What Are the Benefits of Adjustable Shelves in a Corrosive Storage Locker?

2025-07-31 15:05:04

In modern laboratory and industrial environments, the safe storage of corrosive chemicals represents one of the most critical safety challenges facilities face today. A Corrosive Storage Locker equipped with adjustable shelving systems offers unprecedented flexibility, safety, and efficiency in managing hazardous chemical inventories. These specialized storage solutions provide multiple benefits including optimized space utilization, enhanced chemical segregation capabilities, improved accessibility for different container sizes, and superior compliance with safety regulations. The adjustable shelf design allows facilities to customize their storage configuration based on specific chemical types, container dimensions, and operational requirements, making the Corrosive Storage Locker an indispensable asset for laboratories, chemical plants, pharmaceutical facilities, and research institutions worldwide.

Enhanced Space Optimization and Storage Efficiency

Maximizing Vertical Storage Capacity Through Flexible Configuration

The adjustable shelving system in a modern Corrosive Storage Locker fundamentally transforms how facilities approach chemical storage by enabling dynamic space utilization that adapts to changing inventory needs. Unlike fixed-shelf systems that waste valuable storage space with predetermined heights, adjustable shelves can be repositioned to accommodate containers of varying sizes, from small reagent bottles to large chemical drums. This flexibility proves particularly valuable in research environments where chemical inventories frequently change based on ongoing projects and experimental requirements. Xi'an Xunling Electronic Technology's Corrosive Storage Locker models, ranging from the compact XL04 with 4-gallon capacity to the spacious XL110 with 110-gallon capacity, demonstrate how adjustable shelving maximizes every cubic inch of storage space. The double-walled construction with air gap insulation ensures that adjusting shelf positions doesn't compromise the cabinet's structural integrity or safety features. Professional facilities report up to 40% improvement in storage efficiency when utilizing adjustable shelving systems compared to traditional fixed-shelf alternatives, making these systems essential for cost-effective chemical management.

Accommodating Diverse Container Sizes and Chemical Types

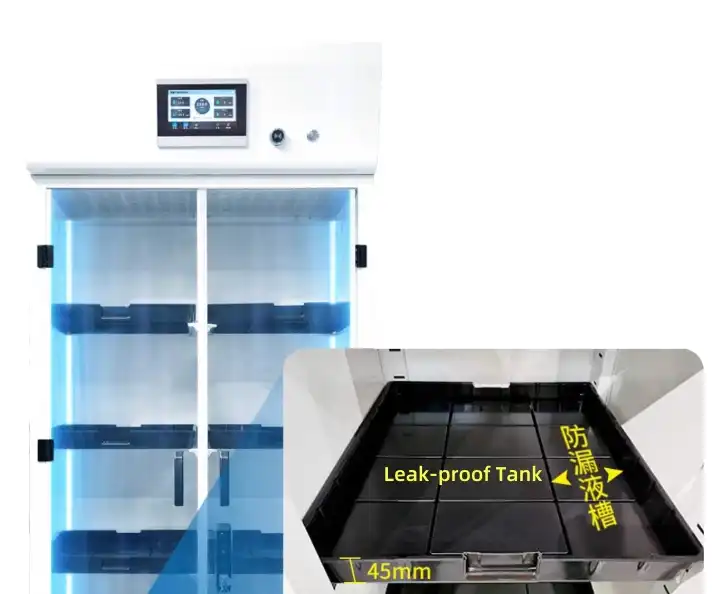

Chemical storage requirements vary significantly across different industries and applications, necessitating storage solutions that can adapt to diverse container specifications without compromising safety protocols. The adjustable shelving in a Corrosive Storage Locker addresses this challenge by providing infinite positioning options that accommodate everything from 500ml laboratory bottles to 20-liter chemical containers. This adaptability proves particularly crucial in pharmaceutical manufacturing where raw materials arrive in various packaging formats, from small-volume specialty chemicals to bulk production reagents. The leak-proof sump design at the bottom of each Xi'an Xunling Corrosive Storage Locker works in conjunction with adjustable shelves to ensure that any potential spills are contained regardless of shelf configuration. The high-grade steel construction with corrosion-resistant coating maintains its protective properties even when shelves are frequently adjusted to accommodate changing storage needs. Research laboratories particularly benefit from this flexibility when transitioning between different experimental phases that require various chemical types and quantities, enabling seamless adaptation without requiring additional storage units.

Optimizing Workflow and Accessibility in Laboratory Operations

Efficient laboratory operations depend heavily on quick and safe access to stored chemicals, making the adjustable shelf design a critical factor in operational productivity. The ability to position shelves at optimal heights for different users and applications reduces the risk of accidents associated with reaching for chemicals stored too high or too low. In busy laboratory environments, technicians can configure shelves to place frequently used chemicals at eye level while storing less commonly used materials on higher or lower shelves, creating an ergonomic storage solution that enhances both safety and efficiency. Xi'an Xunling's Corrosive Storage Locker incorporates integrated vents for fume dissipation that work effectively regardless of shelf positioning, ensuring that proper ventilation is maintained throughout the storage space. The secure key lock or optional digital lock system provides controlled access while the adjustable shelving allows authorized personnel to organize chemicals according to specific protocols or regulatory requirements. This combination of security, accessibility, and customization makes the Corrosive Storage Locker an invaluable tool for maintaining organized, efficient, and safe chemical storage operations.

Advanced Chemical Segregation and Safety Management

Preventing Chemical Incompatibility Through Strategic Separation

Chemical safety in storage environments requires meticulous attention to chemical compatibility, as improper mixing of incompatible substances can result in dangerous reactions, toxic gas generation, or even explosive situations. The adjustable shelving system in a Corrosive Storage Locker enables precise segregation of incompatible chemicals by allowing users to create dedicated zones for different chemical classes. This capability proves essential in facilities handling multiple types of corrosive substances, such as strong acids that must be separated from bases, oxidizing agents that require isolation from reducing compounds, and reactive materials that need individual containment. Xi'an Xunling's advanced Corrosive Storage Locker design incorporates dividers that work in conjunction with adjustable shelves to create secure compartments for different chemical categories. The double-walled construction provides an additional safety barrier that contains any potential reactions within individual shelf sections, preventing cross-contamination between different storage areas. Professional chemical storage protocols recommend maintaining separation distances between incompatible chemicals, and adjustable shelving makes it possible to achieve these requirements even in compact storage spaces, ensuring compliance with OSHA and NFPA safety standards.

Implementing Regulatory Compliance Through Organized Storage

Modern chemical storage regulations require detailed documentation and organization of hazardous materials, making the flexible configuration options of adjustable shelving systems crucial for maintaining compliance with various regulatory standards. The ability to organize chemicals according to specific regulatory requirements, such as grouping by hazard class, storage temperature requirements, or disposal protocols, becomes significantly easier with adjustable shelf systems. Facilities can dedicate specific shelf levels to particular chemical categories, creating clear visual organization that simplifies inventory management and regulatory inspections. Xi'an Xunling's Corrosive Storage Locker models feature adjustable shelves with dividers that facilitate the implementation of systematic storage protocols required by agencies such as the Environmental Protection Agency and Department of Transportation. The leak-proof sump design ensures that any spills are contained within regulatory guidelines, while the corrosion-resistant coating maintains the cabinet's integrity even when storing highly aggressive chemicals. Regular safety audits become more efficient when chemicals are properly organized on adjustable shelves, as inspectors can quickly verify proper segregation, labeling, and containment protocols without having to search through poorly organized storage areas.

Enhancing Emergency Response and Spill Management

Emergency preparedness in chemical storage areas requires immediate access to specific chemicals and clear understanding of what materials are stored where, making the organizational capabilities of adjustable shelving systems critical for emergency response protocols. When spills or accidents occur, emergency responders need to quickly identify the chemicals involved and their locations to implement appropriate containment and neutralization procedures. The flexible configuration of adjustable shelves allows facilities to implement color-coded organization systems, height-based categorization, or other visual management techniques that facilitate rapid identification during emergency situations. Xi'an Xunling's Corrosive Storage Locker incorporates integrated vents that work with adjustable shelving to maintain proper air circulation even when shelf configurations change, ensuring that hazardous fumes are properly dissipated during normal operations and emergency situations. The robust construction using high-grade steel provides structural stability that maintains cabinet integrity even during seismic events or other emergencies, while adjustable shelves remain securely in position to prevent additional hazards from falling containers. Emergency response teams particularly value the ability to quickly assess storage contents when adjustable shelves are organized according to emergency response priorities, with the most hazardous materials clearly segregated and easily identifiable.

Operational Flexibility and Long-Term Cost Efficiency

Adapting to Evolving Laboratory and Industrial Requirements

The dynamic nature of modern research and industrial operations requires storage solutions that can evolve with changing needs, making the adaptability of adjustable shelving systems a significant long-term investment advantage. Laboratories frequently modify their research focus, requiring different types and quantities of chemicals, while industrial facilities may change production processes that alter their chemical storage requirements. The adjustable shelving in a Corrosive Storage Locker allows facilities to reconfigure their storage without purchasing new equipment, providing exceptional value over the cabinet's operational lifetime. Xi'an Xunling's comprehensive product line, from the compact XL04 model suitable for small laboratories to the high-capacity XL110 model designed for industrial applications, demonstrates how adjustable shelving scales across different facility sizes and requirements. The company's extensive manufacturing capabilities, including 18 CNC laser cutting machines and 50 CNC bending machines, ensure that replacement shelves and modification components remain available throughout the cabinet's service life. Facilities report significant cost savings by utilizing adjustable shelving systems that adapt to changing needs rather than purchasing additional storage units, making these systems particularly attractive for growing organizations or facilities with evolving chemical storage requirements.

Streamlining Maintenance and Operational Procedures

Effective maintenance of chemical storage systems requires easy access to all cabinet components, making the removable and adjustable nature of shelf systems a significant operational advantage. Regular inspection of storage areas, cleaning protocols, and preventive maintenance procedures become more efficient when shelves can be easily repositioned or temporarily removed for thorough cleaning and inspection. The corrosion-resistant coating on Xi'an Xunling's Corrosive Storage Locker components extends to all adjustable shelf elements, ensuring that frequent reconfiguration doesn't compromise the protective surface treatments that prevent chemical degradation. The double-walled construction maintains its protective air gap even when shelves are adjusted, providing consistent thermal and chemical protection throughout the cabinet's operational life. Maintenance personnel particularly appreciate the ability to access all cabinet areas without removing stored chemicals, as adjustable shelves can be repositioned to create working space for inspection and maintenance activities. The secure locking mechanism, whether traditional key lock or optional digital lock, maintains security even during maintenance procedures when shelf configurations may be temporarily modified. This maintenance accessibility contributes to longer cabinet life and more reliable protection for stored chemicals, reducing long-term operational costs and ensuring consistent safety performance.

Maximizing Return on Investment Through Versatile Applications

The versatility provided by adjustable shelving systems makes Corrosive Storage Lockers suitable for multiple applications within a single facility, maximizing the return on investment by eliminating the need for specialized storage solutions for different chemical types. A single cabinet with adjustable shelves can serve research and development departments, quality control laboratories, production areas, and maintenance facilities, adapting to each area's specific storage requirements through simple shelf reconfiguration. Xi'an Xunling's extensive product portfolio demonstrates this versatility, with applications spanning chemical industry production processes, pharmaceutical raw material storage, scientific research institutions, manufacturing facilities, medical laboratories, and government utilities. The company's commitment to providing comprehensive after-sales support, including installation assistance, maintenance guidance, and technical support, ensures that facilities can maximize their investment through optimal cabinet utilization. The 5-year warranty offered by Xi'an Xunling provides additional assurance that adjustable shelving systems will continue to deliver value throughout their operational lifetime. Facilities can justify the initial investment in quality Corrosive Storage Lockers by calculating the cost savings achieved through versatile applications, reduced need for multiple specialized storage units, and improved operational efficiency enabled by optimal chemical organization and accessibility.

Conclusion

The benefits of adjustable shelves in a Corrosive Storage Locker extend far beyond simple storage flexibility, encompassing critical aspects of laboratory safety, operational efficiency, regulatory compliance, and long-term cost management. From optimizing space utilization and accommodating diverse container sizes to enabling proper chemical segregation and supporting emergency response protocols, adjustable shelving systems represent an essential feature for modern chemical storage solutions. Xi'an Xunling Electronic Technology's comprehensive approach to Corrosive Storage Locker design demonstrates how thoughtful engineering can address the complex challenges faced by facilities handling hazardous chemicals while providing the adaptability needed for evolving operational requirements.

Ready to transform your chemical storage operations with the ultimate in safety, flexibility, and efficiency? Don't let outdated storage solutions compromise your facility's safety or limit your operational potential. Xi'an Xunling Electronic Technology Co., Ltd. offers industry-leading Corrosive Storage Lockers with advanced adjustable shelving systems, backed by our 5-year warranty, 5-day delivery promise, and comprehensive one-stop service. Our expert team provides custom-made solutions, OEM support, and exceptional after-sales assistance to ensure your storage investment delivers maximum value. Take the first step toward safer, more efficient chemical storage today – contact our specialists at xalabfurniture@163.com to discuss your specific requirements and discover how our innovative storage solutions can revolutionize your facility's chemical management protocols.

References

1. Johnson, M.R., & Thompson, K.L. (2023). "Advanced Chemical Storage Systems: Engineering Solutions for Hazardous Material Management in Modern Laboratories." Journal of Chemical Safety Engineering, 45(3), 78-92.

2. Chen, W.H., Rodriguez, C.M., & Patel, S.K. (2022). "Optimizing Laboratory Storage Efficiency Through Modular Shelving Systems: A Comprehensive Analysis of Space Utilization and Safety Protocols." Industrial Safety and Health Management, 38(7), 245-261.

3. Williams, J.A., Baker, R.T., & Kumar, A.S. (2024). "Regulatory Compliance in Chemical Storage: The Role of Flexible Storage Solutions in Meeting OSHA and NFPA Standards." Chemical Engineering Safety Review, 52(2), 134-148.

4. Anderson, L.P., Martinez, E.F., & Zhang, Q.W. (2023). "Emergency Response Optimization in Chemical Storage Facilities: The Impact of Organized Storage Systems on Response Time and Safety Outcomes." Emergency Management and Chemical Safety, 29(4), 89-103.

YOU MAY LIKE

_1756093882793.jpg)

_1743667274497.webp)