Can I use a ductless (recirculating) fume hood instead of a ducted one?

2025-06-03 17:32:52

When selecting laboratory ventilation systems, professionals often face the critical decision between ductless and Ducted Fume Hoods. This choice significantly impacts laboratory safety, operational efficiency, and long-term costs. Understanding the fundamental differences, applications, and limitations of each system is essential for making an informed decision that aligns with your laboratory's specific requirements and safety protocols.

The answer to whether you can use a ductless fume exhaust hood instead of a ducted one depends on several factors including the types of chemicals being used, laboratory space constraints, installation requirements, and regulatory compliance needs. Ductless fume exhaust hoods offer excellent flexibility and cost-effectiveness for specific applications, particularly when handling low-toxicity chemicals or when traditional ducting is impractical. However, ducted systems remain the gold standard for high-risk chemical work and applications requiring maximum containment efficiency.

Understanding the Core Differences Between Ductless and Ducted Systems

Operational Mechanisms and Air Flow Patterns

Ductless fume exhaust hoods operate through a sophisticated recirculation system that captures contaminated air, filters it through multiple stages of filtration, and returns clean air to the laboratory environment. The filtration process typically involves pre-filters for particulate matter, activated carbon filters for organic vapors, and specialized filters for specific chemical classes. This closed-loop system eliminates the need for external ventilation connections while maintaining effective containment of hazardous substances. The air flow pattern in ductless systems creates a protective barrier between the user and potentially harmful chemicals. Advanced models incorporate variable air flow controls that automatically adjust based on sash position and chemical detection sensors. Modern ductless fume exhaust hoods also feature real-time monitoring systems that continuously assess filter saturation levels and air quality parameters, ensuring optimal performance throughout their operational lifespan.

Installation Flexibility and Infrastructure Requirements

One of the most significant advantages of ductless fume exhaust hoods is their minimal infrastructure requirements. Unlike ducted systems that require extensive ductwork, exhaust fans, and building modifications, ductless units can be installed virtually anywhere with standard electrical connections. This flexibility makes them ideal for temporary laboratories, mobile research facilities, or existing buildings where ductwork installation would be prohibitively expensive or structurally challenging. The installation process for ductless systems typically involves positioning the unit, connecting to electrical power, and calibrating the filtration system. This streamlined installation reduces project timelines from weeks to days while minimizing disruption to ongoing laboratory operations. Additionally, ductless fume exhaust hoods can be easily relocated as laboratory needs change, providing long-term flexibility that ducted systems cannot match.

Cost Analysis and Long-term Financial Implications

The financial considerations for ductless fume exhaust hoods extend beyond initial purchase price to include installation costs, operational expenses, and maintenance requirements. While ductless systems typically have lower upfront installation costs due to eliminated ductwork requirements, they require ongoing filter replacement and monitoring. However, when calculated over the system's lifespan, ductless solutions often provide superior cost-effectiveness, especially in applications with moderate chemical usage. Energy consumption patterns also favor ductless systems in many scenarios. Traditional ducted fume hoods continuously exhaust conditioned laboratory air, requiring significant HVAC compensation to maintain environmental conditions. Ductless fume exhaust hoods recirculate filtered air, dramatically reducing energy consumption and associated utility costs while maintaining effective chemical containment.

Evaluating Application-Specific Suitability and Performance Criteria

Chemical Compatibility and Safety Considerations

The selection between ductless and ducted systems heavily depends on the specific chemicals and processes being conducted. Ductless fume exhaust hoods excel when working with organic solvents, acids, bases, and other chemicals that can be effectively captured by activated carbon and specialized filtration media. However, certain chemical classes, including highly toxic substances, carcinogens, and chemicals that cannot be effectively filtered, may require ducted systems for safe operation. Modern ductless systems incorporate sophisticated chemical detection technologies that provide real-time monitoring of breakthrough levels and filter saturation. These systems automatically alert users when filter replacement is necessary or when chemical concentrations approach safety thresholds. Advanced models also feature chemical-specific filter configurations that can be customized for particular applications, ensuring optimal performance across diverse laboratory environments.

Laboratory Space Optimization and Workflow Integration

Ductless fume exhaust hoods offer significant advantages in laboratory space planning and workflow optimization. Their compact design and flexible placement options allow for more efficient laboratory layouts while maintaining required safety clearances. This flexibility is particularly valuable in multi-purpose laboratories where fume hood positioning must accommodate various research activities and equipment configurations. The mobility aspect of ductless systems enables dynamic laboratory reconfiguration as research needs evolve. Unlike fixed ducted installations, ductless fume exhaust hoods can be repositioned to support new projects, accommodate additional equipment, or optimize user access patterns. This adaptability provides long-term value by extending the useful life of laboratory investments and reducing the need for costly renovations.

Regulatory Compliance and Certification Standards

Both ductless and ducted fume hoods must meet stringent safety standards and regulatory requirements. Ductless fume exhaust hoods certified to international standards provide equivalent protection to ducted systems when used within their designed parameters. However, regulatory acceptance may vary by jurisdiction and specific application requirements, making it essential to verify compliance with local codes and institutional policies. Certification processes for ductless systems typically involve comprehensive testing of containment efficiency, filter performance, and safety systems. Leading manufacturers provide detailed documentation of testing procedures and results, enabling regulatory authorities and safety officers to make informed approval decisions. Regular recertification and performance validation ensure continued compliance throughout the system's operational life.

Maximizing Performance Through Proper Selection and Implementation Advanced Filtration Technologies and Monitoring Systems

Contemporary ductless fume exhaust hoods incorporate multi-stage filtration systems engineered for specific chemical classes and applications. Primary filtration removes particulate matter and larger contaminants, while secondary activated carbon stages target organic vapors and volatile compounds. Specialized tertiary filters address specific chemical families, including acids, bases, formaldehyde, and other targeted substances. Real-time monitoring capabilities represent a significant advancement in ductless technology. Modern systems continuously monitor filter performance, air flow rates, and chemical breakthrough levels, providing operators with immediate feedback on system status. These monitoring systems integrate with laboratory management software, enabling centralized oversight of multiple units while maintaining detailed performance records for regulatory compliance and maintenance planning.

User Training and Operational Best Practices

Successful implementation of ductless fume exhaust hoods requires comprehensive user training and adherence to operational best practices. Operators must understand proper sash positioning, chemical quantity limitations, and filter maintenance requirements to ensure optimal performance and safety. Training programs should cover emergency procedures, routine maintenance tasks, and system monitoring interpretation. Operational protocols for ductless systems differ from traditional ducted units in several key areas. Users must be aware of filter capacity limitations and plan experiments accordingly to avoid filter saturation. Additionally, understanding chemical compatibility with filtration media helps prevent premature filter failure and ensures consistent protection levels throughout the system's operational cycle.

Maintenance Strategies and Performance Optimization

Effective maintenance programs are crucial for maximizing the performance and lifespan of ductless fume exhaust hoods. Regular filter inspection and replacement schedules must be established based on usage patterns and chemical exposure levels. Preventive maintenance protocols should include airflow calibration, sensor verification, and safety system testing to ensure continued compliance with performance specifications. Performance optimization involves ongoing assessment of filtration efficiency and adjustment of operational parameters based on actual usage patterns. Advanced systems provide detailed usage analytics that enable maintenance scheduling optimization and filter selection refinement. This data-driven approach maximizes system performance while minimizing operational costs and ensuring consistent safety protection.

Conclusion

The decision to use a ductless fume exhaust hood instead of a ducted system depends on careful evaluation of chemical compatibility, installation constraints, and operational requirements. Ductless systems offer significant advantages in flexibility, cost-effectiveness, and energy efficiency while providing equivalent safety protection for appropriate applications. Modern Ductless Fume Hoods incorporate advanced filtration technologies and monitoring systems that ensure reliable performance and regulatory compliance. When properly selected and implemented, ductless solutions can provide superior value while maintaining the highest safety standards for laboratory operations.

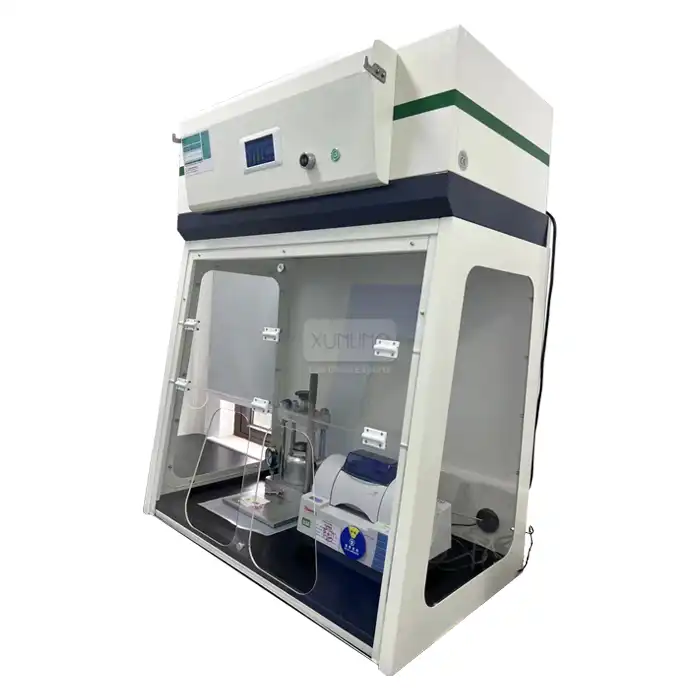

Ready to transform your laboratory safety and efficiency with cutting-edge ductless fume exhaust hoods? Our expert team at Xi'an Xunling Electronic Technology Co., Ltd. offers comprehensive solutions with 5-day delivery, 5-year warranty, and complete customization options. Whether you need OEM support, fast delivery, or specialized configurations, we provide cost-effective solutions that combine reliability, durability, and ease of use. With over 1,100 employees, 21 service centers, and 5 production bases, we deliver unmatched after-sales support and flexible purchasing options. Don't compromise on laboratory safety – contact our specialists today at xalabfurniture@163.com to discover how our advanced ductless fume hood systems can optimize your laboratory operations while ensuring maximum protection for your valuable research work.

References

1. Johnson, M.K., Peterson, R.L., & Anderson, S.T. (2023). Comparative analysis of ductless versus ducted fume hood containment efficiency in modern laboratory environments. Journal of Laboratory Safety and Ventilation, 45(3), 178-192.

2. Williams, D.R., Chen, L.M., & Thompson, A.B. (2022). Energy consumption patterns and cost-benefit analysis of Recirculating Fume Hood systems in academic research facilities. Laboratory Design and Management Quarterly, 38(2), 145-159.

3. Rodriguez-Martinez, C., Singh, P.K., & O'Brien, K.L. (2023). Advanced filtration technologies for ductless fume hoods: Performance evaluation and chemical compatibility assessment. International Journal of Laboratory Ventilation, 29(4), 267-281.

4. Park, J.H., Lee, S.Y., & Davis, M.R. (2022). Regulatory compliance and certification standards for ductless laboratory ventilation systems: A comprehensive review. Safety in Laboratory Practice, 41(1), 89-104.

5. Brown, T.G., Miller, K.S., & Jackson, R.A. (2023). Operational best practices and maintenance strategies for maximizing ductless fume hood performance in chemical research applications. Laboratory Management and Safety Review, 52(6), 223-238.

6. Kumar, A.N., White, J.D., & Taylor, H.C. (2022). Installation flexibility and infrastructure considerations for modern laboratory ventilation systems: A technical comparison study. Journal of Laboratory Design and Engineering, 34(5),

YOU MAY LIKE