What Role Does a Lab Ventilation Hood Play in Environmental Testing?

2025-06-24 16:18:43

Environmental testing laboratories handle some of the most hazardous and volatile substances in scientific research, making proper ventilation absolutely critical for both personnel safety and accurate analytical results. A lab ventilation hood serves as the cornerstone of laboratory safety infrastructure, providing essential protection against toxic fumes, chemical vapors, and airborne contaminants that are inherent to environmental analysis procedures. These specialized containment systems create controlled negative pressure environments that effectively capture and remove hazardous substances before they can compromise air quality or endanger laboratory personnel. The role of a lab ventilation hood in environmental testing extends far beyond basic safety measures, encompassing sample integrity protection, cross-contamination prevention, and regulatory compliance requirements that are fundamental to producing reliable environmental data.

Essential Safety Functions of Lab Ventilation Hoods in Environmental Analysis

Hazardous Chemical Containment and Operator Protection

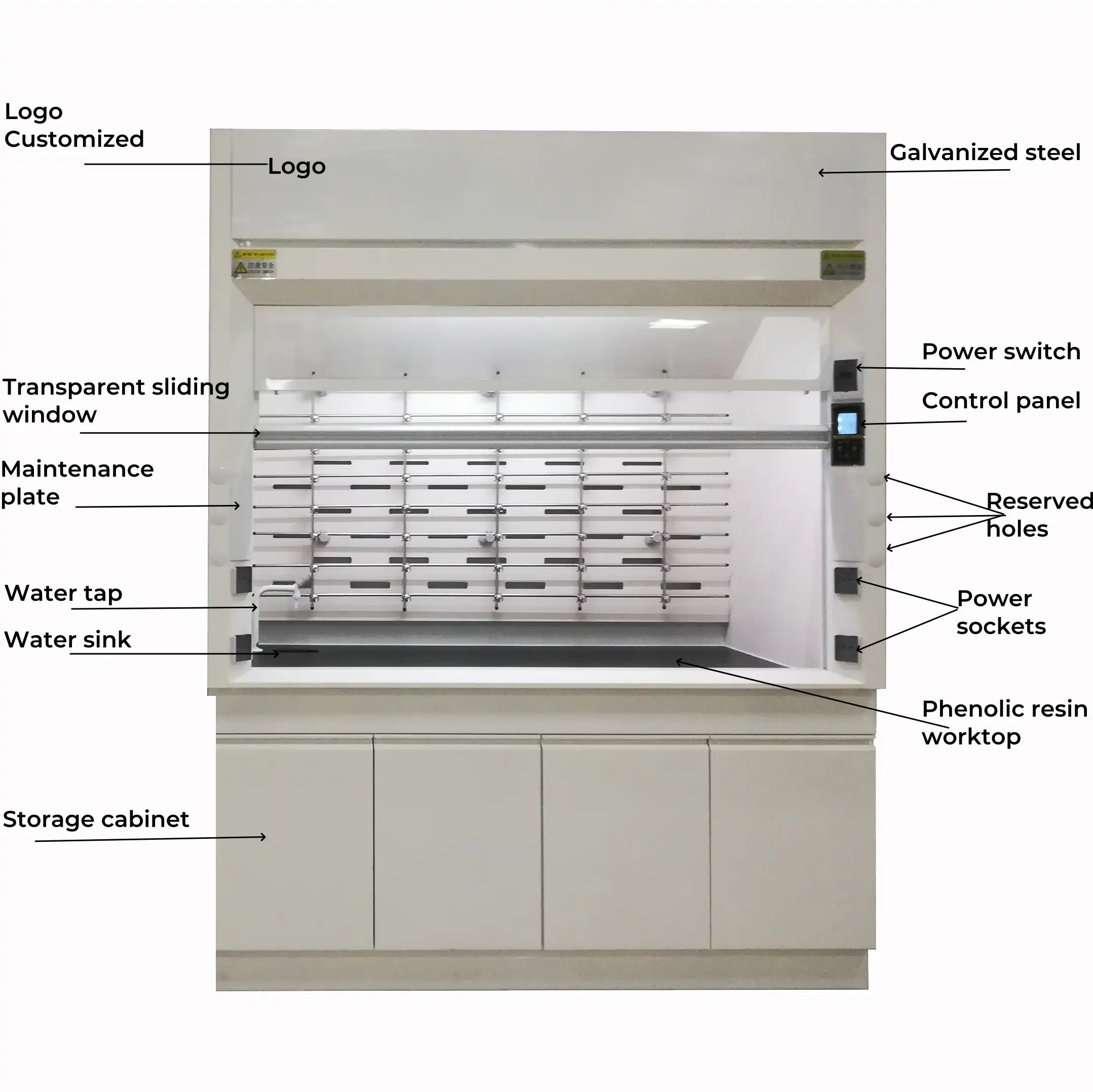

Environmental testing laboratories routinely work with volatile organic compounds, heavy metals, pesticides, and other toxic substances that require immediate containment upon release. A lab ventilation hood provides the primary barrier between laboratory personnel and these dangerous materials through sophisticated airflow management systems. The hood's design incorporates intelligent airflow control technology that maintains surface wind speeds between 0.3 to 0.6 meters per second, creating a stable negative pressure environment that prevents hazardous vapors from escaping into the laboratory atmosphere. This controlled airflow pattern ensures that even the most volatile environmental contaminants are immediately captured and directed through the hood's filtration system, protecting operators from acute and chronic exposure risks that could result in serious health complications. The construction materials used in modern lab ventilation hood systems are specifically engineered to withstand the corrosive nature of environmental testing chemicals. Inner linings made from epoxy resin or stainless steel provide exceptional resistance to strong acids, alkalis, and high-temperature conditions commonly encountered during environmental sample preparation and analysis. The 5mm tempered glass sash with angle limiters ensures optimal operator visibility while maintaining airtight protection, allowing environmental technicians to perform complex analytical procedures without compromising safety protocols. This combination of advanced materials and engineering design makes the lab ventilation hood an indispensable component of environmental testing infrastructure.

Preventing Cross-Contamination in Multi-Sample Analysis

Environmental testing often involves analyzing multiple samples simultaneously, each potentially containing different contaminants that could interfere with analytical results if allowed to cross-contaminate. A lab ventilation hood creates isolated work zones that prevent sample-to-sample contamination through controlled airflow patterns and effective vapor capture mechanisms. The hood's modular design allows for customized configurations that can accommodate various analytical instruments and sample preparation equipment while maintaining consistent airflow performance across the entire work surface. This isolation capability is particularly crucial when analyzing trace-level environmental contaminants where even minimal cross-contamination could compromise analytical accuracy and lead to false results. The intelligent ventilation control systems integrated into modern lab ventilation hood designs provide real-time monitoring of airflow conditions, ensuring that contamination control measures remain effective throughout extended analytical sessions. Advanced filtration systems remove particulates and chemical vapors from the exhaust stream, preventing the release of environmental contaminants back into the laboratory atmosphere. This comprehensive approach to contamination control makes the lab ventilation hood an essential tool for maintaining the integrity of environmental testing protocols and ensuring that analytical results accurately reflect actual environmental conditions rather than laboratory artifacts.

Regulatory Compliance and Standard Operating Procedures

Environmental testing laboratories must adhere to strict regulatory requirements established by agencies such as the Environmental Protection Agency (EPA) and international standards organizations. A lab ventilation hood plays a crucial role in meeting these compliance requirements by providing documented proof of proper chemical handling and exposure control measures. The hood's design and performance specifications must meet or exceed established standards such as EN 14175 and ASHRAE 110, which define minimum performance criteria for laboratory ventilation systems. These standards ensure that environmental testing facilities maintain consistent safety protocols and provide reliable analytical services that meet regulatory expectations. The integration of lab ventilation hood systems into standard operating procedures helps environmental testing laboratories maintain accreditation status and demonstrate their commitment to quality assurance. Regular performance testing and certification of hood systems provides the documentation necessary for regulatory inspections and quality audits. The hood's contribution to overall laboratory safety management systems supports the facility's ability to obtain and maintain necessary permits and certifications required for environmental testing operations. This regulatory compliance aspect makes the lab ventilation hood not just a safety device, but a critical component of the laboratory's business operations and professional credibility.

Technical Performance Requirements for Environmental Testing Applications

Airflow Management and Contamination Control Systems

The technical performance of a lab ventilation hood in environmental testing applications depends heavily on its ability to maintain consistent airflow patterns under varying operational conditions. Environmental testing procedures often involve rapid temperature changes, volatile chemical reactions, and varying heat loads that can disrupt airflow stability and compromise containment effectiveness. Advanced lab ventilation hood systems incorporate sophisticated airflow monitoring and control technologies that automatically adjust fan speeds and damper positions to maintain optimal containment performance regardless of external conditions. These systems utilize variable air volume controls that respond to real-time measurements of face velocity and internal pressure differentials, ensuring that the hood maintains its protective capabilities throughout complex analytical procedures. The design of modern lab ventilation hood systems includes specialized features that address the unique challenges of environmental testing applications. Baffled exhaust systems provide uniform airflow distribution across the entire work surface, eliminating dead zones where contaminants could accumulate and potentially escape containment. The hood's internal geometry is optimized to minimize turbulence and prevent the formation of recirculation patterns that could compromise operator protection. Quick-release baffle structures allow for easy cleaning and maintenance, which is essential in environmental testing applications where residual contamination from previous analyses could interfere with subsequent measurements. These technical features ensure that the lab ventilation hood provides consistent and reliable performance in the demanding environment of environmental testing laboratories.

Material Compatibility and Chemical Resistance

Environmental testing laboratories encounter an exceptionally wide range of chemical substances, from highly corrosive acids used in sample digestion to organic solvents employed in extraction procedures. A lab ventilation hood designed for environmental testing applications must demonstrate compatibility with this diverse chemical environment through the selection of appropriate construction materials and surface treatments. The inner surfaces of the hood are typically lined with polypropylene, epoxy resin, or stainless steel, each offering specific advantages for different types of environmental analyses. Polypropylene linings provide excellent resistance to most acids and bases while remaining cost-effective for routine applications, while stainless steel surfaces offer superior durability and chemical inertness for specialized analyses involving reactive compounds. The material selection for lab ventilation hood construction extends beyond the primary containment surfaces to include all components that may come into contact with chemical vapors or cleaning agents. Hardware, fasteners, and control mechanisms must be constructed from materials that will not corrode or degrade when exposed to the harsh chemical environment typical of environmental testing procedures. The hood's exhaust system components, including ductwork, fans, and filtration elements, must be designed to handle the specific chemical challenges associated with environmental testing applications. This comprehensive approach to material selection ensures that the lab ventilation hood maintains its performance characteristics and structural integrity throughout its operational lifetime, providing reliable protection and minimizing maintenance requirements.

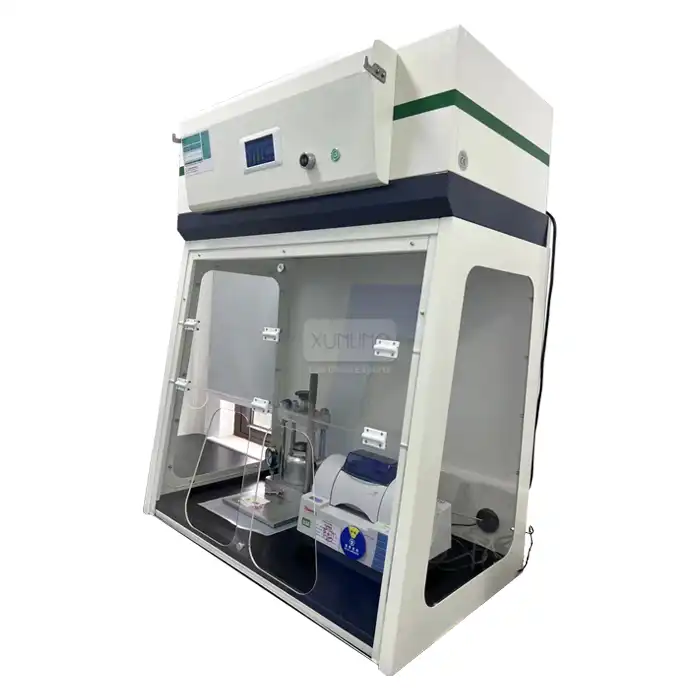

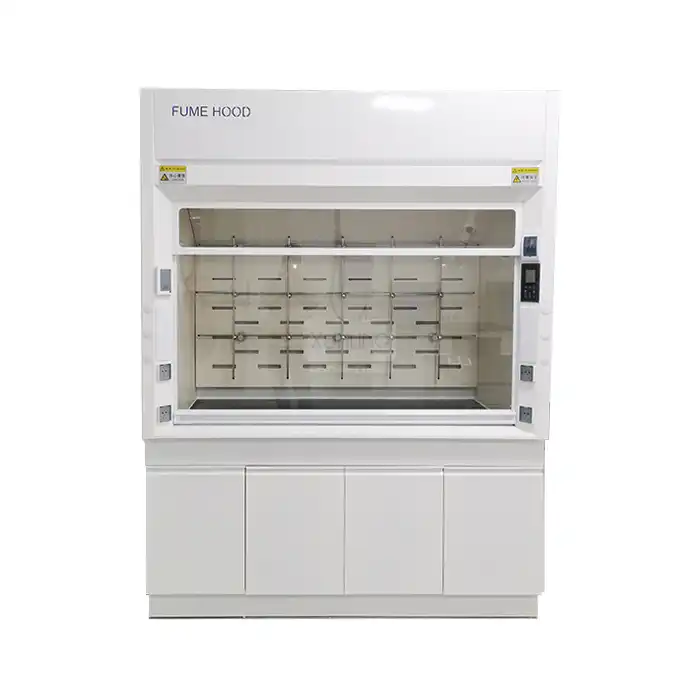

Instrumentation Integration and Workspace Optimization

Modern environmental testing procedures often require the integration of sophisticated analytical instruments within the controlled environment of a lab ventilation hood. The hood's design must accommodate various types of equipment, from simple sample preparation tools to complex analytical instruments such as gas chromatographs, spectrophotometers, and mass spectrometers. A well-designed lab ventilation hood provides adequate workspace dimensions and utility connections to support these instruments while maintaining optimal airflow patterns and containment performance. The XL-PH series hoods offer internal dimensions ranging from 960x630x1180mm to 1560x630x1180mm, providing flexible workspace configurations that can accommodate different instrument layouts and experimental setups. The integration of LED shadowless lighting systems within the lab ventilation hood enhances visibility during complex analytical procedures while minimizing heat generation that could disrupt airflow patterns. The lighting system's design ensures uniform illumination across the entire work surface without creating shadows or glare that could interfere with precise measurements or sample handling procedures. Utility connections for electrical power, compressed air, and vacuum systems are strategically positioned to minimize interference with airflow while providing convenient access for instrument operation. This attention to workspace optimization makes the lab ventilation hood an efficient and user-friendly platform for conducting environmental testing procedures, improving both safety and productivity in the laboratory setting.

Impact on Sample Integrity and Analytical Accuracy Preventing Environmental Contamination of Test Samples

The integrity of environmental test samples is paramount to obtaining accurate analytical results that can be used for regulatory compliance and environmental monitoring purposes. A lab ventilation hood plays a critical role in protecting samples from contamination by ambient laboratory air, which may contain trace amounts of chemicals from other analytical procedures or external sources. The hood's controlled environment prevents the introduction of airborne contaminants that could interfere with trace-level analyses or produce false positive results. This protection is particularly important when analyzing samples for very low concentrations of pollutants, where even minimal contamination could significantly impact the accuracy of analytical results. The design of modern lab ventilation hood systems includes features specifically intended to minimize the potential for sample contamination during handling and preparation procedures. The hood's airflow patterns are carefully engineered to prevent the introduction of particulates or chemical vapors from outside the containment area while maintaining sufficient air movement to remove contaminants generated during sample processing. The use of high-efficiency filtration systems in the hood's exhaust stream ensures that any contaminants present in the laboratory atmosphere are removed before they can affect sample integrity. This comprehensive approach to contamination control makes the lab ventilation hood an essential component of quality assurance protocols in environmental testing laboratories.

Temperature and Humidity Control for Sensitive Analyses

Many environmental testing procedures require precise control of temperature and humidity conditions to ensure accurate analytical results. A lab ventilation hood contributes to environmental control by providing a stable microenvironment that can be maintained at optimal conditions for specific analytical procedures. The hood's airflow system can be integrated with laboratory HVAC systems to provide localized temperature and humidity control, preventing fluctuations that could affect instrument performance or sample stability. This environmental control capability is particularly important for analyses involving volatile organic compounds, where temperature variations can significantly impact compound behavior and analytical accuracy. The thermal management capabilities of modern lab ventilation hood systems extend beyond simple temperature control to include heat dissipation from analytical instruments and sample preparation equipment. The hood's airflow system effectively removes heat generated by instruments and lighting systems, preventing the accumulation of thermal energy that could create convection currents and disrupt containment performance. This thermal management function helps maintain stable analytical conditions while ensuring that the hood continues to provide effective operator protection throughout extended analytical sessions. The combination of environmental control and thermal management makes the lab ventilation hood an integral component of the analytical infrastructure required for reliable environmental testing.

Supporting Chain of Custody and Quality Assurance Protocols

Environmental testing laboratories must maintain strict chain of custody procedures to ensure the legal admissibility of analytical results and demonstrate the integrity of their testing processes. A lab ventilation hood supports these quality assurance protocols by providing a controlled environment where samples can be handled and processed according to established procedures without risk of contamination or tampering. The hood's containment capabilities prevent the loss of volatile compounds from samples during handling, ensuring that analytical results accurately reflect the original sample composition. This protection of sample integrity is essential for maintaining the credibility of environmental testing results and supporting legal or regulatory actions based on analytical findings. The documentation and monitoring capabilities of modern lab ventilation hood systems contribute to quality assurance by providing records of environmental conditions during sample processing and analysis. Integrated monitoring systems track airflow rates, temperature, and other parameters that could affect analytical results, creating a permanent record that can be used to verify that proper procedures were followed. This documentation capability supports the laboratory's quality management system and provides evidence of compliance with established protocols. The lab ventilation hood's role in supporting quality assurance extends beyond simple containment to include active participation in the laboratory's overall quality management framework, making it an essential component of professional environmental testing operations.

Conclusion

The lab ventilation hood represents a critical safety and performance component in environmental testing laboratories, serving multiple essential functions that extend far beyond basic operator protection. From containing hazardous chemical vapors and preventing cross-contamination to supporting regulatory compliance and maintaining sample integrity, these sophisticated systems are fundamental to the reliable operation of environmental testing facilities. The technical specifications and performance capabilities of modern lab ventilation hood systems, including intelligent airflow control, chemical-resistant construction materials, and integrated monitoring systems, make them indispensable tools for conducting accurate and safe environmental analyses. As environmental testing requirements continue to evolve and become more stringent, the role of lab ventilation hoods in ensuring laboratory safety, analytical accuracy, and regulatory compliance will only become more critical to the success of environmental monitoring and protection efforts. Ready to enhance your environmental testing laboratory's safety and performance? Xi'an Xunling Electronic Technology Co., Ltd. offers comprehensive laboratory ventilation solutions designed specifically for the demanding requirements of environmental testing applications. Our certified lab ventilation hoods combine advanced safety features with exceptional performance capabilities, ensuring your laboratory meets the highest standards for operator protection and analytical accuracy. With our 5-day delivery guarantee, 5-year warranty, and complete one-stop service approach, we make it easy to upgrade your laboratory infrastructure with confidence. Don't compromise on safety or accuracy – contact our expert team today to discuss your specific requirements and discover how our custom-made solutions can optimize your environmental testing operations. Contact Us now at: xalabfurniture@163.com

References

1. American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2019). Laboratory Ventilation Design Guide: ASHRAE 110 Performance Testing Standards. Atlanta: ASHRAE Publications.

2. Environmental Protection Agency Office of Research and Development. (2020). Quality Assurance Requirements for Environmental Testing Laboratories: Ventilation and Safety Protocols. Washington, DC: EPA Scientific Publications.

3. International Organization for Standardization. (2018). Laboratory Equipment Safety Standards: EN 14175 Compliance Requirements for Chemical Fume Hoods. Geneva: ISO Technical Committee Publications.

4. National Institute for Occupational Safety and Health. (2021). Criteria for Laboratory Ventilation Systems in Environmental Testing Facilities: NIOSH Safety Guidelines. Cincinnati: NIOSH Publications Division.

YOU MAY LIKE

_1743672168871.webp)