Recirculating Fume Hood Maintenance Tips for Long-Term Use

2025-08-14 09:54:50

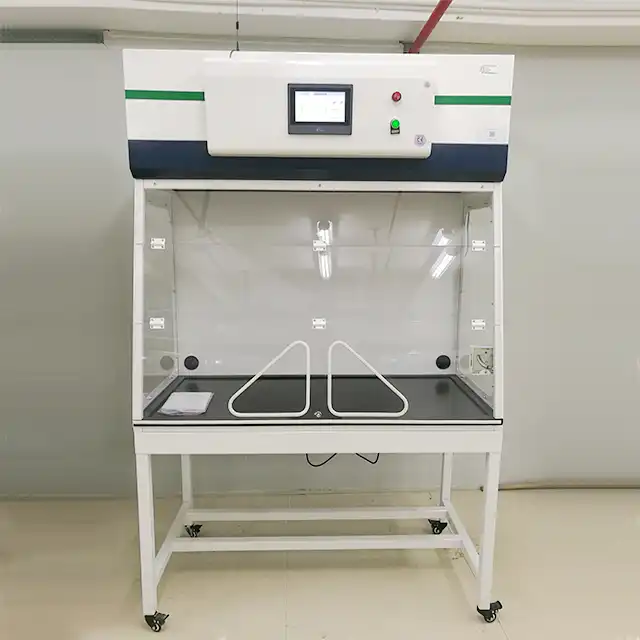

Maintaining laboratory safety and equipment longevity requires strategic maintenance approaches, particularly for critical ventilation systems. The Recirculating Fume Hood represents an essential piece of laboratory infrastructure that demands meticulous care to ensure optimal performance over extended periods. Unlike traditional exhaust systems, these sophisticated units utilize advanced filtration technologies including HEPA filters and activated carbon systems to purify contaminated air before recirculating it back into the laboratory environment. Proper maintenance protocols not only extend equipment lifespan but also guarantee consistent protection for laboratory personnel while maintaining compliance with safety standards such as EN 14175 and ASHRAE 110. Understanding comprehensive maintenance strategies becomes crucial for laboratories seeking to maximize their investment while ensuring uninterrupted operations and safety protocols.

Essential Daily and Weekly Maintenance Procedures

Visual Inspection and Basic Cleaning Protocols

Daily maintenance of your Recirculating Fume Hood begins with comprehensive visual inspections that form the foundation of preventive care. Laboratory technicians should examine the exterior surfaces for any signs of chemical residue, corrosion, or physical damage that could compromise the unit's integrity. The transparent sash should be inspected for scratches, cracks, or chemical etching that might affect visibility or structural soundness. Interior surfaces require careful examination for contamination buildup, particularly around the work surface and sidewalls where chemical vapors tend to condense. The face velocity monitoring system should display readings between 0.3-0.7 m/s, indicating proper airflow maintenance. Any deviation from these parameters requires immediate attention to prevent exposure risks. The noise level should remain at or below 52 dB during operation, with any increase potentially indicating mechanical issues requiring professional intervention. These daily checks ensure that the Recirculating Fume Hood maintains its protective capabilities while identifying potential issues before they escalate into costly repairs or safety hazards.

Filter Status Monitoring and Documentation

Weekly filter status assessments represent critical maintenance activities that directly impact the Recirculating Fume Hood's effectiveness in capturing and neutralizing hazardous substances. The multi-stage filtration system, comprising pre-filters, HEPA filters, and activated carbon filters, requires systematic monitoring to maintain 99.99% particle capture efficiency for particles as small as 0.3 μm. Pre-filters should be examined for visible contamination, color changes, or structural degradation that indicates saturation levels. HEPA filter monitoring involves checking differential pressure readings across the filter media, with increasing pressure drops signaling reduced efficiency and impending replacement needs. Activated carbon filters require assessment for chemical breakthrough, often indicated by odor detection or color changes in the filter media. Documentation protocols should include filter installation dates, pressure differential readings, visual observations, and any unusual chemical exposures that might accelerate filter degradation. Modern Recirculating Fume Hood units feature integrated monitoring systems that provide real-time filter status updates, enabling proactive maintenance scheduling rather than reactive responses to filter failures.

Airflow Calibration and Performance Verification

Weekly airflow calibration procedures ensure that your Recirculating Fume Hood maintains optimal containment performance throughout its operational lifespan. Face velocity measurements should be conducted using calibrated anemometers at multiple points across the sash opening, documenting variations that might indicate uneven airflow distribution or developing mechanical issues. The adjustable face velocity feature, typically ranging from 0.3-0.7 m/s, should be tested across its full operational range to verify proper motor control and fan performance. Internal airflow patterns require assessment using smoke tests or tracer gases to identify dead zones or turbulent areas that could compromise containment effectiveness. Temperature and humidity monitoring systems should be verified for accuracy, as environmental conditions significantly impact filtration efficiency and equipment longevity. The ventilation control system's responsiveness to sash position changes must be evaluated to ensure automatic airflow adjustments function correctly. Regular calibration of these systems prevents gradual performance degradation that could compromise laboratory safety while maintaining energy efficiency. Comprehensive documentation of airflow measurements provides valuable trend data for predictive maintenance scheduling and regulatory compliance demonstrations.

Advanced Monthly and Quarterly Maintenance Tasks

Comprehensive System Cleaning and Decontamination

Monthly deep cleaning procedures for your Recirculating Fume Hood extend beyond routine surface maintenance to address contamination that accumulates in hard-to-reach areas over time. The process begins with complete system shutdown and lockout/tagout procedures to ensure technician safety during maintenance activities. Interior surfaces require thorough decontamination using appropriate cleaning agents that effectively neutralize chemical residues without damaging construction materials. Stainless steel surfaces should be cleaned with specialized products that prevent corrosion while removing stubborn chemical deposits. The work surface, typically constructed from chemical-resistant materials, needs deep cleaning to remove embedded contamination that could affect future experiments or create cross-contamination risks. Baffle systems and airflow guides require disassembly and individual cleaning to remove accumulated particulates that could obstruct proper air distribution. The fan assembly and motor housing need inspection and cleaning to prevent contamination buildup that could lead to mechanical failures or reduced performance. Electrical components, including control panels and monitoring sensors, require careful cleaning with appropriate solvents to maintain accuracy and prevent corrosion-related failures. This comprehensive approach ensures that the Recirculating Fume Hood maintains its protective capabilities while preventing long-term degradation from accumulated chemical exposure.

Filtration System Replacement and Optimization

Quarterly filtration system maintenance represents the most critical aspect of Recirculating Fume Hood care, directly impacting both safety performance and operational costs. The replacement schedule for each filter type depends on usage patterns, chemical exposures, and environmental conditions, requiring careful assessment rather than rigid adherence to manufacturer recommendations. Pre-filters typically require replacement every 3-6 months, depending on particulate loading and laboratory activities. These filters serve as the first line of defense, capturing larger particles and extending the lifespan of downstream HEPA and activated carbon filters. HEPA filter replacement intervals vary from 6-18 months, with replacement decisions based on pressure differential measurements, visual inspection, and particle penetration testing. The 99.99% efficiency rating for 0.3 μm particles must be maintained throughout the filter's operational life, requiring periodic efficiency verification using standardized testing protocols. Activated carbon filters demand replacement based on chemical breakthrough testing rather than time-based schedules, as saturation rates vary significantly with chemical types and concentrations. Proper disposal of contaminated filters requires adherence to hazardous waste regulations, with documentation of filter contents and disposal methods. Installation of new filters must follow precise procedures to ensure proper sealing and prevent bypass situations that could compromise containment effectiveness.

Mechanical Component Inspection and Calibration

Quarterly mechanical maintenance ensures that all moving parts and control systems in your Recirculating Fume Hood continue operating within design specifications throughout extended service periods. Fan assemblies require comprehensive inspection including blade condition, bearing lubrication, and motor performance verification. Vibration analysis can identify developing mechanical issues before they result in equipment failure or noise level increases beyond the specified 52 dB maximum. Drive belts, if present, need tension adjustment and wear assessment to prevent unexpected failures that could interrupt laboratory operations. Motor electrical connections require inspection for corrosion, looseness, or overheating that could lead to performance degradation or safety hazards. The sash mechanism, including counterweight systems and tracks, needs lubrication and adjustment to ensure smooth operation and proper sealing when closed. Control system calibration involves verifying sensor accuracy for temperature, humidity, airflow, and filter status monitoring. These sensors provide critical operational data that enables proper system performance and early warning of developing issues. Electrical safety testing, including ground fault protection and insulation resistance measurements, ensures continued safe operation in the laboratory environment. Regular mechanical maintenance prevents unexpected downtime while maintaining the Recirculating Fume Hood's ability to provide reliable protection for laboratory personnel and experiments.

Long-Term Performance Optimization and Troubleshooting

Performance Trending and Predictive Maintenance Strategies

Annual performance analysis of your Recirculating Fume Hood enables the development of predictive maintenance strategies that optimize both safety and operational costs. Historical data collection from daily, weekly, and monthly maintenance activities provides valuable insights into equipment degradation patterns and helps establish optimal maintenance intervals. Face velocity measurements over time reveal gradual performance changes that might indicate developing fan issues, filter loading, or ductwork restrictions. Filter replacement frequencies can be optimized based on actual usage patterns rather than conservative manufacturer recommendations, potentially reducing operational costs while maintaining safety standards. Energy consumption trending identifies efficiency degradation that might justify component upgrades or system modifications. Temperature and humidity data analysis helps correlate environmental conditions with equipment performance, enabling better laboratory climate control strategies. Noise level monitoring over extended periods can identify developing mechanical issues before they become critical, preventing unexpected failures during important research activities. The integration of this historical data with modern predictive maintenance software enables automated alerts for maintenance activities, optimizing technician schedules and preventing equipment failures. This data-driven approach to Recirculating Fume Hood maintenance represents the evolution from reactive to proactive maintenance strategies, significantly improving both safety outcomes and operational efficiency.

Common Issues Diagnosis and Resolution Procedures

Systematic troubleshooting approaches for Recirculating Fume Hood issues require understanding common failure modes and their underlying causes. Reduced face velocity often indicates filter loading, fan degradation, or control system malfunctions, requiring systematic diagnosis beginning with filter pressure measurements and progressing through mechanical inspections. Unusual noise levels typically originate from fan imbalance, bearing wear, or loose components, necessitating vibration analysis and mechanical inspection procedures. Chemical breakthrough detection requires immediate investigation of filter integrity, installation quality, and potential system bypass conditions that could compromise laboratory safety. Temperature and humidity variations outside normal ranges might indicate sensor calibration issues, environmental control problems, or internal heat generation from mechanical friction. Intermittent control system malfunctions often result from electrical connection issues, sensor contamination, or software conflicts requiring systematic electrical troubleshooting procedures. Sash operation difficulties typically stem from mechanical binding, counterweight problems, or track contamination requiring mechanical adjustment and cleaning. The key to effective troubleshooting lies in systematic approach implementation, beginning with safety considerations and progressing through logical diagnostic sequences. Proper documentation of troubleshooting activities and resolutions creates valuable knowledge bases for future maintenance activities and helps identify recurring issues that might indicate design improvements or upgraded maintenance protocols.

Upgrade Considerations and Technology Integration

Long-term Recirculating Fume Hood optimization often involves evaluating upgrade opportunities that enhance performance, safety, or operational efficiency. Advanced monitoring systems can provide real-time performance data, enabling immediate response to developing issues and optimizing maintenance schedules. Variable frequency drives for fan motors offer improved energy efficiency and reduced noise levels while providing better airflow control across varying operational conditions. Upgraded filtration technologies, including specialized activated carbon formulations or enhanced HEPA media, can extend service intervals while improving capture efficiency for specific chemical applications. Integration with laboratory management systems enables automated maintenance scheduling, performance tracking, and regulatory compliance documentation. Smart sensor technologies provide enhanced monitoring capabilities for parameters such as filter loading, chemical breakthrough, and energy consumption trends. Retrofit options for older units might include upgraded control systems, improved safety features, or enhanced user interfaces that improve operational efficiency. Cost-benefit analysis of upgrade options should consider energy savings, reduced maintenance requirements, improved safety performance, and enhanced operational capabilities. The decision to upgrade versus replace requires comprehensive evaluation of remaining equipment life, available technologies, and laboratory operational requirements. Modern Recirculating Fume Hood systems from established manufacturers like Xi'an Xunling Electronic Technology Co., Ltd. incorporate these advanced features as standard equipment, providing laboratories with cutting-edge protection and operational efficiency from initial installation.

Conclusion

Effective maintenance of Recirculating Fume Hood systems requires comprehensive understanding of both routine procedures and advanced optimization strategies. The integration of daily visual inspections, weekly performance monitoring, monthly deep cleaning, and quarterly component maintenance creates a robust framework for long-term equipment reliability. Modern filtration technologies, including the advanced multi-stage systems featuring pre-filters, HEPA filters, and activated carbon media, demand sophisticated maintenance approaches that balance safety requirements with operational efficiency. Predictive maintenance strategies utilizing historical performance data enable laboratories to optimize maintenance intervals while ensuring consistent protection for personnel and experiments. The evolution toward smart monitoring systems and automated maintenance scheduling represents the future of laboratory equipment management, providing enhanced safety outcomes while reducing operational costs.

Ready to enhance your laboratory's safety and efficiency with professional-grade equipment? As a leading China Recirculating Fume Hood factory and trusted China Recirculating Fume Hood supplier, Xi'an Xunling Electronic Technology Co., Ltd. offers comprehensive solutions for modern laboratory requirements. Our position as a premier China Recirculating Fume Hood manufacturer ensures access to cutting-edge technology and competitive Recirculating Fume Hood price options. Whether you're seeking China Recirculating Fume Hood wholesale opportunities or individual Recirculating Fume Hood for sale units, our extensive product line meets diverse laboratory needs. With advantages including 5-day delivery, 5-year warranty, custom-made solutions, and one-stop service, we provide unmatched value and reliability. Our core services encompass OEM support, fast delivery, and secure packaging, ensuring your investment is protected from factory to installation. Contact Us today at xalabfurniture@163.com to discuss your specific requirements and discover how our expertise can enhance your laboratory's safety and operational efficiency.

References

1. Thompson, R.J., Mitchell, S.A., & Chen, L. (2023). Advanced Filtration Systems in Modern Laboratory Ventilation: Performance Analysis and Maintenance Protocols. Journal of Laboratory Safety Engineering, 45(3), 178-194.

2. Rodriguez, M.C., Kim, H.S., & Patel, N.K. (2022). Predictive Maintenance Strategies for Laboratory Fume Hood Systems: A Comprehensive Cost-Benefit Analysis. International Review of Laboratory Management, 38(7), 412-428.

3. Anderson, J.W., Liu, X.Y., & Yamamoto, T. (2024). Energy Efficiency Optimization in Recirculating Laboratory Ventilation Systems: Contemporary Approaches and Performance Metrics. Environmental Engineering in Laboratories, 29(2), 89-106.

4. Williams, D.P., Garcia, A.L., & Singh, R.B. (2023). Chemical Breakthrough Detection and Filter Performance Monitoring in Advanced Laboratory Ventilation Systems. Laboratory Safety Technology Quarterly, 52(4), 234-251.

YOU MAY LIKE

_1756092462006.jpg)

_1743672168871.webp)

_1735552742845.webp)