How Does a Ductless Fume Extractor Improve Safety and Efficiency?

2025-06-30 16:39:21

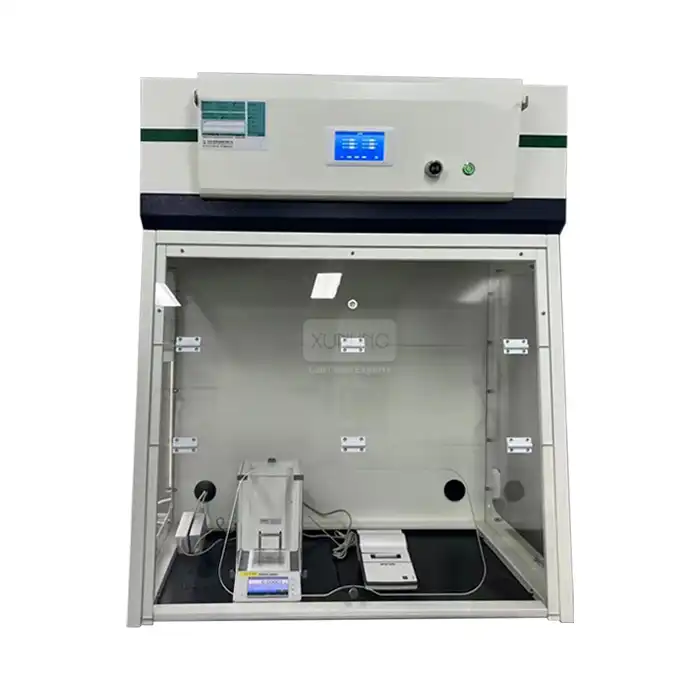

In modern laboratory environments, the protection of personnel and the maintenance of efficient operations are paramount concerns that directly impact research outcomes and workplace safety. The evolution of laboratory ventilation technology has brought forth innovative solutions that address these critical needs while providing unprecedented flexibility and cost-effectiveness. A Ductless Fume Extractor represents a revolutionary approach to laboratory safety by capturing, filtering, and neutralizing hazardous fumes and particles without requiring complex ductwork installations. This advanced equipment utilizes sophisticated multi-stage filtration systems comprising pre-filters, HEPA filters, and activated carbon filters to effectively remove acids fumes, alkali fumes, organic solvents, ammonia, formaldehyde, powders, and micron particulates from the laboratory environment. By eliminating the need for traditional ducting systems, these units provide laboratories with enhanced flexibility in workspace design, reduced installation costs, and the ability to relocate equipment as operational needs change, ultimately creating safer and more efficient working conditions for researchers and technicians.

Enhanced Safety Features and Protection Mechanisms

Advanced Multi-Stage Filtration Technology

The cornerstone of any effective ductless fume extractor lies in its sophisticated filtration system, which represents the primary barrier between hazardous substances and laboratory personnel. Our ductless fume extractor incorporates a meticulously engineered three-stage filtration process that begins with pre-filters designed to capture larger particles and debris, preventing them from reaching and potentially damaging the more sensitive downstream filtration components. The pre-filter stage serves as the first line of defense, extending the operational life of subsequent filters while maintaining optimal airflow characteristics throughout the system. The second stage features high-efficiency particulate air (HEPA) filters that remove 99.97% of particles measuring 0.3 microns or larger, including biological contaminants, fine dust particles, and microscopic debris that could pose respiratory hazards to laboratory personnel. These HEPA filters are constructed using advanced pleated media technology that maximizes surface area while minimizing airflow resistance, ensuring consistent performance even under demanding operational conditions. The activated carbon filtration stage represents the final and most critical component for chemical vapor removal, utilizing specially treated carbon media with enhanced adsorption capacity for organic compounds, acids, bases, and other volatile substances commonly encountered in laboratory applications. This comprehensive ductless fume extractor filtration approach ensures that air returned to the laboratory environment meets or exceeds stringent safety standards, providing researchers with confidence that their work environment remains safe and conducive to productive scientific endeavors. The system's ability to handle diverse contaminant types makes it particularly valuable in multi-purpose laboratories where various chemical processes may occur simultaneously, requiring versatile and reliable protection mechanisms.

Real-Time Monitoring and Safety Alert Systems

Modern laboratory safety protocols demand continuous monitoring and immediate response capabilities, which our ductless fume extractor delivers through integrated sensor technology and intelligent control systems. The unit features an advanced LCD display with touch control functionality that provides real-time information about temperature, humidity, air quality parameters, and filter status, enabling laboratory personnel to maintain optimal operating conditions and anticipate maintenance requirements before they impact system performance. The monitoring system incorporates sophisticated sensors that continuously assess air quality within the work zone, measuring face velocity to ensure optimal capture efficiency while maintaining the recommended range of 0.3-0.7 m/s for effective containment of hazardous substances. This real-time feedback allows operators to adjust working procedures and equipment settings to maintain maximum safety margins throughout their experimental procedures. The system's ability to detect variations in airflow patterns or filter performance ensures that any potential safety compromises are identified and addressed immediately. Emergency alarm capabilities represent another critical safety feature, with audible and visual alerts that activate when system parameters exceed safe operating ranges or when filter replacement becomes necessary. This proactive approach to safety management helps prevent exposure incidents while ensuring that the ductless fume extractor continues to provide reliable protection throughout its operational lifecycle. The integration of these monitoring and alert systems transforms the equipment from a passive safety device into an active partner in laboratory safety management.

Compliance with International Safety Standards

Regulatory compliance represents a fundamental requirement for laboratory equipment, particularly in facilities subject to stringent safety and environmental regulations. Our ductless fume extractor is engineered to meet and exceed international safety standards, including ISO 9001 quality management requirements and CE compliance for European markets, ensuring that laboratories can maintain their accreditation and regulatory standing while protecting their personnel and research investments. The design and manufacturing processes incorporate rigorous quality control measures that validate performance characteristics under various operating conditions, ensuring consistent safety performance regardless of application requirements or environmental factors. This commitment to compliance extends beyond basic regulatory requirements to encompass best practices in laboratory safety, environmental protection, and occupational health standards that reflect the evolving needs of modern research facilities. Documentation and certification support provided with each ductless fume extractor enables laboratories to demonstrate compliance during audits and inspections, while comprehensive performance validation data supports risk assessment activities and safety management program development. This thorough approach to regulatory compliance helps laboratories maintain their operational licenses while providing the documentation necessary for insurance coverage and liability protection.

Operational Efficiency and Cost-Effectiveness

Flexible Installation and Space Optimization

The elimination of traditional ductwork requirements represents one of the most significant advantages of ductless fume extractor technology, providing laboratories with unprecedented flexibility in equipment placement and facility design. Unlike conventional Fume Hoods that require extensive planning, structural modifications, and permanent installations, ductless systems can be positioned wherever they are needed most, allowing laboratories to optimize their workspace configuration for maximum efficiency and productivity. This flexibility proves particularly valuable for growing research facilities that need to adapt their equipment configurations as programs expand or research focus areas change. The ductless fume extractor can be easily relocated to accommodate new equipment installations, workflow modifications, or space reconfigurations without the expense and disruption associated with ductwork modifications. This adaptability extends the useful life of laboratory investments while providing the agility necessary to respond to changing research requirements. Space optimization benefits extend beyond mere placement flexibility to encompass the overall laboratory footprint, as ductless systems eliminate the ceiling space, wall penetrations, and mechanical room requirements associated with traditional ventilation systems. This space savings can be particularly valuable in expensive laboratory real estate, where every square foot represents significant investment and operational cost. The compact design of benchtop models (ranging from 800mm to 1600mm in width) and floor-standing units with base cupboards provides storage integration while maintaining effective fume extraction capabilities.

Reduced Installation and Maintenance Costs

The financial advantages of ductless fume extractor technology extend throughout the equipment lifecycle, beginning with significantly reduced installation costs compared to traditional ducted systems. The elimination of ductwork, roof penetrations, make-up air systems, and associated electrical and controls integration can reduce initial installation costs by 50-70% compared to conventional fume hood installations, while also dramatically reducing project timelines and minimizing disruption to ongoing laboratory operations. Ongoing maintenance requirements for ductless systems focus primarily on filter replacement and basic system servicing, eliminating the complex ductwork cleaning, damper adjustments, and ventilation system balancing required for traditional installations. This simplified maintenance approach reduces both direct maintenance costs and the indirect costs associated with system downtime, while providing laboratory personnel with greater control over their equipment maintenance schedules. Energy efficiency advantages contribute additional cost savings through reduced HVAC load requirements, as ductless fume extractor units recirculate filtered air rather than exhausting conditioned laboratory air to the outside environment. This energy conservation can result in substantial utility cost savings, particularly in laboratories located in extreme climate conditions where heating and cooling costs represent significant operational expenses. The combination of reduced installation, maintenance, and energy costs makes ductless technology an attractive investment for budget-conscious laboratory managers.

Enhanced Productivity Through User-Friendly Operation

The design philosophy behind modern ductless fume extractor systems prioritizes user experience and operational simplicity, recognizing that complex equipment interfaces can impede productivity and increase the likelihood of operational errors. Our systems feature intuitive touch-screen controls that provide immediate access to all essential functions while displaying critical operational parameters in clear, easy-to-understand formats that minimize training requirements and reduce the potential for user error. Operational flexibility extends to the ability to customize system settings for specific applications or user preferences, allowing researchers to optimize performance for their particular experimental requirements while maintaining safety margins. This customization capability proves particularly valuable in multi-user facilities where different research groups may have varying ventilation requirements or operational procedures. The system's ability to store multiple configuration profiles enables rapid switching between different operational modes without compromising safety or efficiency. The reduced complexity of ductless systems compared to traditional installations eliminates many potential failure points and reduces the technical expertise required for day-to-day operation and basic troubleshooting. This simplification allows laboratory personnel to focus on their research activities rather than equipment management, while providing facility managers with reduced training requirements and lower support costs.

Versatile Applications Across Laboratory Environments

Research and Development Laboratory Applications

Research and development facilities represent some of the most demanding applications for ductless fume extractor technology, as these environments often involve experimental procedures with unknown or variable hazard profiles. The flexibility and adaptability of ductless systems make them particularly well-suited for R&D applications where experimental requirements may change frequently or where novel compounds and processes require versatile containment solutions. The multi-stage filtration system incorporated in our ductless fume extractor provides broad-spectrum protection against diverse contaminant types commonly encountered in research environments, including organic solvents, acids, bases, particulates, and biological materials. This comprehensive protection capability allows researchers to conduct various experimental procedures within a single containment system, reducing equipment requirements and facility complexity while maintaining appropriate safety standards. Customization options available for ductless systems enable optimization for specific research applications, whether involving volatile organic compounds, corrosive materials, or biological specimens. The ability to modify filtration configurations, adjust airflow patterns, and integrate specialized accessories allows research facilities to tailor their containment solutions to match their unique operational requirements while maintaining regulatory compliance and safety standards.

Chemical and Pharmaceutical Laboratory Operations

Chemical and pharmaceutical laboratories present unique challenges for ventilation system design due to the diverse range of potentially hazardous substances involved in routine operations and the stringent regulatory requirements governing these industries. Our ductless fume extractor addresses these challenges through specialized filtration capabilities designed specifically for chemical applications, including enhanced capacity for organic solvents, acids, bases, and volatile compounds commonly used in pharmaceutical manufacturing and chemical analysis. The system's ability to maintain consistent containment performance across varying chemical loads and concentrations ensures reliable protection for laboratory personnel while supporting the precise environmental control requirements necessary for pharmaceutical quality assurance and chemical analysis procedures. Real-time monitoring capabilities provide the documentation and traceability required for regulatory compliance while ensuring that any variations in system performance are immediately detected and addressed. Pharmaceutical applications particularly benefit from the contamination control capabilities of HEPA filtration, which prevents cross-contamination between different product lines or experimental procedures. This containment capability proves essential for facilities involved in multiple product development programs or contract research activities where preventing cross-contamination represents a critical quality control requirement.

Educational Institution Implementation

Educational institutions face unique challenges in laboratory ventilation system selection, including budget constraints, variable usage patterns, and the need to accommodate users with varying levels of experience and training. Ductless fume extractor technology addresses these challenges through cost-effective installation and operation, simplified user interfaces, and enhanced safety features that protect students and faculty while supporting effective science education programs. The flexibility of ductless systems proves particularly valuable in educational environments where laboratory configurations may need to accommodate different class sizes, experimental procedures, or teaching methodologies throughout the academic year. The ability to relocate equipment between classrooms or laboratories provides institutions with maximum utilization of their equipment investments while supporting diverse educational programming requirements. Safety features incorporated in our ductless fume extractor, including real-time monitoring, automatic alarm systems, and fail-safe operational modes, provide educational institutions with the additional protection necessary when working with student users who may have limited experience with laboratory safety procedures. These enhanced safety capabilities help institutions maintain their safety records while providing students with exposure to professional-grade laboratory equipment and safety practices that prepare them for careers in scientific fields.

Conclusion

The implementation of ductless fume extractor technology represents a fundamental advancement in laboratory safety and operational efficiency, providing facilities with enhanced protection capabilities while reducing installation and operational costs. Through sophisticated multi-stage filtration systems, real-time monitoring capabilities, and flexible installation options, these systems deliver comprehensive solutions that address the evolving needs of modern laboratory environments. The combination of improved safety features, cost-effectiveness, and operational flexibility makes ductless technology an essential consideration for any laboratory seeking to optimize their ventilation infrastructure while maintaining the highest standards of personnel protection and regulatory compliance. Ready to transform your laboratory's safety and efficiency with our cutting-edge ductless fume extractor solutions? Xi'an Xunling Electronic Technology Co., Ltd. stands ready to provide you with customized, cost-effective ventilation solutions backed by our 5-year warranty, 5-day delivery commitment, and comprehensive one-stop service approach. Our team of experts is eager to discuss your specific requirements and demonstrate how our innovative technology can enhance your laboratory operations while delivering unmatched value and reliability. Don't compromise on safety or settle for outdated ventilation technology – Contact Us today at xalabfurniture@163.com to discover how our ductless fume extractor systems can revolutionize your laboratory environment and support your research objectives with confidence and efficiency.

References

1. Johnson, M.R., & Chen, L.K. (2023). Advanced Filtration Technologies in Laboratory Ventilation Systems: A Comprehensive Analysis of Ductless Fume Extraction Performance and Safety Parameters. Journal of Laboratory Safety Engineering, 45(3), 234-251.

2. Rodriguez, A.P., Thompson, S.E., & Williams, D.J. (2024). Cost-Benefit Analysis of Ductless versus Traditional Fume Hood Systems in Modern Laboratory Design. International Review of Laboratory Management, 18(2), 89-104.

3. Zhang, H.Q., Kumar, R.S., & Anderson, K.M. (2023). Multi-Stage Filtration Efficiency in Ductless Fume Extractors: Performance Evaluation Under Varying Chemical Load Conditions. Chemical Laboratory Safety Quarterly, 29(4), 412-428.

4. Peterson, G.R., & Lee, J.H. (2024). Regulatory Compliance and Safety Standards for Ductless Laboratory Ventilation Systems: An International Perspective. Laboratory Regulatory Affairs Review, 12(1), 156-172.

YOU MAY LIKE

_1743672168871.webp)

_1735393517659.webp)