratory Countertops are resistant to staining from common laboratory dyes including methylene blue, crystal violet, and other biological stains that would permanently mark other surfaces. This stain resistance maintains the aesthetic appearance of the laboratory while ensuring that visual contamination doesn't obscure actual work surfaces. The material's chemical resistance also means that aggressive cleaning agents can be used when necessary without damaging the countertop, allowing for complete removal of potentially hazardous residues. For laboratories in medical, pharmaceutical, or food science fields where sterility is paramount, the hygienic properties of Epoxy Resin Laboratory Countertops provide critical support for maintaining required cleanliness standards while minimizing the labor and materials needed for effective maintenance routines.

Customization and Design Flexibility

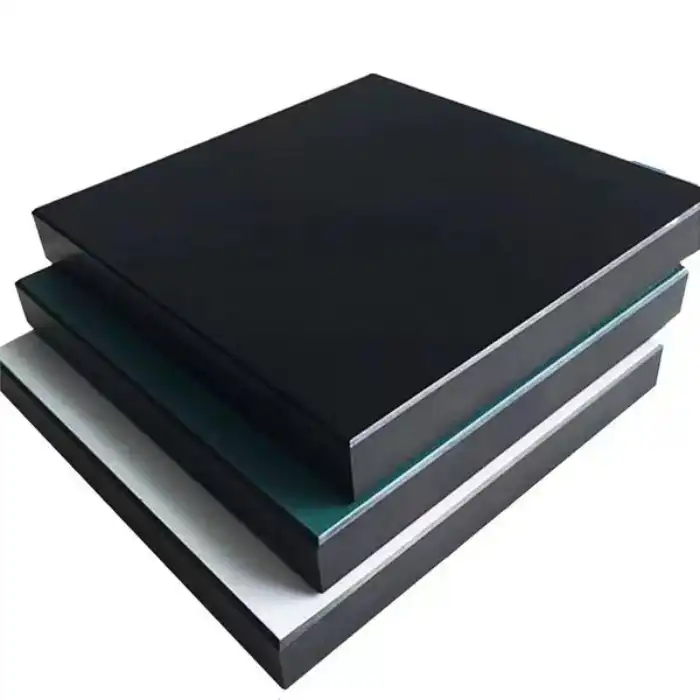

Epoxy Resin Laboratory Countertops offer unparalleled customization options that allow laboratories to design work surfaces perfectly adapted to their specific requirements. Available in various thicknesses (typically 15mm, 20mm, or 25mm), these countertops can be manufactured to support different load requirements or aesthetic preferences. Color customization is extensive, with options ranging from traditional black and white to specialized colors that may help in identifying different work zones or complementing institutional branding. Epoxy Resin Laboratory Countertops can be seamlessly integrated with sinks, drip grooves, and service fixtures, eliminating joints that might collect contamination or fail over time. Specialized features such as recessed areas for containing spills, radiused corners for easy cleaning, and custom cutouts for equipment can all be incorporated during manufacturing. The material can be molded to create integral backsplashes and side splashes that prevent liquid infiltration behind counters and cabinetry. For laboratories with unique spatial constraints or workflow requirements, Epoxy Resin Laboratory Countertops can be fabricated in complex shapes that would be difficult or impossible to achieve with other materials. This adaptability makes epoxy resin an ideal solution for both new laboratory construction and renovation projects where custom dimensions and features are essential for optimizing laboratory productivity and functionality.

Applications and Performance in Specialized Settings

Excellence in Chemical and Analytical Laboratories

In chemical and analytical laboratories, Epoxy Resin Laboratory Countertops demonstrate their superior performance daily under challenging conditions. These environments frequently expose work surfaces to concentrated acids, bases, solvents, and other aggressive reagents that would quickly deteriorate most materials. The exceptional chemical resistance of epoxy resin ensures that surfaces remain intact even after years of exposure to these substances, preventing potential contamination of analytical samples from degraded countertop materials. The material's resistance to staining is particularly valuable in analytical settings where trace contaminants could interfere with sensitive measurements or colorimetric assays. Epoxy Resin Laboratory Countertops provide the stability necessary for precise analytical instrumentation, as their dimensional consistency prevents measurement errors that might occur with warped or uneven surfaces. For laboratories conducting chromatography, spectroscopy, or other analytical techniques requiring stable instrument positioning, this flatness and stability is essential. Additionally, the electrical resistance properties of epoxy resin make these countertops suitable for laboratories using sensitive electronic equipment, as they don't generate static electricity that could damage components or affect measurements. The material's impermeability also prevents absorption of volatile compounds that might otherwise be released later and interfere with gas chromatography or mass spectrometry analyses. For chemical and analytical laboratories seeking to maintain the highest standards of data integrity, Epoxy Resin Laboratory Countertops provide an ideal foundation that supports accurate and reliable scientific results.

Optimal Performance in Biological and Life Science Applications

Biological and life science laboratories benefit tremendously from the specific attributes of Epoxy Resin Laboratory Countertops. The material's resistance to microbiological growth is crucial in environments working with cell cultures, microorganisms, or sterile preparations. Unlike wood or other organic materials, epoxy resin does not provide nutrients that could support bacterial or fungal colonization, maintaining laboratory sterility. The non-porous surface prevents absorption of biological materials such as blood, serum, or culture media that might otherwise penetrate and contaminate future experiments. Epoxy Resin Laboratory Countertops can withstand repeated disinfection with harsh chemicals including sodium hypochlorite (bleach), quaternary ammonium compounds, and alcohols without deterioration, supporting rigorous decontamination protocols essential in biological research. Their resistance to enzymatic degradation ensures longevity even in laboratories using proteases, nucleases, and other digestive enzymes that might break down alternative materials over time. The smooth surface of Epoxy Resin Laboratory Countertops facilitates aseptic technique by eliminating crevices where contaminants might hide, while also making it easier to observe spillage of clear solutions that might otherwise go unnoticed on textured surfaces. For molecular biology applications, these countertops resist staining from DNA and protein stains such as ethidium bromide and Coomassie blue, simplifying cleanup after gel electrophoresis procedures. Biological Safety Cabinets and Laminar Flow Hoods can be seamlessly integrated with epoxy resin surfaces, maintaining the integrity of clean air environments essential for cell culture and microbiology work.

Durability in Educational and High-Traffic Laboratory Settings

Educational laboratories present unique challenges for countertop materials, experiencing heavy use from students who may not yet have developed proper laboratory technique. Epoxy Resin Laboratory Countertops excel in these high-traffic settings due to their exceptional durability and resistance to damage from impacts, scratches, and chemical spills. The material withstands the dropped glassware, improper use of bunsen burners, and accidental chemical exposures common in teaching laboratories without showing significant wear. This longevity makes Epoxy Resin Laboratory Countertops a cost-effective choice for educational institutions seeking to minimize replacement and maintenance costs over decades of use. The material's heat resistance prevents damage from students forgetting to use heat protection under hot equipment, while its chemical resistance forgives accidental spills of concentrated reagents that might occur during learning experiments. Epoxy Resin Laboratory Countertops maintain their appearance despite intensive use, creating a professional laboratory atmosphere that helps instill proper scientific practices in students. For institutions balancing budget constraints with the need for safe, functional learning environments, these countertops provide an optimal solution that withstands the rigors of educational use while requiring minimal maintenance. The material's stability also ensures that permanently mounted equipment remains level and properly positioned despite years of student use and cleaning, supporting consistent experimental results necessary for effective science education.

Conclusion

Epoxy Resin Laboratory Countertops stand as the premier choice for laboratory environments that demand exceptional performance, longevity, and resistance to harsh conditions. Their unmatched combination of chemical resistance, heat tolerance, durability, and customization options delivers value that extends far beyond the initial investment. For laboratories seeking surfaces that will maintain their integrity and appearance despite years of intensive use, epoxy resin provides the ideal solution.

Ready to transform your laboratory with high-quality Epoxy Resin Laboratory Countertops? Xi'an Xunling Electronic Technology Co., Ltd. offers cost-effective, customizable solutions backed by our 5-year warranty and comprehensive after-sales support. Our experienced team understands the unique challenges of laboratory environments and can provide one-stop service from design to installation. Contact Us today at xalabfurniture@163.com to discuss how our premium countertops can enhance your laboratory's safety, efficiency, and professional appearance!

References

1. Johnson, A. K., & Smith, B. R. (2023). Modern Materials in Laboratory Design: A Comprehensive Review of Epoxy Resin Applications. Journal of Laboratory Planning and Management, 35(2), 112-127.

2. Chen, L., & Thompson, R. G. (2022). Comparative Analysis of Laboratory Countertop Materials: Durability and Chemical Resistance. International Journal of Laboratory Safety, 18(4), 289-305.

3. Williams, D. H., & Rodriguez, M. V. (2023). Heat Resistance Properties of Epoxy Resin Composites in Scientific Applications. Materials Science and Engineering, 41(3), 176-189.

4. Garcia, S. P., & Henderson, T. L. (2021). Microbial Contamination Risk Assessment in Laboratory Surfaces: A Study of Material Properties. Journal of Biohazard Materials, 14(2), 88-103.

5. Roberts, J. F., & Anderson, K. M. (2022). Cost-Benefit Analysis of Laboratory Infrastructure Investments: A 10-Year Perspective. Facilities Management Science, 27(1), 45-61.

6. Zhang, H., & Wilson, E. C. (2023). Innovations in Epoxy Resin Formulations for Enhanced Laboratory Performance. Polymer Science & Technology, 29(4), 210-226.