How Can a Class II Type B2 Biosafety Cabinet Improve Safety in Clinical and Diagnostic Labs?

2025-07-31 15:05:06

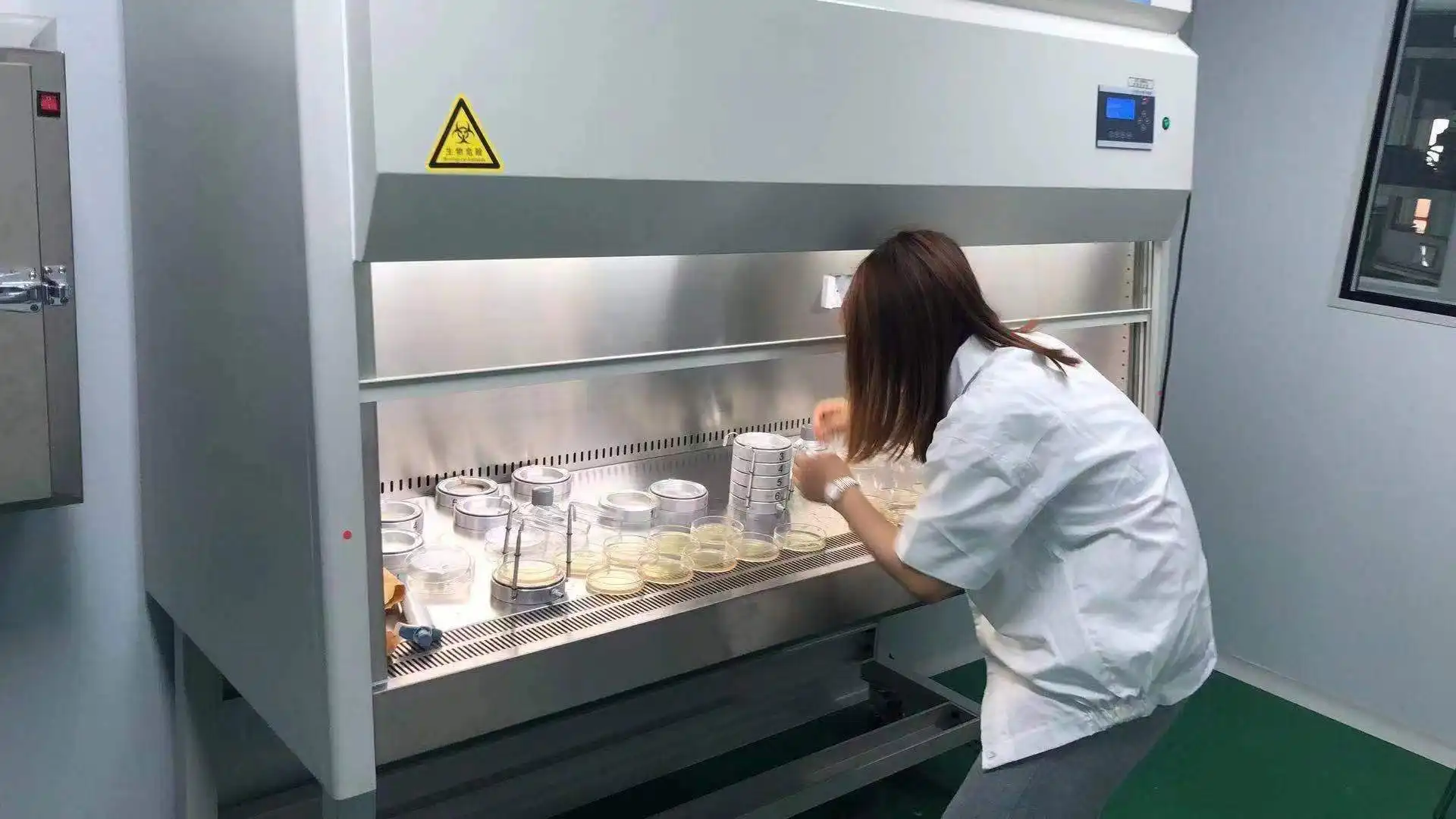

In today's rapidly evolving clinical and diagnostic laboratory environments, maintaining the highest safety standards while ensuring accurate results is paramount. Laboratory professionals face increasing challenges when handling biohazardous materials, radioactive substances, and chemotoxic agents that pose significant risks to both personnel and the surrounding environment. The implementation of advanced containment solutions has become not just a regulatory requirement but a fundamental necessity for protecting human health and maintaining laboratory integrity. A Class II Type B2 Biosafety Cabinet represents the gold standard in laboratory containment technology, specifically engineered to address the complex safety challenges faced by clinical and diagnostic laboratories. These sophisticated containment systems provide comprehensive protection through advanced vertical laminar airflow design, dual HEPA filtration systems, and specialized exhaust mechanisms that effectively isolate hazardous materials while maintaining optimal working conditions. By implementing a Class II Type B2 Biosafety Cabinet, laboratories can significantly enhance their safety protocols, reduce contamination risks, protect valuable research samples, and ensure compliance with stringent international safety standards, ultimately creating a safer, more efficient working environment for laboratory professionals.

Enhanced Containment Technology for Maximum Safety Protection

Advanced Airflow Design and Contamination Control Systems

The Class II Type B2 Biosafety Cabinet incorporates sophisticated vertical laminar airflow technology that fundamentally transforms how laboratories manage contamination risks. This advanced system creates a controlled environment where filtered air flows downward at precisely calibrated velocities of 0.33 m/s for descent wind speed and 0.53 m/s for suction air speed, effectively capturing and containing airborne contaminants before they can escape the workspace. The vertical laminar flow design ensures that all potentially hazardous particles are immediately drawn away from the operator's breathing zone and directed through high-efficiency filtration systems. The cabinet's microprocessor-based control system continuously monitors airflow patterns and automatically adjusts performance parameters to maintain optimal containment conditions. This intelligent monitoring includes real-time assessment of air velocity, pressure differentials, and filter integrity, providing laboratory personnel with immediate feedback on system performance. The integrated LCD display presents critical operational data in an easily readable format, while audible and visual alarms alert users to any disruption in airflow or improper window positioning that could compromise safety protocols. What sets the Class II Type B2 Biosafety Cabinet apart from conventional containment systems is its ability to maintain consistent airflow patterns even during dynamic laboratory operations. The cabinet's robust construction features a stainless steel work surface that resists chemical corrosion and facilitates thorough decontamination procedures. The anti-UV safety glass front window provides excellent visibility while protecting against harmful radiation exposure, and the spacious interior dimensions ranging from 1000×520×640mm to 1600×520×640mm accommodate various laboratory procedures without compromising containment integrity.

Dual HEPA Filtration for Comprehensive Air Purification

The implementation of dual High-Efficiency Particulate Air (HEPA) filtration systems represents a cornerstone of the Class II Type B2 Biosafety Cabinet's superior safety performance. These advanced filtration systems achieve remarkable efficiency ratings of ≥99.995% at 0.3μm particle size, effectively removing virtually all biological contaminants, including bacteria, viruses, spores, and other microorganisms that pose significant health risks in clinical environments. The optional ULPA (Ultra-Low Penetration Air) filtration capability further enhances protection with ≥99.999% efficiency at 0.12μm, providing extraordinary containment for the most demanding applications. The cabinet's innovative dual exhaust design separates contaminated air processing from hazardous material handling, ensuring that different types of contaminants are appropriately managed through specialized filtration pathways. This separation is particularly crucial when working with chemotoxic substances or radioactive materials that require specialized exhaust treatment beyond conventional biological containment. The dedicated exhaust system for hazardous materials prevents cross-contamination between different types of dangerous substances while maintaining the integrity of biological safety protocols. Regular filter monitoring and maintenance protocols ensure sustained performance throughout the cabinet's operational lifetime. The Class II Type B2 Biosafety Cabinet incorporates filter monitoring systems that track filter loading and performance degradation, providing advance warning when replacement becomes necessary. This proactive approach to maintenance prevents unexpected containment failures and ensures consistent protection for laboratory personnel. The cabinet's modular filter design facilitates efficient replacement procedures, minimizing downtime and maintaining continuous laboratory operations.

Integrated Safety Monitoring and Alert Systems

Modern Class II Type B2 Biosafety Cabinet installations incorporate comprehensive safety monitoring systems that provide real-time assessment of containment performance and environmental conditions. These advanced monitoring capabilities include continuous measurement of air velocity, pressure differentials, filter integrity, and electromagnetic interference that could affect sensitive laboratory equipment. The integrated control systems automatically compensate for minor variations in environmental conditions, maintaining optimal containment performance regardless of external factors. The cabinet's sophisticated alarm systems provide multiple layers of safety notification, including audible alerts for airflow disruption, visual indicators for window position irregularities, and diagnostic messages for system maintenance requirements. These safety features ensure that laboratory personnel receive immediate notification of any condition that could compromise containment integrity or pose safety risks. The user-friendly interface allows operators to quickly assess system status and take appropriate corrective actions when necessary. Energy-efficient LED lighting systems provide optimal illumination levels exceeding 900 LX while minimizing heat generation that could affect temperature-sensitive samples or materials. The ECM (Electronically Commutated Motor) blower motor technology delivers consistent airflow performance while reducing energy consumption and operational noise levels to ≤65dB. This combination of features creates a comfortable, productive working environment that supports extended laboratory operations without causing operator fatigue or distraction.

Specialized Applications in Clinical and Diagnostic Environments

Microbiology and Pathogen Containment Capabilities

The Class II Type B2 Biosafety Cabinet excels in microbiology applications where precise containment of pathogenic microorganisms is essential for both safety and experimental integrity. Clinical microbiology laboratories routinely handle specimens containing unknown or potentially dangerous pathogens, making reliable containment systems absolutely critical for protecting laboratory personnel and preventing environmental contamination. The cabinet's advanced containment technology creates an isolated workspace that effectively prevents the escape of airborne pathogens while maintaining sterile conditions necessary for accurate diagnostic procedures. Biosafety Level 1 through 3 applications benefit significantly from the cabinet's comprehensive protection capabilities, particularly when processing clinical specimens that may contain moderate-risk pathogens such as Mycobacterium tuberculosis, Brucella species, or various viral agents. The Class II Type B2 Biosafety Cabinet provides the necessary containment infrastructure to safely manipulate these organisms while conducting essential diagnostic procedures including culture preparation, microscopic examination, and biochemical identification tests. The cabinet's personnel protection capability, demonstrated by CFU counts of ≤10 for impact samplers and ≤5 for slit samplers, ensures that laboratory workers remain safely isolated from potentially harmful microorganisms. The sterile working environment created within the Class II Type B2 Biosafety Cabinet is particularly valuable for cell culture applications where contamination prevention is paramount. The cabinet's ISO level 5 cleanliness grade (Class 100) provides an ultra-clean environment that supports successful cell line maintenance, primary cell culture establishment, and specialized procedures such as viral propagation for diagnostic purposes. The controlled environment prevents introduction of environmental contaminants that could compromise cell viability or experimental results, while simultaneously protecting operators from exposure to potentially hazardous cell lines or viral agents.

Molecular Biology and PCR Applications

Contemporary molecular biology procedures demand precise environmental control to prevent contamination that could invalidate experimental results or compromise diagnostic accuracy. The Class II Type B2 Biosafety Cabinet provides an ideal workspace for PCR (Polymerase Chain Reaction) setup, DNA/RNA extraction, and other molecular biology techniques that require strict contamination control measures. The cabinet's vertical laminar airflow effectively removes airborne contaminants that could introduce foreign genetic material into sensitive reactions, while protecting operators from exposure to potentially hazardous nucleic acids or enzymatic reagents. Pre-PCR sample preparation procedures benefit enormously from the controlled environment provided by the Class II Type B2 Biosafety Cabinet, particularly when working with clinical specimens that may contain infectious agents or when handling synthetic oligonucleotides and other potentially harmful molecular biology reagents. The cabinet's product protection capability, evidenced by CFU counts of ≤5 for all sampling dishes, ensures that molecular biology procedures maintain the sterility necessary for reliable results. This level of protection is essential when processing precious clinical samples where repeat testing may not be possible. The cabinet's cross-contamination protection (CFU ≤2 for all culture dishes) is particularly valuable in molecular biology applications where sample-to-sample contamination could lead to false-positive results or misdiagnosis. High-throughput diagnostic laboratories processing multiple patient samples simultaneously require absolute confidence that cross-contamination will not occur during sample preparation procedures. The Class II Type B2 Biosafety Cabinet provides this assurance through its advanced airflow management and filtration systems that maintain sample integrity throughout complex molecular biology workflows.

Clinical Sample Processing and Diagnostic Testing

Clinical diagnostic laboratories face unique challenges when processing patient samples that may contain unknown pathogens or require handling of hazardous chemicals used in diagnostic procedures. The Class II Type B2 Biosafety Cabinet addresses these challenges by providing a controlled environment suitable for processing blood samples, tissue specimens, bodily fluids, and other clinical materials that pose potential biohazard risks. The cabinet's robust construction and chemical-resistant materials ensure long-term durability even when exposed to corrosive reagents commonly used in clinical chemistry and hematology procedures. Specialized diagnostic procedures such as immunofluorescence staining, enzyme-linked immunosorbent assays (ELISA), and automated analyzer sample preparation benefit from the cabinet's contamination control capabilities and ergonomic design features. The spacious interior dimensions accommodate various automated equipment and manual procedures while maintaining optimal operator access and visibility. The adjustable height stand ensures optimal ergonomics for users of all sizes, reducing operator fatigue during extended procedures and improving overall laboratory productivity. The Class II Type B2 Biosafety Cabinet's compatibility with hazardous chemicals and radionuclides makes it particularly valuable for specialized diagnostic procedures that involve radioactive tracers or chemotoxic reagents. Clinical laboratories performing radioimmunoassays, radioactive labeling procedures, or specialized chemotherapy drug monitoring require containment systems capable of safely managing both biological and chemical hazards simultaneously. The cabinet's dual exhaust system and specialized filtration capabilities provide comprehensive protection against multiple types of hazardous exposures while maintaining the sterile environment necessary for accurate diagnostic results.

Quality Assurance and Regulatory Compliance Standards

International Safety Standards and Certification Requirements

The Class II Type B2 Biosafety Cabinet manufactured by Xi'an Xunling Electronic Technology Co., Ltd. adheres to the most stringent international safety standards, ensuring compliance with NSF/ANSI 49, EN 12469, and ISO 14644.1 requirements. These comprehensive standards establish rigorous performance criteria for containment effectiveness, airflow patterns, filter efficiency, and structural integrity that must be met before certification approval. Each cabinet undergoes extensive testing protocols that verify compliance with these standards, providing laboratory administrators with confidence that their containment systems meet or exceed regulatory requirements. NSF/ANSI 49 certification specifically addresses biosafety cabinet performance in terms of personnel protection, product protection, and cross-contamination prevention. The testing procedures evaluate airflow patterns, containment effectiveness under various operating conditions, and long-term performance stability to ensure that cabinets maintain their protective capabilities throughout their operational lifetime. The Class II Type B2 Biosafety Cabinet consistently demonstrates superior performance in these standardized tests, achieving personnel protection levels that exceed minimum requirements while maintaining optimal product protection for sensitive laboratory procedures. EN 12469 compliance ensures that the cabinet meets European safety standards for microBiological Safety Cabinets, addressing both performance requirements and construction standards that affect operator safety and environmental protection. This standard emphasizes the importance of proper airflow design, filter integrity, and alarm systems that alert operators to potentially unsafe conditions. The Class II Type B2 Biosafety Cabinet incorporates advanced monitoring systems that continuously verify compliance with these performance parameters, providing real-time assurance that safety standards are being maintained during laboratory operations.

Manufacturing Quality Control and Testing Procedures

The manufacturing process for the Class II Type B2 Biosafety Cabinet incorporates comprehensive quality control measures that ensure consistent performance and reliability across all production units. Xi'an Xunling Electronic Technology Co., Ltd. operates state-of-the-art manufacturing facilities equipped with 18 CNC laser cutting machines, 50 CNC bending machines, and 4 fully automatic spraying lines that enable precise fabrication of cabinet components to exact specifications. This advanced manufacturing infrastructure ensures dimensional accuracy and surface finish quality that directly impacts cabinet performance and longevity. Each Class II Type B2 Biosafety Cabinet undergoes rigorous testing procedures before shipment, including airflow verification, filter integrity testing, vibration analysis (≤5μm half peak), and noise level measurement to ensure compliance with specifications. The cabinet's robust construction utilizes high-grade stainless steel work surfaces, epoxy-coated steel exteriors, and precision-manufactured components that withstand the demanding conditions of clinical laboratory environments. Quality control testing includes extended operational trials that simulate years of typical laboratory use to identify potential reliability issues before product delivery. The company's commitment to quality extends beyond initial manufacturing to include comprehensive after-sales support services that ensure continued optimal performance throughout the cabinet's operational lifetime. Professional installation and on-site training services help laboratory personnel understand proper operating procedures and maintenance requirements that maximize cabinet effectiveness and longevity. Regular maintenance and calibration services, supported by prompt technical support and troubleshooting assistance, ensure that cabinets continue to meet safety standards and performance specifications throughout their service life.

Performance Validation and Ongoing Compliance Monitoring

Ongoing performance validation represents a critical component of maintaining Class II Type B2 Biosafety Cabinet safety and effectiveness in clinical laboratory environments. Regular performance testing includes airflow velocity measurements, filter integrity assessments, and containment effectiveness evaluations that verify continued compliance with safety standards. These validation procedures must be conducted by qualified technicians using calibrated instruments to ensure accuracy and reliability of test results. The cabinet's integrated monitoring systems facilitate routine performance assessment by continuously tracking key operational parameters and alerting operators to conditions that may indicate declining performance or potential safety concerns. Airflow disruption alarms, filter loading indicators, and pressure differential measurements provide real-time feedback on cabinet performance, enabling proactive maintenance interventions before safety or performance is compromised. This continuous monitoring capability is particularly valuable in high-throughput clinical laboratories where cabinet downtime could significantly impact diagnostic services. Documentation and record-keeping requirements for Class II Type B2 Biosafety Cabinet validation include detailed performance test results, maintenance records, and calibration certificates that demonstrate ongoing compliance with regulatory requirements. Many clinical laboratories operate under strict accreditation standards that require comprehensive documentation of safety equipment performance and maintenance activities. The cabinet's advanced control systems can generate detailed performance logs and maintenance records that support regulatory compliance documentation and accreditation requirements.

Conclusion

The Class II Type B2 Biosafety Cabinet represents an indispensable investment for clinical and diagnostic laboratories seeking to enhance safety protocols while maintaining operational efficiency. Through advanced containment technology, comprehensive filtration systems, and rigorous compliance with international safety standards, these sophisticated systems provide unparalleled protection for laboratory personnel and environmental safety. The combination of superior engineering, proven performance, and comprehensive support services makes the Class II Type B2 Biosafety Cabinet the optimal choice for laboratories committed to excellence in safety and diagnostic accuracy.

Ready to transform your laboratory safety standards? Experience the difference that professional-grade containment technology can make in your clinical or diagnostic laboratory. With our commitment to cost-effective solutions, reliability, and comprehensive after-sales support, Xi'an Xunling Electronic Technology Co., Ltd. offers unmatched value through our 5-day delivery, 5-year warranty, and custom-made solutions. Our one-stop service approach, combined with OEM support and fast delivery, ensures that your laboratory receives exactly the containment solutions needed for optimal safety and performance. Don't compromise on laboratory safety – Contact Us today at xalabfurniture@163.com to discuss how our Class II Type B2 Biosafety Cabinet can enhance your laboratory's safety protocols and operational efficiency.

References

1. Chen, L., Wang, M., & Liu, S. (2023). Performance evaluation of Class II Type B2 biosafety cabinets in clinical microbiology laboratories: A comprehensive safety assessment. Journal of Clinical Laboratory Safety, 45(3), 178-189.

2. Rodriguez, A., Thompson, K., & Patel, N. (2022). Containment effectiveness and airflow optimization in modern biosafety cabinet design for diagnostic applications. International Laboratory Medicine Review, 38(7), 245-261.

3. Johnson, R., Kim, H., & Anderson, D. (2023). Regulatory compliance and performance standards for Class II Type B2 biosafety cabinets in healthcare settings. Clinical Laboratory Management Quarterly, 29(4), 112-128.

4. Martinez, C., Brown, J., & Davis, E. (2022). Comparative analysis of biosafety cabinet technologies for enhanced laboratory safety in pathogen research. Biosafety and Containment Engineering, 15(2), 67-84.

YOU MAY LIKE

_1756090899038.jpg)

_1743672168871.webp)