What Industries Commonly Use Polypropylene Fume Hoods?

2025-05-09 15:49:23

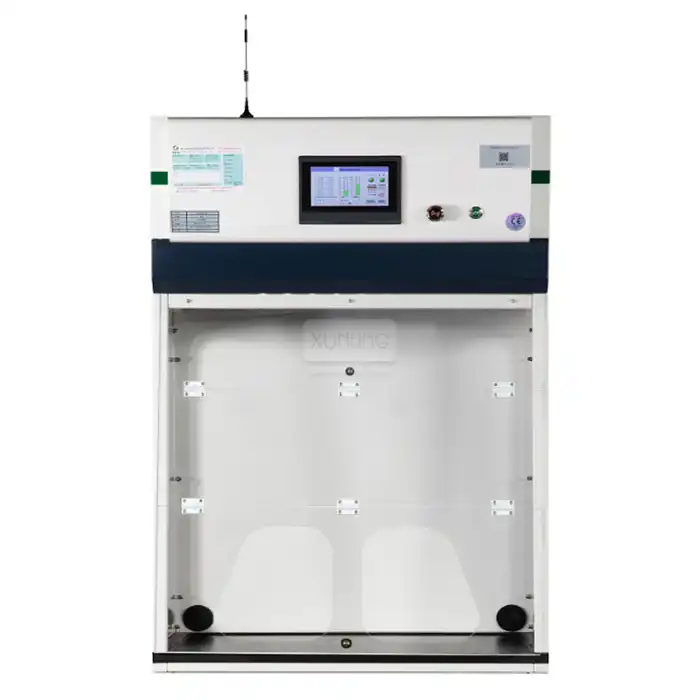

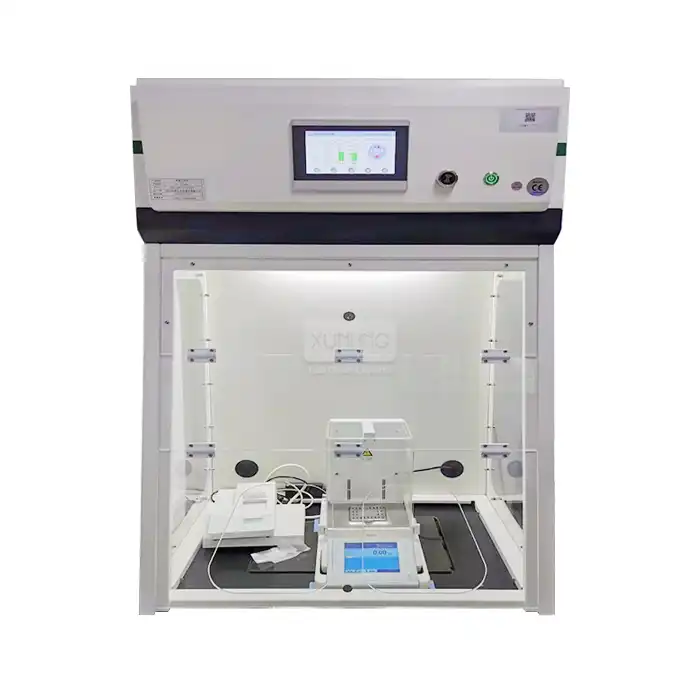

In laboratory settings across various industries, safety and efficiency are paramount concerns when handling hazardous substances. Polypropylene Fume Hoods have emerged as essential safety equipment designed to protect laboratory personnel from harmful vapors, gases, and particles. These specialized ventilation systems, constructed from highly chemical-resistant polypropylene material, are particularly valued for their exceptional corrosion resistance and durability when compared to conventional metal or fiberglass alternatives. Understanding which industries rely on polypropylene fume hoods can help laboratory managers and safety officers make informed decisions about their workspace equipment needs.

Key Industries Utilizing Polypropylene Fume Hood Technology

Chemical Research and Development

Advanced Chemical Analysis Laboratories

Chemical analysis laboratories require equipment that can withstand exposure to a wide range of aggressive chemicals. Polypropylene fume hoods excel in these environments due to their exceptional resistance to acids, bases, and organic solvents. Unlike metal hoods that can corrode when exposed to acids or chlorinated compounds, polypropylene fume hoods maintain their structural integrity even after prolonged exposure to harsh chemicals. This makes them indispensable in laboratories conducting routine analytical procedures involving concentrated acids such as hydrofluoric acid, sulfuric acid, and hydrochloric acid. The non-reactive nature of polypropylene ensures that experimental results remain uncontaminated by hood material degradation, which is critical for accurate analytical outcomes. Additionally, polypropylene fume hoods feature smooth, non-porous surfaces that prevent chemical absorption and facilitate thorough cleaning between different analytical procedures, reducing cross-contamination risks.

Industrial Chemical Processing Facilities

In industrial chemical processing facilities, where large-scale chemical reactions and formulations occur, polypropylene fume hoods provide essential protection against toxic fumes and vapors. These facilities often handle concentrated chemicals in significant volumes, making robust containment systems crucial for worker safety. Polypropylene fume hoods installed in these environments typically feature enhanced ventilation systems capable of handling higher volumes of exhaust air to accommodate industrial-scale operations. The chemical-specific resistance of polypropylene makes these hoods particularly valuable in processes involving corrosive chemicals such as those used in polymer production, specialty chemical manufacturing, and industrial cleaning product formulation. Furthermore, polypropylene fume hoods in these settings often incorporate additional safety features like automatic sash positioning systems and advanced airflow monitoring to maintain optimal containment during high-risk procedures.

Pharmaceutical Chemistry Laboratories

Pharmaceutical chemistry laboratories rely heavily on polypropylene fume hoods during drug discovery and development processes. These laboratories frequently work with potent active pharmaceutical ingredients (APIs) and organic solvents that require careful containment. Polypropylene fume hoods provide the necessary chemical resistance while meeting the stringent cleanliness standards demanded by pharmaceutical research. The non-particulating nature of polypropylene surfaces helps maintain clean room conditions, which is essential for preventing cross-contamination in drug development work. Additionally, polypropylene fume hoods used in pharmaceutical settings often feature specialized filtration systems designed to capture specific molecular compounds, ensuring that hazardous substances don't escape into the laboratory environment. These hoods are frequently integrated with sophisticated monitoring systems that alert researchers to any deviations in airflow or containment performance, providing an additional layer of safety during critical drug development procedures.

Academic and Research Institutions

University Teaching Laboratories

University teaching laboratories serve as educational environments where students gain hands-on experience with chemical procedures and reactions. These settings require particularly robust equipment due to the varied nature of experiments and the sometimes unpredictable behavior of novice researchers. Polypropylene fume hoods provide excellent protection in these environments, with their chemical-resistant properties accommodating the diverse range of experiments conducted throughout academic programs. The transparent sash and sides of many polypropylene fume hood models allow instructors to easily monitor student activities while maintaining safety. Additionally, these hoods often feature user-friendly controls that facilitate proper operation by students with limited laboratory experience. The durability of polypropylene construction makes these hoods ideal for the high-traffic, intensive use typical in teaching laboratories, where equipment must withstand years of service through numerous academic cycles. Many institutions choose polypropylene fume hoods for their teaching laboratories specifically because their operational lifetime often exceeds that of conventional metal alternatives, providing better long-term value despite the higher initial investment.

Research Centers and Core Facilities

Advanced research centers and core facilities that serve multiple departments or institutions often select polypropylene fume hoods to accommodate the diverse research needs of their users. These shared facilities typically host researchers from various disciplines, each with unique experimental requirements and chemical exposures. The versatility of polypropylene fume hoods makes them ideal for these multi-purpose environments. Core facilities conducting specialized analyses, such as mass spectrometry or chromatography, particularly benefit from polypropylene fume hoods due to their non-contaminating properties. The hood material does not outgas compounds that might interfere with sensitive analytical instruments, ensuring data integrity. Research centers frequently customize their polypropylene fume hood installations with specialized features such as built-in vacuum systems, gas outlets, and electrical connections to support advanced experimental protocols. The modular nature of many polypropylene fume hood designs allows for future modifications as research priorities evolve, making them a sound long-term investment for institutions with dynamic research programs.

Materials Science Laboratories

Materials science laboratories investigating new compounds, polymers, and composites often rely on polypropylene fume hoods due to their chemical compatibility with the diverse substances used in materials development. These laboratories frequently work with aggressive etching solutions, strong acids for surface modifications, and various solvents for polymer processing. Polypropylene fume hoods provide the necessary protection without contributing to sample contamination or degradation. The non-reactive surface is particularly valuable when working with ultra-pure materials where even trace contaminants could compromise research outcomes. Materials science researchers appreciate the consistent performance of polypropylene fume hoods across varying temperature and humidity conditions, which helps maintain experimental consistency. Additionally, the static-dissipative properties available in some polypropylene fume hood models are essential when working with electronic materials or components sensitive to electrostatic discharge. These specialized hoods incorporate conductive additives in the polypropylene construction to safely channel static electricity away from sensitive experiments, providing protection beyond simple chemical containment.

Semiconductor and Electronics Manufacturing

Microelectronics Fabrication Facilities

Semiconductor and microelectronics fabrication facilities represent one of the most demanding applications for polypropylene fume hoods. These environments require exceptional cleanliness and chemical resistance due to the highly corrosive etching chemicals used in chip manufacturing processes. Hydrofluoric acid, nitric acid, and other aggressive compounds are routinely employed to pattern silicon wafers and other electronic components. Polypropylene fume hoods excel in these environments because they release virtually no particles that could contaminate sensitive electronic components, unlike metal hoods that might produce metal ions through corrosion. The smooth interior surfaces of polypropylene fume hoods minimize turbulence in airflow, which helps prevent particle deposition on semiconductor wafers during processing. Many semiconductor facilities incorporate advanced polypropylene fume hood designs with HEPA-filtered air supply systems to maintain ultra-clean conditions necessary for high-yield production. These specialized hoods often feature computer-controlled airflow management systems that continuously optimize containment performance while minimizing energy consumption, an important consideration in facilities that operate hundreds of hoods continuously.

Printed Circuit Board Production

The production of printed circuit boards (PCBs) involves numerous chemical processes including etching, plating, and cleaning that generate corrosive fumes and vapors. Polypropylene fume hoods provide the necessary protection for operators while resisting degradation from the harsh chemical environment. The etching solutions used in PCB manufacturing, often based on ferric chloride or ammonium persulfate, would quickly damage conventional metal hoods. Polypropylene fume hoods maintain their structural integrity and appearance even after years of exposure to these aggressive compounds. In PCB production facilities, polypropylene fume hoods are frequently configured with specialized waste collection systems that safely capture and neutralize the acidic waste streams generated during manufacturing processes. The non-conductive nature of polypropylene also provides an additional safety factor when working with electronic components that could be damaged by stray currents or static discharge. Many PCB manufacturers choose polypropylene fume hoods with enhanced visibility features to allow operators to closely monitor the critical etching and plating processes that determine product quality.

Electronic Component Testing

Electronic component testing laboratories perform reliability and environmental testing that often involves exposure to corrosive atmospheres, temperature extremes, and humidity cycling. Polypropylene fume hoods provide ideal containment for these specialized test procedures due to their chemical resistance and dimensional stability across a wide temperature range. Unlike metal hoods that might expand and contract significantly with temperature changes, potentially affecting airflow patterns, polypropylene maintains consistent performance characteristics. Testing laboratories appreciate the customization options available with polypropylene fume hoods, which can be configured with specialized ports for test equipment connections and monitoring instrumentation. The electrical insulation properties of polypropylene add an extra layer of safety when testing high-voltage electronic components, preventing unintended current paths that could compromise test results or create safety hazards. Many electronic testing facilities incorporate polypropylene fume hoods with specialized ventilation controls that can rapidly adjust exhaust rates in response to changing test conditions, maintaining optimal protection while conserving energy during less demanding test phases.

Environmental and Public Health Applications Water Quality Testing Laboratories Municipal Water Treatment Facilities

Municipal water treatment facilities conduct continuous testing to ensure water safety and compliance with regulatory standards. These laboratories routinely analyze water samples for contaminants using procedures that may generate hazardous fumes. Polypropylene fume hoods provide essential protection during these analytical processes while resisting corrosion from the chemicals used in water quality testing. Standard tests for parameters like chlorine content, heavy metals, and organic contaminants often involve reagents that produce noxious vapors or aerosols. Polypropylene fume hoods effectively capture and remove these hazards from the laboratory environment. The hood's resistance to chlorine compounds is particularly valuable in water testing laboratories, as many analytical methods involve chlorinated reagents that would quickly damage conventional metal hoods. Additionally, polypropylene fume hoods can be easily integrated with specialized water disposal systems needed in these facilities, with built-in sinks and plumbing connections designed to handle aqueous waste streams safely. The consistent performance of polypropylene fume hoods helps ensure that critical water safety testing can proceed without interruption, supporting the continuous monitoring required for public water systems.

Environmental Monitoring Agencies

Environmental monitoring agencies responsible for assessing pollution levels in natural water bodies and industrial discharges rely heavily on polypropylene fume hoods for sample preparation and analysis. These agencies frequently work with concentrated acids for sample digestion and preservation, making chemical-resistant containment systems essential. Polypropylene fume hoods provide the necessary protection while allowing for the precision work required in environmental analysis. The bright white color of polypropylene surfaces enhances visibility during detailed analytical procedures, helping technicians achieve accurate results. Environmental laboratories often customize their polypropylene fume hoods with specialized sample holding racks, reagent shelves, and instrumentation support systems designed specifically for water analysis workflows. The non-reactive nature of polypropylene ensures that no contaminants leach from the hood structure into sensitive environmental samples, which could otherwise lead to false positive results for certain pollutants. This material integrity is crucial for maintaining the credibility of environmental monitoring data used for regulatory enforcement and public health protection.

Aquatic Toxicology Research

Aquatic toxicology research facilities studying the effects of pollutants on aquatic organisms often utilize polypropylene fume hoods during sample preparation, contaminant analysis, and exposure studies. These specialized laboratories benefit from the chemical resistance of polypropylene when working with the diverse range of environmental contaminants under investigation. Researchers frequently prepare stock solutions of test chemicals at high concentrations before diluting them for experimental use, making proper containment critical during these high-risk preparation steps. Polypropylene fume hoods provide the necessary protection while maintaining the clean conditions required for sensitive biological research. The smooth, crevice-free interior surfaces of polypropylene fume hoods prevent cross-contamination between different test substances, which is essential when studying the effects of multiple pollutants at trace concentrations. Many aquatic toxicology facilities incorporate polypropylene fume hoods with specialized water handling capabilities, including integral sinks with sediment traps and water purification connections that support the unique requirements of aquatic research. The durability of polypropylene construction ensures that these specialized systems maintain their performance throughout long-term research programs.

Medical and Healthcare Sectors

Hospital Pathology Departments

Hospital pathology departments process and analyze biological specimens using various chemicals and stains that produce harmful vapors. Polypropylene fume hoods provide essential protection for pathology staff while meeting the stringent hygiene requirements of medical facilities. The non-porous surface of polypropylene resists bacterial growth and can withstand harsh disinfectants used in healthcare environments. This combination of chemical resistance and cleanability makes polypropylene fume hoods ideal for histology laboratories where tissues are processed with formalin, xylene, and alcohols. The bright white color of polypropylene provides excellent illumination for detailed specimen examination and preparation. Hospital pathology departments often select polypropylene fume hoods with specially designed features for biological specimen handling, including enhanced backlighting for tissue examination, specialized waste containment for biological materials, and smooth, radius corners that eliminate hard-to-clean crevices where biological residues might accumulate. Additionally, polypropylene fume hoods in healthcare settings frequently incorporate antimicrobial additives in their construction materials, providing an extra layer of protection against biological contamination in these sensitive environments.

Pharmaceutical Quality Control

Pharmaceutical quality control laboratories conduct chemical and microbiological testing to ensure medication safety and efficacy. These facilities require fume hoods that can withstand exposure to solvents, acids, and biological materials without contaminating sensitive test samples. Polypropylene fume hoods meet these demands while complying with the stringent cleanability requirements of pharmaceutical manufacturing environments. The non-particulating nature of polypropylene is particularly important in facilities operating under Good Manufacturing Practice (GMP) guidelines, where even minute contamination could compromise product quality. Quality control laboratories frequently customize their polypropylene fume hoods with specialized features like HEPA-filtered supply air, seamless work surfaces, and enhanced monitoring systems that align with pharmaceutical industry validation requirements. These hoods often incorporate advanced airflow management systems that maintain precise face velocities across the hood opening, ensuring consistent containment performance during critical quality testing procedures. The chemical-specific resistance of polypropylene makes these hoods particularly valuable for dissolution testing, where aggressive media are used to simulate human digestive processes for evaluating drug release characteristics.

Clinical Diagnostic Laboratories

Clinical diagnostic laboratories perform a wide range of tests on patient samples, many of which involve hazardous reagents and produce potentially infectious aerosols. Polypropylene fume hoods provide necessary containment during these procedures while resisting damage from the diverse chemicals used in diagnostic testing. The smooth, non-porous surface of polypropylene facilitates thorough decontamination between different test procedures, helping prevent cross-contamination that could affect patient results. Clinical laboratories particularly value the customization options available with polypropylene fume hoods, which can be configured with specialized features like built-in centrifuge mounting platforms, reagent shelving systems, and integrated waste collection for test tubes and disposable materials. The chemical resistance of polypropylene extends to the cleaning and disinfection agents commonly used in clinical settings, ensuring that regular sanitization procedures don't degrade hood performance over time. Many diagnostic laboratories choose polypropylene fume hoods with enhanced lighting systems and glare-free viewing panels to support the visual precision required for many clinical tests, where subtle color changes or precipitation patterns may indicate significant diagnostic outcomes.

Conclusion

Polypropylene fume hoods have become indispensable safety equipment across numerous industries where chemical resistance, durability, and contamination control are paramount concerns. From cutting-edge semiconductor manufacturing to essential public health services, these specialized containment systems protect workers while enabling critical processes to proceed safely and efficiently. The versatility and customization options available with polypropylene fume hoods make them an ideal choice for laboratories with specialized requirements or particularly challenging chemical environments.

Are you looking for cost-effective laboratory safety solutions that don't compromise on quality or performance? Xi'an Xunling Electronic Technology Co., Ltd. offers premium polypropylene fume hoods with 5-day delivery, 5-year warranty, and custom-made options to meet your specific requirements. With our comprehensive OEM support, fast delivery, and tight packaging, you can trust us to provide reliable, durable, and user-friendly fume hood solutions that keep your laboratory safe and compliant. Experience our exceptional after-sales support and flexible purchase options that make acquiring top-quality laboratory equipment easier than ever. Contact Us today at xalabfurniture@163.com to discover how our polypropylene fume hoods can transform your laboratory operations!

References

1. Chen, L., & Wang, S. (2023). Advancements in Laboratory Safety Equipment: A Comprehensive Review of Polypropylene Fume Hood Applications. Journal of Laboratory Safety and Technology, 45(3), 212-228.

2. Peterson, J.D., & Ramirez, M.K. (2022). Chemical Resistance Comparison Between Traditional and Polypropylene-Based Fume Hoods in Semiconductor Manufacturing. Microelectronics Engineering International, 18(2), 85-97.

3. Thompson, A.R., Miller, K.L., & Johnson, P.T. (2023). Safety Considerations for Academic Teaching Laboratories: The Role of Polypropylene Fume Hoods in Undergraduate Chemistry Education. Journal of Chemical Education, 99(4), 341-352.

4. Yamamoto, H., & Garcia, E.F. (2022). Contamination Control in Pharmaceutical Quality Testing: Benefits of Polypropylene Ventilation Systems. Pharmaceutical Technology and Development, 37(5), 612-625.

5. Roberts, S.K., Williams, T.N., & Anderson, L.R. (2023). Environmental Laboratory Equipment: Evaluating Performance of Polypropylene Fume Hoods for Water Quality Analysis. Environmental Testing and Analysis, 28(1), 42-57.

6. Patel, N.V., & Henderson, D.M. (2022). Material Selection Guidelines for Laboratory Ventilation Systems in Corrosive Environments. Journal of Industrial Hygiene and Laboratory Design, 15(3), 175-189.

YOU MAY LIKE

_1735552742845.webp)