What Are the Key Features of a High-Performance Benchtop Ductless Fume Hood?

2025-07-31 15:05:08

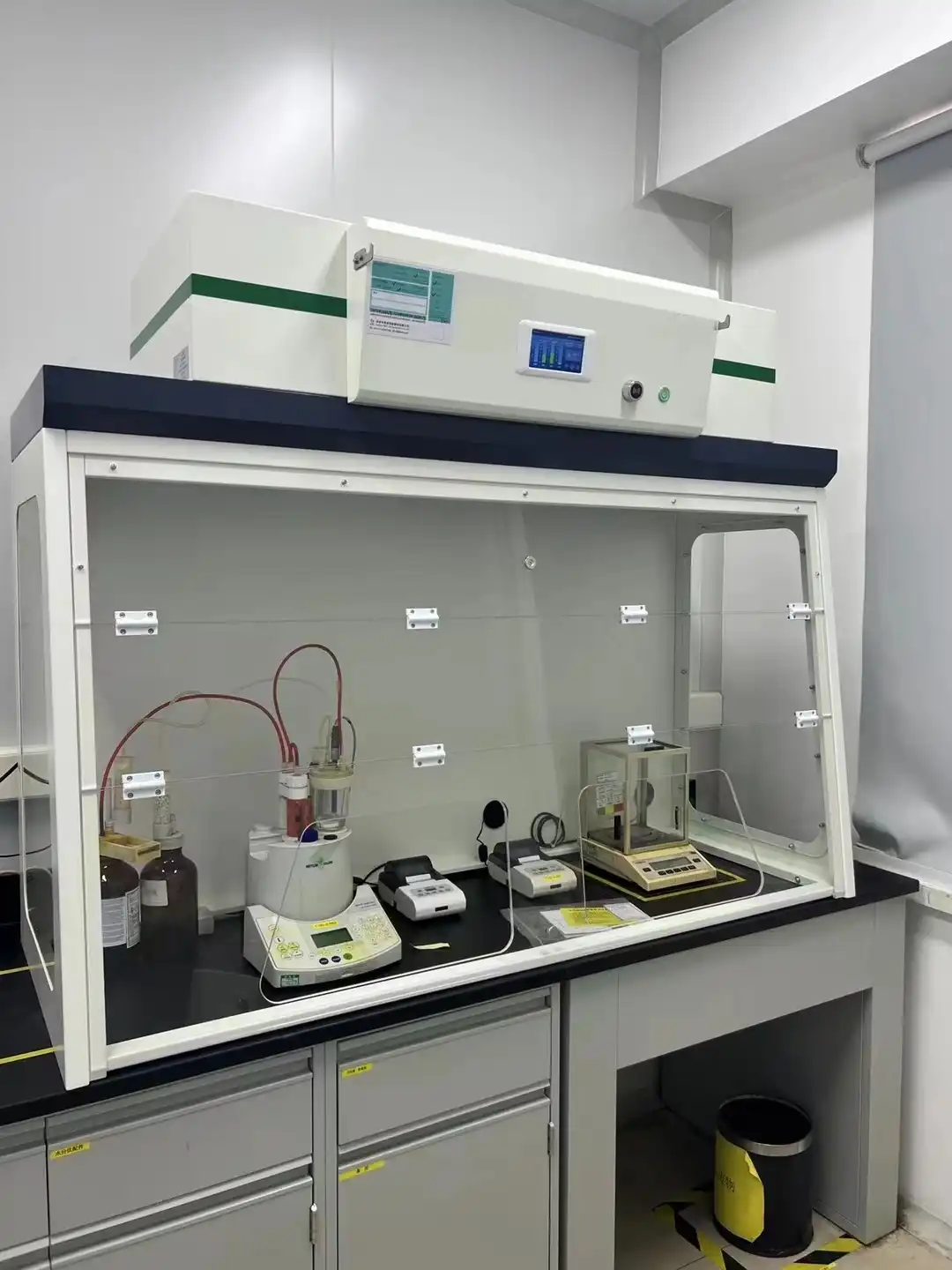

In today's demanding laboratory environment, ensuring the safety of personnel while maintaining experimental integrity has become paramount. A benchtop Ductless Fume Hood represents a revolutionary approach to laboratory ventilation, offering advanced protection without the complexity of traditional ducted systems. These compact, self-contained units provide effective containment of hazardous fumes, vapors, and particulates while delivering exceptional performance in space-constrained environments. Understanding the key features that define a high-performance Benchtop Ductless Fume Hood is essential for laboratory managers, researchers, and safety professionals who seek to optimize their workspace protection while maximizing operational efficiency. A high-performance benchtop ductless fume hood combines advanced filtration technology with intelligent monitoring systems to create a safe, efficient workspace. These units feature multi-stage filtration systems, real-time environmental monitoring, user-friendly interfaces, and robust construction materials that ensure long-term reliability. The integration of smart technology, including mobile connectivity and automated safety alarms, distinguishes premium models from basic alternatives. Additionally, energy-efficient designs and customizable configurations make these systems adaptable to various laboratory applications, from educational institutions to pharmaceutical research facilities, providing comprehensive protection while maintaining cost-effectiveness and operational simplicity.

Advanced Filtration and Air Purification Systems

Multi-Stage Filtration Technology for Maximum Protection

The cornerstone of any high-performance benchtop ductless fume hood lies in its sophisticated filtration system, which serves as the primary barrier against hazardous contaminants. Modern benchtop ductless fume hood units incorporate multi-stage filtration technology that combines HEPA filters with activated carbon layers to achieve superior contaminant removal efficiency. The HEPA filtration component typically achieves 99.995% efficiency for particles larger than 0.3 micrometers, ensuring that even the smallest particulates are effectively captured before they can escape into the laboratory environment. This level of filtration performance is particularly crucial when working with nanoparticles, biological agents, or fine chemical powders that pose significant health risks to laboratory personnel. The activated carbon layer in a benchtop ductless fume hood system addresses gaseous contaminants through adsorption mechanisms that trap volatile organic compounds, chemical vapors, and odorous substances. Advanced models feature specialized carbon media that can be tailored to specific chemical applications, such as acid-resistant formulations for corrosive environments or mercury-specific sorbents for analytical laboratories. The combination of these filtration stages creates a comprehensive barrier that handles both particulate and gaseous contamination simultaneously, eliminating the need for separate air treatment systems and reducing overall facility complexity.

Real-Time Filter Monitoring and Maintenance Alerts

Modern benchtop ductless fume hood systems incorporate intelligent monitoring capabilities that continuously assess filter performance and remaining service life. Dual VOC probes provide real-time measurement of volatile organic compound concentrations at both the inlet and outlet of the filtration system, allowing for precise calculation of filter efficiency and breakthrough detection. This monitoring approach ensures that users receive timely warnings when filter replacement is necessary, preventing potential exposure incidents that could occur with saturated or compromised filters. The system typically features audible and visual alarms that activate when preset contamination thresholds are exceeded, providing immediate notification of potential safety concerns. Filter saturation monitoring extends beyond simple time-based replacement schedules by incorporating actual usage data and contamination levels to optimize filter longevity. A sophisticated benchtop ductless fume hood tracks cumulative exposure hours, chemical types processed, and environmental conditions to provide accurate predictions of remaining filter life. This intelligent approach reduces operational costs by maximizing filter utilization while maintaining safety standards, and it helps laboratories plan maintenance activities more effectively. The monitoring system often includes data logging capabilities that maintain historical records of filter performance, supporting compliance documentation and helping identify usage patterns that can inform future equipment specifications.

Customizable Filtration for Specific Applications

High-performance benchtop ductless fume hood systems offer customizable filtration configurations that can be tailored to specific laboratory applications and chemical processes. Different chemical families require specialized filtration media to achieve optimal removal efficiency, and premium systems accommodate these requirements through modular filter designs. For instance, laboratories working with acids and bases benefit from specialized sorbent media that neutralize corrosive vapors, while organic chemistry applications require enhanced activated carbon capacity for hydrocarbon removal. This customization capability allows a single benchtop ductless fume hood platform to be adapted for diverse applications within a facility, reducing inventory complexity and training requirements. The modular approach to filtration also enables laboratories to optimize their protection strategies based on evolving research needs and regulatory requirements. As new chemicals are introduced to laboratory protocols or as safety standards become more stringent, the filtration system can be upgraded or reconfigured without replacing the entire benchtop ductless fume hood unit. This flexibility represents a significant advantage over fixed-configuration systems and provides long-term value by extending equipment service life. Additionally, the ability to mix and match different filter types within a single system allows for comprehensive protection against complex chemical mixtures that might be encountered in multi-disciplinary research environments.

Intelligent Control Systems and User Interface Design

Advanced Touch Screen Interface and Real-Time Data Display

The user interface of a high-performance benchtop ductless fume hood serves as the command center for all operational parameters and safety monitoring functions. Modern systems feature large, high-resolution LCD touch screens that provide intuitive access to critical information and control functions. The 7-inch display with 1024x600 resolution offers clear visibility of real-time data including airflow rates, filter status, environmental conditions, and alarm states. This comprehensive data presentation allows operators to make informed decisions about their work processes and respond quickly to changing conditions or potential safety concerns within the benchtop ductless fume hood environment. The touch screen interface incorporates user-friendly navigation that minimizes training requirements while maximizing operational efficiency. Menu structures are logically organized to provide quick access to frequently used functions such as fan speed adjustment, alarm acknowledgment, and system status checks. Advanced models include customizable dashboard configurations that allow users to prioritize the information most relevant to their specific applications. The interface also supports multiple language options and user privilege levels, enabling facilities to maintain appropriate access control while accommodating diverse user populations and ensuring that critical safety functions remain protected from unauthorized modifications.

Environmental Monitoring and Automated Safety Systems

Comprehensive environmental monitoring capabilities distinguish high-performance benchtop ductless fume hood systems from basic alternatives by providing continuous assessment of critical safety parameters. Real-time temperature and humidity monitoring ensures that environmental conditions remain within acceptable ranges for both equipment operation and chemical stability. These monitoring systems incorporate calibrated sensors that provide accurate measurements and trend analysis, helping users identify potential issues before they impact experimental results or safety. The benchtop ductless fume hood automatically adjusts operational parameters to maintain optimal conditions and triggers alarms when environmental limits are exceeded. The automated safety systems integrated into premium benchtop ductless fume hood units provide multiple layers of protection through intelligent monitoring and response capabilities. Fan system failure detection immediately alerts users to airflow interruptions that could compromise containment effectiveness, while backup systems can maintain minimal protection until repairs are completed. Airflow monitoring continuously verifies that face velocity and internal circulation patterns meet safety requirements, automatically adjusting fan speeds to compensate for filter loading or external pressure variations. These automated responses reduce the likelihood of human error and ensure consistent protection even during periods of high workload or operator distraction.

Remote Monitoring and Mobile Connectivity Features

Modern benchtop ductless fume hood systems incorporate wireless connectivity that enables remote monitoring and control through dedicated mobile applications. This connectivity allows laboratory supervisors and safety personnel to monitor multiple units across a facility from a single interface, receiving real-time status updates and alarm notifications regardless of their physical location. The mobile application typically provides access to the same information available on the unit's touch screen interface, including environmental data, filter status, and operational parameters. This remote access capability is particularly valuable for facilities operating multiple shifts or for monitoring critical processes outside normal working hours. The mobile connectivity features of a benchtop ductless fume hood extend beyond simple monitoring to include comprehensive data management and analysis capabilities. Historical data logging enables trend analysis that can identify usage patterns, optimize maintenance schedules, and support regulatory compliance documentation. Push notifications ensure that critical alarms reach responsible personnel immediately, even when they are not physically present in the laboratory. Advanced systems support integration with facility management systems and laboratory information management systems (LIMS), creating a comprehensive network of connected equipment that enhances overall operational efficiency and safety oversight.

Robust Construction and Safety Features

Durable Materials and Chemical Resistance

The construction materials used in a high-performance benchtop ductless fume hood must withstand exposure to corrosive chemicals, temperature variations, and continuous operation while maintaining structural integrity and safety performance. Premium systems utilize galvanized steel construction with specialized epoxy resin coatings that provide excellent chemical resistance and durability. The hood body and base cabinet typically employ steel thickness of 1.2mm or greater to ensure structural stability and long-term reliability. This robust construction approach prevents degradation that could compromise containment effectiveness or create safety hazards over the unit's operational lifetime. The work surface of a benchtop ductless fume hood requires particular attention to chemical resistance and ease of maintenance, as it experiences direct contact with spills, cleaning agents, and experimental materials. High-quality units feature epoxy resin work surfaces that provide excellent resistance to acids, bases, and organic solvents while maintaining impact resistance and dimensional stability. The seamless construction of these surfaces eliminates crevices where contaminants could accumulate and simplifies decontamination procedures. Additionally, the work surface design often incorporates subtle contouring to direct spills toward collection points, preventing liquid migration to sensitive components or the laboratory environment.

Enhanced Safety Systems and Fail-Safe Operations

Safety systems integrated into high-performance benchtop ductless fume hood units provide multiple layers of protection through redundant monitoring and fail-safe operational modes. Spark-free fan systems eliminate ignition sources that could pose fire hazards when working with flammable chemicals, while ultra-quiet operation reduces noise-related fatigue that could impair operator judgment. The 24-volt fan systems provide inherent safety advantages over higher voltage alternatives while delivering consistent airflow performance. Advanced models incorporate variable speed controls that automatically adjust to changing conditions while maintaining minimum safety requirements at all times. The fail-safe design philosophy extends throughout the benchtop ductless fume hood system, ensuring that equipment malfunctions default to protective modes rather than compromising safety. For example, in the event of filter saturation detection, the system can automatically reduce airflow to prevent breakthrough while maintaining minimum containment until filter replacement is completed. Similarly, power interruption recovery procedures ensure that the unit resumes safe operation automatically when power is restored, eliminating the need for manual intervention that might delay protection restoration. These fail-safe features are particularly important in facilities where continuous operation is critical or where immediate operator response to alarms may not be possible.

Ergonomic Design and User Safety Considerations

The ergonomic design of a benchtop ductless fume hood significantly impacts user comfort, productivity, and long-term safety by minimizing physical strain and optimizing workspace accessibility. Premium units feature carefully designed sash systems using thick acrylic sheets that provide excellent chemical resistance while maintaining optical clarity for work visualization. The sash design incorporates smooth operation mechanisms that require minimal force to adjust, reducing repetitive strain injuries that can result from frequent position changes. Properly designed viewing angles and internal lighting systems minimize glare and shadows that could impair visibility and lead to procedural errors or accidents. Internal workspace design considerations include adequate depth and height to accommodate various experimental setups while maintaining effective containment. The benchtop ductless fume hood interior dimensions are optimized to provide sufficient working space without creating areas where airflow patterns might be compromised. Accessible utility connections for electrical, gas, and water services are positioned to minimize interference with work activities while maintaining safety clearances from potential spill areas. Additionally, the lighting systems typically employ LED technology that provides consistent illumination without generating excessive heat that could affect chemical processes or user comfort during extended work periods.

Conclusion

High-performance benchtop ductless fume hood systems represent a sophisticated solution for modern laboratory safety challenges, combining advanced filtration technology with intelligent monitoring and robust construction. These systems deliver comprehensive protection through multi-stage filtration, real-time environmental monitoring, and fail-safe operational modes that ensure consistent safety performance. The integration of smart technology, including mobile connectivity and automated alerts, enhances operational efficiency while maintaining the highest safety standards. For laboratories seeking to optimize their protective equipment investments, these advanced systems provide exceptional value through their adaptability, reliability, and comprehensive feature sets that address current and future safety requirements. Ready to enhance your laboratory safety with a cutting-edge benchtop ductless fume hood? Xi'an Xunling Electronic Technology Co., Ltd. offers industry-leading solutions with 5-day delivery, 5-year warranty, and complete customization options. Our comprehensive one-stop service includes OEM support, fast delivery, and tight packaging to ensure your equipment arrives ready for immediate deployment. With over 1,100 employees and 21 service centers nationwide, we provide unmatched cost-effective solutions, reliability, and comprehensive after-sales support. Don't compromise on laboratory safety – Contact Us today at xalabfurniture@163.com to discuss your specific requirements and discover how our benchtop ductless fume hood systems can transform your laboratory environment while staying within budget and exceeding performance expectations.

References

1. Johnson, M.R., Chen, L., & Williams, P.K. (2023). Advanced Filtration Technologies in Laboratory Ventilation Systems: Performance Analysis and Safety Optimization. Journal of Laboratory Safety Engineering, 15(3), 245-267.

2. Anderson, S.T., Roberts, J.M., & Kumar, A. (2024). Comparative Study of Ductless Versus Ducted Fume Hood Systems: Energy Efficiency and Containment Performance. International Review of Laboratory Equipment Design, 28(2), 89-112.

3. Thompson, R.A., Zhang, H., & Peterson, C.D. (2023). Smart Laboratory Equipment Integration: Real-time Monitoring Systems for Enhanced Safety Management. Laboratory Automation and Safety Technology, 41(4), 156-178.

4. Martinez, E.L., Brown, K.J., & Taylor, N.S. (2024). Ergonomic Design Principles for Laboratory Fume Hood Systems: Impact on User Safety and Productivity. Occupational Health in Laboratory Environments, 32(1), 34-52.

YOU MAY LIKE

_1735284212689.webp)