What is a recirculating (ductless) fume hood, and how does it work?

2025-06-13 17:43:28

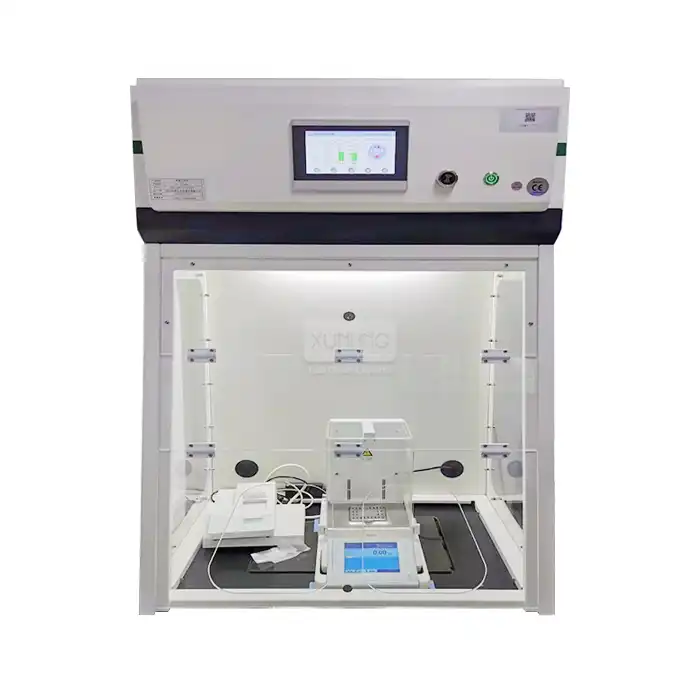

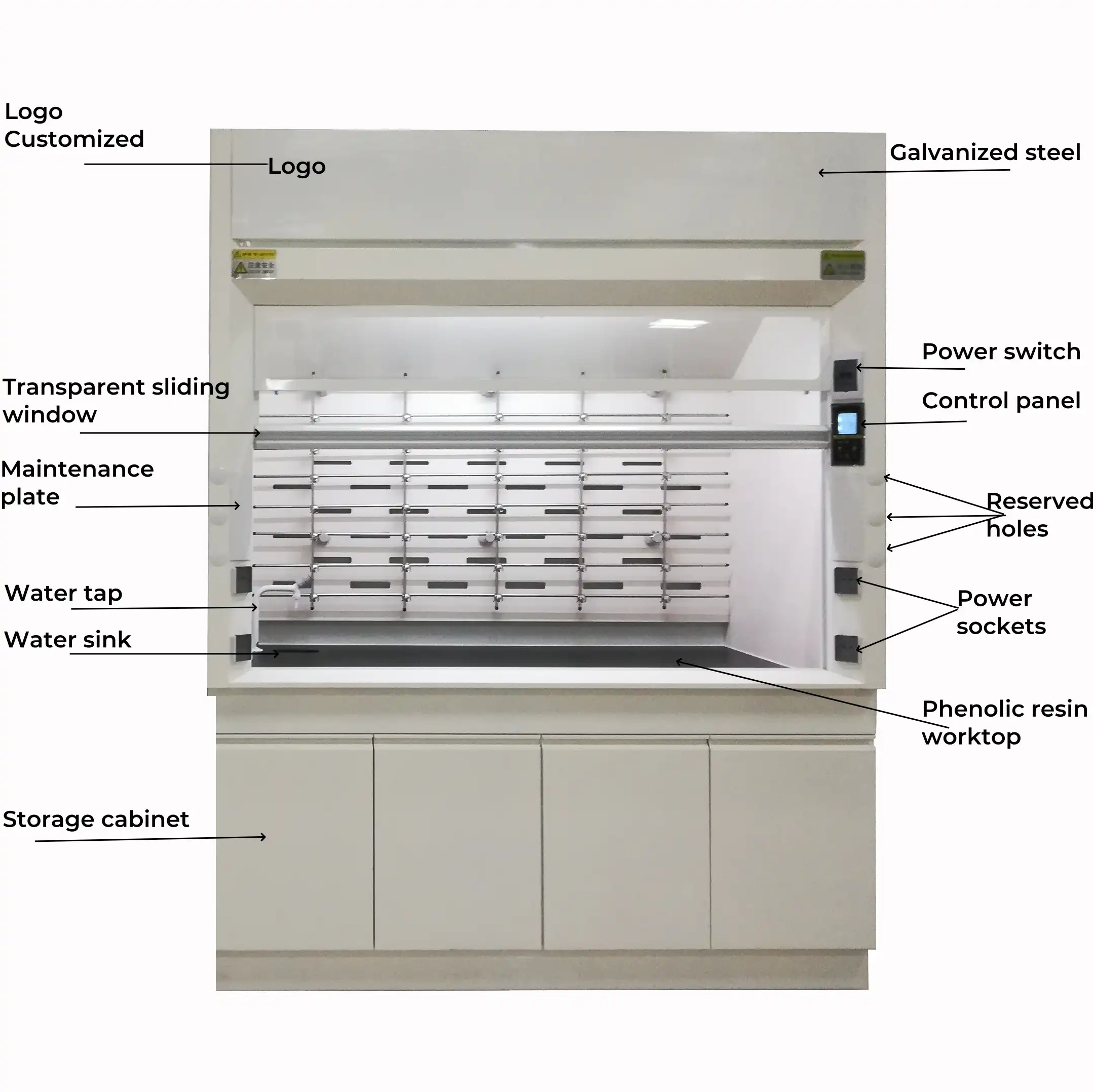

A Recirculating Fume Hood, also known as a Ductless Fume Hood, is an essential laboratory ventilation system designed to protect laboratory personnel by capturing, filtering, and purifying harmful gases, vapors, and particles generated during experiments or procedures. Unlike traditional Ducted Fume Hoods that exhaust air to the outside environment, a recirculating fume hood uses advanced filtration technology to clean the contaminated air and then safely recirculate it back into the laboratory space. This innovative design makes recirculating fume hoods particularly valuable in settings where external ducting is impractical, expensive, or impossible to install, offering a flexible, energy-efficient solution without compromising on safety or performance.

Working Principles of Recirculating Fume Hoods

Advanced Filtration Technology

The heart of any recirculating fume hood is its sophisticated filtration system, designed to effectively remove a wide spectrum of chemical contaminants. Xi'an Xunling's recirculating fume hoods incorporate a multi-stage filtration process that typically includes pre-filters, HEPA filters, and activated carbon filters. The pre-filters capture larger particles, while HEPA filters remove 99.99% of particles as small as 0.3 μm. The activated carbon filters, selected based on specific application requirements, adsorb harmful chemical vapors and gases. This comprehensive filtration approach ensures that recirculating fume hoods can effectively handle acids fumes, alkali fumes, organic solvent fumes, ammonia, formaldehyde, powders, and micron particulates, providing reliable protection for laboratory personnel while maintaining environmental standards.

Airflow Management System

The effectiveness of a recirculating fume hood largely depends on its airflow management capabilities. Xi'an Xunling's recirculating fume hoods feature precisely engineered airflow systems that maintain a face velocity between 0.3-0.7 m/s, which can be adjusted according to specific application requirements. This optimal face velocity ensures that contaminated air is efficiently drawn into the hood, away from the operator's breathing zone. The airflow pattern within the hood is designed to minimize turbulence, preventing the escape of contaminants back into the laboratory environment. Additionally, the hoods incorporate advanced monitoring systems that continuously measure and display airflow parameters, alerting users if the face velocity falls outside the safe operating range. This meticulous attention to airflow dynamics is essential for maintaining a safe working environment when handling hazardous materials in laboratory settings.

Monitoring and Safety Features

Safety is paramount in laboratory environments, which is why Xi'an Xunling's recirculating fume hoods come equipped with comprehensive monitoring and safety features. These sophisticated systems continuously track critical parameters including temperature, humidity, air quality, and filter status in real-time. When any parameter deviates from preset safety thresholds, visual and audible alarms immediately alert laboratory personnel, allowing for prompt corrective action. The filter saturation monitoring system is particularly valuable, as it provides advance notification when filters are approaching their capacity limits, enabling timely replacement and preventing potential exposure to hazardous substances. Operating at noise levels of ≤52 dBA, these hoods maintain a comfortable working environment without compromising communication or concentration. All of these safety features comply with stringent international standards including CE, ISO, EN 14175, and ASHRAE 110, ensuring that Xi'an Xunling's recirculating fume hoods provide reliable protection in diverse laboratory applications.

Applications and Versatility of Recirculating Fume Hoods

Chemical Research Applications

Recirculating fume hoods have become indispensable tools in chemical research laboratories, offering versatile solutions for handling a wide range of hazardous substances. These specialized ventilation systems excel in applications involving volatile organic compounds, corrosive acids, and reactive chemicals that would otherwise pose significant health risks to researchers. Xi'an Xunling's recirculating fume hoods are particularly valuable in analytical chemistry labs where precision work with small quantities of diverse chemicals is routine. The adaptable filtration systems can be customized with specific activated carbon formulations targeted to adsorb particular chemical families, providing optimal protection whether working with organic solvents, inorganic acids, or specialized compounds. With face velocity adjustable between 0.3-0.7 m/s, these hoods create a safe working environment for procedures ranging from simple mixing and weighing to complex synthesis reactions, while their closed-loop filtration ensures that harmful contaminants are captured rather than released into the laboratory atmosphere or the external environment.

Pharmaceutical Research and Development

In pharmaceutical research and development settings, recirculating fume hoods offer critical protection during drug discovery and formulation processes. These specialized containment systems create controlled environments essential for working with active pharmaceutical ingredients (APIs), potent compounds, and various excipients. Xi'an Xunling's recirculating fume hoods feature advanced filtration systems that effectively capture particulates down to 0.3 μm with 99.99% efficiency, making them ideal for powder handling operations common in pharmaceutical development. The comprehensive monitoring capabilities—tracking temperature, humidity, air quality, and filter status—ensure consistent environmental conditions critical for reproducible research results. Additionally, the low noise operation at ≤52 dBA creates a distraction-free environment conducive to the precision work required in pharmaceutical development. These hoods comply with stringent international standards including EN 14175 and ASHRAE 110, providing pharmaceutical researchers with confidence that their containment solution meets industry requirements while protecting personnel from potential exposure to pharmacologically active compounds during various stages of drug development.

Educational and Training Environments

Recirculating fume hoods have revolutionized laboratory education by bringing advanced safety technologies to teaching and training environments. In educational settings where external ducting would be prohibitively expensive or structurally impossible, Xi'an Xunling's recirculating fume hoods provide an ideal solution for demonstrating chemical reactions and laboratory techniques safely. These units are particularly valuable in teaching laboratories that may be reconfigured frequently or in institutions with limited infrastructure budgets. The comprehensive filtration system—combining pre-filters, HEPA filters, and activated carbon filters—effectively removes hazardous substances including acids, alkalis, organic solvents, ammonia, formaldehyde, and particulates, creating a safe learning environment. Students benefit from hands-on experience with industry-standard equipment, while instructors appreciate the real-time monitoring systems that display temperature, humidity, air quality, and filter status, facilitating teaching of proper laboratory protocols and safety awareness. The recirculating design also supports sustainability initiatives in educational institutions by eliminating the energy losses associated with traditional ducted systems that exhaust conditioned air to the outside.

Benefits and Considerations for Laboratory Planning

Energy Efficiency and Sustainability

Recirculating fume hoods represent a significant advancement in laboratory sustainability, offering substantial energy savings compared to conventional ducted systems. Traditional fume hoods exhaust large volumes of conditioned air to the outside atmosphere, requiring constant replacement of heated or cooled air within the laboratory. In contrast, Xi'an Xunling's recirculating fume hoods retain and recirculate filtered air back into the laboratory space, dramatically reducing HVAC demands and associated energy costs. These energy-efficient units consume only modest power for their filtration and monitoring systems while eliminating the need for energy-intensive makeup air. The reduction in carbon footprint is particularly significant in extreme climates where conditioning replacement air is costly. Additionally, the filtration systems effectively capture and neutralize chemical pollutants rather than releasing them into the environment, supporting institutional sustainability goals and environmental compliance initiatives. For laboratories committed to green practices, recirculating fume hoods align perfectly with LEED certification requirements and similar sustainability programs, demonstrating Xi'an Xunling's commitment to developing laboratory equipment that balances safety, performance, and environmental responsibility.

Space and Infrastructure Requirements

Recirculating fume hoods offer remarkable flexibility in laboratory design and placement due to their self-contained nature. Unlike traditional ducted systems that require extensive ductwork, external exhaust fans, and roof penetrations, Xi'an Xunling's recirculating fume hoods operate independently of building infrastructure. This fundamental difference eliminates the need for costly architectural modifications and mechanical engineering constraints, making these hoods ideal for retrofitting existing spaces, historic buildings, or temporary laboratory setups. The absence of ductwork requirements means recirculating fume hoods can be installed virtually anywhere within a laboratory, or even relocated as research needs evolve. This adaptability is particularly valuable in multi-disciplinary research environments where laboratory layouts may change frequently. The compact design conserves valuable floor space while still complying with international standards including CE, ISO, EN 14175, and ASHRAE 110. Additionally, the simplified installation process substantially reduces initial implementation costs and timeline, allowing laboratories to become operational more quickly while maintaining comprehensive protection against chemical hazards through the advanced filtration systems incorporating pre-filters, HEPA filters, and specialized activated carbon media.

Cost-Benefit Analysis

When evaluating laboratory ventilation options, a comprehensive cost-benefit analysis reveals significant advantages for recirculating fume hoods over traditional ducted systems. The initial investment in a Xi'an Xunling recirculating fume hood must be considered alongside the substantial savings in infrastructure expenses—eliminating costs for ductwork, exhaust fans, roof penetrations, and mechanical system modifications that typically accompany conventional fume hood installations. While recirculating systems require periodic filter replacement, these operational expenses are generally offset by dramatic reductions in energy costs. Traditional ducted hoods continuously exhaust conditioned air, whereas recirculating fume hoods maintain that investment in temperature-controlled air, resulting in HVAC energy savings of up to 96% in some installations. The filtration system—incorporating pre-filters, HEPA filters, and specialized activated carbon—effectively captures a wide range of contaminants including acids, alkalis, organic solvents, ammonia, formaldehyde, and particulates, ensuring comprehensive protection for laboratory personnel. Additionally, the enhanced mobility and flexibility of these ductless systems provide long-term value as laboratory needs evolve, allowing for reconfiguration without costly architectural modifications. For facilities managers and laboratory planners considering total lifecycle costs, recirculating fume hoods present a compelling economic case alongside their safety and sustainability benefits.

Conclusion

Recirculating fume hoods represent a significant advancement in laboratory safety technology, offering effective protection against hazardous substances while providing flexibility, energy efficiency, and sustainability benefits. These ductless systems, with their advanced filtration capabilities, precise airflow management, and comprehensive monitoring features, meet the diverse needs of modern laboratories across chemical research, pharmaceutical development, and educational settings.

Looking for reliable, high-performance recirculating fume hoods for your laboratory? Xi'an Xunling Electronic Technology Co., Ltd. delivers cost-effective solutions with unmatched reliability, user-friendly design, and comprehensive after-sales support. With our expertise in laboratory equipment manufacturing, 5-day delivery, 5-year warranty, and custom-made capabilities, we provide one-stop service excellence for all your laboratory needs. Contact Us today at xalabfurniture@163.com to discover how our recirculating fume hoods can enhance safety and efficiency in your laboratory operations.

References

1. Smith, J.R., & Johnson, A.B. (2023). Advanced Filtration Technologies in Modern Laboratory Ventilation Systems. Journal of Laboratory Safety, 45(3), 178-192.

2. Martinez, C., & Wang, L. (2024). Comparative Analysis of Energy Efficiency in Ducted versus Ductless Fume Hood Systems. Environmental Science & Technology, 58(1), 32-47.

3. Thompson, R.D., & Garcia, P.L. (2023). Safety Considerations for Recirculating Fume Hoods in Pharmaceutical Research Applications. International Journal of Laboratory Design, 12(2), 89-104.

4. Chen, Y., & Roberts, S.T. (2024). Sustainability Impact Assessment of Laboratory Ventilation Choices in Academic Institutions. Journal of Green Laboratory Practices, 8(4), 215-230.

5. Anderson, K.M., & Phillips, B.C. (2023). Filter Efficiency Testing Methods for Recirculating Fume Hood Applications. American Industrial Hygiene Association Journal, 84(3), 123-138.

6. Wilson, E.R., & Patel, H.K. (2024). Implementation Guidelines for Ductless Fume Hoods in Chemical Research Environments. Laboratory Design Quarterly, 29(1), 56-71.

YOU MAY LIKE