Walk In Fume Hood: Solving Space Constraints in Modern Labs

2025-10-09 09:00:02

As modern laboratories continue to expand their research capabilities and handle increasingly complex experiments, space limitations have become a critical challenge that demands innovative solutions. Walk In Fume Hood technology represents a revolutionary approach to addressing these spatial constraints while maintaining the highest safety standards. These large-scale ventilation systems provide researchers with the expansive workspace necessary for sophisticated experimental setups, multi-researcher collaborations, and large equipment operations. Unlike traditional bench-mounted fume hoods, Walk In Fume Hood units offer floor-to-ceiling protection with generous interior dimensions that can accommodate equipment and processes that would otherwise be impossible to safely contain within standard laboratory ventilation systems.

Understanding Walk In Fume Hood Design and Functionality

Advanced Engineering for Maximum Space Utilization

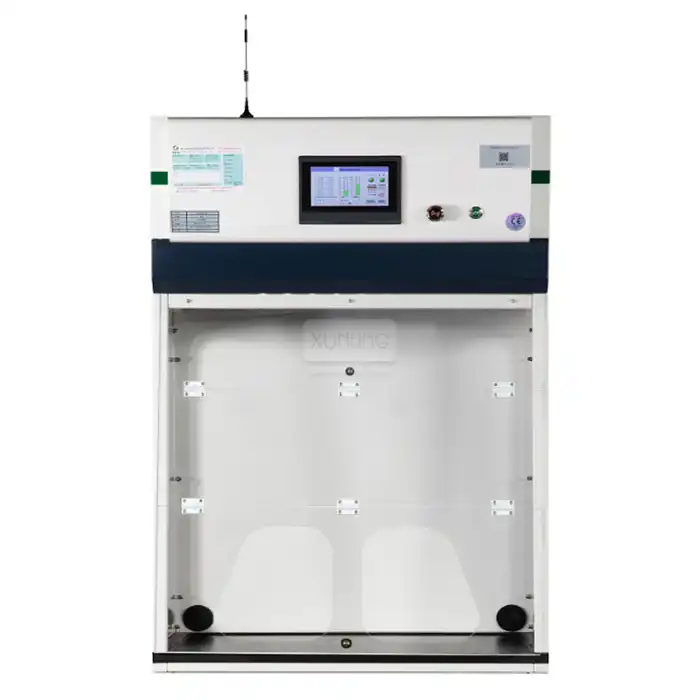

Walk In Fume Hood systems represent the pinnacle of laboratory ventilation engineering, designed specifically to address the growing need for expansive, protected workspaces in modern research facilities. These units feature robust construction utilizing high-quality cold-rolled steel sheets with advanced surface treatments including phosphating and electrostatic powder spraying with epoxy resin, ensuring exceptional durability and chemical resistance. The spacious interior dimensions, ranging from standard configurations of 1200×850×2350mm to 1800×850×2350mm, with customization options available, provide researchers with unprecedented freedom to conduct complex experiments requiring multiple apparatus setups simultaneously. The intelligent digital display controller system enables precise management of power distribution, fan speed regulation, lighting control, electrical outlets, sterilization functions, and damper operations, creating an integrated environment that responds dynamically to experimental requirements. This sophisticated control system ensures optimal airflow patterns are maintained throughout the workspace, regardless of the complexity or scale of operations being conducted within the Walk In Fume Hood enclosure.

Safety-First Ventilation Technology

The safety mechanisms integrated into Walk In Fume Hood systems surpass traditional laboratory ventilation standards through advanced airflow control methodologies and multi-layered protection systems. The dual vertical sash design, featuring weight-balanced 5mm tempered explosion-proof glass panels, provides researchers with excellent visibility while maintaining structural integrity under demanding laboratory conditions. The sophisticated airflow management system incorporates precision-engineered baffles constructed from durable PP materials, working in conjunction with compact grade laminate liners to ensure consistent air velocity distribution throughout the expansive workspace. This comprehensive approach to air movement control guarantees effective removal of harmful gases, vapors, chemical fumes, and particulate matter, protecting both researchers and sensitive equipment from potential contamination. The system's ability to maintain negative pressure conditions while accommodating multiple simultaneous operations makes Walk In Fume Hood installations particularly valuable in high-throughput research environments where traditional ventilation solutions would compromise either safety protocols or operational efficiency.

Customizable Interior Configurations

Modern Walk In Fume Hood systems excel in their ability to adapt to diverse laboratory requirements through extensive customization capabilities that address specific research needs and workflow optimization. The internal layout flexibility allows for strategic placement of specialized workbenches, integrated storage solutions, dedicated equipment mounting systems, and optimized lighting configurations that enhance both functionality and user experience. Advanced LED purification lighting systems, typically featuring 30W units capable of delivering illumination levels exceeding 300LUX, ensure consistent visibility throughout the workspace while contributing to the overall safety profile through UV sterilization capabilities. The electrical infrastructure supports voltage ranges from 110V to 230V, incorporating convenient circuit boards and AC contactors that facilitate seamless integration with existing laboratory power systems. Optional accessories such as PP oval cupsinks, remote-controlled gas and water faucets, explosion-proof lighting systems, distillation grid kits, and specialized ductwork components enable laboratories to create truly bespoke Walk In Fume Hood installations that align perfectly with their specific operational requirements and safety protocols.

Applications and Industry Benefits

Complex Chemical Synthesis Operations

Walk In Fume Hood systems have revolutionized the approach to complex chemical synthesis operations in research and industrial laboratories by providing the spatial freedom necessary for sophisticated multi-step reactions and parallel processing protocols. These expansive ventilation enclosures enable chemists to safely manage multiple reaction vessels, distillation apparatus, and analytical equipment simultaneously within a single protected environment, dramatically improving workflow efficiency and experimental throughput. The generous workspace dimensions accommodate large-scale glassware assemblies, automated synthesis equipment, and multi-component reaction setups that would be impossible to safely operate within traditional bench-mounted fume hoods. The superior ventilation capacity ensures rapid removal of reaction byproducts, solvent vapors, and potentially hazardous chemical emissions, maintaining safe working conditions even during extended synthesis campaigns or high-temperature operations. Research facilities conducting pharmaceutical development, specialty chemical manufacturing, and advanced materials research have found Walk In Fume Hood installations indispensable for maintaining productivity while adhering to stringent safety regulations and environmental compliance requirements.

Biological Research and Biotechnology Applications

The biotechnology sector has embraced Walk In Fume Hood technology as an essential tool for conducting advanced biological research that requires both sterile conditions and expansive workspace capabilities. These systems provide the controlled environment necessary for cell culture operations, protein purification procedures, and genetic engineering protocols that involve multiple researchers working collaboratively on complex experimental procedures. The integrated sterilization capabilities, combined with precise airflow control, create optimal conditions for sensitive biological materials while preventing cross-contamination between different research projects conducted within the same facility. Microbiology laboratories, pharmaceutical research divisions, and biotechnology companies utilize Walk In Fume Hood installations for vaccine development, therapeutic protein production, and diagnostic assay development where traditional containment solutions would limit experimental scale or compromise research timelines. The ability to accommodate large bioreactors, automated liquid handling systems, and sophisticated analytical equipment within a single protected environment has transformed how modern biological research is conducted, enabling breakthrough discoveries in medicine, agriculture, and environmental science.

Industrial Process Development and Quality Control

Industrial laboratories and process development facilities have recognized Walk In Fume Hood systems as critical infrastructure for scaling up laboratory discoveries into commercial manufacturing processes. These installations provide the protected environment necessary for pilot-scale reactions, process optimization studies, and quality control procedures that require handling significant quantities of materials under controlled conditions. Manufacturing companies in the chemical, pharmaceutical, and materials industries rely on Walk In Fume Hood technology to safely evaluate new production methods, conduct accelerated stability testing, and perform analytical validations that support regulatory compliance initiatives. The robust construction and superior ventilation capacity enable industrial researchers to work with corrosive chemicals, high-temperature processes, and volatile compounds at scales that bridge the gap between laboratory research and full-scale manufacturing. Quality control laboratories utilize these systems for environmental monitoring, product testing, and analytical method development where traditional ventilation solutions would inadequately protect personnel or compromise analytical accuracy through environmental interference.

Selection Criteria and Implementation Considerations

Technical Specifications and Performance Standards

Selecting the appropriate Walk In Fume Hood system requires careful evaluation of technical specifications that align with specific laboratory requirements and operational objectives. Key performance parameters include airflow velocity maintenance, typically requiring face velocities between 0.4-0.6 m/s to ensure adequate containment, while maintaining energy efficiency through variable air volume control systems. The structural specifications must accommodate the anticipated equipment loads, chemical compatibility requirements, and spatial constraints of the installation environment. Construction materials, including the grade of steel utilized for the frame, the thickness and composition of protective coatings, and the chemical resistance properties of interior components, directly impact both performance longevity and maintenance requirements. Electrical specifications must align with facility power infrastructure while providing adequate capacity for anticipated equipment loads, lighting requirements, and ventilation system demands. The integration of intelligent control systems enables real-time monitoring of critical parameters such as airflow rates, filter saturation levels, and energy consumption, providing facility managers with the data necessary to optimize performance and schedule preventive maintenance activities.

Installation Planning and Infrastructure Requirements

Successful Walk In Fume Hood implementation demands comprehensive planning that addresses infrastructure requirements, regulatory compliance, and operational workflow integration from project inception through commissioning and ongoing operation. Site preparation must account for adequate ceiling height, typically requiring minimum clearances of 3 meters to accommodate the full-height design and associated ductwork connections. Electrical infrastructure planning must provide sufficient capacity for high-powered ventilation systems, LED lighting arrays, and multiple electrical outlets while incorporating appropriate safety circuits and emergency shutdown capabilities. The ductwork design requires careful attention to air balance calculations, ensuring adequate exhaust capacity while maintaining proper pressure relationships throughout the laboratory facility. Facility managers must coordinate with HVAC specialists, electrical contractors, and laboratory design consultants to ensure seamless integration with existing building systems. Regulatory compliance considerations include adherence to local building codes, environmental regulations, and industry-specific safety standards that may impact design specifications, installation procedures, and operational protocols.

Maintenance and Long-term Performance Optimization

Long-term success with Walk In Fume Hood installations depends on implementing comprehensive maintenance programs that address both preventive care and performance optimization strategies. Regular inspection protocols should encompass airflow verification, filter condition assessment, electrical system functionality checks, and structural integrity evaluations to ensure continued safe operation and regulatory compliance. The modular design of modern systems facilitates component replacement and system upgrades without requiring complete reinstallation, protecting the initial investment while accommodating evolving laboratory needs. Energy efficiency optimization through periodic calibration of variable air volume controls, LED lighting system updates, and airflow pattern analysis can significantly reduce operational costs while maintaining superior safety performance. Maintenance scheduling should align with laboratory operational cycles to minimize disruption to research activities while ensuring critical safety systems remain fully functional. Training programs for laboratory personnel and maintenance staff ensure proper operation, early identification of potential issues, and appropriate response to emergency situations, maximizing both safety and equipment longevity.

Conclusion

Walk In Fume Hood technology represents a transformative solution for modern laboratories facing space constraints while demanding uncompromising safety standards. These advanced ventilation systems successfully address the dual challenges of providing expansive workspace capabilities and maintaining superior protection for researchers and equipment. Through innovative engineering, customizable configurations, and intelligent control systems, Walk In Fume Hood installations enable laboratories to pursue complex research objectives that would otherwise be limited by traditional ventilation constraints.

Xi'an Xunling Electronic Technology Co., Ltd. stands at the forefront of this technological advancement, combining extensive manufacturing expertise with comprehensive customer support to deliver world-class laboratory solutions. As a leading China Walk In Fume Hood factory and China Walk In Fume Hood supplier, our company leverages advanced manufacturing capabilities including 18 CNC laser cutting machines, 50 CNC bending machines, and 4 fully automatic spraying lines to ensure exceptional quality and rapid delivery. Our position as a trusted China Walk In Fume Hood manufacturer enables us to offer competitive China Walk In Fume Hood wholesale pricing while maintaining the highest quality standards. When searching for Walk In Fume Hood for sale, laboratories worldwide trust our High Quality Walk In Fume Hood solutions that combine competitive Walk In Fume Hood price with superior performance and reliability.

Our comprehensive approach includes 5-day delivery, 5-year warranty, custom-made solutions, and one-stop service that addresses every aspect of laboratory ventilation needs. For laboratories seeking cost-effective, reliable, and user-friendly Walk In Fume Hood solutions backed by comprehensive after-sales support and flexible purchase options, Xi'an Xunling Electronic Technology Co., Ltd. provides the expertise and manufacturing excellence necessary to transform your laboratory capabilities. Contact Us at xalabfurniture@163.com to discover how our Walk In Fume Hood solutions can solve your space constraints while enhancing safety and operational efficiency.

References

1. American Society of Heating, Refrigerating and Air-Conditioning Engineers. "Laboratory Design Guide: HVAC Systems for Laboratories." ASHRAE Publications, 2018.

2. National Institute for Occupational Safety and Health. "Criteria for a Recommended Standard: Occupational Exposure to Chemical Fume Hoods." Department of Health and Human Services, 2019.

3. International Organization for Standardization. "Laboratory Equipment - Fume Cupboards - Part 1: Vocabulary." ISO 14175-1:2020, International Standards Organization, 2020.

4. Laboratory Equipment Manufacturers Association. "Guidelines for Laboratory Ventilation Design and Performance Testing." LEMA Technical Report 2021-03, Scientific Equipment and Furniture Association, 2021.

_1741166473547.webp)

_1735469892197.webp)

_1735472430670.webp)