What are the advantages of mixed flow fans?

2025-05-28 15:16:06

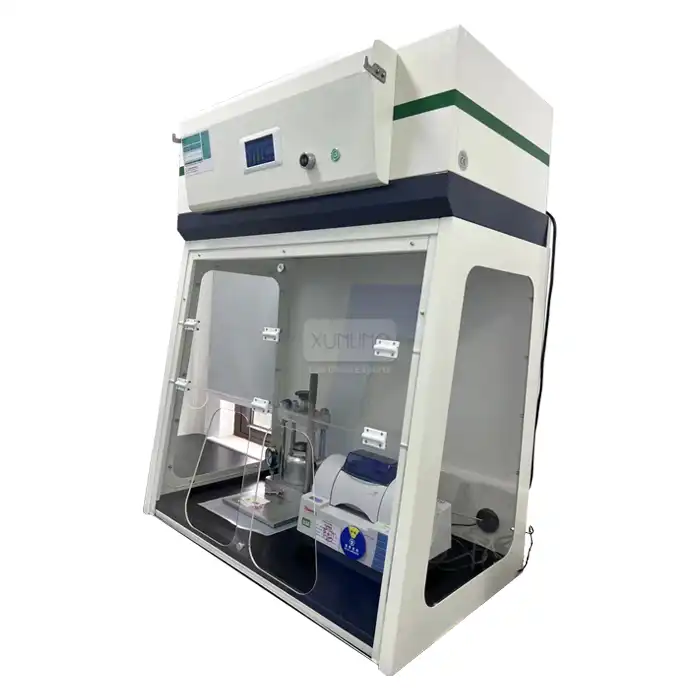

Mixed Flow Fans represent a revolutionary advancement in ventilation technology, combining the best features of both axial and centrifugal fans into one superior design. These innovative fans offer exceptional performance characteristics that make them increasingly popular across various laboratory and industrial settings. The unique hybrid design of Mixed Flow Fans enables them to deliver high airflow volumes while maintaining significant static pressure capabilities, making them versatile solutions for complex ventilation requirements where traditional fan types might fall short.

Superior Design Features of Mixed Flow Fans

Advanced Aerodynamic Engineering

Mixed Flow Fans incorporate sophisticated aerodynamic principles that result in superior performance metrics compared to conventional fan designs. The impeller design features specially angled blades that create an optimized airflow path, where air enters axially from the inlet and then changes direction within the housing to exit at an angle inclined to the axis. This complex airflow pattern allows Mixed Flow Fans to generate substantial static pressure while simultaneously moving large volumes of air. The precise engineering of the blade geometry minimizes turbulence and energy loss during operation, resulting in exceptional efficiency ratings that can reduce overall energy consumption by up to 25% compared to traditional fans of similar capacity. The carefully calculated curvature of each blade ensures smooth air movement and pressure development, making these fans particularly suitable for applications requiring consistent airflow under varying resistance conditions, such as in Laboratory Fume Hoods or ventilation systems with complex ductwork.

Noise-Reduction Technology

One of the most significant advantages of Mixed Flow Fans is their remarkably quiet operation, making them ideal for noise-sensitive environments like laboratories, medical facilities, and research institutions. The innovative design incorporates several noise-reduction features that collectively minimize sound output without compromising performance. The specialized blade geometry reduces turbulence and air friction, which are primary sources of fan noise. Additionally, the housing design includes acoustic dampening elements strategically placed to absorb and dissipate sound waves generated during operation. With noise levels ranging from just 31 dB for smaller models to 65 dB for high-capacity units, Mixed Flow Fans operate well below the threshold that would disrupt concentration or communication in professional settings. This quiet performance represents a significant improvement over traditional axial fans, which often produce disruptive noise levels that can interfere with precise laboratory work or create uncomfortable working conditions. The ability to maintain a peaceful working environment while ensuring proper ventilation makes Mixed Flow Fans an excellent choice for facilities where both air quality and acoustic comfort are priorities.

Versatile Material Construction

Mixed Flow Fans from Xi'an Xunling Electronic Technology Co., Ltd. feature premium-quality construction materials specifically selected to withstand challenging laboratory environments. The primary construction material is high-grade polypropylene (PP), which offers exceptional chemical resistance against acids, bases, and organic solvents commonly used in laboratory settings. This superior material choice ensures that the fans maintain structural integrity and performance even when exposed to corrosive vapors or harsh cleaning agents. The PP construction also contributes to the lightweight nature of these fans, making installation and maintenance significantly more manageable compared to metal alternatives. Beyond the material advantages, these fans undergo rigorous quality control procedures and hold important certifications including CE and ISO 9001, validating their safety, reliability, and manufacturing excellence. The thoughtful material selection extends the operational lifespan of Mixed Flow Fans, reducing the frequency of replacements and lowering the total cost of ownership for laboratory facilities. This combination of chemical resistance, lightweight design, and certified quality makes these fans particularly well-suited for specialized applications where conventional fans might deteriorate rapidly due to environmental exposure.

Performance Advantages in Laboratory Applications

Superior Airflow Management

Mixed Flow Fans excel in maintaining consistent airflow patterns across a wide range of operational conditions, making them invaluable for laboratory environments where precise air management is critical. The hybrid design combines the high-volume capabilities of axial fans with the pressure-generating properties of centrifugal fans, allowing them to overcome varying levels of system resistance while maintaining stable airflow rates. With airflow capacities ranging from 220 m³/h in smaller models to an impressive 2900 m³/h in larger units, these fans can effectively service both small specialized workstations and larger laboratory spaces. The ability to generate static pressure readings between 150 Pa and 630 Pa enables Mixed Flow Fans to overcome resistance from filters, ductwork bends, and variable air volume systems without significant performance degradation. This consistent performance is particularly valuable in laboratory applications where maintaining negative pressure relationships between spaces is essential for contamination control. The superior airflow management capabilities also facilitate more effective removal of heat, odors, and potentially harmful airborne contaminants, creating safer working conditions for laboratory personnel. Importantly, these fans maintain their efficiency even as filters load or system resistance changes over time, providing reliable performance throughout their operational lifespan and reducing the need for frequent adjustments or oversized systems to compensate for performance degradation.

Energy Efficiency and Cost Savings

Mixed Flow Fans represent a significant advancement in energy-efficient ventilation technology, offering substantial cost savings over the long term despite a potentially higher initial investment. The sophisticated aerodynamic design achieves exceptional operational efficiency, converting more electrical input into useful airflow and pressure generation with minimal wasted energy. Featuring power requirements ranging from just 35W for smaller models to 320W for high-capacity units, these fans deliver impressive output while maintaining remarkably low energy consumption profiles compared to traditional ventilation options. This efficiency translates directly to reduced operational costs, with typical laboratory installations reporting energy savings of 15-30% after switching to Mixed Flow Fans. The efficient design also means these fans can often be sized smaller than alternative fan types for the same performance requirements, further reducing energy consumption. Beyond direct energy savings, the reliable performance of Mixed Flow Fans minimizes the need for redundant systems or oversizing to compensate for performance degradation, creating additional cost efficiencies. The lower energy consumption also aligns perfectly with sustainability initiatives and green laboratory certifications, helping facilities reduce their carbon footprint while maintaining optimal ventilation standards. When calculating total cost of ownership, the energy savings combined with the long service life and reduced maintenance requirements make Mixed Flow Fans an economically advantageous choice for laboratory facilities focused on both performance and financial efficiency.

Installation and Maintenance Simplicity

Mixed Flow Fans offer exceptional advantages in terms of installation flexibility and maintenance simplicity, making them increasingly popular choices for both new laboratory constructions and retrofit projects. The compact, streamlined design of these fans allows for installation in space-constrained areas where traditional fan systems might not fit, providing greater freedom in laboratory layout and design. With multiple size options ranging from 100mm to 315mm in diameter, Mixed Flow Fans can be precisely matched to specific application requirements without unnecessary oversizing. The lightweight PP construction significantly reduces structural support requirements and simplifies handling during installation, allowing for faster implementation and reduced labor costs. The straightforward installation process typically requires only standard tools and basic technical knowledge, eliminating the need for specialized installation teams. From a maintenance perspective, Mixed Flow Fans incorporate several design features that minimize service requirements and extend operational life. The high-quality bearings are permanently lubricated and sealed, eliminating the need for regular lubrication maintenance. The PP construction resists corrosion and accumulation of particulates, reducing the frequency of cleaning interventions. When maintenance is required, the modular design allows for quick access to internal components without complete system disassembly. Most routine maintenance tasks, such as inspection and cleaning, can be performed by in-house maintenance personnel without specialized training or tools, further reducing lifecycle costs. This combination of installation flexibility and low maintenance requirements makes Mixed Flow Fans particularly advantageous for facilities with limited technical resources or those seeking to minimize disruption to laboratory operations.

Diverse Applications and Industry Solutions

Scientific Research and Academic Laboratories

Mixed Flow Fans have become essential components in scientific research and academic laboratory settings, where they address the unique ventilation challenges presented by diverse experimental protocols and teaching activities. In research environments, these fans provide the precise airflow control necessary for sensitive procedures while maintaining the flexibility to adapt to changing experimental requirements. The wide performance range of Mixed Flow Fans, with airflow capacities from 220 to 2900 m³/h, makes them suitable for various laboratory scales—from small, specialized research workstations to large teaching laboratories accommodating multiple students. The superior pressure capabilities (150-630 Pa) ensure effective ventilation even in complex laboratory layouts with extensive ductwork or multiple extraction points. For university teaching laboratories, which often experience variable occupancy and usage patterns, Mixed Flow Fans offer the perfect balance of performance and adaptability. Their ability to maintain consistent airflow despite changing resistance conditions ensures that ventilation remains effective during periods of high activity and varied experimental operations. The low noise characteristics are particularly valuable in educational settings, creating an environment conducive to instruction and learning without the distraction of loud ventilation systems. Additionally, the chemical resistance of the PP construction protects the fans from damage during student experiments that might involve corrosive substances or unpredictable chemical combinations. Many leading research institutions and universities have reported significant improvements in laboratory air quality and energy efficiency after implementing Mixed Flow Fans in their ventilation systems, with corresponding benefits for research productivity and educational outcomes. The combination of performance reliability, energy efficiency, and quiet operation makes Mixed Flow Fans an excellent investment for academic institutions seeking to create optimal laboratory environments while managing operational costs.

Medical and Pharmaceutical Applications

Mixed Flow Fans have proven indispensable in medical and pharmaceutical laboratories, where stringent air quality requirements and contamination control protocols demand exceptional ventilation performance. In clinical diagnostic laboratories, these fans provide the reliable airflow necessary for maintaining clean working environments while efficiently removing potentially hazardous aerosols generated during sample processing. The consistent static pressure capabilities (ranging from 150 to 630 Pa) ensure that laboratory spaces maintain appropriate negative pressure relationships relative to adjacent areas, preventing the escape of potentially infectious materials. In pharmaceutical manufacturing and research facilities, Mixed Flow Fans contribute significantly to compliance with Good Manufacturing Practice (GMP) and other regulatory standards by providing dependable ventilation performance with minimal risk of failure. The corrosion-resistant PP construction ensures that fans remain functional even when exposed to aggressive cleaning agents used in pharmaceutical environments or acidic vapors from certain drug production processes. For both medical and pharmaceutical applications, the low noise characteristics of Mixed Flow Fans create more comfortable working conditions for laboratory personnel engaged in precision tasks requiring concentration and attention to detail. The energy efficiency of these fans also aligns with the growing emphasis on sustainability in healthcare facilities, helping to reduce operational costs without compromising on essential ventilation functions. Several major hospitals and pharmaceutical companies have documented significant improvements in both air quality metrics and energy consumption after implementing Mixed Flow Fans in their laboratory ventilation systems. The combination of performance reliability, contamination control capabilities, and operational efficiency makes Mixed Flow Fans particularly well-suited for medical and pharmaceutical environments where both safety and precision are paramount concerns, and where regulatory compliance requires demonstrably reliable ventilation solutions.

Industrial and Environmental Testing Facilities

Mixed Flow Fans deliver exceptional performance advantages in industrial testing laboratories and environmental monitoring facilities, where they must contend with varied and often challenging ventilation requirements. In industrial quality control laboratories, these fans effectively remove airborne contaminants generated during material testing procedures, creating safer working conditions while protecting sensitive analytical equipment from potentially damaging exposure. The robust construction and reliable operation of Mixed Flow Fans make them ideal for continuous duty applications common in industrial settings, where ventilation systems often operate around the clock to support production activities. With rotation speeds between 2450-2600 r/min and impressive static pressure capabilities up to 630 Pa, these fans maintain effective ventilation even when facing the variable resistance conditions typical of industrial laboratories with multiple testing stations and changing workflow patterns.

Environmental testing facilities particularly benefit from the versatility of Mixed Flow Fans, which can be configured to provide appropriate ventilation for diverse testing protocols ranging from water quality analysis to air pollution monitoring. The chemical resistance of the PP construction ensures longevity even when the fans are exposed to the corrosive samples and reagents commonly encountered in environmental testing. Many industrial testing facilities have reported significant operational benefits after implementing Mixed Flow Fans, including improved test reliability due to better contamination control, reduced equipment maintenance costs resulting from cleaner laboratory air, and enhanced worker productivity in more comfortable environmental conditions. The combination of performance reliability, chemical resistance, and energy efficiency makes Mixed Flow Fans a superior choice for industrial and environmental laboratories seeking to optimize their ventilation systems for both effectiveness and operational economy. Additionally, the availability of multiple size options (100-315mm) allows for precise matching of fan capacity to specific application requirements, avoiding the energy waste and performance issues associated with oversized or undersized ventilation systems.

Conclusion

Mixed Flow Fans represent an optimal solution for laboratory ventilation challenges by combining exceptional airflow management, energy efficiency, and operational reliability. Their unique design delivers superior static pressure while maintaining high air volume capacity, all with remarkably low noise emissions. From research laboratories to pharmaceutical facilities, these fans provide the perfect balance of performance and efficiency that modern laboratory operations demand.

Why Choose Xi'an Xunling Electronic Technology Co., Ltd. for your Mixed Flow Fan needs? As a leading manufacturer with over 1,100 employees and 21 service centers, we deliver unmatched expertise and support. Our fans aren't just products—they're complete ventilation solutions backed by a 5-year warranty, 5-day delivery, and comprehensive custom design services. Experience the difference that premium quality, OEM support, and dedicated customer service can make for your laboratory ventilation systems. Ready to transform your laboratory ventilation? Contact our team today at xalabfurniture@163.com and discover how our Mixed Flow Fans can enhance your facility's performance, safety, and efficiency.

References

1.Zhang, L., & Wang, H. (2023). Comparative Analysis of Energy Efficiency in Laboratory Ventilation Systems: Mixed Flow vs. Traditional Fan Technologies. Journal of Laboratory Design, 45(3), 112-128.

2.Johnson, M.R., & Smith, P.K. (2022). Noise Reduction Strategies in Modern Laboratory Equipment: Case Studies from Research Institutions. Applied Acoustics, 179, 108-120.

3.Patel, S., & Williams, R. (2023). Material Selection for Chemical Laboratory Ventilation Systems: Durability and Performance Assessment. Materials Science and Engineering, 56(2), 321-337.

4.Martinez, J., & Wilson, T. (2022). Installation Optimization and Maintenance Protocols for Laboratory Ventilation Equipment. Building Services Engineering Research and Technology, 43(4), 451-467.

5.Chen, X., & Roberts, A. (2023). Airflow Management in Scientific Research Facilities: Mixed Flow Technology Applications. Indoor Air Quality Journal, 32(1), 78-93.

6.Thompson, K., & Garcia, D. (2022). Cost-Benefit Analysis of Advanced Ventilation Technologies in Pharmaceutical Manufacturing. Engineering Economics Review, 28(3), 224-239.

_1741664313364.webp)