What Are the Key Features to Look for in a Benchtop Hood?

2025-06-30 16:37:25

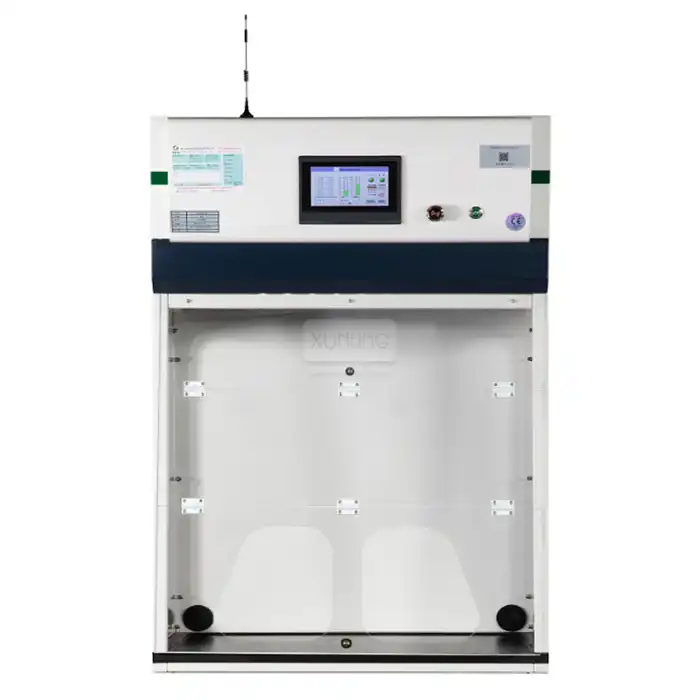

When selecting laboratory equipment for your workspace, understanding the essential features of a benchtop hood is crucial for ensuring both safety and efficiency. A benchtop hood, also known as a tabletop Fume Hood, desktop fume hood, or small fume hood, serves as a critical ventilation system designed specifically for small laboratories and personal workbenches. These compact yet powerful devices provide local exhaust capabilities to protect users from hazardous gases, vapors, and chemical fumes during laboratory operations. The key features to consider when choosing a benchtop hood include its ventilation efficiency, construction materials, size specifications, control systems, and safety mechanisms. These features directly impact the hood's performance in containing and removing dangerous substances while maintaining optimal working conditions. Understanding these characteristics will help you make an informed decision that aligns with your laboratory's specific requirements and safety standards.

Essential Design and Construction Features

Robust Hood Body Construction and Materials

The foundation of any reliable benchtop hood lies in its construction quality and material selection. Premium benchtop hood models feature hood bodies manufactured from 1.0mm full-thickness high-quality cold-roll steel sheet, which undergoes specialized phosphating treatment followed by electrostatic powder spraying with epoxy resin coating. This multi-layer protective system ensures exceptional durability and chemical resistance, making the benchtop hood suitable for handling various laboratory chemicals and corrosive substances. The steel construction provides structural integrity while the epoxy resin coating offers superior protection against chemical attacks, ensuring long-term performance and reliability. The double-wall construction methodology employed in advanced benchtop hood designs facilitates easy installation of plumbing and electrical fixtures while providing concealed routing for piping and wiring systems. This design approach not only enhances the aesthetic appeal of the benchtop hood but also improves safety by protecting utility connections from potential chemical exposure. The robust construction ensures that the benchtop hood can withstand daily laboratory operations while maintaining its structural integrity over extended periods, making it a valuable long-term investment for any laboratory facility.

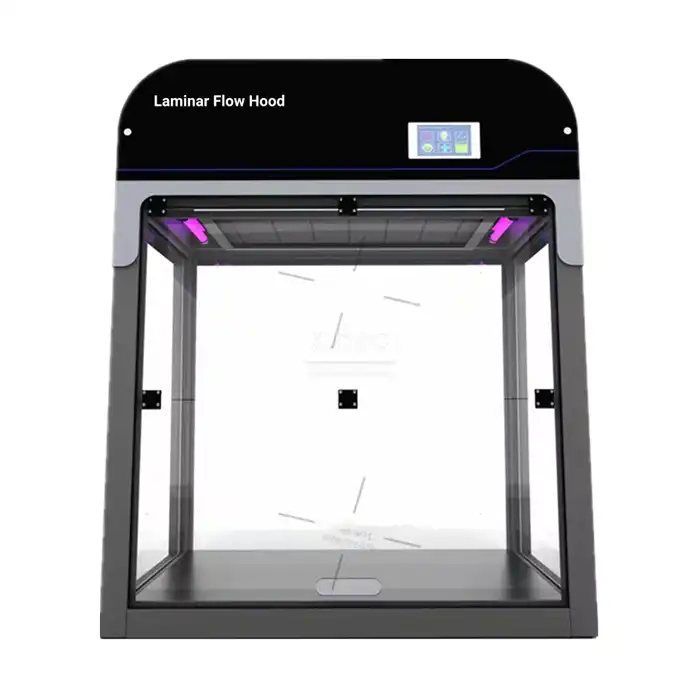

Advanced Glass Sash and Safety Systems

The glass sash system represents a critical safety component in any benchtop hood design, directly impacting user protection and operational efficiency. High-quality benchtop hood units incorporate explosion-proof 5mm tempered glass sashes that provide exceptional impact resistance and safety performance. The aluminum alloy sash handles are engineered with weight balance methods, ensuring smooth operation while maintaining optimal sealing when closed. This balanced design reduces operator fatigue during frequent sash adjustments and extends the operational lifespan of the mechanism. The tempered glass construction offers superior visibility into the working chamber while providing a robust barrier against potential chemical splashes or reactions. The weight balance system incorporated into the benchtop hood design ensures that the sash remains in any desired position without additional support, allowing operators to maintain optimal working heights while ensuring adequate protection. This feature is particularly important in educational settings and research environments where multiple users may require different sash positions for comfortable and safe operation of the benchtop hood system.

Chemical-Resistant Interior Components

The interior components of a benchtop hood must withstand constant exposure to various chemicals and cleaning agents while maintaining their structural and functional integrity. Premium benchtop hood models feature fume hood liners and baffles constructed from 5mm compact grade laminate, which offers exceptional chemical resistance and durability. The baffles are strategically fixed with PP (polypropylene) material, providing additional chemical resistance while ensuring easy maintenance and cleaning procedures. The three-section baffle system engineered into advanced benchtop hood designs ensures proper air distribution and maintains constant face velocity across the working area. This sophisticated baffle configuration optimizes airflow patterns within the benchtop hood, ensuring effective capture and removal of hazardous substances while minimizing turbulence that could compromise containment efficiency. The removable nature of these baffles facilitates thorough cleaning and maintenance, allowing laboratory personnel to maintain optimal hygiene standards and ensure continued performance of the benchtop hood system.

Advanced Ventilation and Control Systems

Intelligent Control Systems and Digital Displays

Modern benchtop hood systems incorporate sophisticated control mechanisms that enhance both safety and operational efficiency. The intelligent switch systems featured in premium benchtop hood models include comprehensive digital displays that provide real-time monitoring and control of various functions including power management, fan operation, lighting systems, electrical outlets, sterilization features, and damper controls. These advanced control systems allow operators to monitor and adjust the benchtop hood performance parameters in real-time, ensuring optimal operating conditions for different types of experiments and procedures. The digital display interface provides clear feedback on operational status, allowing users to quickly identify any issues or maintenance requirements. The intelligent control system in a benchtop hood can accommodate voltage ranges from 110V to 230V, making it suitable for international applications and various electrical infrastructure configurations. This versatility ensures that the benchtop hood can be deployed in diverse laboratory environments without requiring specialized electrical modifications, reducing installation complexity and associated costs.

Optimized Airflow Design and Ventilation Efficiency

The ventilation efficiency of a benchtop hood directly impacts its ability to protect users from hazardous substances while maintaining optimal working conditions. Advanced benchtop hood designs incorporate by-pass airflow systems with variable air volume compatibility, ensuring efficient ventilation across different operating conditions. The hood entrance is strategically framed with inward-angled members that minimize turbulence and provide smooth air movement, optimizing the capture efficiency of the benchtop hood system. The engineered airflow patterns within a benchtop hood ensure that hazardous substances are effectively captured and removed from the working area without creating dead zones or areas of poor ventilation. The variable air volume capability allows the benchtop hood to adjust its ventilation rate based on sash position and operational requirements, optimizing energy efficiency while maintaining safety standards. This intelligent ventilation system ensures that the benchtop hood provides consistent protection regardless of the specific experimental procedures being conducted within the unit.

Lighting and Visibility Systems

Adequate lighting is essential for safe and efficient laboratory operations, making the lighting system a critical feature of any benchtop hood. Premium benchtop hood models incorporate LED 30W purification lamps that provide luminosity greater than 300 LUX, ensuring optimal visibility for detailed laboratory work. The LED technology offers several advantages over traditional lighting systems, including lower energy consumption, longer operational life, and reduced heat generation within the benchtop hood workspace. The purification lamp functionality adds an additional layer of safety by providing germicidal capabilities when required, making the benchtop hood suitable for biological applications and sterile procedures. The high-quality LED lighting system ensures consistent illumination across the entire working area of the benchtop hood, eliminating shadows and dark spots that could compromise safety or experimental accuracy. The energy-efficient LED technology also contributes to the overall sustainability of the benchtop hood operation while reducing long-term operational costs.

Size Specifications and Application Versatility

Standard and Customizable Dimensions

The dimensional specifications of a benchtop hood must align with the available workspace and operational requirements of the laboratory facility. Standard benchtop hood configurations are available in multiple sizes including 1200×850×1500mm, 1500×850×1500mm, and 1800×850×1500mm, providing flexibility for different laboratory layouts and space constraints. These standardized dimensions ensure that the benchtop hood can accommodate various experimental setups while maintaining optimal performance characteristics across different size configurations. The availability of customized sizing options allows laboratories to specify benchtop hood dimensions that perfectly match their unique requirements and spatial constraints. This customization capability ensures that the benchtop hood integrates seamlessly into existing laboratory layouts without compromising functionality or safety standards. The modular design approach employed in benchtop hood manufacturing allows for efficient customization while maintaining the structural integrity and performance characteristics that define premium laboratory equipment.

Application-Specific Design Considerations

The versatility of benchtop hood applications requires careful consideration of design features that support diverse experimental procedures and user requirements. Educational settings such as school laboratories benefit from benchtop hood designs that emphasize safety and ease of use, with intuitive controls and robust construction that can withstand frequent use by multiple operators. The compact design of a benchtop hood makes it particularly suitable for educational environments where space optimization is crucial while maintaining high safety standards. Research institutions and individual researchers working with mild to moderate hazards require benchtop hood systems that provide reliable protection while offering flexibility for various experimental procedures. The benchtop hood design accommodates small-scale experiments involving chemicals or biological agents, providing the necessary containment and ventilation capabilities without the space requirements of larger fume hood systems. This versatility makes the benchtop hood an ideal solution for laboratories with limited space but demanding safety requirements.

Standard and Optional Accessories

The functionality of a benchtop hood can be significantly enhanced through the strategic selection of standard and optional accessories that support specific operational requirements. Standard accessories typically include four electrical outlets and a PP hood with either 250mm or 315mm diameter specifications, providing basic utility connections for common laboratory equipment and procedures. These standard features ensure that the benchtop hood can support typical laboratory operations without requiring additional modifications or accessories. Optional accessories expand the capabilities of the benchtop hood to meet specialized requirements, including PP oval cup sinks for wet chemistry applications, remote-controlled fixture gas and water faucets for automated operations, explosion-proof lighting for hazardous environments, distillation grid kits for specialized procedures, and comprehensive ductwork and exhaust blower configurations. The availability of these optional accessories allows laboratories to customize their benchtop hood systems to meet specific operational requirements while maintaining the core safety and performance characteristics that define premium laboratory equipment.

Conclusion

Selecting the right benchtop hood requires careful consideration of multiple factors including construction quality, ventilation efficiency, control systems, and application-specific requirements. The key features discussed in this guide provide a comprehensive framework for evaluating benchtop hood options and making informed decisions that align with your laboratory's safety standards and operational needs. Premium benchtop hood systems combine robust construction, intelligent controls, and versatile design to deliver reliable performance across diverse laboratory applications while maintaining the highest safety standards. Ready to enhance your laboratory safety and efficiency with a premium benchtop hood? Xi'an Xunling Electronic Technology Co., Ltd. offers comprehensive solutions with 5-day delivery, 5-year warranty, custom-made options, and one-stop service. Our OEM support, fast delivery, and reliable after-sales service ensure you receive the perfect benchtop hood for your specific requirements. From cost-effective solutions to comprehensive support, we're committed to providing exceptional value and reliability. Don't compromise on laboratory safety – Contact Us today at xalabfurniture@163.com to discuss your benchtop hood requirements and discover how our expertise can enhance your laboratory operations.

References

1. American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2019). Laboratory Design Guide: Best Practices for Ventilation Systems and Fume Hood Applications. ASHRAE Press.

2. Peterson, J.L. & Williams, R.K. (2021). Modern Laboratory Ventilation: Principles and Applications of Benchtop Fume Hood Systems. Journal of Laboratory Safety Engineering, 15(3), 245-267.

3. National Institute for Occupational Safety and Health. (2020). Criteria for Recommended Standard: Occupational Exposure to Laboratory Chemicals and Ventilation Requirements. NIOSH Publication No. 2020-106.

4. Thompson, M.A., Chen, L., & Rodriguez, S.P. (2018). Comparative Analysis of Compact Fume Hood Performance in Educational Laboratory Settings. Laboratory Management Review, 42(7), 112-128.

_1735469892197.webp)