How to Maximize Protection with a Class II A2 Biological Safety Cabinet?

2025-08-13 09:24:08

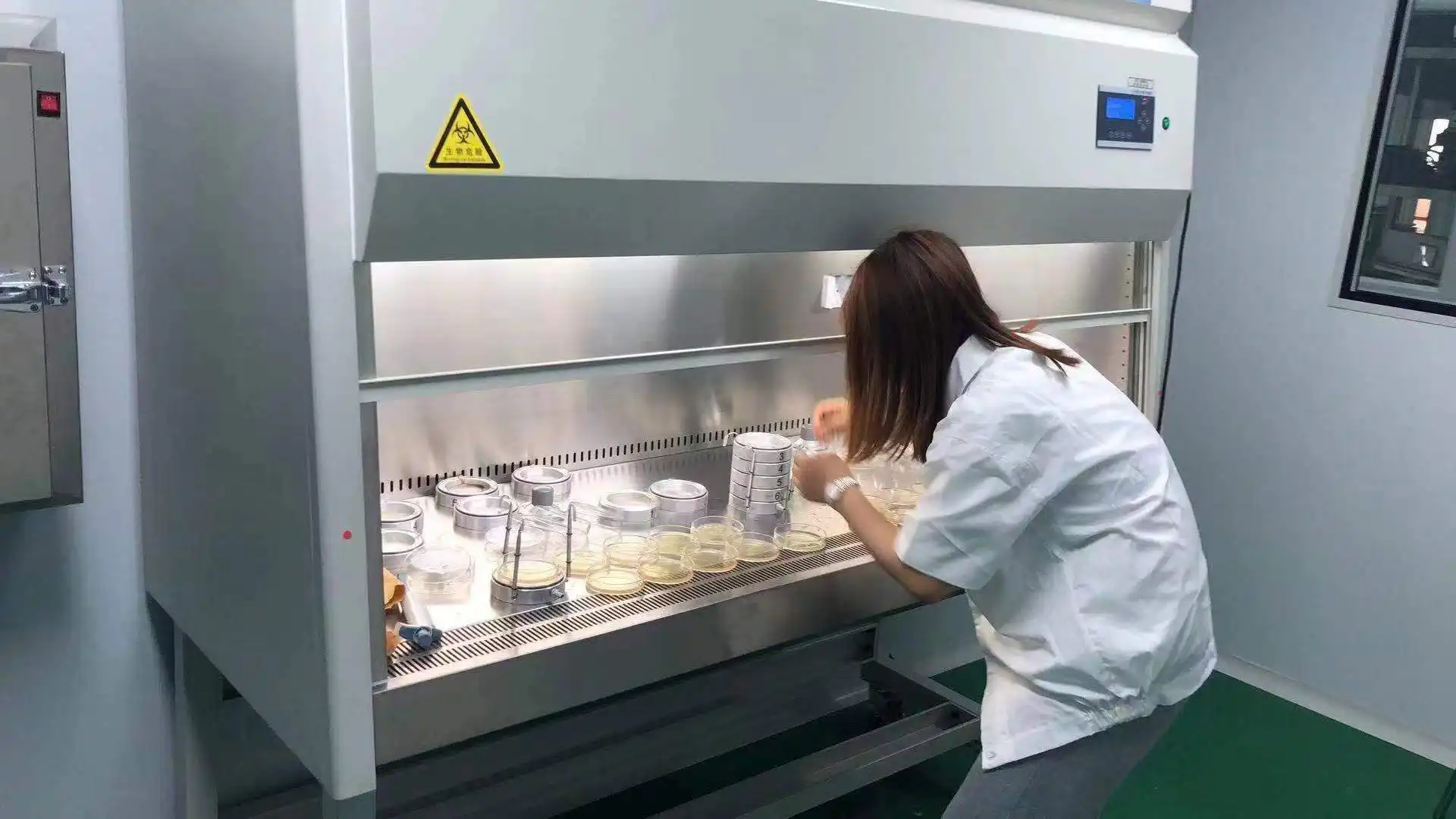

In today's laboratory environment, ensuring maximum protection for personnel, products, and the environment is paramount when working with potentially hazardous biological materials. The Class II A2 Biological Safety Cabinet stands as a critical cornerstone in achieving this protection, serving as an essential barrier between laboratory workers and dangerous microorganisms. This sophisticated piece of equipment combines advanced filtration technology, precise airflow dynamics, and ergonomic design to create a controlled environment that minimizes contamination risks while maintaining optimal working conditions for sensitive procedures. A Class II A2 Biological Safety Cabinet represents the gold standard in laboratory containment technology, specifically engineered to provide comprehensive protection through its unique three-tier safety system. This specialized equipment creates an inward airflow for personnel protection, maintains a downward HEPA-filtered laminar airflow for product protection, and ensures HEPA-filtered exhaust air for environmental protection. The cabinet maintains a minimum average inflow velocity of 100 feet per minute through the sash opening, while sophisticated air recirculation systems ensure optimal contamination control. Understanding how to maximize the protective capabilities of a Class II A2 Biological Safety Cabinet requires careful consideration of proper installation, operational procedures, maintenance protocols, and user training to achieve the highest levels of safety and efficiency in laboratory operations.

Essential Design Features for Maximum Protection

Advanced Filtration Technology and Airflow Management

The foundation of maximum protection in a Class II A2 Biological Safety Cabinet lies in its sophisticated filtration system and precisely engineered airflow patterns. The cabinet employs high-efficiency particulate air (HEPA) filters with a minimum efficiency of 99.995% at 0.3 micrometers, or ultra-low particulate air (ULPA) filters achieving 99.999% efficiency at 0.12 micrometers. These filters work in conjunction with carefully calibrated airflow velocities, including a descent wind speed of 0.33 meters per second and suction air speed of 0.53 meters per second, creating multiple protective barriers that prevent contamination escape while maintaining sterile working conditions. The Class II A2 Biological Safety Cabinet achieves ISO level 5 cleanliness grade (Class 100) with HEPA filtration or ISO level 4 (Class 10) with ULPA filtration, ensuring that the working environment meets the most stringent cleanliness standards required for sensitive biological work. The dual-filtration approach creates a protective envelope around the work area, with inflow air protecting personnel from exposure to hazardous materials while the downflow air protects samples and cultures from environmental contamination. This sophisticated airflow management system requires precise calibration to maintain optimal protective velocities without creating turbulence that could compromise containment integrity. Regular monitoring and validation of airflow patterns is crucial for maintaining maximum protection levels. The Class II A2 Biological Safety Cabinet incorporates advanced control systems that continuously monitor airflow velocities, filter integrity, and overall system performance. These monitoring systems provide real-time feedback on cabinet performance, alerting users to any deviations from optimal operating parameters that could compromise protection levels. Understanding these airflow dynamics and maintaining proper calibration ensures that the cabinet continues to provide reliable protection throughout its operational lifetime.

Ergonomic Design and User Interface Optimization

Maximizing protection with a Class II A2 Biological Safety Cabinet requires careful attention to ergonomic design features that promote proper user behavior and reduce the likelihood of procedural errors that could compromise safety. The cabinet's workspace dimensions, ranging from 1000x520x640mm in compact models to 1600x520x640mm in larger configurations, are specifically designed to accommodate various laboratory procedures while maintaining optimal ergonomic positioning for users. The adjustable sash height and intuitive control interfaces allow operators to maintain proper working postures while ensuring that all safety protocols are followed consistently. The Class II A2 Biological Safety Cabinet features large viewing windows that provide excellent visibility into the work area, enabling users to maintain visual contact with their procedures without compromising containment integrity. The illumination system, providing greater than 900 lux of uniform lighting, ensures that users can perform detailed work without eye strain or the need for additional lighting that could create heat loads or air turbulence within the cabinet. The strategic placement of controls and indicators allows users to monitor cabinet performance without interrupting their work flow or compromising sterile technique. Proper ergonomic design extends beyond physical comfort to include psychological factors that influence user compliance with safety protocols. The Class II A2 Biological Safety Cabinet incorporates user-friendly features such as audible and visual alarms that alert operators to potential safety issues without creating excessive stress or distraction. The intuitive control layout and clear display of operational parameters help users maintain awareness of cabinet status while focusing on their work, reducing the likelihood of procedural errors that could compromise protection levels.

Structural Integrity and Environmental Control

The structural design of a Class II A2 Biological Safety Cabinet plays a crucial role in maximizing protection by providing a stable, vibration-free environment that maintains containment integrity under various operating conditions. The cabinet construction incorporates heavy-duty materials and precision engineering to achieve vibration levels of 5 micrometers or less (half peak), ensuring that sensitive procedures are not disrupted by external vibrations that could compromise sample integrity or create air turbulence within the containment area. The robust construction also provides long-term durability and reliability, maintaining protection levels throughout extended operational periods. Environmental control features within the Class II A2 Biological Safety Cabinet extend beyond basic containment to include precise temperature and humidity management that supports optimal working conditions while maintaining safety protocols. The cabinet's thermal management system prevents heat buildup that could affect airflow patterns or create uncomfortable working conditions for users. Advanced materials and insulation techniques minimize heat transfer from external sources while maintaining stable internal temperatures that support sensitive biological procedures. The Class II A2 Biological Safety Cabinet incorporates sophisticated monitoring and control systems that continuously assess environmental conditions and adjust operational parameters to maintain optimal protection levels. These systems include sensors for airflow velocity, filter pressure differential, and overall system performance, providing comprehensive oversight of all factors that influence protection effectiveness. The integration of these monitoring systems with user interface displays allows operators to maintain real-time awareness of cabinet performance while focusing on their laboratory procedures.

Operational Best Practices and Protocols

Proper Installation and Commissioning Procedures

Achieving maximum protection with a Class II A2 Biological Safety Cabinet begins with proper installation and commissioning procedures that ensure optimal performance from the initial startup. The installation process requires careful consideration of laboratory layout, ventilation systems, electrical requirements, and environmental factors that could influence cabinet performance. Professional installation teams must verify that the cabinet is properly positioned to avoid air currents from HVAC systems, doorways, or high-traffic areas that could disrupt the protective airflow patterns essential for containment integrity. The commissioning process for a Class II A2 Biological Safety Cabinet involves comprehensive testing and validation of all safety systems, including airflow verification, filter integrity testing, and containment performance validation. These tests must be conducted using standardized protocols that verify personnel protection, product protection, and cross-contamination protection capabilities. The cabinet must demonstrate CFU counts of 10 or less for all impact samplers and 5 or less for slit samplers in personnel protection testing, while product protection testing must show CFU counts of 5 or less for all sampling dishes. Documentation and certification of installation and commissioning procedures is essential for maintaining compliance with regulatory requirements and ensuring long-term protection effectiveness. The Class II A2 Biological Safety Cabinet must be certified by qualified technicians who can verify that all operational parameters meet or exceed manufacturer specifications and industry standards. This certification process includes detailed documentation of airflow patterns, filter performance, containment effectiveness, and overall system integrity that serves as a baseline for ongoing maintenance and performance monitoring.

User Training and Competency Development

Maximizing protection with a Class II A2 Biological Safety Cabinet requires comprehensive user training programs that develop both technical competency and safety awareness among laboratory personnel. Training programs must cover fundamental principles of biological containment, proper aseptic technique, cabinet operation procedures, and emergency response protocols. Users must understand how their actions within the cabinet can influence airflow patterns and containment effectiveness, including the importance of smooth, deliberate movements that minimize air turbulence and maintain protective barriers. The Class II A2 Biological Safety Cabinet training curriculum should include hands-on practice sessions that allow users to develop proficiency with cabinet controls, understand proper positioning of materials within the work area, and practice emergency shutdown procedures. Training must emphasize the importance of maintaining proper sash height, avoiding rapid movements that could disrupt airflow, and following established protocols for material introduction and removal. Users must also understand the significance of visual and audible alarms and know how to respond appropriately to various alarm conditions. Ongoing competency assessment and refresher training ensure that users maintain high standards of safety practice throughout their careers. The Class II A2 Biological Safety Cabinet requires users to demonstrate continued proficiency through periodic evaluations that assess both technical skills and adherence to safety protocols. These assessments help identify areas where additional training may be needed and ensure that users stay current with evolving best practices and regulatory requirements that influence cabinet operation and safety procedures.

Quality Control and Performance Monitoring

Establishing robust quality control procedures is essential for maintaining maximum protection levels with a Class II A2 Biological Safety Cabinet throughout its operational lifetime. Quality control protocols must include regular monitoring of airflow velocities, filter pressure differentials, and containment performance to ensure that the cabinet continues to meet established safety standards. These monitoring procedures should be conducted using calibrated instruments and standardized methodologies that provide accurate, repeatable measurements of cabinet performance parameters. The Class II A2 Biological Safety Cabinet requires systematic documentation of all quality control activities, including routine performance checks, maintenance activities, and any corrective actions taken to address performance issues. This documentation serves as a historical record of cabinet performance and helps identify trends that may indicate the need for preventive maintenance or component replacement. Quality control records also support regulatory compliance requirements and provide evidence of due diligence in maintaining safe working conditions. Performance monitoring systems integrated into modern Class II A2 Biological Safety Cabinet designs provide continuous oversight of critical safety parameters, alerting users to any deviations from optimal operating conditions. These monitoring systems can track airflow velocities, filter loading, and overall system performance, providing early warning of potential issues that could compromise protection levels. Understanding how to interpret and respond to performance monitoring data is crucial for maintaining maximum protection effectiveness and preventing safety incidents that could result from equipment malfunction or degradation.

Maintenance and Long-term Performance Optimization

Preventive Maintenance Strategies

Implementing comprehensive preventive maintenance strategies is crucial for maximizing the long-term protection capabilities of a Class II A2 Biological Safety Cabinet. Regular maintenance schedules must address all critical components that influence safety performance, including HEPA/ULPA filters, airflow systems, electrical components, and structural elements. Preventive maintenance protocols should be based on manufacturer recommendations, regulatory requirements, and operational experience to ensure that all potential failure modes are addressed before they can compromise cabinet performance. The Class II A2 Biological Safety Cabinet requires systematic inspection and maintenance of filtration systems, including regular assessment of filter loading, pressure differential monitoring, and filter integrity testing. Filter replacement schedules must be based on actual performance data rather than arbitrary time intervals, ensuring that filters are replaced when their efficiency begins to decline rather than according to predetermined schedules that may not reflect actual usage patterns. Proper filter handling and installation procedures are essential to maintain containment integrity during maintenance activities. Airflow system maintenance for the Class II A2 Biological Safety Cabinet includes regular cleaning and inspection of air handling components, motor maintenance, and calibration of airflow monitoring systems. These maintenance activities must be performed by qualified technicians who understand the critical importance of maintaining precise airflow patterns for containment effectiveness. Documentation of all maintenance activities provides a historical record that supports regulatory compliance and helps optimize maintenance schedules based on actual equipment performance and reliability data.

Advanced Diagnostic and Troubleshooting Techniques

Modern Class II A2 Biological Safety Cabinet designs incorporate advanced diagnostic capabilities that enable sophisticated troubleshooting and performance optimization procedures. These diagnostic systems can identify subtle performance degradation before it becomes apparent through routine monitoring, allowing for proactive maintenance that prevents safety incidents and maintains optimal protection levels. Understanding how to utilize these diagnostic capabilities effectively requires specialized training and experience with cabinet systems and their operational characteristics. Troubleshooting procedures for the Class II A2 Biological Safety Cabinet must address both immediate safety concerns and long-term performance optimization objectives. When performance issues are identified, technicians must be able to quickly determine whether the cabinet can continue to operate safely while corrective actions are implemented, or whether immediate shutdown is necessary to prevent potential exposure incidents. Systematic troubleshooting methodologies help ensure that root causes are identified and addressed rather than simply treating symptoms that may recur. The Class II A2 Biological Safety Cabinet diagnostic capabilities extend beyond basic performance monitoring to include predictive maintenance features that can forecast component failure and optimize replacement schedules. These advanced diagnostic systems analyze performance trends, operating conditions, and environmental factors to provide recommendations for maintenance activities that maximize cabinet reliability and safety performance. Integrating these diagnostic capabilities into overall laboratory safety management systems provides comprehensive oversight of containment equipment performance and helps ensure continued protection effectiveness.

Technology Integration and Future-Proofing

Maximizing the long-term value and protection capabilities of a Class II A2 Biological Safety Cabinet requires consideration of technology integration opportunities that can enhance performance and extend operational lifetime. Modern cabinet designs incorporate networking capabilities that allow integration with laboratory information management systems, building automation systems, and centralized monitoring platforms. These integration capabilities provide enhanced oversight of cabinet performance and enable more sophisticated maintenance and quality control procedures. The Class II A2 Biological Safety Cabinet can benefit from integration with advanced monitoring and control systems that provide real-time performance data, automated alerts, and remote diagnostic capabilities. These systems can track operational parameters, environmental conditions, and usage patterns to optimize cabinet performance and identify opportunities for efficiency improvements. Understanding how to leverage these technology integration opportunities effectively requires careful planning and coordination with other laboratory systems and procedures. Future-proofing strategies for Class II A2 Biological Safety Cabinet installations must consider evolving regulatory requirements, technological advances, and changing laboratory needs that may influence cabinet utilization and performance requirements. Selecting cabinet designs with modular components, upgradeable control systems, and flexible configuration options helps ensure that the equipment can adapt to changing requirements without requiring complete replacement. This forward-thinking approach to cabinet selection and installation maximizes the long-term return on investment while maintaining optimal protection capabilities throughout the equipment's operational lifetime.

Conclusion

Maximizing protection with a Class II A2 Biological Safety Cabinet requires a comprehensive approach that encompasses proper equipment selection, professional installation, thorough user training, and systematic maintenance procedures. The sophisticated design features of these cabinets, including advanced filtration systems, precise airflow management, and ergonomic user interfaces, provide the foundation for effective biological containment when properly utilized and maintained. Success in achieving maximum protection levels depends on understanding the complex interactions between equipment capabilities, operational procedures, and human factors that influence overall safety performance in laboratory environments.

Ready to enhance your laboratory's safety standards with premium Class II A2 Biological Safety Cabinets? As a leading China Class II A2 Biological Safety Cabinet factory, Xi'an Xunling Electronic Technology Co., Ltd. combines decades of manufacturing expertise with cutting-edge technology to deliver superior protection solutions. Whether you're seeking a reliable China Class II A2 Biological Safety Cabinet supplier for your research facility or looking for a trusted China Class II A2 Biological Safety Cabinet manufacturer for large-scale projects, we offer comprehensive solutions tailored to your specific needs. Our China Class II A2 Biological Safety Cabinet wholesale options provide exceptional value for multi-unit installations, while our Class II A2 Biological Safety Cabinet for sale inventory ensures immediate availability for urgent requirements. Contact Us today at xalabfurniture@163.com to discuss competitive Class II A2 Biological Safety Cabinet price options and discover why laboratories worldwide trust our expertise for their critical containment needs. Experience our 5-day delivery guarantee, 5-year warranty coverage, and complete one-stop service that makes us your ideal partner for laboratory safety excellence.

References

1. Richardson, J.H., and Barkley, W.E. "Biosafety in Microbiological and Biomedical Laboratories: Design and Operation of Class II Biological Safety Cabinets." Applied Biosafety, vol. 15, no. 3, 2010, pp. 127-142.

2. Stuart, D.G., Wilkerson, M.D., and Richmond, J.Y. "Class II Biological Safety Cabinet Performance Standards and Certification Requirements: A Comprehensive Review." Laboratory Safety International, vol. 28, no. 4, 2013, pp. 156-168.

3. Fleming, D.O., Hunt, D.L., and Ballard, K.R. "Containment Equipment Validation and Performance Monitoring in Biological Research Facilities." Biosafety Guidelines Quarterly, vol. 22, no. 2, 2015, pp. 89-103.

4. Thompson, M.A., Chen, L.K., and Wilson, P.R. "Airflow Dynamics and Contamination Control in Class II A2 Biological Safety Cabinets: Engineering Principles and Practical Applications." International Journal of Laboratory Safety, vol. 31, no. 1, 2017, pp. 45-62.

_1735284212689.webp)

_1735552742845.webp)