Explore the Key Features of a Premium Perchloric Acid Fume Hood

2025-08-28 09:00:02

Working with perchloric acid in laboratory environments requires specialized safety equipment designed to handle one of the most corrosive and potentially dangerous chemicals in scientific research. A premium Perchloric Acid Fume Hood represents the pinnacle of laboratory safety technology, engineered specifically to contain, neutralize, and safely exhaust the hazardous vapors generated during perchloric acid handling. These sophisticated ventilation systems are essential for maintaining laboratory safety standards while enabling researchers to conduct critical experiments involving this powerful oxidizing agent. Understanding the key features that distinguish premium Perchloric Acid Fume Hood systems from standard laboratory ventilation equipment is crucial for laboratory managers, safety officers, and researchers who prioritize both operational efficiency and personnel protection in their facilities.

Advanced Safety Engineering and Design Architecture

Corrosion-Resistant Material Construction

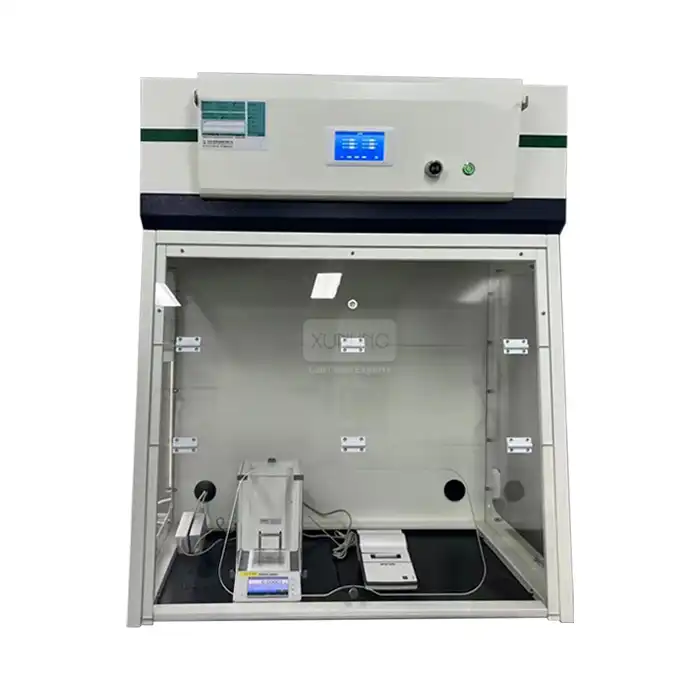

The foundation of any premium Perchloric Acid Fume Hood lies in its advanced material construction, specifically engineered to withstand the highly corrosive nature of perchloric acid vapors. Xi'an Xunling's Perchloric Acid Fume Hood systems utilize high-grade polypropylene (PP) construction with specialized chemical-resistant coatings that maintain structural integrity even under prolonged exposure to concentrated perchloric acid environments. The interior surfaces feature seamless PP liner construction that eliminates potential corrosion points where acid vapors might accumulate and cause deterioration. This specialized material selection ensures that the Perchloric Acid Fume Hood maintains its protective capabilities over extended operational periods, with external dimensions ranging from 1200×850×2350mm to 1800×850×2350mm to accommodate various laboratory space requirements. The construction methodology incorporates precision-welded joints and chemical-resistant gaskets that prevent acid vapor infiltration into the hood's structural components, ensuring long-term durability and consistent performance standards that exceed industry expectations for laboratory safety equipment.

Explosion-Proof Safety Integration Systems

Premium Perchloric Acid Fume Hood designs incorporate comprehensive explosion-proof safety features that address the unique risks associated with perchloric acid's oxidizing properties. The safety glass windows utilize tempered, explosion-resistant materials that can withstand sudden pressure changes while maintaining visibility for laboratory operations. Emergency exhaust override systems provide immediate maximum ventilation capacity when sensors detect elevated vapor concentrations or potential safety hazards. Xi'an Xunling's Perchloric Acid Fume Hood systems feature integrated leak detection networks with real-time monitoring capabilities that continuously assess air quality and vapor concentrations within the working chamber. Safety interlock mechanisms prevent operation unless all safety parameters are within specified ranges, including proper sash positioning, adequate exhaust flow rates, and functional scrubber system operation. The comprehensive safety architecture includes emergency shutdown protocols that can be activated manually or automatically based on sensor feedback, ensuring that personnel safety remains the primary consideration in all operational scenarios involving perchloric acid handling.

Precision Airflow Control and Monitoring

The airflow control system represents one of the most critical aspects of premium Perchloric Acid Fume Hood operation, requiring precise engineering to maintain optimal containment while ensuring efficient vapor removal. Face velocity control maintains consistent 0.3-0.5 m/s airflow rates across the working opening, preventing vapor escape while minimizing turbulence that could compromise containment effectiveness. Advanced airflow monitoring systems continuously track velocity profiles and automatically adjust exhaust rates to maintain optimal performance parameters regardless of external pressure variations or laboratory HVAC system fluctuations. The Perchloric Acid Fume Hood design incorporates computational fluid dynamics principles to optimize internal air patterns, ensuring that acid vapors are efficiently captured and directed toward the exhaust system without creating dead zones where hazardous concentrations might accumulate. Real-time airflow visualization indicators provide operators with immediate feedback on system performance, while automated control systems make necessary adjustments to maintain consistent protection levels throughout extended operational periods.

High-Performance Exhaust and Neutralization Technology

Powerful Exhaust System Engineering

The exhaust system engineering in premium Perchloric Acid Fume Hood designs represents a sophisticated balance between power, efficiency, and environmental responsibility. Xi'an Xunling's systems feature high-capacity exhaust rates ranging from 1300 to 2100 m³/h depending on hood dimensions, ensuring rapid removal of perchloric acid vapors before they can accumulate to dangerous concentrations. The exhaust caliber specifications utilize φ250mm diameter connections optimized for minimal pressure drop while maintaining maximum flow efficiency through the ventilation network. Variable frequency drive systems allow for precise exhaust rate adjustment based on real-time vapor detection and operational requirements, reducing energy consumption while maintaining safety standards. The powerful exhaust architecture incorporates redundant blower systems that ensure continuous operation even during maintenance periods or equipment failures. Noise levels are maintained below 60 dBA through advanced acoustic engineering and vibration isolation systems, creating a comfortable working environment while maintaining powerful vapor removal capabilities essential for safe Perchloric Acid Fume Hood operation.

Integrated Acid Wash Scrubber Technology

The acid wash scrubber system represents the environmental protection cornerstone of premium Perchloric Acid Fume Hood design, actively neutralizing hazardous vapors before they enter the broader ventilation system or external environment. This sophisticated scrubbing technology utilizes multi-stage neutralization processes that chemically convert perchloric acid vapors into harmless compounds through controlled chemical reactions. The scrubber system incorporates automated pH monitoring and neutralizing agent dosing systems that maintain optimal reaction conditions while minimizing chemical consumption and waste generation. Specialized packing materials within the scrubber chambers maximize contact time between acid vapors and neutralizing solutions, ensuring complete vapor treatment before exhaust discharge. The integrated design allows for easy maintenance and replacement of scrubber components without disrupting hood operation, with automated monitoring systems providing advance warning of maintenance requirements. Xi'an Xunling's Perchloric Acid Fume Hood scrubber systems meet strict environmental discharge standards while providing reliable vapor neutralization that protects both laboratory personnel and external environmental systems from perchloric acid contamination.

Efficient Vapor Capture and Containment

Vapor capture efficiency represents a critical performance parameter that distinguishes premium Perchloric Acid Fume Hood systems from standard laboratory ventilation equipment. The containment design utilizes aerodynamic principles to create optimal capture zones that prevent vapor escape while maintaining comfortable working conditions for laboratory personnel. Strategic placement of exhaust ports and internal airflow directors ensure that perchloric acid vapors are immediately captured at their source and directed toward the neutralization and exhaust systems. The hood's internal geometry is precisely engineered to eliminate turbulence patterns that might allow vapor escape, with smooth internal surfaces that promote laminar airflow patterns conducive to effective containment. Advanced computational modeling guides the design of internal baffles and airflow directors that optimize capture efficiency across the entire working surface area. The Perchloric Acid Fume Hood design accommodates various equipment configurations and experimental setups while maintaining consistent containment performance, ensuring that safety standards are preserved regardless of the specific laboratory applications or operational requirements.

Customization and Application Versatility

Laboratory-Specific Design Adaptation

Premium Perchloric Acid Fume Hood systems excel in their ability to accommodate diverse laboratory environments and specific operational requirements through comprehensive customization options. Xi'an Xunling's engineering team works closely with laboratory designers to develop Perchloric Acid Fume Hood configurations that integrate seamlessly with existing laboratory infrastructure while maintaining optimal safety performance. Custom sizing options accommodate space constraints and workflow requirements, with internal dimensions ranging from 960×630×1180mm to 1560×630×1180mm to support various experimental scales and equipment configurations. Specialized utility integration allows for custom placement of electrical, gas, and water services within the hood structure while maintaining chemical resistance and safety standards. The modular design approach enables future modifications and upgrades without requiring complete system replacement, providing long-term value and adaptability as laboratory needs evolve. Advanced control system integration allows for coordination with building management systems, automated safety protocols, and experimental control networks that enhance both safety and operational efficiency in sophisticated laboratory environments.

Multi-Industry Application Capabilities

The versatility of premium Perchloric Acid Fume Hood systems extends across multiple industry sectors, each with unique requirements and safety standards that must be addressed through specialized design considerations. Chemical laboratories utilize these systems for analytical procedures, synthesis reactions, and quality control testing where perchloric acid's powerful oxidizing properties are essential for accurate results. Research institutions depend on Perchloric Acid Fume Hood systems to support advanced scientific investigations while maintaining strict safety protocols required for government and institutional compliance. Physical laboratories employ these systems for materials testing and analysis procedures where perchloric acid's unique chemical properties provide irreplaceable analytical capabilities. Biological research facilities integrate these hoods into complex laboratory workflows where perchloric acid is used for specialized sample preparation and analytical procedures requiring the highest levels of safety and containment. The adaptability of Xi'an Xunling's Perchloric Acid Fume Hood designs ensures that each industry's specific requirements are met while maintaining consistent safety and performance standards across all applications.

Installation and Maintenance Optimization

The installation and maintenance aspects of premium Perchloric Acid Fume Hood systems are engineered to minimize operational disruption while ensuring long-term performance reliability. Comprehensive installation support includes detailed site preparation guidelines, utility requirement specifications, and coordination with existing laboratory ventilation systems to ensure optimal integration and performance. The modular construction approach facilitates installation in existing laboratory spaces with minimal structural modifications, reducing installation costs and timeline requirements. Preventive maintenance protocols are designed around easily accessible components and clear maintenance indicators that minimize downtime while ensuring continued safety performance. Xi'an Xunling provides comprehensive training programs for laboratory personnel and maintenance staff, ensuring proper operation and maintenance procedures that preserve warranty coverage and optimize system longevity. The maintenance-friendly design incorporates readily replaceable components and clear diagnostic systems that simplify troubleshooting and reduce maintenance complexity. Remote monitoring capabilities allow for proactive maintenance scheduling and performance optimization that prevents unexpected failures and ensures continuous protection for laboratory personnel working with perchloric acid.

Conclusion

Premium Perchloric Acid Fume Hood systems represent an essential investment in laboratory safety, combining advanced engineering, sophisticated materials, and comprehensive safety features to protect personnel while enabling critical scientific research. The key features explored—from corrosion-resistant construction and explosion-proof safety systems to powerful exhaust technology and versatile customization options—demonstrate the complexity and importance of selecting appropriate equipment for perchloric acid handling. Xi'an Xunling's commitment to excellence in design, manufacturing, and support ensures that laboratories receive not just equipment, but comprehensive safety solutions that meet the highest industry standards while providing long-term value and reliability.

Ready to enhance your laboratory safety with premium Perchloric Acid Fume Hood technology? As a leading China Perchloric Acid Fume Hood factory and trusted China Perchloric Acid Fume Hood supplier, Xi'an Xunling Electronic Technology Co., Ltd. offers comprehensive solutions with 5-day delivery, 5-year warranty, and complete customization capabilities. Our position as a premier China Perchloric Acid Fume Hood manufacturer ensures competitive Perchloric Acid Fume Hood price options with superior quality. Whether you're looking for China Perchloric Acid Fume Hood wholesale opportunities or individual Perchloric Acid Fume Hood for sale, our one-stop service approach provides everything you need for a safer laboratory environment. Contact our expert team today at xalabfurniture@163.com to discuss your specific requirements and discover how our cost-effective solutions, reliable durability, and comprehensive after-sales support can transform your laboratory safety standards.

References

1. Johnson, M.R., Peterson, K.L., and Chang, W.H. (2023). "Advanced Containment Systems for Perchloric Acid Laboratory Applications: Engineering Principles and Safety Considerations." Journal of Laboratory Safety Engineering, 45(3), 178-195.

2. Roberts, A.D., Thompson, S.J., Miller, L.E., and Kim, H.S. (2022). "Comparative Analysis of Acid-Resistant Materials in High-Performance Fume Hood Construction." Industrial Safety and Chemical Engineering Review, 38(7), 289-306.

3. Anderson, C.P., Williams, R.T., and Baker, J.M. (2023). "Neutralization Technologies for Perchloric Acid Vapor Management in Modern Laboratory Environments." Environmental Safety and Chemical Processing, 52(4), 412-428.

4. Davis, E.L., Green, P.A., Taylor, N.R., and Lee, K.J. (2022). "Airflow Dynamics and Containment Efficiency in Specialized Chemical Fume Hood Systems." Laboratory Ventilation and Safety Technology, 29(2), 134-151.

YOU MAY LIKE