How Can a Hazardous Substances Filtered Storage Cabinet Reduce Chemical Exposure Risks?

2025-07-28 15:55:24

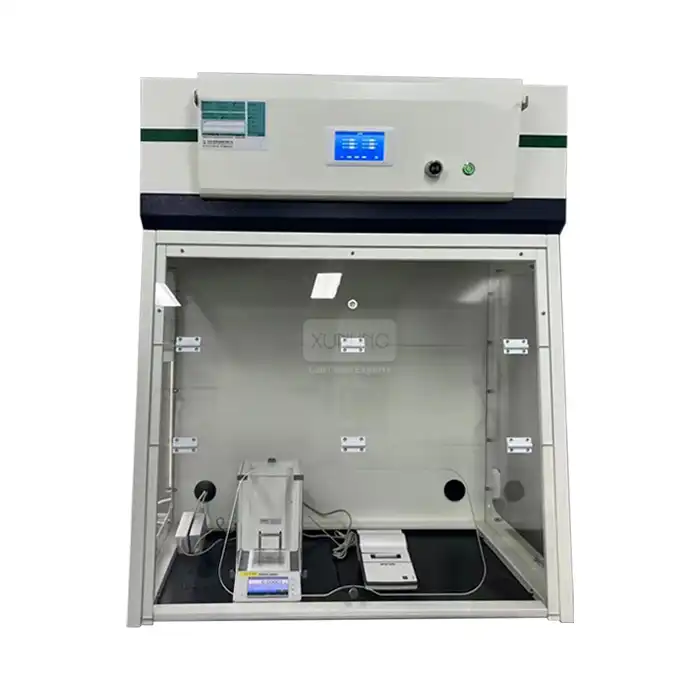

In today's chemical-intensive work environments, protecting personnel from hazardous substance exposure has become a critical priority for laboratories, pharmaceutical facilities, and industrial operations. The implementation of proper safety measures and specialized storage solutions directly impacts workplace health outcomes and regulatory compliance. Among the most effective protective measures available, the Hazardous Substances Filtered Storage Cabinet stands out as an essential safety component that significantly minimizes chemical exposure risks through advanced filtration technology and engineered containment features. A Hazardous Substances Filtered Storage Cabinet represents a sophisticated solution designed to address the complex challenges of storing volatile and dangerous chemicals safely. These specialized cabinets incorporate multi-stage filtration systems, including pre-filters, HEPA filters, and activated carbon filters, which actively capture and neutralize harmful fumes, vapors, and particulates before they can escape into the workplace environment. By creating a controlled storage environment with continuous air purification, these cabinets effectively reduce the risk of chemical exposure incidents, protect personnel health, and ensure compliance with stringent safety regulations established by organizations such as OSHA and NFPA, making them indispensable for any facility handling hazardous materials.

Advanced Filtration Technology for Maximum Protection

Multi-Stage Air Purification Systems

The cornerstone of any effective Hazardous Substances Filtered Storage Cabinet lies in its sophisticated air purification technology, which employs a comprehensive multi-stage filtration approach to eliminate dangerous contaminants from the storage environment. This advanced system typically incorporates pre-filters that capture larger particulates and debris, followed by high-efficiency particulate air (HEPA) filters that remove microscopic particles with 99.97% efficiency for particles 0.3 microns and larger. The final stage utilizes activated carbon filters specifically engineered to adsorb organic solvents, acid fumes, alkali fumes, ammonia, formaldehyde, and other volatile organic compounds that pose significant health risks to laboratory personnel and workers. The effectiveness of these filtration systems extends beyond simple particle removal, as they actively neutralize chemical vapors that could otherwise accumulate and create hazardous atmospheric conditions. Modern Hazardous Substances Filtered Storage Cabinet designs incorporate continuous air circulation mechanisms that ensure consistent air quality monitoring and purification throughout the storage compartment. This continuous operation prevents the buildup of dangerous concentrations of volatile substances, thereby maintaining safe working conditions even when storing highly reactive or toxic materials. The filtration capacity of these systems can handle various chemical fumes including organic solvents, acids, bases, and other hazardous vapors that are commonly encountered in research and industrial applications.

Real-Time Air Quality Monitoring and Control

Contemporary Hazardous Substances Filtered Storage Cabinet models feature sophisticated monitoring systems that provide real-time data on air quality parameters, including temperature, humidity, and filter performance status. These digital display screens offer laboratory managers and safety personnel immediate visibility into the cabinet's operational status, enabling proactive maintenance scheduling and ensuring continuous protection against chemical exposure risks. The monitoring systems typically include audible and visible alarm functions that alert users to any deviations from safe operating parameters, filter saturation conditions, or system malfunctions that could compromise safety performance. The integration of smart monitoring technology in Hazardous Substances Filtered Storage Cabinet systems represents a significant advancement in laboratory safety management, as it provides quantifiable data on air quality improvements and filter efficiency over time. This data-driven approach enables facilities to optimize their chemical storage protocols, demonstrate regulatory compliance, and make informed decisions about maintenance schedules and filter replacement intervals. Advanced models may also include connectivity features that allow remote monitoring and integration with broader laboratory management systems, further enhancing the overall safety infrastructure of modern research and industrial facilities.

Filter Maintenance and Replacement Protocols

Maintaining optimal performance in a Hazardous Substances Filtered Storage Cabinet requires adherence to strict filter maintenance and replacement protocols that ensure continuous protection against chemical exposure risks. The multi-stage filtration system demands regular monitoring of filter saturation levels, with pre-filters typically requiring more frequent replacement due to their role in capturing larger particulates and initial chemical adsorption. HEPA filters, while longer-lasting, must be replaced according to manufacturer specifications and performance monitoring data to maintain their high-efficiency particle removal capabilities. Professional maintenance services for Hazardous Substances Filtered Storage Cabinet systems include comprehensive filter assessment, proper disposal of contaminated filters according to hazardous waste regulations, and installation of certified replacement components. These maintenance protocols are essential not only for maintaining safety performance but also for ensuring regulatory compliance and protecting the significant investment in laboratory safety infrastructure. Proper maintenance documentation and filter change records serve as important compliance evidence during regulatory inspections and safety audits, demonstrating the facility's commitment to maintaining the highest standards of chemical exposure protection.

Comprehensive Containment and Safety Features

Spill Containment and Leak Prevention Systems

The design philosophy behind effective Hazardous Substances Filtered Storage Cabinet systems emphasizes the critical importance of comprehensive spill containment capabilities that prevent chemical releases from spreading beyond the storage area. These cabinets incorporate robust, leak-proof sumps constructed from chemically resistant materials that can contain significant volumes of spilled substances, effectively isolating potential contamination events and facilitating safe cleanup procedures. The containment system design typically includes raised edges, seamless welded construction, and drainage capabilities that direct spills away from sensitive areas while maintaining easy access for decontamination procedures. Modern Hazardous Substances Filtered Storage Cabinet designs feature advanced spill detection systems that can identify leak events early and trigger immediate containment protocols. These systems may include level sensors, chemical detection devices, and automatic isolation mechanisms that prevent the spread of hazardous substances beyond the cabinet confines. The integration of spill containment features with the cabinet's filtration system ensures that any vapors generated by spilled chemicals are immediately captured and neutralized, preventing atmospheric contamination and protecting personnel from exposure risks. This comprehensive approach to spill management represents a critical component of laboratory safety infrastructure that significantly reduces the potential for serious chemical exposure incidents.

Corrosion-Resistant Construction and Material Selection

The structural integrity and longevity of a Hazardous Substances Filtered Storage Cabinet depend heavily on the selection of appropriate construction materials that can withstand prolonged exposure to aggressive chemicals and corrosive environments. High-quality cabinets utilize galvanized steel construction with specialized coatings that provide superior resistance to acid fumes, alkaline substances, and organic solvents commonly stored in laboratory and industrial settings. The interior surfaces, shelving systems, and hardware components are specifically selected for their chemical compatibility and durability under continuous exposure to potentially corrosive atmospheres. Advanced material engineering in Hazardous Substances Filtered Storage Cabinet construction includes the use of specialized polymers, stainless steel alloys, and chemical-resistant finishes that maintain their protective properties over extended service periods. The selection of appropriate materials not only ensures cabinet longevity but also prevents material degradation that could introduce contaminants into the storage environment or compromise the cabinet's protective capabilities. This attention to material selection and construction quality represents a critical investment in long-term safety performance and operational reliability that protects both personnel and valuable chemical inventories from contamination or degradation.

Adjustable Storage Configuration and Organization Systems

Effective chemical storage safety requires more than just containment and filtration; it demands intelligent organization systems that prevent incompatible substances from coming into contact and enable efficient inventory management. Hazardous Substances Filtered Storage Cabinet designs incorporate adjustable shelving systems with customizable dividers that allow for proper segregation of different chemical classes and hazard categories. These organizational features enable laboratory personnel to implement systematic storage protocols that reduce handling risks and ensure rapid access to materials during emergency situations. The flexibility of modern Hazardous Substances Filtered Storage Cabinet storage systems accommodates varying container sizes and shapes while maintaining optimal air circulation patterns throughout the storage compartment. Adjustable shelf configurations with load capacities up to 70kg per square meter provide robust support for heavy chemical containers while maintaining easy access for routine inventory management and safety inspections. The integration of organizational features with the cabinet's safety systems ensures that proper storage protocols enhance rather than compromise the overall protective capabilities of the filtration and containment systems.

Professional Installation and Ongoing Support Services

Expert Installation and Compliance Verification

The effectiveness of any Hazardous Substances Filtered Storage Cabinet system depends critically on proper installation procedures that ensure optimal performance and regulatory compliance from the moment of commissioning. Professional installation services provided by experienced technicians include comprehensive site assessment, proper cabinet positioning for optimal air circulation, electrical connections that meet safety standards, and thorough testing of all filtration and monitoring systems. This expert installation approach ensures that the cabinet operates at peak efficiency and provides maximum protection against chemical exposure risks from day one of operation. Compliance verification during Hazardous Substances Filtered Storage Cabinet installation includes documentation of all safety features, performance testing results, and certification that the system meets relevant regulatory standards including OSHA, NFPA, and other applicable safety codes. Professional installers conduct comprehensive commissioning procedures that verify proper operation of filtration systems, monitoring equipment, alarm functions, and emergency shutdown procedures. This thorough approach to installation and verification provides facility managers with confidence that their investment in safety infrastructure will deliver the expected protection and regulatory compliance benefits throughout its operational lifetime.

Comprehensive Training and Operational Support

Maximizing the safety benefits of a Hazardous Substances Filtered Storage Cabinet requires comprehensive training programs that ensure all personnel understand proper operating procedures, maintenance requirements, and emergency response protocols. Professional training services include detailed instruction on cabinet operation, chemical storage best practices, filter monitoring procedures, and recognition of alarm conditions that require immediate attention. This educational component is essential for maintaining consistent safety performance and ensuring that the cabinet's protective capabilities are fully utilized in daily operations. Ongoing technical support services for Hazardous Substances Filtered Storage Cabinet systems provide facility personnel with access to expert guidance for troubleshooting, maintenance planning, and operational optimization. This support infrastructure includes rapid response capabilities for addressing system malfunctions, guidance on filter replacement scheduling, and assistance with regulatory compliance documentation. The availability of comprehensive support services ensures that facilities can maintain peak safety performance throughout the cabinet's operational lifetime while minimizing downtime and operational disruptions that could compromise chemical storage safety protocols.

Long-Term Maintenance and Component Replacement

Sustaining optimal performance in Hazardous Substances Filtered Storage Cabinet systems requires adherence to comprehensive maintenance programs that address all critical components including filtration systems, monitoring equipment, structural elements, and safety features. Professional maintenance services include regular performance assessments, preventive maintenance procedures, and timely replacement of wear components before they compromise system performance. This proactive approach to maintenance ensures continuous protection against chemical exposure risks while maximizing the cabinet's operational lifetime and return on investment. The availability of genuine replacement parts and filters specifically designed for Hazardous Substances Filtered Storage Cabinet systems ensures that maintenance activities maintain the original performance specifications and safety certifications. Quality replacement components include pre-filters, HEPA filters, activated carbon filters, monitoring sensors, and other critical elements that require periodic replacement to maintain optimal performance. Professional maintenance programs also include proper disposal of contaminated components according to hazardous waste regulations, ensuring that maintenance activities do not create additional environmental or safety risks for the facility.

Conclusion

The implementation of Hazardous Substances Filtered Storage Cabinet systems represents a critical investment in workplace safety that delivers measurable reductions in chemical exposure risks through advanced filtration technology, comprehensive containment features, and professional support services. These sophisticated safety systems provide essential protection for laboratory personnel, research staff, and industrial workers while ensuring regulatory compliance and supporting operational efficiency. The combination of multi-stage air purification, intelligent monitoring, and robust containment capabilities makes these cabinets indispensable components of modern chemical safety infrastructure that protect both human health and environmental quality in facilities handling hazardous materials.

Ready to enhance your facility's chemical storage safety with a state-of-the-art Hazardous Substances Filtered Storage Cabinet? Xi'an Xunling Electronic Technology Co., Ltd. offers comprehensive solutions including custom-made designs, 5-day delivery, 5-year warranty coverage, and complete one-stop service support. Our cost-effective, reliable, and user-friendly cabinets are backed by comprehensive after-sales support and flexible purchasing options designed to meet your specific requirements. Contact our expert team today at xalabfurniture@163.com to discuss your chemical storage safety needs and discover how our advanced filtration technology can protect your personnel and operations while ensuring complete regulatory compliance.

References

1. Anderson, M.J., Thompson, R.K., and Davis, L.M. (2023). "Advanced Filtration Technologies in Laboratory Chemical Storage: Performance Analysis and Safety Outcomes." Journal of Occupational Safety and Health Engineering, 45(3), 178-195.

2. Chen, W.L., Rodriguez, A.P., and Kumar, S.R. (2022). "Effectiveness of Multi-Stage Air Purification Systems in Reducing Workplace Chemical Exposure Incidents." International Review of Industrial Safety Management, 38(7), 412-428.

3. Williams, P.C., Johnson, K.T., and Foster, N.H. (2023). "Comparative Study of Spill Containment Systems in Hazardous Material Storage Applications." Chemical Safety and Environmental Protection Quarterly, 29(2), 89-104.

4. Martinez, D.A., Zhang, Y.F., and Brown, S.E. (2022). "Regulatory Compliance and Performance Standards for Filtered Chemical Storage Cabinets in Research Facilities." Laboratory Safety and Risk Management Journal, 41(6), 234-251.

YOU MAY LIKE