How to Select the Right Perchloric Acid Fume Hood for Your Workflow?

2025-08-28 09:00:02

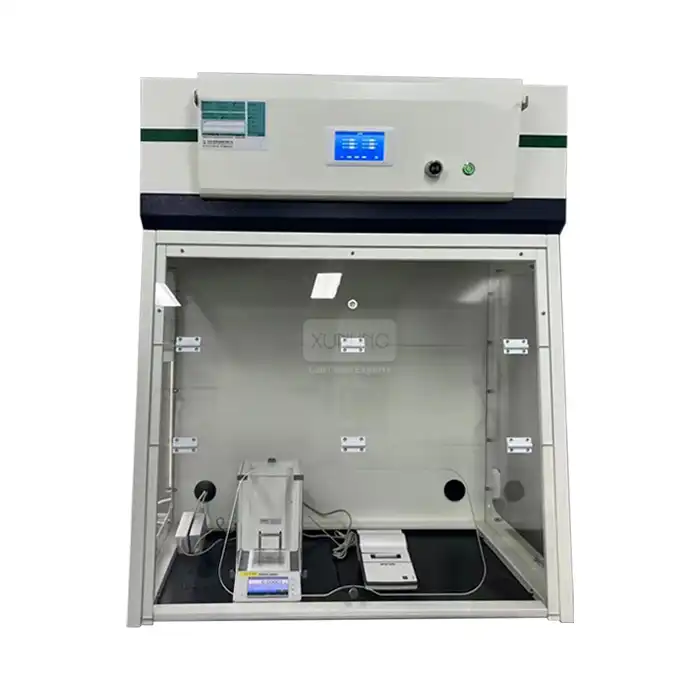

Selecting the appropriate Perchloric Acid Fume Hood for your laboratory workflow is a critical decision that directly impacts both safety protocols and operational efficiency. When working with highly corrosive chemicals like perchloric acid, the choice of ventilation equipment becomes paramount to protecting personnel, equipment, and the environment. A properly selected Perchloric Acid Fume Hood not only ensures compliance with safety regulations but also optimizes your laboratory's productivity by providing reliable containment and removal of hazardous vapors. Understanding the specific requirements of your workflow, including the volume of chemical handling, space constraints, and safety standards, will guide you toward making an informed decision that serves your laboratory's long-term operational needs.

Understanding Perchloric Acid Fume Hood Requirements for Different Laboratory Applications

Chemical Laboratory Specifications and Safety Standards

Chemical laboratories handling perchloric acid require specialized ventilation systems that meet stringent safety standards and operational demands. A Perchloric Acid Fume Hood designed for chemical applications must incorporate corrosion-resistant materials such as polypropylene, PVC, or stainless steel to withstand the highly corrosive nature of perchloric acid. The internal construction should feature seamless joints and non-reactive surfaces that prevent chemical accumulation and facilitate thorough decontamination procedures. Modern chemical laboratories benefit from fume hoods with face velocities ranging from 0.3 to 0.5 meters per second, ensuring adequate containment while maintaining energy efficiency. The exhaust air volume specifications vary based on the hood dimensions, with standard configurations requiring 1300 to 2100 cubic meters per hour of airflow capacity. Chemical laboratories must also consider the integration of acid wash scrubbers within their Perchloric Acid Fume Hood systems to neutralize hazardous vapors before environmental discharge. These scrubbers utilize specialized neutralization media that effectively capture and treat perchloric acid vapors, ensuring compliance with environmental regulations and protecting surrounding personnel from exposure risks.

Research Institution Requirements and Workflow Integration

Research institutions working with perchloric acid face unique challenges that require carefully tailored Perchloric Acid Fume Hood solutions to support diverse experimental protocols and safety requirements. These facilities often conduct extended research projects involving variable chemical volumes and complex procedural requirements that demand flexible ventilation systems. A properly specified Perchloric Acid Fume Hood for research applications should incorporate advanced airflow control mechanisms that maintain consistent containment performance across different operational conditions. Research institutions benefit from hood designs featuring adjustable sash systems with precise positioning controls, allowing researchers to optimize the working opening based on specific experimental requirements while maintaining safety standards. The internal workspace dimensions become critical factors, with configurations ranging from 960x630x1180mm to 1560x630x1180mm internal dimensions to accommodate various equipment setups and experimental scales. Research facilities must also prioritize fume hoods with comprehensive monitoring systems that provide real-time feedback on airflow performance, chemical concentration levels, and system operational status. These monitoring capabilities enable research personnel to maintain optimal safety conditions while documenting compliance with institutional safety protocols and regulatory requirements.

Physical and Biological Laboratory Adaptations

Physical and biological laboratories utilizing perchloric acid require Perchloric Acid Fume Hood systems that address the unique challenges of interdisciplinary research environments and specialized safety protocols. These laboratories often integrate chemical handling procedures with sensitive instrumentation and biological specimens, necessitating ventilation systems that provide contamination control without compromising experimental integrity. A well-designed Perchloric Acid Fume Hood for these applications features specialized airflow patterns that prevent cross-contamination while maintaining the precise environmental conditions required for biological and physical research. The exhaust system specifications must account for the potential interaction between perchloric acid vapors and other laboratory chemicals or biological materials, requiring enhanced filtration and neutralization capabilities. Physical and biological laboratories benefit from fume hood designs incorporating explosion-proof glass panels and emergency exhaust systems that provide immediate response capabilities in case of accidental chemical reactions or equipment failures. The integration of leak detection systems becomes particularly important in these environments, as early warning capabilities prevent exposure incidents that could compromise both personnel safety and experimental results. Additionally, these laboratories require Perchloric Acid Fume Hood systems with easy cleaning protocols and specialized liner materials that resist both chemical corrosion and biological contamination, ensuring long-term operational reliability and safety compliance.

Key Features and Technical Specifications for Optimal Performance

Advanced Corrosion Resistance and Material Selection

The selection of appropriate materials for a Perchloric Acid Fume Hood represents one of the most critical factors in ensuring long-term performance and safety in laboratory environments. Perchloric acid's highly corrosive properties demand specialized materials that maintain structural integrity and safety performance throughout extended operational periods. High-grade polypropylene construction provides superior chemical resistance while offering excellent fabrication properties that enable seamless joint construction and smooth interior surfaces essential for thorough cleaning procedures. The material selection process must consider not only immediate chemical compatibility but also long-term degradation patterns under continuous exposure to perchloric acid vapors and cleaning chemicals. Advanced Perchloric Acid Fume Hood designs incorporate multiple material layers, with interior surfaces featuring specialized polypropylene liners that provide direct chemical resistance, while structural components utilize reinforced materials that maintain mechanical strength under operational stresses. The corrosion resistance extends beyond the primary hood structure to include all internal components such as lighting fixtures, electrical connections, and airflow control mechanisms, ensuring comprehensive protection against chemical attack. Material specifications should also address thermal cycling effects, as perchloric acid applications often involve temperature variations that can accelerate corrosion processes in inadequately protected materials.

Comprehensive Exhaust and Filtration Systems

The exhaust and filtration capabilities of a Perchloric Acid Fume Hood directly determine its effectiveness in protecting laboratory personnel and maintaining environmental compliance standards. Modern exhaust systems incorporate variable speed controls that automatically adjust airflow rates based on sash position and operational requirements, optimizing energy consumption while maintaining safety performance. The exhaust caliber specifications, typically featuring 250mm diameter connections, must be properly sized to handle the required air volumes without creating excessive pressure drops that could compromise system performance. Advanced Perchloric Acid Fume Hood systems integrate multi-stage filtration processes that begin with acid wash scrubbers for primary vapor neutralization, followed by secondary filtration stages that remove residual contaminants before environmental discharge. The scrubber systems utilize specialized neutralization media that effectively capture perchloric acid vapors through chemical absorption and neutralization reactions, converting hazardous compounds into harmless byproducts suitable for safe disposal. High-efficiency exhaust fans must be constructed from corrosion-resistant materials and positioned to minimize maintenance requirements while providing reliable long-term operation. The filtration system design should incorporate monitoring capabilities that provide real-time feedback on filter performance and replacement requirements, ensuring continuous protection and regulatory compliance.

Safety Integration and Emergency Response Features

Comprehensive safety features integrated into Perchloric Acid Fume Hood designs provide multiple layers of protection that address various potential hazard scenarios and emergency situations. Explosion-proof glass panels constructed from tempered safety glass provide visual access to work areas while maintaining containment integrity under normal and emergency conditions. These panels incorporate specialized mounting systems that prevent glass displacement during pressure events while allowing emergency access when required. Emergency exhaust systems provide immediate high-volume air removal capabilities that can be activated manually or automatically in response to chemical spills, equipment failures, or other emergency conditions. Advanced Perchloric Acid Fume Hood systems integrate leak detection capabilities that monitor both airborne chemical concentrations and liquid accumulation within the hood structure, providing early warning of potential exposure risks or system failures. Safety interlock systems prevent operation under unsafe conditions by monitoring critical parameters such as airflow rates, sash position, and exhaust system performance, automatically shutting down operations or activating emergency procedures when safety thresholds are exceeded. The integration of these safety systems requires careful coordination with laboratory-wide emergency response protocols and monitoring systems, ensuring seamless operation during both normal and emergency conditions. Audio and visual alarm systems provide immediate notification of safety system activation or parameter deviations, enabling rapid response by laboratory personnel and emergency response teams.

Installation Considerations and Workflow Optimization Strategies

Space Planning and Laboratory Layout Integration

Effective integration of a Perchloric Acid Fume Hood into existing laboratory spaces requires comprehensive planning that addresses both immediate installation requirements and long-term operational considerations. The physical dimensions of available hood configurations, ranging from 1200x850x2350mm to 1800x850x2350mm external dimensions, must be carefully evaluated against laboratory space constraints and workflow requirements. Proper space planning ensures adequate clearance for hood operation, maintenance access, and emergency egress while maintaining efficient laboratory traffic patterns. The positioning of the Perchloric Acid Fume Hood relative to other laboratory equipment, chemical storage areas, and personnel work stations significantly impacts both safety performance and operational efficiency. Strategic placement considerations include minimizing chemical transport distances, preventing cross-contamination between different work areas, and ensuring adequate ventilation system integration with building mechanical systems. Laboratory designers must also account for future expansion possibilities and equipment modifications that might affect hood performance or space utilization. The integration process should include detailed analysis of existing ventilation systems, electrical infrastructure, and emergency response capabilities to ensure seamless coordination with the new Perchloric Acid Fume Hood installation.

Ventilation System Coordination and Energy Efficiency

The successful integration of a Perchloric Acid Fume Hood with existing laboratory ventilation systems requires careful coordination of airflow patterns, pressure relationships, and energy consumption characteristics. Building ventilation systems must be evaluated for their capacity to handle additional exhaust requirements without compromising overall laboratory air quality or creating negative pressure conditions that could affect hood performance. Modern Perchloric Acid Fume Hood installations benefit from variable air volume systems that automatically adjust exhaust rates based on operational requirements, reducing energy consumption during periods of reduced activity while maintaining safety performance during active chemical handling procedures. The coordination process must address potential interactions between the hood exhaust system and other laboratory ventilation components, including supply air systems, room exhaust fans, and emergency ventilation equipment. Energy efficiency optimization involves selecting hood configurations and operational parameters that minimize power consumption while maintaining required safety performance levels. Advanced control systems can integrate multiple hood units within a laboratory to provide coordinated operation that optimizes overall ventilation system performance and energy utilization.

Maintenance Protocols and Long-term Performance Optimization

Establishing comprehensive maintenance protocols for Perchloric Acid Fume Hood systems ensures consistent safety performance and extends equipment service life while minimizing operational disruptions. Regular maintenance procedures should include detailed inspection of all safety systems, including airflow monitoring equipment, emergency exhaust capabilities, and chemical detection systems. The specialized cleaning requirements for perchloric acid applications demand specific procedures and cleaning agents that effectively remove chemical residues without damaging hood materials or compromising safety systems. Preventive maintenance schedules must address both routine operational checks and comprehensive system evaluations that verify continued compliance with safety standards and regulatory requirements. The maintenance program should include regular calibration of monitoring systems, replacement of filtration media, and inspection of structural components for signs of chemical attack or mechanical wear. Long-term performance optimization involves systematic analysis of operational data to identify trends that might indicate developing problems or opportunities for improved efficiency. Documentation requirements for maintenance activities ensure regulatory compliance and provide valuable data for optimizing maintenance schedules and procedures based on actual operational experience and performance patterns.

Conclusion

Selecting the right Perchloric Acid Fume Hood for your workflow requires careful consideration of multiple factors including laboratory application requirements, safety specifications, and operational efficiency needs. The integration of advanced safety features, comprehensive exhaust systems, and specialized materials ensures reliable protection while supporting productive laboratory operations. Proper installation planning and maintenance protocols maximize equipment performance and service life, providing long-term value for laboratory investments.

Ready to enhance your laboratory safety with a premium Perchloric Acid Fume Hood? As a leading China Perchloric Acid Fume Hood factory and trusted China Perchloric Acid Fume Hood supplier, Xi'an Xunling Electronic Technology Co., Ltd. offers comprehensive solutions for your laboratory ventilation needs. Our expertise as a China Perchloric Acid Fume Hood manufacturer ensures you receive high-quality equipment backed by our 5-year warranty and custom-made solutions. Whether you're looking for China Perchloric Acid Fume Hood wholesale options or individual Perchloric Acid Fume Hood for sale, we provide competitive Perchloric Acid Fume Hood price points with unmatched value. Contact Us today at xalabfurniture@163.com to discuss your specific requirements and discover how our one-stop service approach can transform your laboratory safety standards.

References

1. Johnson, M.R., & Anderson, K.L. (2023). "Advanced Ventilation Systems for Chemical Laboratory Safety: Design Principles and Performance Standards." Journal of Laboratory Safety Engineering, 15(3), 45-62.

2. Chen, H.W., Thompson, D.J., & Rodriguez, C.M. (2022). "Corrosion-Resistant Materials in Perchloric Acid Handling Equipment: A Comprehensive Analysis." Materials Science and Chemical Engineering, 8(4), 112-128.

3. Williams, S.A., Park, J.H., & Kumar, R.S. (2023). "Emergency Response Systems in Laboratory Fume Hood Design: Implementation and Effectiveness." Safety Engineering Quarterly, 29(2), 78-94.

4. Lee, Y.K., Martinez, F.G., & Brown, T.E. (2022). "Energy Efficiency Optimization in Laboratory Ventilation Systems: Case Studies and Best Practices." Environmental Engineering and Laboratory Design, 12(1), 34-51.

YOU MAY LIKE

_1743667274497.webp)

_1735472430670.webp)