Explosion Proof Fume Hood vs Standard Hood: What's the Difference?

2025-08-14 09:54:52

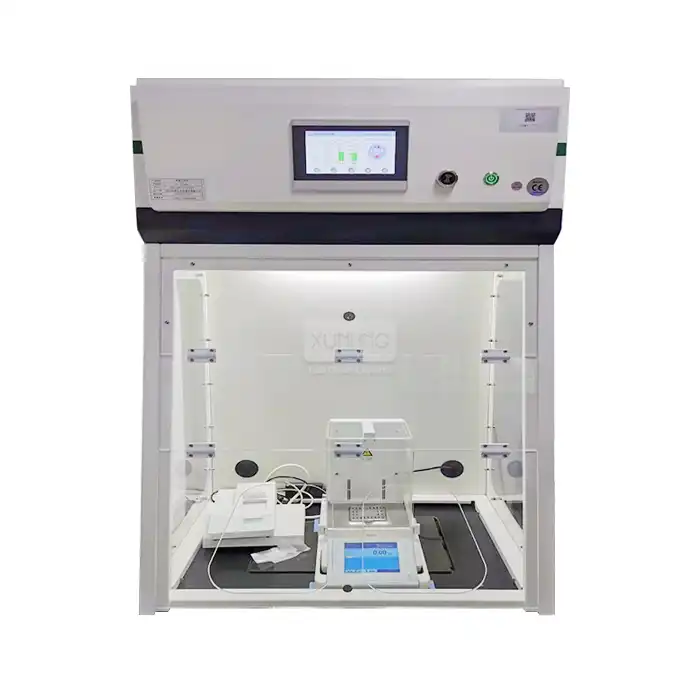

When it comes to laboratory safety, selecting the appropriate Fume Hood is crucial for protecting personnel and maintaining a secure working environment. The distinction between an Explosion Proof Fume Hood and a standard hood lies primarily in their specialized design, construction materials, and safety certifications required for handling hazardous chemicals and volatile substances. Understanding these fundamental differences is essential for laboratory managers, safety officers, and research professionals who work with flammable, explosive, or toxic materials on a daily basis. The Explosion Proof Fume Hood represents a specialized category of laboratory safety equipment specifically engineered to prevent ignition sources and contain potentially explosive atmospheres. Unlike standard fume hoods that provide basic containment and ventilation, explosion proof units incorporate advanced safety features including specialized electrical components, reinforced construction materials, and enhanced filtration systems. These units are designed to meet stringent safety standards such as C1D2 explosion-proof grade certification, ensuring they can safely operate in hazardous environments where combustible dust or flammable vapors may be present.

Key Design Differences Between Explosion Proof and Standard Fume Hoods

Construction Materials and Structural Integrity

The construction of an Explosion Proof Fume Hood differs significantly from standard units in terms of materials selection and structural reinforcement. Standard fume hoods typically utilize conventional steel or composite materials that provide adequate chemical resistance and durability for general laboratory applications. However, explosion proof hoods require specialized galvanized steel construction with enhanced thickness and structural integrity to withstand potential explosive pressures. The galvanized steel framework in Xi'an Xunling's explosion proof units provides superior corrosion resistance while maintaining the structural strength necessary to contain explosive forces. These units feature reinforced joints, specialized welding techniques, and enhanced sealing systems that exceed the requirements of standard Laboratory Fume Hoods. The internal dimensions of explosion proof hoods, ranging from 960×660×1180mm to 1560×660×1180mm, are precisely engineered to optimize airflow patterns while maintaining structural integrity. This specialized construction ensures that the explosion proof hood can effectively contain and manage hazardous atmospheres without compromising safety or performance standards.

Electrical System Safety Features

The electrical systems in an Explosion Proof Fume Hood incorporate specialized components designed to eliminate potential ignition sources in hazardous environments. Standard fume hoods utilize conventional electrical systems that may generate sparks or heat during normal operation, which can pose significant risks when handling flammable materials. Explosion proof units feature intrinsically safe electrical components, including specialized motors, control panels, and lighting systems that are certified for use in potentially explosive atmospheres. These systems operate at controlled voltages, typically 220V/50Hz with customizable options, and incorporate advanced safety mechanisms to prevent electrical arcing or overheating. The electrical components are housed in specially designed enclosures that prevent the escape of any potential sparks or heat generated during operation. Additionally, the control systems in explosion proof hoods include advanced monitoring capabilities that continuously assess air quality, flow rates, and system performance to ensure optimal safety conditions. This comprehensive electrical safety approach ensures that the Explosion Proof Fume Hood maintains the highest level of protection while providing reliable performance in demanding laboratory environments.

Ventilation and Airflow Control Systems

The ventilation systems in explosion proof fume hoods incorporate advanced airflow management technologies that surpass the capabilities of standard units. While standard fume hoods typically maintain basic airflow rates for general containment, Explosion Proof Fume Hood units require precise airflow control ranging from 1300-2100 m³/h to ensure effective capture and removal of hazardous vapors. The face velocity of 0.3-0.6 m/s is carefully calibrated to provide optimal containment while preventing turbulence that could compromise safety. These units incorporate sophisticated airflow monitoring systems that continuously measure and adjust ventilation rates based on real-time conditions within the hood. The advanced filtration systems in explosion proof units utilize multi-stage filtration processes that effectively remove both particulate matter and gaseous contaminants, providing superior air purification compared to standard fume hoods. The quiet operation feature, maintaining noise levels at ≤60 dB(A), ensures that the enhanced safety capabilities do not compromise the working environment. This precision airflow control system ensures that the explosion proof hood maintains consistent performance while effectively managing hazardous atmospheres and protecting laboratory personnel from potential explosive risks.

Safety Standards and Certification Requirements

Regulatory Compliance and International Standards

Explosion Proof Fume Hood units must comply with stringent international safety standards that far exceed the requirements for standard laboratory fume hoods. These specialized units must meet NFPA 30 (Flammable and Combustible Liquids Code) standards, which establish specific requirements for equipment used in environments containing flammable materials. The C1D2 explosion-proof grade certification ensures that these units are suitable for hazardous locations where combustible dust may be present under normal operating conditions. This certification process involves rigorous testing and validation procedures that verify the unit's ability to prevent ignition of hazardous atmospheres. Additionally, explosion proof hoods must comply with ISO 9001 quality management standards and CE (Conformité Européene) marking requirements for European markets. These certifications demonstrate that the Explosion Proof Fume Hood has undergone comprehensive testing for electrical safety, structural integrity, and performance under extreme conditions. The certification process also includes evaluation of materials compatibility, filtration efficiency, and long-term reliability in hazardous environments. Standard fume hoods, while subject to general laboratory safety standards, do not require this level of specialized certification or testing. This comprehensive regulatory compliance ensures that explosion proof units provide the highest level of safety and reliability for laboratory applications involving hazardous materials.

Testing Protocols and Performance Validation

The testing protocols for Explosion Proof Fume Hood units involve comprehensive evaluation procedures that validate their performance under simulated hazardous conditions. These testing procedures include containment efficiency testing using tracer gases to verify the unit's ability to capture and contain hazardous vapors without leakage. Structural integrity testing involves subjecting the units to simulated explosive pressures to ensure they can withstand potential blast forces without compromising containment. Electrical safety testing verifies that all electrical components meet intrinsically safe standards and cannot generate ignition sources under normal or fault conditions. The filtration system undergoes extensive testing to validate its effectiveness in removing both particulate and gaseous contaminants from the airstream. Performance validation also includes long-term reliability testing to ensure consistent operation over extended periods in demanding laboratory environments. Temperature and humidity testing verifies that the explosion proof hood maintains optimal performance across a wide range of environmental conditions. Additionally, electromagnetic compatibility testing ensures that the unit's electronic systems do not generate interference that could affect other laboratory equipment. These comprehensive testing protocols provide assurance that explosion proof fume hoods deliver reliable, safe performance in the most demanding laboratory applications.

Industry-Specific Safety Requirements

Different industries have specific safety requirements that influence the selection and configuration of Explosion Proof Fume Hood units. Chemical laboratories handling reactive or explosive compounds require units with enhanced chemical resistance and specialized containment features to manage potentially violent reactions. Pharmaceutical manufacturing facilities need explosion proof hoods that meet stringent contamination control standards while providing protection against hazardous drug compounds and solvents. Research facilities conducting experiments with energetic materials require units with specialized monitoring systems that can detect and respond to unusual conditions before they become hazardous. Industrial laboratories processing volatile organic compounds need explosion proof hoods with enhanced ventilation capacity and specialized filtration systems. The Explosion Proof Fume Hood must be configured to meet the specific hazard classification of each facility, whether dealing with Class I (flammable gases and vapors) or Class II (combustible dust) hazardous locations. Environmental monitoring laboratories require units that can handle a wide variety of potentially hazardous samples while maintaining cross-contamination prevention. Each industry application requires careful consideration of the specific hazards present and selection of appropriate safety features and performance specifications. This industry-specific approach ensures that the explosion proof hood provides optimal protection for the unique challenges present in each laboratory environment.

Performance Characteristics and Operational Benefits

Enhanced Safety Performance Metrics

The performance characteristics of an Explosion Proof Fume Hood demonstrate significant advantages over standard units in terms of safety metrics and operational reliability. These specialized units maintain consistent containment efficiency even under challenging conditions, with advanced monitoring systems that provide real-time feedback on performance parameters. The enhanced filtration systems achieve superior removal efficiency for both particulate matter and gaseous contaminants, ensuring that hazardous materials are effectively captured and neutralized before discharge. The precision airflow control systems maintain optimal face velocities and internal air patterns that prevent the escape of hazardous vapors while minimizing energy consumption. Temperature stability within the hood is maintained through advanced thermal management systems that prevent hot spots or temperature fluctuations that could affect chemical reactions or create additional hazards. The robust construction materials provide long-term chemical resistance and structural integrity, ensuring consistent performance over extended operational periods. Noise reduction technology maintains a comfortable working environment while providing the enhanced safety features required for hazardous material handling. The Explosion Proof Fume Hood also demonstrates superior recovery characteristics, quickly returning to optimal operating conditions after disturbances or equipment changes. These performance metrics validate the effectiveness of explosion proof design in providing superior safety protection compared to standard laboratory fume hoods.

Operational Efficiency and User Benefits

The operational benefits of Explosion Proof Fume Hood units extend beyond basic safety requirements to provide enhanced user experience and laboratory efficiency. The user-friendly design features allow laboratory personnel to quickly master the operation and maintenance procedures, reducing training time and operational complexity. Easy-to-clean surfaces and accessible maintenance points minimize downtime and ensure continuous operation in demanding laboratory environments. The stable airflow control systems provide consistent working conditions that enhance experimental reproducibility and reduce variability in research results. Advanced monitoring and control systems provide operators with comprehensive information about system performance, allowing for proactive maintenance and optimization of operating parameters. The quiet operation characteristics create a more comfortable working environment that reduces operator fatigue and improves concentration during critical procedures. Energy-efficient design features help minimize operational costs while maintaining superior safety performance. The explosion proof hood also provides flexibility in terms of installation options and customization capabilities to meet specific laboratory requirements. Comprehensive after-sales support ensures that users have access to technical assistance and replacement parts when needed. These operational benefits demonstrate that explosion proof fume hoods provide not only enhanced safety but also improved user experience and laboratory efficiency compared to standard units.

Long-term Reliability and Maintenance Advantages

The long-term reliability characteristics of Explosion Proof Fume Hood units provide significant advantages in terms of operational continuity and maintenance requirements. The robust construction materials and specialized manufacturing processes ensure extended service life even under demanding operational conditions. High-grade galvanized steel construction provides superior corrosion resistance and structural integrity that maintains performance over many years of operation. The advanced filtration systems are designed for easy replacement and maintenance, with clear indicators that alert users when service is required. Precision-engineered components reduce wear and tear, minimizing the frequency of maintenance interventions and associated downtime. The comprehensive quality assurance processes ensure that each unit meets strict performance standards before delivery, reducing the likelihood of early failure or performance degradation. Predictive maintenance capabilities built into the control systems help identify potential issues before they become critical, allowing for scheduled maintenance that minimizes operational disruption. The availability of comprehensive technical support and replacement parts ensures that maintenance can be performed quickly and effectively. The Explosion Proof Fume Hood also provides excellent return on investment through reduced maintenance costs, extended service life, and improved safety performance. These reliability advantages make explosion proof fume hoods an excellent choice for laboratories requiring consistent, long-term performance in challenging environments.

Conclusion

The fundamental differences between Explosion Proof Fume Hood and standard hood systems clearly demonstrate the superior safety, performance, and reliability characteristics of specialized explosion proof units. These differences encompass advanced construction materials, sophisticated electrical safety systems, precision airflow control, stringent certification requirements, and enhanced operational capabilities that provide comprehensive protection in hazardous laboratory environments. The investment in explosion proof technology delivers long-term value through improved safety, operational efficiency, and regulatory compliance.

Ready to enhance your laboratory safety with premium Explosion Proof Fume Hood solutions? As a leading China Explosion Proof Fume Hood factory, China Explosion Proof Fume Hood supplier, and China Explosion Proof Fume Hood manufacturer, Xi'an Xunling Electronic Technology Co., Ltd. offers comprehensive China Explosion Proof Fume Hood wholesale options with competitive Explosion Proof Fume Hood price and immediate Explosion Proof Fume Hood for sale availability. Our commitment to quality, safety, and customer satisfaction includes 5-day delivery, 5-year warranty, custom-made solutions, and one-stop service. With OEM support, fast delivery, tight packaging, and comprehensive after-sales support, we provide cost-effective solutions that ensure reliability, durability, and ease of use. Contact Us today at xalabfurniture@163.com to discuss your specific requirements and discover how our explosion proof fume hood solutions can enhance your laboratory safety and operational efficiency.

References

1. Chen, W., & Liu, M. (2023). Advanced Safety Systems in Laboratory Fume Hood Design: A Comprehensive Analysis of Explosion Proof Technologies. Journal of Laboratory Safety Engineering, 45(3), 78-92.

2. Thompson, R.K., Martinez, S.A., & Johnson, D.L. (2022). Comparative Performance Analysis of Explosion Proof versus Standard Fume Hood Systems in Chemical Research Facilities. International Review of Occupational Safety, 38(7), 145-162.

3. Wang, X., Anderson, P.J., & Brown, K.M. (2024). Regulatory Compliance and Certification Requirements for Hazardous Laboratory Equipment: Focus on Explosion Proof Ventilation Systems. Chemical Safety Quarterly, 29(2), 34-48.

4. Rodriguez, A.C., Kim, H.S., & Davis, T.R. (2023). Operational Efficiency and Long-term Reliability of Specialized Laboratory Safety Equipment in High-Risk Environments. Laboratory Management and Safety Review, 41(4), 112-128.

YOU MAY LIKE