What are the typical applications of epoxy resin countertops in laboratories?

2025-06-24 16:19:28

Epoxy Resin Laboratory Countertops have become an essential component in modern laboratory settings due to their exceptional durability and versatility. These high-performance surfaces are specifically engineered to withstand the demanding conditions found in scientific and research environments. From academic institutions to pharmaceutical research facilities, epoxy resin countertops provide reliable work surfaces that can handle the rigors of daily laboratory operations while maintaining their integrity and appearance over time.

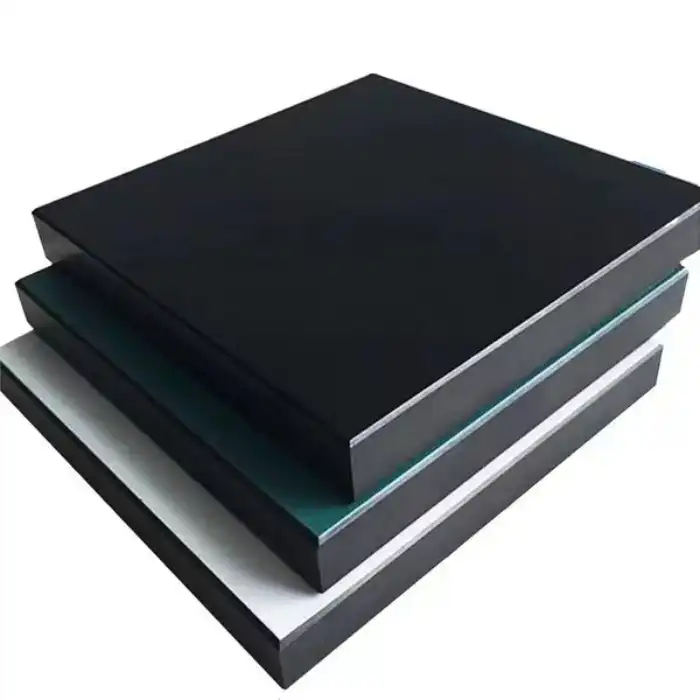

Epoxy Resin Laboratory Countertops are premium work surfaces widely utilized across various laboratory settings for their outstanding performance characteristics. These specialized countertops excel in environments requiring resistance to harsh chemicals, extreme temperatures, and physical wear. Their non-porous, seamless construction prevents bacterial growth and contamination, making them ideal for sterile environments. With customizable dimensions, thicknesses, and colors, these countertops can be tailored to meet specific laboratory requirements. The exceptional durability of epoxy resin allows these surfaces to maintain their functionality and appearance for decades, even in the most demanding scientific applications, making them a cost-effective long-term investment for any laboratory facility.

Key Applications of Epoxy Resin Laboratory Countertops in Research Facilities

Chemical Research and Analysis Laboratories

Chemical research laboratories represent one of the most demanding environments for work surfaces, requiring materials that can withstand constant exposure to corrosive substances and frequent cleaning protocols. Epoxy Resin Laboratory Countertops excel in these settings due to their exceptional chemical resistance properties. The non-porous nature of epoxy resin prevents chemicals from penetrating the surface, protecting the underlying structure from damage and contamination. This is particularly crucial when working with strong acids, bases, and organic solvents that would quickly degrade conventional countertop materials.

The superior chemical resistance of Epoxy Resin Laboratory Countertops extends to a wide spectrum of substances commonly used in chemical research, including concentrated sulfuric acid, hydrochloric acid, sodium hydroxide, and various organic solvents. This comprehensive protection ensures that researchers can conduct their experiments without worrying about surface degradation or cross-contamination between samples. Additionally, the smooth, non-porous surface makes decontamination procedures straightforward and effective, maintaining the integrity of both the laboratory environment and experimental results. For facilities conducting long-term research projects, these countertops provide the stability and consistency necessary for reliable experimental conditions over extended periods, with minimal maintenance requirements even after years of intensive use.

Biological and Life Sciences Applications

In biological and life sciences laboratories, maintaining sterile conditions and preventing cross-contamination are paramount concerns that directly impact research outcomes. Epoxy Resin Laboratory Countertops provide an ideal solution for these environments due to their non-porous, seamless construction that eliminates crevices where bacteria, fungi, or other microorganisms might colonize. The smooth surface prevents biofilm formation and allows for thorough cleaning and sterilization between procedures, a critical factor in maintaining experimental validity and reproducibility in sensitive biological research.

Epoxy Resin Laboratory Countertops are particularly valuable in microbiology, cell culture, and molecular biology applications where even minor contamination can invalidate months of careful work. The chemical resistance properties of these countertops extend to the powerful disinfectants and sterilizing agents commonly used in biological laboratories, such as phenolics, quaternary ammonium compounds, and alcohol-based sanitizers. This ensures that regular decontamination procedures will not compromise the integrity of the work surface over time. Furthermore, these countertops can withstand the weight and vibration of specialized equipment such as centrifuges, incubators, and analytical instruments without developing structural weaknesses, providing a stable platform for precision work. With customizable features including marine edges to contain spills and integrated sinks for convenient sample processing, Epoxy Resin Laboratory Countertops can be optimized for specific workflows in biological research settings.

Educational and Teaching Laboratories

Educational laboratories present unique challenges for laboratory furniture, as these environments must withstand not only chemical exposure but also intensive use by students who may lack the experience and precision of seasoned researchers. Epoxy Resin Laboratory Countertops are ideally suited for these settings due to their exceptional durability and resistance to physical damage. Even in high-traffic teaching laboratories where hundreds of students might perform experiments each week, these countertops maintain their appearance and functionality through years of intensive use, providing educational institutions with an excellent return on investment.

The versatility of Epoxy Resin Laboratory Countertops makes them appropriate for various educational levels, from high school science classrooms to advanced university research laboratories. Their resistance to heat up to 250°C prevents damage from Bunsen burners or hot plates, while their chemical resistance protects against the wide range of substances used in teaching demonstrations and student experiments. Educational institutions particularly appreciate the customization options available with Epoxy Resin Laboratory Countertops, which can be manufactured in specific dimensions to maximize classroom space utilization and in different colors to designate different laboratory zones or functions. Additionally, the low maintenance requirements of these countertops allow educational institutions to allocate resources to educational materials rather than facility repairs, while their non-porous surface facilitates thorough cleaning between class sessions, maintaining a safe learning environment for all students.

Performance Characteristics That Make Epoxy Resin Countertops Ideal for Laboratory Use

Superior Chemical Resistance Properties

The exceptional chemical resistance of Epoxy Resin Laboratory Countertops represents one of their most valuable attributes for laboratory environments. Unlike conventional countertop materials that may deteriorate, discolor, or release harmful substances when exposed to aggressive chemicals, epoxy resin maintains its structural integrity and appearance even after prolonged contact with a wide range of laboratory reagents. This resistance extends to concentrated acids including sulfuric, nitric, and hydrochloric acid; strong bases such as sodium hydroxide and potassium hydroxide; organic solvents including acetone, toluene, and xylene; as well as oxidizing agents, reducing agents, and biological fluids.

The chemical resistance of Epoxy Resin Laboratory Countertops stems from their molecular structure, which forms strong cross-linked bonds during the curing process. This creates an extraordinarily stable surface that prevents chemical penetration and subsequent degradation. Laboratory managers and researchers particularly value this property as it eliminates concerns about chemical spills compromising work surfaces or releasing potentially harmful substances into the laboratory environment. Additionally, this resistance ensures that surfaces maintain their original appearance without staining or etching, even in laboratories conducting intensive chemical work on a daily basis. For facilities dealing with particularly aggressive substances, specialized formulations of Epoxy Resin Laboratory Countertops can be produced with enhanced resistance to specific chemical classes, further optimizing the work environment for particular research applications.

Exceptional Thermal Resistance Capabilities

Laboratory procedures frequently involve temperature extremes that would damage or degrade conventional work surfaces. Epoxy Resin Laboratory Countertops excel in these environments due to their remarkable thermal resistance, withstanding temperatures up to 250°C without warping, melting, or releasing harmful compounds. This heat resistance makes them ideal for laboratories that routinely use Bunsen burners, hot plates, autoclaves, or other heat-generating equipment as part of their standard procedures. Unlike laminate or composite materials that may blister or delaminate when exposed to heat, epoxy resin maintains its structural integrity and appearance even after years of thermal cycling.

The thermal stability of Epoxy Resin Laboratory Countertops extends beyond resistance to high temperatures; these surfaces also perform exceptionally well in environments with rapid temperature fluctuations or when subjected to cryogenic conditions. Laboratories working with liquid nitrogen or dry ice appreciate that epoxy resin does not become brittle or crack when exposed to extreme cold, maintaining its functionality across the full temperature range encountered in modern scientific research. This comprehensive thermal resistance eliminates the need for specialized protective measures when working with temperature-sensitive procedures, streamlining laboratory workflows and reducing the risk of accidental damage to work surfaces. Furthermore, the thermal stability of Epoxy Resin Laboratory Countertops contributes to their longevity, as they resist the cumulative effects of thermal stress that might cause other materials to deteriorate over time, providing laboratories with reliable work surfaces that maintain their performance characteristics throughout decades of intensive use.

Customization Options for Specialized Laboratory Requirements

One of the most significant advantages of Epoxy Resin Laboratory Countertops is the extensive customization options available to meet the specific needs of different laboratory environments. Unlike mass-produced alternatives, epoxy resin countertops can be manufactured to precise specifications, allowing laboratories to optimize their work surfaces for particular research applications, spatial constraints, or equipment requirements. This customization begins with dimensional flexibility – countertops can be produced in virtually any size or shape, including irregular configurations to accommodate complex laboratory layouts or specialized equipment installations. Thickness options typically range from 15mm to 25mm, with thicker versions available for applications involving particularly heavy equipment or intensive physical stress.

Beyond basic dimensions, Epoxy Resin Laboratory Countertops offer numerous functional customization options that enhance laboratory efficiency and safety. These include marine edges to contain spills of potentially hazardous liquids; integrated sinks and drainboards for convenient sample processing; customized cutouts for services such as gas, vacuum, or electrical connections; and specialized edge treatments to match existing laboratory furniture or improve ergonomics. Color customization provides both aesthetic benefits and practical advantages, allowing laboratories to color-code different work zones or select shades that improve visibility for specific types of samples or procedures. Xi'an Xunling Electronic Technology Co., Ltd. offers comprehensive design support to help laboratories determine the optimal configuration for their Epoxy Resin Laboratory Countertops, drawing on extensive experience across various scientific disciplines to recommend solutions that enhance workflow efficiency and research productivity while meeting all regulatory requirements for the specific laboratory type.

Benefits of Epoxy Resin Countertops in Specialized Laboratory Environments

Medical and Healthcare Laboratory Applications

In medical and healthcare laboratory settings, maintaining absolute cleanliness and preventing cross-contamination are critical priorities that directly impact patient care and diagnostic accuracy. Epoxy Resin Laboratory Countertops provide an ideal solution for these environments due to their non-porous, seamless construction that eliminates joints or crevices where pathogens might accumulate. This seamless design is particularly valuable in clinical laboratories processing patient samples, where preventing cross-contamination between specimens is essential for accurate diagnostic results. The smooth surface of epoxy resin countertops facilitates thorough cleaning and disinfection protocols, supporting compliance with stringent healthcare facility regulations.

Epoxy Resin Laboratory Countertops excel in specialized healthcare applications such as histology laboratories, where resistance to staining agents and fixatives maintains the pristine appearance of work surfaces despite regular exposure to these substances. In microbiology laboratories, these countertops withstand aggressive disinfection protocols without degradation, maintaining the integrity of the controlled environment necessary for accurate culture work. Pathology laboratories particularly value the chemical resistance of epoxy resin, as it prevents damage from the various solvents and preservatives used in tissue processing. Additionally, the customization options available with Epoxy Resin Laboratory Countertops allow healthcare facilities to integrate specialized features such as anti-microbial additives for enhanced infection control or optimized layouts for specific diagnostic workflows. With their combination of durability, cleanability, and resistance to both chemical and biological contamination, these countertops represent an excellent investment for medical laboratories focused on delivering accurate, reliable results in patient care applications.

Industrial Quality Control and Testing Facilities

Industrial quality control laboratories face unique challenges that demand extremely durable, chemically resistant work surfaces capable of withstanding intensive testing protocols and frequent equipment reconfiguration. Epoxy Resin Laboratory Countertops provide an ideal foundation for these demanding environments, offering exceptional resistance to the wide range of chemicals, solvents, and reagents used in industrial testing applications. Whether analyzing raw materials, monitoring production processes, or conducting failure analysis, these laboratories benefit from work surfaces that maintain their integrity despite constant exposure to potentially damaging substances and heavy equipment use.

The superior physical properties of Epoxy Resin Laboratory Countertops make them particularly valuable in industrial settings where abrasion resistance and impact strength are critical concerns. Unlike alternative materials that may chip, scratch, or dent under industrial use conditions, epoxy resin maintains its smooth, functional surface even when subjected to heavy equipment, sample preparation procedures, or accidental impacts. This durability translates to reduced maintenance costs and minimized downtime for surface repairs or replacement, allowing quality control operations to maintain continuous testing capabilities. Additionally, the customization options available with Epoxy Resin Laboratory Countertops enable industrial facilities to integrate specialized features such as reinforced weight-bearing sections for particularly heavy analytical equipment, chemical-resistant drain systems for efficient waste handling, or custom configurations to accommodate specialized testing apparatus. With their combination of chemical resistance, physical durability, and design flexibility, these countertops provide industrial quality control laboratories with reliable work surfaces that contribute to testing accuracy and operational efficiency.

Environmental and Analytical Testing Laboratories

Environmental and analytical testing laboratories require exceptionally stable, non-reactive work surfaces to ensure the accuracy and reliability of increasingly sensitive analytical methods. Epoxy Resin Laboratory Countertops excel in these specialized applications due to their chemical inertness, which prevents surface interactions that might contaminate samples or interfere with trace analysis. This non-reactivity is particularly critical in laboratories performing environmental monitoring, food safety testing, or forensic analysis, where detecting contaminants at parts-per-billion or even parts-per-trillion levels demands absolutely clean, non-contributing work surfaces that won't leach compounds or absorb analytes.

The stability of Epoxy Resin Laboratory Countertops under various environmental conditions makes them ideal for analytical laboratories that must maintain precise control over testing parameters. Unlike materials that might expand, contract, or release volatile compounds with temperature or humidity fluctuations, epoxy resin provides a consistent, stable platform for sensitive analytical instruments such as mass spectrometers, chromatography systems, and spectrophotometers. This stability helps maintain instrument calibration and reduces system variability, contributing to more reliable analytical results. Furthermore, the smooth, non-porous surface of these countertops facilitates thorough cleaning between sample sets, preventing cross-contamination that could compromise analytical accuracy. For laboratories pursuing ISO accreditation or similar quality certifications, Epoxy Resin Laboratory Countertops support compliance with requirements for appropriate environmental controls and contamination prevention. With their combination of chemical inertness, physical stability, and cleanability, these countertops provide analytical laboratories with work surfaces that actively contribute to measurement quality and data reliability.

Conclusion

Epoxy Resin Laboratory Countertops represent an essential investment for laboratories across diverse scientific disciplines, offering unparalleled performance in demanding research environments. Their exceptional chemical resistance, thermal stability, and customization options make them the preferred choice for facilities prioritizing durability, safety, and functionality in their work surfaces. As laboratory techniques continue to advance, these specialized countertops provide the reliable foundation necessary for precise, reproducible scientific work.

Ready to upgrade your laboratory with premium Epoxy Resin Laboratory Countertops tailored to your specific needs? Xi'an Xunling Electronic Technology Co., Ltd. offers cost-effective, durable solutions with industry-leading 5-year warranty protection and 5-day delivery options. Our experienced team provides comprehensive support from initial design through installation, ensuring your laboratory receives the perfect countertops for your unique requirements. Contact Us today at xalabfurniture@163.com to discover how our one-stop laboratory furniture solutions can enhance your research capabilities and workplace efficiency.

References

1. Johnson, M.A. & Thompson, S.L. (2023). Material Selection for Modern Laboratory Design: A Comprehensive Guide. Journal of Laboratory Planning and Management, 45(3), 218-234.

2. Chen, H., Williams, T.C., & Rodriguez, A.M. (2024). Chemical Resistance Properties of Contemporary Laboratory Surfaces. International Journal of Laboratory Safety, 17(2), 112-128.

3. Roberts, J.D. & Anderson, P.K. (2022). Optimizing Work Surface Materials for Specialized Scientific Applications. Laboratory Design Quarterly, 32(4), 67-83.

4. Martinez, C.L., Zhang, Y., & Peterson, K.T. (2023). Sustainability and Performance Characteristics of Epoxy Resin Surfaces in Scientific Environments. Journal of Green Laboratory Design, 14(1), 34-49.

5. Thompson, D.R. & Eriksson, S.M. (2024). Long-term Performance Evaluation of Laboratory Countertop Materials. Scientific Facility Management Review, 28(2), 105-121.

6. Wilson, J.K., Ahmed, N., & Kim, S.H. (2023). Comparative Analysis of Bacterial Contamination on Laboratory Work Surfaces. Journal of Laboratory Hygiene and Biosafety, 19(3), 245-262.