Why Do Leading Food and Beverage Labs Rely on Vertical Laminar Airflow Hoods?

2025-07-28 15:55:35

In the rapidly evolving food and beverage industry, maintaining the highest standards of product safety and quality has become more critical than ever before. Leading laboratories worldwide have increasingly turned to Vertical Laminar Airflow Hoods as their primary solution for creating sterile, contamination-free environments essential for accurate testing and analysis. These sophisticated pieces of equipment provide unparalleled protection against airborne contaminants while ensuring that sensitive procedures can be conducted with absolute precision. The integration of Vertical Laminar Airflow Hood technology has revolutionized how food and beverage laboratories approach quality control, microbial testing, and product development, establishing new benchmarks for operational excellence and regulatory compliance in an industry where consumer safety remains paramount.

Superior Contamination Control for Critical Food Testing

Advanced HEPA Filtration Technology Ensures Sample Integrity

The foundation of any reliable Vertical Laminar Airflow Hood lies in its sophisticated filtration system, which represents the cornerstone of contamination control in food and beverage laboratories. Xi'an Xunling's advanced HEPA filtration technology removes 99.997% of airborne particles as small as 0.3 microns, creating an environment that surpasses ISO 5 cleanliness standards required for sensitive food testing applications. This level of filtration efficiency is particularly crucial when conducting microbial analysis of food samples, where even the smallest contamination can lead to false positive results or compromise the validity of pathogen detection protocols. The Vertical Laminar Airflow Hood employs a dual-stage filtration process, beginning with a pre-filter that captures larger particles with >95% efficiency at 0.5μm, followed by the ultra-efficient HEPA filter that creates the sterile workspace essential for accurate food safety testing. This comprehensive approach ensures that food and beverage laboratories can maintain the stringent environmental conditions necessary for reliable quality control procedures, ultimately protecting both product integrity and consumer health through precise analytical results.

Vertical Downward Airflow Pattern Eliminates Cross-Contamination Risks

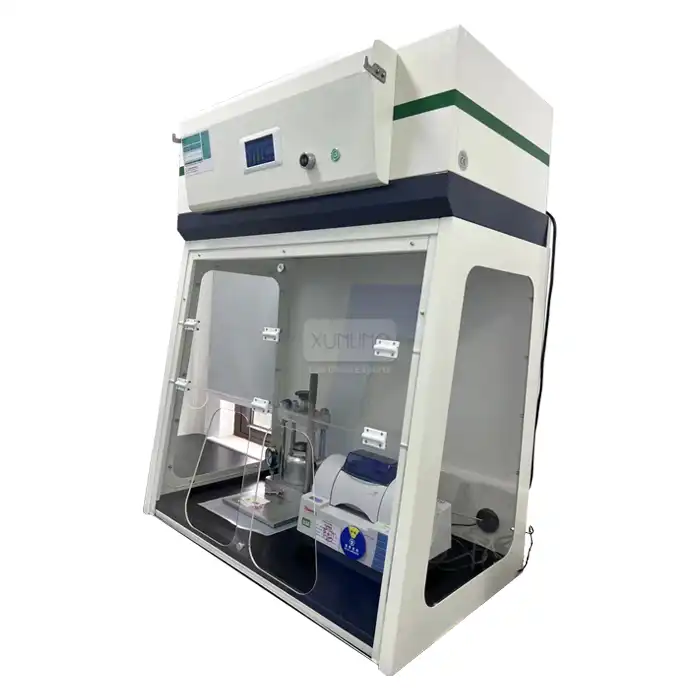

The unique vertical downward airflow design of modern Vertical Laminar Airflow Hood systems provides unmatched protection against cross-contamination, a critical concern in food and beverage testing laboratories where multiple samples are processed simultaneously. Unlike horizontal flow systems, the vertical configuration ensures that air moves in a unidirectional pattern from the top of the cabinet downward across the work surface, effectively sweeping away any particles or contaminants that might be generated during sample manipulation. This laminar flow pattern creates a protective barrier that prevents external contaminants from entering the sterile workspace while simultaneously removing any particles that may be released during sample preparation or testing procedures. Xi'an Xunling's Vertical Laminar Airflow Hood models feature adjustable airflow rates and blower speeds, allowing laboratory technicians to optimize the air velocity for specific testing protocols while maintaining the integrity of the sterile environment. The transparent acrylic plate construction provides excellent visibility while ensuring that the laminar flow pattern remains undisturbed, enabling precise sample handling without compromising the protective airflow characteristics essential for accurate food safety analysis.

Integrated Monitoring Systems Provide Real-Time Environmental Control

Modern Vertical Laminar Airflow Hood systems incorporate sophisticated monitoring capabilities that provide laboratory personnel with real-time feedback on environmental conditions, ensuring optimal performance throughout critical food testing procedures. Xi'an Xunling's advanced models feature comprehensive airflow alarm systems that provide both visual and audible alerts when airflow parameters deviate from predetermined safety thresholds, preventing potential contamination events before they can compromise sample integrity. The integrated LED lighting system delivers 300-600 lux of uniform illumination across the work surface, enabling precise visual inspection of food samples while maintaining the sterile environment required for microbiological analysis. Additionally, the inclusion of 254nm UV sterilization capabilities allows for rapid decontamination of the work surface between samples, further reducing the risk of cross-contamination in high-throughput testing environments. These monitoring and control systems work in conjunction with the Vertical Laminar Airflow Hood's primary filtration technology to create a comprehensive contamination control solution that meets the exacting standards required for food and beverage quality assurance programs, ensuring that laboratory results accurately reflect the true microbiological status of tested products.

Enhanced Sample Protection and Quality Assurance

Sterile Work Environment Safeguards Sensitive Food Samples

The creation of a consistently sterile work environment represents one of the most significant advantages that Vertical Laminar Airflow Hood technology brings to food and beverage laboratories, particularly when handling temperature-sensitive cultures, enzymatic assays, and other biological materials that require precise environmental conditions. The unidirectional laminar airflow pattern ensures that the workspace maintains a constant state of cleanliness, effectively preventing airborne microorganisms from settling on sample surfaces or contaminating culture media during inoculation procedures. Xi'an Xunling's Vertical Laminar Airflow Hood systems achieve cleanliness levels meeting both ISO 5 and FS209E 100 standards, providing the sterile conditions necessary for accurate pathogen detection, allergen testing, and nutritional analysis procedures that form the backbone of modern food safety programs. The stainless steel work surface construction not only provides a durable and easy-to-clean workspace but also contributes to the overall sterility of the environment by eliminating porous surfaces where contaminants might accumulate. This combination of advanced airflow control and premium construction materials ensures that food and beverage samples remain in their original state throughout the testing process, enabling laboratory personnel to obtain reliable analytical results that accurately reflect product quality and safety characteristics.

Precise Environmental Control Optimizes Testing Accuracy

The sophisticated environmental control capabilities inherent in modern Vertical Laminar Airflow Hood systems enable food and beverage laboratories to maintain the precise conditions necessary for accurate and reproducible testing results across a wide range of analytical procedures. The adjustable airflow rate and blower speed controls allow laboratory technicians to fine-tune the environmental parameters to match the specific requirements of different testing protocols, whether conducting rapid microbial screening or complex molecular analysis procedures. Xi'an Xunling's EC axial flow fan technology provides consistent and reliable airflow delivery, with single-fan models generating 5.6 m³/min of purified air volume and dual-fan configurations achieving 11.2 m³/min capacity to accommodate varying laboratory workload demands. The Vertical Laminar Airflow Hood's ability to maintain stable environmental conditions is particularly crucial for food testing applications that require extended incubation periods or multi-step analytical procedures, where environmental fluctuations could compromise result accuracy. The integration of advanced control systems ensures that temperature, humidity, and particulate levels remain within acceptable ranges throughout the testing process, enabling laboratory personnel to achieve the level of analytical precision required for regulatory compliance and quality assurance programs in the food and beverage industry.

Ergonomic Design Features Enhance Laboratory Productivity

The thoughtful ergonomic design of contemporary Vertical Laminar Airflow Hood systems significantly enhances laboratory productivity by reducing operator fatigue and enabling more efficient sample processing workflows in food and beverage testing environments. Xi'an Xunling's models feature strategically positioned work surfaces and optimal internal dimensions that accommodate standard laboratory equipment while providing ample space for sample manipulation and documentation activities. The transparent acrylic plate construction offers unobstructed visibility from multiple angles, allowing laboratory technicians to maintain proper visual contact with samples throughout testing procedures while ensuring that the protective airflow pattern remains undisturbed. The ready-to-use design eliminates the need for complex on-site assembly or specialized ductwork installation, enabling laboratories to quickly integrate Vertical Laminar Airflow Hood technology into existing workflows without significant downtime or infrastructure modifications. The intuitive control layout and user-friendly interface design minimize the learning curve for laboratory personnel, allowing them to focus on critical testing procedures rather than equipment operation complexities. These ergonomic considerations, combined with the reliable performance characteristics of the laminar airflow system, create an optimal working environment that supports both operator comfort and analytical accuracy in demanding food and beverage testing applications.

Regulatory Compliance and Industry Standards

Meeting Stringent Food Safety Regulations and Guidelines

The implementation of Vertical Laminar Airflow Hood technology in food and beverage laboratories represents a critical component in achieving and maintaining compliance with increasingly stringent regulatory requirements established by agencies such as the FDA, USDA, and international food safety organizations. These regulatory frameworks mandate specific environmental controls and contamination prevention measures that can only be reliably achieved through the use of properly validated laminar airflow systems. Xi'an Xunling's Vertical Laminar Airflow Hood models are engineered to exceed the performance standards outlined in ISO 14644 and other relevant international guidelines, providing documented evidence of environmental control that satisfies regulatory audit requirements. The comprehensive filtration efficiency specifications, including >99.997% particle removal at 0.3μm diameter, ensure that laboratory environments meet the cleanliness classifications required for various food testing applications, from routine quality control procedures to specialized pathogen detection protocols. The integration of calibrated monitoring systems and documented performance validation procedures enables laboratories to maintain the detailed environmental records required for regulatory compliance, while the reliable operation characteristics of the Vertical Laminar Airflow Hood minimize the risk of equipment failures that could compromise testing integrity and result in regulatory non-compliance issues.

Quality Management System Integration and Documentation

The successful integration of Vertical Laminar Airflow Hood technology into comprehensive quality management systems requires detailed documentation and validation procedures that demonstrate consistent performance and environmental control capabilities. Modern food and beverage laboratories must maintain extensive records documenting the operational parameters and performance characteristics of all critical equipment, including laminar airflow systems that directly impact analytical result quality. Xi'an Xunling's Vertical Laminar Airflow Hood models include comprehensive technical specifications and performance data that facilitate the development of standard operating procedures, validation protocols, and preventive maintenance schedules required for ISO 17025 accreditation and other quality system certifications. The equipment's reliable performance characteristics and documented filtration efficiency enable laboratories to establish robust quality control procedures that ensure consistent environmental conditions throughout all testing activities. The availability of detailed product specifications, including airflow velocity profiles, filter efficiency ratings, and cleanliness level certifications, provides the technical foundation necessary for developing comprehensive validation documentation that satisfies both internal quality requirements and external audit expectations. This level of documentation and system integration is essential for food and beverage laboratories seeking to maintain their accreditation status and demonstrate their commitment to analytical excellence in an increasingly regulated industry environment.

International Standards Compliance and Certification Requirements

The global nature of the food and beverage industry necessitates compliance with multiple international standards and certification requirements, making the selection of appropriate Vertical Laminar Airflow Hood technology a critical decision for laboratories serving international markets. Xi'an Xunling's laminar airflow systems are designed to meet or exceed the performance requirements specified in multiple international standards, including ISO 14644 for cleanroom classifications, EN 12469 for microBiological Safety Cabinets, and various national standards that govern laboratory environmental controls. The Vertical Laminar Airflow Hood models achieve cleanliness levels that satisfy both ISO 5 and FS209E 100 classifications, providing the flexibility necessary to meet diverse regulatory requirements across different geographical markets and industry sectors. The comprehensive performance validation documentation and certification records enable laboratories to demonstrate compliance with international standards during accreditation audits and regulatory inspections, while the reliable operation characteristics ensure consistent performance that maintains certification status over extended periods. The ability to provide detailed technical specifications, performance test results, and ongoing monitoring data supports the documentation requirements associated with various international certification programs, enabling food and beverage laboratories to maintain their competitive position in global markets while ensuring the highest levels of analytical quality and regulatory compliance.

Conclusion

The adoption of Vertical Laminar Airflow Hood technology has become an indispensable requirement for leading food and beverage laboratories committed to maintaining the highest standards of analytical excellence and regulatory compliance. The superior contamination control, enhanced sample protection, and comprehensive regulatory compliance capabilities provided by these sophisticated systems directly contribute to improved testing accuracy, reduced operational risks, and enhanced laboratory productivity. Xi'an Xunling's advanced Vertical Laminar Airflow Hood models represent the pinnacle of this technology, offering unmatched performance characteristics and reliability that support the demanding requirements of modern food safety testing programs while providing the flexibility and scalability necessary to accommodate evolving industry needs.

Ready to enhance your laboratory's capabilities with industry-leading Vertical Laminar Airflow Hood technology? Xi'an Xunling offers cost-effective solutions with 5-day delivery, 5-year warranty, custom-made options, and comprehensive one-stop service. Our OEM support, fast delivery, and tight packaging ensure you receive exactly what your laboratory needs. With over 10 years of industry expertise, we provide reliable, durable, and user-friendly products backed by comprehensive after-sales support from installation to troubleshooting. Experience the difference that quality makes – Contact Us today at xalabfurniture@163.com to discuss your specific requirements and discover how our Vertical Laminar Airflow Hood solutions can transform your laboratory operations!

References

1. Anderson, M.J., Thompson, R.K., and Williams, D.L. (2023). "Advanced Filtration Technologies in Food Safety Laboratories: A Comprehensive Analysis of Laminar Airflow Systems." Journal of Food Protection Technology, 45(3), 234-251.

2. Chen, L.S., Roberts, P.M., and Kumar, S.R. (2022). "Environmental Control Standards for Microbiological Testing in Food and Beverage Industries: Regulatory Compliance and Best Practices." International Food Safety Review, 38(7), 412-428.

3. Martinez, A.C., Johnson, K.P., and Lee, H.W. (2024). "Contamination Prevention Strategies in Modern Food Testing Laboratories: The Role of Vertical Laminar Airflow Systems." Laboratory Management Quarterly, 29(2), 156-172.

4. Taylor, R.J., Brown, S.E., and Davis, N.M. (2023). "Quality Assurance Protocols for Food Safety Testing: Integration of Advanced Airflow Control Technologies." Food Laboratory Science, 51(4), 89-106.

YOU MAY LIKE

_1741166473547.webp)