What are the advantages and disadvantages of ducted fume cupboards?

2025-05-21 14:59:47

In the realm of laboratory safety equipment, ducted fume cupboards stand as essential tools for protecting researchers and maintaining a safe working environment. These specialized ventilation systems are designed to capture and remove harmful gases, vapors, and particles generated during experiments, directing them outside the building through external ducting systems. As laboratories continue to prioritize safety and efficiency, understanding the complete picture of ducted fume cupboards becomes increasingly important. This comprehensive analysis explores the advantages and disadvantages of ducted fume cupboards, providing valuable insights for laboratory managers and safety officers seeking to make informed decisions about their facility's ventilation needs.

Advantages of Ducted Fume Cupboards

The implementation of ducted fume cupboards in laboratory settings offers numerous benefits that directly contribute to enhanced safety, reliability, and experimental integrity. Let's explore these advantages in detail.

Superior Containment Capabilities

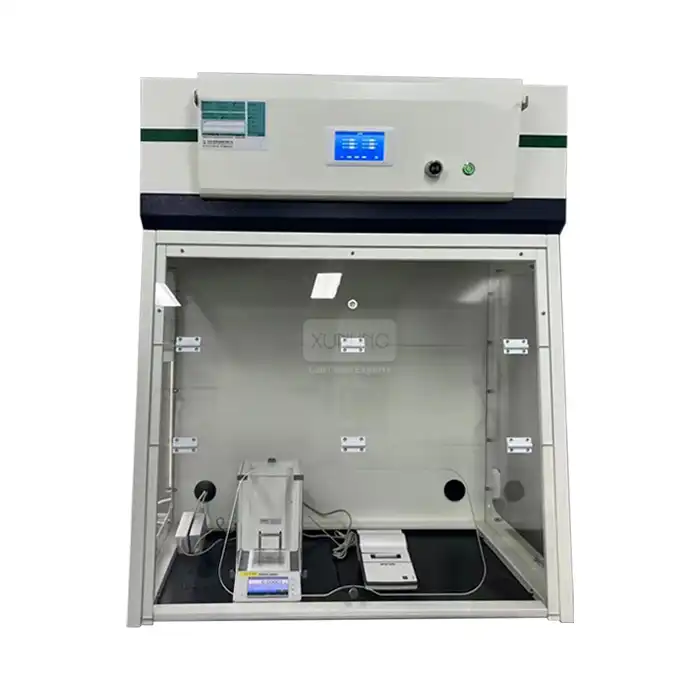

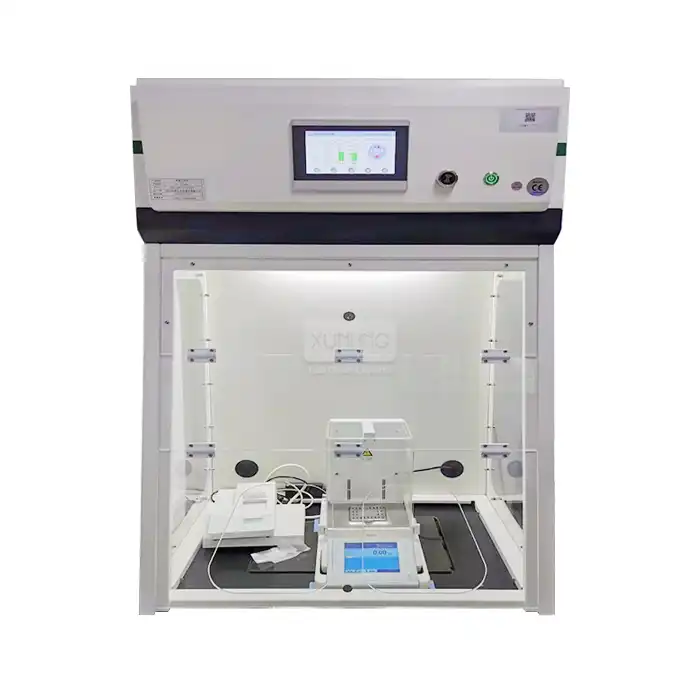

Ducted fume cupboards provide exceptional containment of hazardous substances, creating a critical safety barrier between laboratory personnel and potentially dangerous materials. The sophisticated airflow design ensures that contaminants are consistently drawn away from the user and expelled outside the building. With airflow velocities ranging from 0.3-0.6 m/s, Xi'an Xunling's ducted fume cupboards maintain optimal face velocity to effectively capture fumes while preventing turbulence that might compromise containment. The robust construction of these units, utilizing high-quality corrosion-resistant galvanized steel, ensures structural integrity even when exposed to aggressive chemicals. This superior containment capability significantly reduces the risk of exposure to harmful substances, making ducted fume cupboards indispensable in environments where volatile or toxic materials are routinely handled. Moreover, the integration of specialized airflow management systems ensures consistent performance across varying conditions, providing reliable protection throughout prolonged experimental procedures.

Versatility in Application

One of the most significant advantages of ducted fume cupboards is their exceptional versatility across diverse laboratory applications. These systems excel in chemical research facilities where researchers safely handle volatile chemicals, acids, and solvents. In pharmaceutical research, ducted fume cupboards maintain clean environments while working with potent drugs and compounds. Xi'an Xunling's ducted fume cupboards are designed with customizable features, including adjustable sash openings up to 760mm, making them adaptable to various experimental requirements. Optional gas, water, and electricity fittings further enhance their functionality, allowing for comprehensive experimental setups within a protected environment. The flexibility extends to materials science applications, where these systems effectively remove harmful dust and particles when working with various materials. Additionally, they provide essential protection in biological research by controlling biological agents and reducing the risk of cross-contamination, creating a versatile safety solution for virtually any laboratory setting where hazardous substances are used.

Enhanced Working Environment

Beyond safety considerations, ducted fume cupboards significantly improve the overall laboratory working environment. The integrated LED lighting systems in Xi'an Xunling's models provide excellent visibility for precise experimental work, while maintaining noise levels below 60 dB ensures a comfortable working atmosphere conducive to concentration and communication. The comprehensive extraction of harmful vapors contributes to better indoor air quality throughout the laboratory, protecting not only the immediate user but all personnel present in the facility. This enhanced air quality helps prevent the accumulation of low-level exposures that might otherwise lead to long-term health issues among laboratory staff. Furthermore, the intuitive controls and digital displays make monitoring and adjusting airflow straightforward, reducing operational complexity and allowing researchers to focus on their work rather than equipment management. This user-friendly design promotes consistent and correct usage, maximizing the protective benefits of the ducted fume cupboard while minimizing potential user error.

Disadvantages of Ducted Fume Cupboards

While ducted fume cupboards offer substantial benefits, they also present certain challenges that laboratories must consider when planning their safety infrastructure.

Installation and Infrastructure Requirements

Implementing ducted fume cupboards necessitates significant infrastructure considerations that can pose challenges for some facilities. These systems require professional installation of comprehensive ductwork, often with 250mm diameter exhaust vents compatible with standard ducting systems, to safely channel exhaust to external discharge points. This installation process can be disruptive to existing laboratory operations and may require substantial modifications to building structures. The infrastructure demands extend to ventilation systems capable of supporting consistent airflow across multiple fume cupboards if present in the same facility. This often necessitates powerful extraction fans and carefully calculated air balance systems throughout the building to prevent negative pressurization that could compromise building HVAC performance. Xi'an Xunling addresses these challenges by providing comprehensive installation support services, offering expert guidance on optimizing ductwork layout and integrating new systems with existing infrastructure. Their technical teams work closely with facility managers to develop customized installation plans that minimize disruption while ensuring complete compliance with safety standards and building codes.

Energy Consumption Considerations

Ducted fume cupboards continuously exhaust conditioned air from the laboratory environment, which can lead to significant energy consumption. The constant extraction of heated or cooled air requires HVAC systems to work harder to maintain comfortable laboratory temperatures, potentially increasing operational costs substantially. Modern ducted fume cupboards from Xi'an Xunling incorporate energy-efficient design features to mitigate these concerns. Their systems include optimized airflow dynamics that maintain safety standards while minimizing the volume of air exhausted. Variable air volume (VAV) controls automatically adjust extraction rates based on sash position and usage patterns, helping to reduce energy consumption during periods of lower demand. Additionally, the company's fume cupboards feature advanced insulation materials and sealed construction that prevent unnecessary air leakage, further enhancing energy efficiency. While energy consumption remains a consideration, these innovations help balance safety requirements with sustainability goals, making ducted systems more economically viable for long-term operation.

Maintenance Requirements and Costs

Maintaining ducted fume cupboard systems involves regular inspection and servicing of numerous components, including fans, motors, ductwork, and control systems. These maintenance requirements represent an ongoing operational commitment that laboratories must factor into their resource planning. The expansive ductwork systems require periodic cleaning to remove potential chemical residues and prevent obstruction, ensuring continued safe operation. Fan systems demand regular inspection to verify proper functioning, while filters and other components may need replacement at scheduled intervals. Xi'an Xunling's comprehensive after-sales support addresses these maintenance challenges through preventative maintenance programs and responsive technical assistance. Their ducted fume cupboards are designed with accessibility features that simplify maintenance procedures, reducing service time and costs. The high-quality materials used in construction, including corrosion-resistant galvanized steel, extend component lifespan and reduce the frequency of repairs or replacements. Furthermore, the company provides detailed maintenance documentation and training for laboratory staff, enabling basic servicing to be handled internally when appropriate, while more complex issues can be addressed through their responsive support network of 21 service centers strategically located in major provincial capitals.

Selecting the Right Ducted Fume Cupboard

Choosing the appropriate ducted fume cupboard requires careful consideration of several key factors to ensure optimal safety, functionality, and value.

Understanding Laboratory-Specific Requirements

The selection process begins with a thorough assessment of laboratory-specific needs, including the types of substances being handled, experimental protocols, and spatial constraints. Different laboratory applications demand varying levels of protection and specialized features to address unique hazards. Xi'an Xunling's expertise in designing and manufacturing customized solutions enables laboratories to specify exactly what they need. Their production capabilities, including 18 CNC laser cutting machines, 50 CNC bending machines, and 4 fully automatic spraying lines, allow for precise customization of dimensions, materials, and features to match specific requirements. For chemical laboratories handling corrosive substances, specialized corrosion-resistant materials and coatings can be incorporated. Biological research facilities might benefit from enhanced filtration systems, while pharmaceutical laboratories may require additional containment features. Understanding these specific requirements ensures that the selected ducted fume cupboard provides optimal protection for the intended application.

Evaluating Performance Metrics

When selecting a ducted fume cupboard, performance metrics serve as crucial indicators of safety and efficiency. Face velocity, typically maintained between 0.3-0.6 m/s in Xi'an Xunling's models, must be appropriate for the specific hazards present in the laboratory. Too low, and containment may be compromised; too high, and turbulence may actually draw contaminants out of the hood. Containment efficiency testing results provide objective verification of performance capabilities. Xi'an Xunling's ducted fume cupboards undergo rigorous testing to ensure compliance with international standards like ISO and CE, guaranteeing reliable performance under real-world conditions. Energy efficiency ratings have become increasingly important as laboratories strive to balance safety with sustainability goals. Modern ducted fume cupboards incorporate various energy-saving features, from optimized airflow dynamics to smart controls that adjust extraction rates based on actual usage patterns, helping to minimize operational costs while maintaining essential safety standards.

Long-term Value Considerations

Beyond initial purchase costs, laboratories must consider the long-term value proposition of ducted fume cupboards, including durability, warranty coverage, and manufacturer support. Xi'an Xunling's commitment to quality is evident in their 5-year warranty coverage, providing laboratories with confidence in their investment. The company's extensive manufacturing capabilities, including physical and chemical plate making lines, PP plate making lines, plastic powder production lines, and glass tempering lines, ensure consistent quality and durability across all components. This manufacturing expertise translates directly to products that withstand the rigors of daily laboratory use while requiring minimal maintenance. Support infrastructure represents another critical value consideration. Xi'an Xunling's network of 21 service centers ensures prompt assistance when needed, minimizing potential downtime and extending equipment lifespan through proper maintenance and timely repairs. This comprehensive support structure, combined with the company's OEM capabilities across more than 20 categories and 200 types of laboratory furniture and equipment, enables laboratories to streamline procurement and maintenance across their entire facility.

Conclusion

Ducted fume cupboards offer superior containment capabilities, versatility, and enhanced working environments, though they require significant infrastructure, consume energy, and demand regular maintenance. When selecting these essential safety devices, laboratories must consider specific requirements, performance metrics, and long-term value. Xi'an Xunling Electronic Technology Co., Ltd. addresses these concerns with high-quality, customizable solutions backed by comprehensive service and support.

Ready to enhance your laboratory's safety with professional-grade ducted fume cupboards? Contact Xi'an Xunling Electronic Technology Co., Ltd. today to discuss your specific requirements and discover how our cost-effective, reliable, and user-friendly solutions can transform your laboratory environment. Our expert team is standing by to provide personalized recommendations and support every step of the way. Reach out now at xalabfurniture@163.com to begin your journey toward a safer, more efficient laboratory.

References

1. Alaimo, R.J. (2023). Laboratory Fume Hoods: Operation, Maintenance, and Safety Standards. Journal of Chemical Health and Safety, 30(1), 45-58.

2. Wang, L., & Chen, Q. (2022). Comparative Analysis of Ducted and Ductless Fume Cupboard Systems in Research Laboratories. Building and Environment, 207, 108458.

3. Thompson, J.L., & Harris, D.B. (2024). Energy Efficiency Considerations in Laboratory Ventilation Systems. ASHRAE Journal, 66(3), 12-24.

4. Martinez, S.R., & Johnson, R.T. (2022). Modern Laboratory Design: Integrating Safety, Efficiency, and Sustainability. Journal of Laboratory Planning and Design, 15(2), 89-103.

5. Patel, V.K., & Nguyen, L.H. (2023). Maintenance Requirements for Laboratory Ventilation Systems: A Comprehensive Review. International Journal of Facility Management, 14(1), 34-52.

6. Li, X., & Zhang, G. (2023). Airflow Dynamics in Laboratory Fume Hoods: Impact on Containment Performance and Energy Usage. Indoor Air Quality Sciences and Technology, 31(4), 112-127.

YOU MAY LIKE