The Hidden ROI of Professional Walk In Fume Hood Systems

2025-10-09 09:00:02

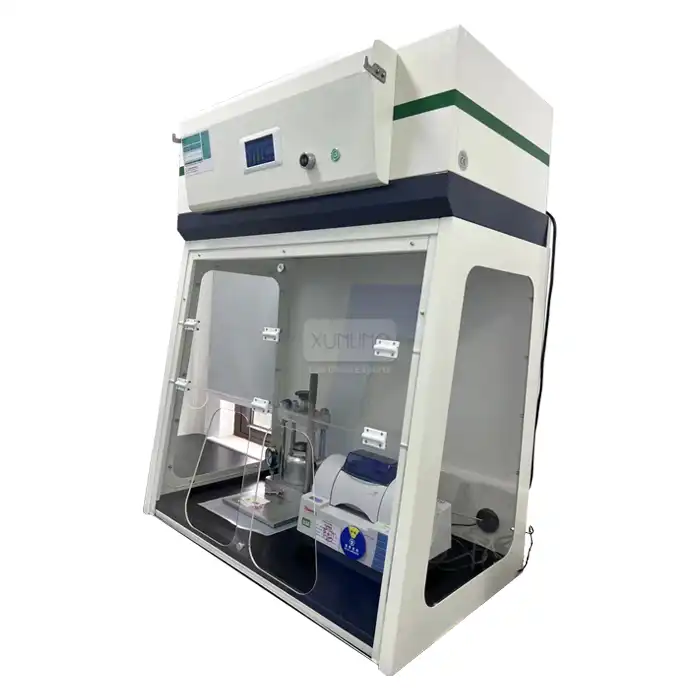

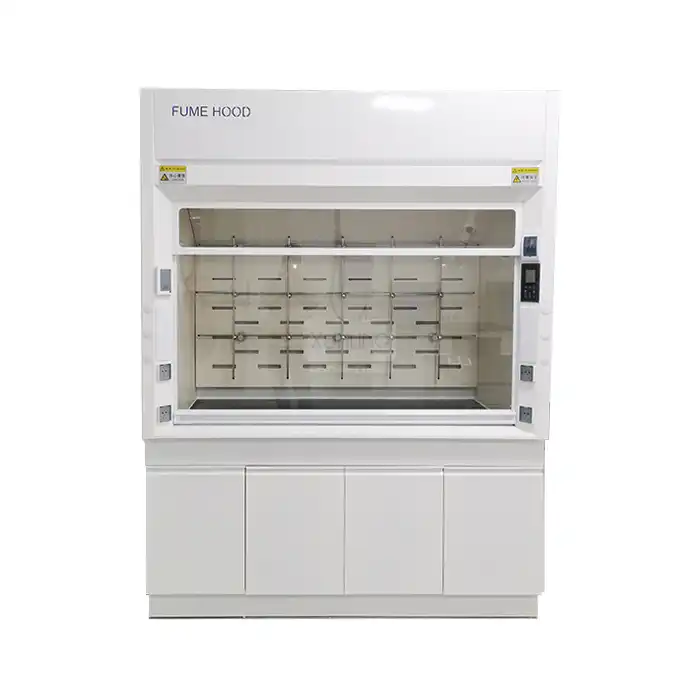

When laboratory managers and facility planners evaluate equipment investments, the immediate costs often overshadow the long-term financial benefits. However, professional Walk In Fume Hood systems deliver substantial hidden returns on investment that extend far beyond their initial purchase price. These large-scale ventilation solutions provide measurable value through energy efficiency, operational flexibility, regulatory compliance, and enhanced safety protocols that translate into significant cost savings over time. Walk in fume hoods are the ideal way to eliminate fumes, toxins, and odors from being exposed into the environment while working with applications that are too large for benchtop solutions. The hidden ROI of professional Walk In Fume Hood systems encompasses multiple financial benefits including reduced energy consumption, decreased maintenance costs, improved worker productivity, minimized regulatory penalties, and enhanced laboratory space utilization efficiency.

Long-Term Financial Benefits and Cost Optimization

Energy Efficiency and Operational Cost Reduction

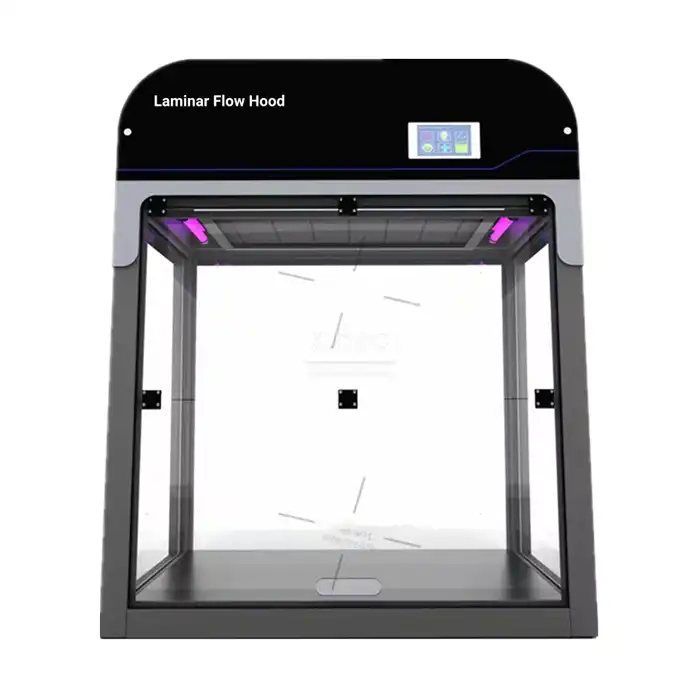

Professional Walk In Fume Hood systems deliver substantial energy savings through advanced airflow management and intelligent control systems. Modern units incorporate variable air volume technology and sophisticated monitoring systems that adjust ventilation rates based on actual usage patterns rather than maintaining constant maximum airflow. This intelligent approach can reduce energy consumption by up to 40% compared to traditional constant air volume systems. The energy savings accumulate significantly over the typical 15-20 year lifespan of these systems, often offsetting the initial investment within the first five years of operation. The sophisticated design of contemporary Walk In Fume Hood systems includes features such as digital display controllers that optimize fan speed, lighting, and damper operations based on real-time conditions. These systems automatically adjust ventilation rates when the hood is not in active use, reducing unnecessary energy expenditure during off-peak hours. Additionally, the integration of LED lighting systems, such as the 30W LED purification lamps standard in many professional units, provides superior illumination while consuming significantly less electricity than traditional fluorescent alternatives. Energy optimization extends beyond the immediate hood operation to impact the entire laboratory HVAC infrastructure. High-performance fume hoods can also yield substantial first-cost savings by allowing downsizing of heating, ventilating, and air-conditioning infrastructure. This downstream effect reduces both capital expenditure and ongoing operational costs throughout the facility's lifecycle, creating compound savings that contribute to the hidden ROI of these systems.

Maintenance Cost Reduction and Equipment Longevity

Professional Walk In Fume Hood systems constructed with high-quality materials demonstrate exceptional durability that translates into reduced maintenance costs and extended operational lifespans. Premium units feature robust construction with cold-rolled steel bodies treated with advanced phosphating and electrostatic powder spraying using epoxy resins, providing superior corrosion resistance and maintaining structural integrity under demanding laboratory conditions. The use of specialized materials such as 5mm Compact grade laminate for liners and polypropylene for baffles ensures chemical resistance and minimizes replacement requirements. The modular design of professional systems facilitates easier maintenance and component replacement, reducing both labor costs and system downtime. Standardized components and readily available replacement parts minimize inventory costs and ensure rapid restoration of full operational capacity when maintenance is required. The intelligent monitoring systems incorporated in these units provide predictive maintenance capabilities, alerting facility managers to potential issues before they result in costly failures or emergency repairs. Quality construction materials and precision manufacturing processes contribute to extended equipment lifespans that exceed 20 years with proper maintenance. This longevity amortizes the initial investment over a longer period while maintaining consistent performance standards throughout the operational life. The reduced frequency of major repairs and component replacements represents a significant hidden cost benefit that accumulates over time, particularly when compared to lower-quality alternatives that require more frequent intervention and replacement.

Space Utilization and Operational Flexibility

The spacious design of Walk In Fume Hood systems provides exceptional operational flexibility that maximizes laboratory space utilization and accommodates evolving research requirements. Standard configurations ranging from 1200mm to 1800mm widths with customizable dimensions allow laboratories to optimize their layout for maximum efficiency. A walk-in fume hood keeps the lab environment clean and breathable by removing toxic gases, vapors, and dust. This capability enables laboratories to consolidate multiple smaller operations into a single, more efficient workspace, reducing overall facility requirements and associated costs. The ability to accommodate large equipment and multiple researchers simultaneously eliminates the need for separate specialized ventilation systems for different applications. This consolidation reduces capital equipment costs, simplifies maintenance schedules, and optimizes facility utilization rates. The customizable internal configurations allow laboratories to adapt the space for various research activities without requiring additional equipment investments or facility modifications.

Safety Compliance and Risk Mitigation Returns

Regulatory Compliance and Penalty Avoidance

Professional Walk In Fume Hood systems ensure consistent compliance with evolving safety regulations and industry standards, protecting organizations from costly penalties and legal liabilities. These systems meet stringent international standards including ISO, CE, and NFPA certifications, providing assurance that installations comply with current regulatory requirements. The comprehensive documentation and certification processes associated with professional systems streamline regulatory inspections and reduce the risk of compliance violations. Modern Walk In Fume Hood systems incorporate advanced safety features that exceed minimum regulatory requirements, providing additional protection against future regulatory changes. The integration of sophisticated airflow monitoring, emergency shutdown capabilities, and comprehensive alarm systems ensures that safety standards are maintained even under adverse conditions. This proactive approach to safety compliance reduces the risk of regulatory penalties, which can range from thousands to hundreds of thousands of dollars depending on the severity and duration of violations. The professional installation and commissioning processes associated with high-quality Walk In Fume Hood systems ensure that all safety protocols are properly implemented and documented. This comprehensive approach provides clear audit trails for regulatory inspections and demonstrates organizational commitment to safety standards. The resulting protection from regulatory penalties and legal liabilities represents a significant but often overlooked component of the system's return on investment.

Worker Safety and Productivity Enhancement

The enhanced safety provided by professional Walk In Fume Hood systems directly impacts worker productivity and reduces costs associated with occupational health incidents. Advanced airflow control systems effectively remove harmful gases, vapors, and particulates from the work environment, minimizing exposure risks and creating healthier working conditions. This protection reduces the incidence of work-related health issues, decreasing workers' compensation claims and associated insurance costs. Improved air quality and safety conditions enable researchers to work more efficiently without the distraction of safety concerns or the need for additional personal protective equipment. The spacious interior design of Walk In Fume Hood systems allows multiple researchers to work simultaneously on complex projects, increasing overall laboratory throughput and research productivity. This enhanced efficiency translates into faster project completion times and improved return on research investments. The psychological benefits of working in a demonstrably safe environment contribute to improved job satisfaction and employee retention rates. Reduced turnover costs, including recruitment, training, and productivity losses associated with staff changes, represent additional hidden returns on investment. The reputation for safety excellence that accompanies proper ventilation infrastructure also enhances an organization's ability to attract top research talent, contributing to long-term competitive advantages.

Equipment Protection and Asset Preservation

Professional Walk In Fume Hood systems protect valuable laboratory equipment from corrosive environments and contamination, extending asset lifespans and reducing replacement costs. The effective removal of harmful vapors and particles prevents damage to sensitive instruments and analytical equipment located within or adjacent to the ventilation system. This protection is particularly valuable in laboratories housing expensive analytical instruments that could suffer significant damage from exposure to corrosive chemicals or particulates. The controlled environment maintained by professional ventilation systems ensures consistent conditions that optimize the performance and accuracy of laboratory instruments. Stable temperature and humidity conditions, combined with effective contaminant removal, create ideal operating environments that maximize equipment reliability and measurement precision. This improved performance reduces the need for frequent recalibration and maintenance interventions while enhancing the quality and reliability of research results.

Productivity and Operational Efficiency Gains

Research Throughput and Project Acceleration

The operational advantages of Walk In Fume Hood systems significantly impact research productivity and project completion timelines. The spacious working area accommodates large equipment and complex experimental setups that would be impossible or impractical in smaller ventilation systems. This capability enables researchers to conduct more ambitious experiments and handle larger sample volumes, increasing the scope and scale of research activities within the same timeframe. The ability to accommodate multiple researchers working simultaneously on related projects enhances collaboration and accelerates project timelines. The flexible internal configuration options allow laboratories to optimize workspace layouts for specific research activities, reducing setup times and improving workflow efficiency. These operational improvements translate into faster project completion times, increased research output, and improved return on research investments. Professional Walk In Fume Hood systems eliminate bottlenecks associated with limited ventilation capacity, allowing laboratories to operate at higher utilization rates without compromising safety standards. This increased operational efficiency maximizes the return on facility investments and enables organizations to take on additional research projects without expanding physical infrastructure. The resulting revenue opportunities and cost efficiencies contribute significantly to the overall return on investment.

Multi-Application Versatility and Resource Optimization

The versatility of Walk In Fume Hood systems enables laboratories to support diverse research activities within a single ventilation solution, optimizing resource utilization and reducing capital equipment requirements. These systems effectively support chemical synthesis, biological research, physics experiments, and industrial applications through customizable configurations and specialized accessories. This multi-application capability eliminates the need for separate specialized ventilation systems for different research disciplines. The modular design approach allows laboratories to reconfigure internal layouts and equipment arrangements to accommodate changing research priorities without requiring additional capital investments. Optional accessories such as remote-controlled gas and water faucets, explosion-proof lighting, and specialized work surfaces can be added or modified as research requirements evolve. This adaptability extends the useful life of the investment and ensures continued relevance as research programs develop. Resource optimization extends to personnel utilization, as the spacious and flexible design of Walk In Fume Hood systems allows research teams to work more efficiently and collaboratively. The elimination of constraints imposed by smaller ventilation systems enables researchers to focus on their scientific objectives rather than working around equipment limitations. This improved resource utilization translates into higher productivity rates and better returns on research investments.

Facility Integration and Infrastructure Efficiency

Professional Walk In Fume Hood systems integrate seamlessly with existing laboratory infrastructure while providing opportunities for overall facility optimization. The sophisticated control systems can interface with building management systems to coordinate ventilation operations with other HVAC components, optimizing overall energy consumption and operational efficiency. This integration reduces the load on central air handling systems and enables more precise environmental control throughout the facility. The standardized design and installation procedures associated with professional systems streamline facility planning and reduce construction costs for new installations or facility renovations. The comprehensive specifications and performance data provided with professional systems enable accurate facility planning and infrastructure sizing, avoiding costly oversizing or inadequate capacity issues. This precision in facility planning translates into optimized capital expenditures and operational efficiency.

Conclusion

The hidden ROI of professional Walk In Fume Hood systems extends far beyond initial cost considerations to encompass substantial long-term financial benefits. Through energy efficiency improvements, maintenance cost reductions, enhanced safety compliance, and increased productivity, these systems deliver measurable returns that often exceed their initial investment within five to seven years. The combination of operational flexibility, regulatory compliance, and worker safety enhancements creates compound value that continues throughout the system's extended operational lifespan.

Ready to unlock the hidden ROI potential of professional Walk In Fume Hood systems for your laboratory? Xi'an Xunling Electronic Technology Co., Ltd. stands as your trusted China Walk In Fume Hood factory, offering comprehensive solutions backed by over a decade of manufacturing expertise. As a leading China Walk In Fume Hood supplier and manufacturer, we provide cost-effective China Walk In Fume Hood wholesale options that deliver exceptional value. Our High Quality Walk In Fume Hood systems are available for sale with competitive Walk In Fume Hood price points that maximize your return on investment. With 5-day delivery, 5-year warranty, custom-made solutions, and one-stop service, we ensure your laboratory achieves optimal performance while staying within budget. Contact Us today at xalabfurniture@163.com to discover how our Walk In Fume Hood solutions can transform your laboratory's productivity and profitability.

References

1. Mills, E., & Sartor, D. (2006). "Energy Use and Savings Potential for Laboratory Fume Hoods." Lawrence Berkeley National Laboratory Environmental Energy Technologies Division.

2. American Society of Heating, Refrigerating and Air-Conditioning Engineers (2019). "Laboratory Design Guide: Planning and Operation of Laboratory HVAC Systems." ASHRAE Technical Committee.

3. National Institute for Occupational Safety and Health (2020). "Criteria for a Recommended Standard: Occupational Exposure to Laboratory Chemicals in Research and Development." NIOSH Publications.

4. Laboratory Safety Institute (2021). "Economic Benefits of Laboratory Safety Compliance: A Comprehensive Analysis of ROI in Safety Infrastructure." Journal of Laboratory Safety Management.

YOU MAY LIKE

_1735284212689.webp)

_1735472430670.webp)