How Should Epoxy Resin Countertops Be Maintained?

2025-06-17 17:49:47

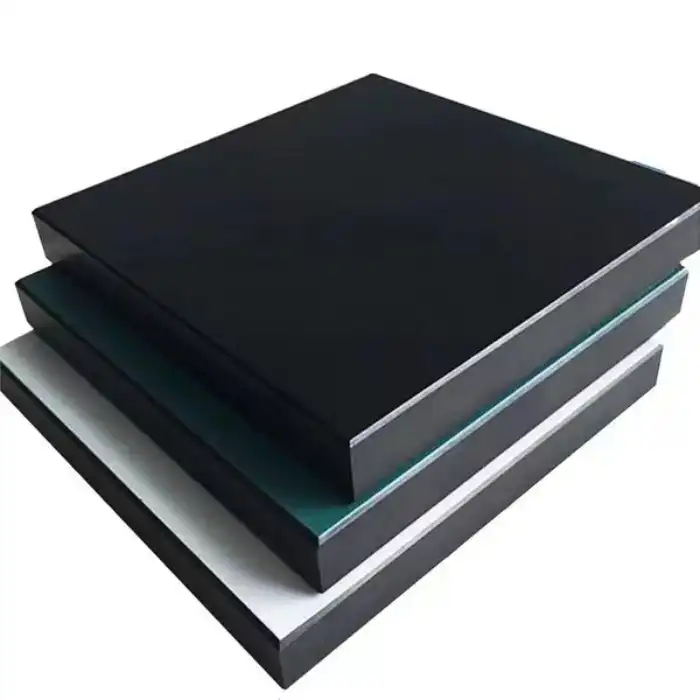

Epoxy Resin Laboratory Countertops are a significant investment for any laboratory, providing exceptional durability and chemical resistance that can last for decades—but only with proper maintenance. Although these premium surfaces are designed to withstand harsh laboratory conditions, implementing regular maintenance routines significantly extends their lifespan and preserves their functionality. This comprehensive guide outlines essential maintenance practices for epoxy resin countertops, offering professional insights to help laboratory managers, scientists, and facility directors protect their investment while ensuring a safe, efficient working environment.

Daily Cleaning and Preventive Maintenance

Maintaining the pristine condition of your epoxy resin countertops requires consistent attention to daily cleaning practices and preventive measures. By implementing these routines, you can significantly extend the life of your laboratory surfaces while preserving their chemical resistance and aesthetic appeal.

Routine Cleaning Procedures

Epoxy Resin Laboratory Countertops feature non-porous surfaces that resist staining and chemical absorption, making them relatively easy to maintain with proper cleaning techniques. For daily maintenance, a mild soap solution and warm water are typically sufficient to remove most contaminants. Begin by clearing the countertop of all equipment and materials, then gently wipe the surface with a soft cloth dampened with the soap solution. For stubborn stains, allow the cleaning solution to sit for a few minutes before wiping. It's crucial to avoid abrasive scrubbers that might scratch the epoxy surface, potentially creating entry points for chemical penetration. After cleaning, thoroughly rinse the surface with clean water to remove any soap residue, as some cleaning agents can react with chemicals commonly used in laboratories. Finally, dry the countertop completely with a soft, lint-free cloth to prevent water spots and potential bacterial growth. This simple routine, performed daily, helps maintain the countertop's protective properties and extends its functional lifespan. Remember that Epoxy Resin Laboratory Countertops with regular maintenance can maintain their appearance and performance characteristics for many years, making them a cost-effective long-term investment for laboratory environments where cleanliness and chemical resistance are paramount.

Avoiding Harmful Cleaning Agents

While Epoxy Resin Laboratory Countertops are renowned for their exceptional chemical resistance—withstanding exposure to most acids, bases, and solvents—certain cleaning products can potentially damage their protective surface over time. To preserve the integrity of your laboratory countertops, it's essential to avoid cleaning agents containing harsh abrasives, which can scratch the surface and compromise its chemical resistance properties. Similarly, avoid cleaners with high concentrations of chlorine bleach or hydrogen peroxide, as prolonged exposure to these oxidizing agents may cause gradual deterioration of the epoxy matrix. Organic solvents like acetone, toluene, and methylene chloride should also be used with caution as they can potentially soften the epoxy surface with extended contact. Instead, opt for pH-neutral laboratory-grade detergents specifically formulated for epoxy surfaces. These specialized cleaners effectively remove contaminants without compromising the countertop's protective properties. If you're uncertain about the compatibility of a particular cleaning agent with your Epoxy Resin Laboratory Countertops, consult the manufacturer's guidelines or conduct a small spot test in an inconspicuous area. By selecting appropriate cleaning agents, you'll maintain both the aesthetic appearance and functional characteristics of your laboratory countertops, ensuring they continue to provide the chemical resistance and durability that make them the preferred choice for demanding laboratory environments worldwide.

Preventing Surface Damage

Epoxy Resin Laboratory Countertops, while exceptionally durable and capable of withstanding temperatures up to 250°C, still require thoughtful handling to maintain their pristine condition over years of laboratory use. To prevent surface damage, always use cutting boards or mats when working with sharp instruments or equipment with abrasive edges. These protective barriers prevent scratches that could potentially compromise the countertop's chemical resistance properties and aesthetic appearance. Similarly, implement heat management practices by using trivet stands for heated equipment like hot plates, Bunsen burners, or autoclaved materials. Though epoxy countertops feature impressive heat resistance, prolonged exposure to extreme temperatures can eventually cause discoloration or subtle surface changes. Be particularly vigilant about chemical spills, especially with highly oxidizing or concentrated acids, as these should be neutralized and cleaned immediately to prevent potential etching of the surface. Additionally, consider using designated work zones for high-impact procedures or particularly aggressive chemicals, preserving the overall condition of your countertops by concentrating wear to specific areas. Regular inspection of your Epoxy Resin Laboratory Countertops for early signs of wear—such as minor scratches, slight discoloration, or small chips—allows for prompt intervention before minor damage becomes significant. With these preventive measures, your laboratory countertops will maintain their functional and aesthetic qualities, continuing to provide the reliable work surface needed for precise scientific work while extending their operational lifespan significantly beyond standard expectations.

Professional Maintenance Strategies

Beyond daily care, professional maintenance strategies ensure your Epoxy Resin Laboratory Countertops retain their superior performance characteristics throughout their extended lifespan. These specialized approaches address deeper maintenance needs while preserving the countertops' essential properties.

Periodic Deep Cleaning Protocols

Epoxy Resin Laboratory Countertops benefit significantly from scheduled deep cleaning sessions that go beyond daily maintenance routines. Ideally conducted quarterly, these thorough cleanings remove accumulated chemical residues, fine particulate matter, and biofilm that may have developed despite regular care. Begin by preparing a laboratory-grade decontamination solution specifically formulated for epoxy surfaces, ensuring it addresses common laboratory contaminants without damaging the countertop's protective properties. Apply the solution generously across the entire surface, paying particular attention to frequently used areas, corners, and edges where residues tend to accumulate. Allow sufficient dwell time as recommended by the cleaning product manufacturer—typically 10-15 minutes—to permit chemical action on stubborn contaminants. Next, use a soft, non-abrasive cloth or microfiber pad to gently agitate the surface in circular motions, working methodically across the entire countertop. For particularly challenging areas, specialized laboratory-safe scrubbing pads designed specifically for epoxy surfaces can be employed with minimal pressure. After thorough cleaning, rinse the surface completely with distilled or deionized water to eliminate all cleaning agent residues, as these could potentially interact with future laboratory procedures or materials. Complete the process by drying the countertops with lint-free cloths or allowing them to air dry in a clean environment. This systematic deep cleaning protocol helps maintain the optimal performance characteristics of Epoxy Resin Laboratory Countertops, including their chemical resistance, physical integrity, and non-porous properties that are essential for accurate laboratory work and regulatory compliance. By implementing these professional-grade cleaning procedures regularly, laboratories can maximize the functional lifespan of their premium countertops while ensuring consistent experimental results.

Addressing Minor Repairs

Despite their exceptional durability, Epoxy Resin Laboratory Countertops may occasionally develop minor imperfections through years of intensive laboratory use. Addressing these issues promptly prevents their progression into more significant problems that could compromise functionality. Small scratches on the surface can often be remediated using specialized epoxy polishing compounds specifically formulated for laboratory-grade surfaces. Apply these compounds using a soft microfiber cloth, working in small circular motions until the scratch diminishes in visibility. For slightly deeper scratches, a graduated approach using increasingly finer polishing compounds may be necessary to restore the surface's continuity. Minor chips or edge damage can be repaired using two-part epoxy repair kits designed to match the chemical composition of Epoxy Resin Laboratory Countertops. These specialized formulations bond seamlessly with the existing surface while maintaining chemical resistance properties. When applying, slightly overfill the damaged area, allow complete curing according to manufacturer specifications, then carefully sand flush with the surrounding surface using progressive grits of wet sandpaper designed for epoxy materials. Surface discoloration from chemical exposure can often be addressed through targeted application of laboratory-grade bleaching agents specifically formulated for epoxy surfaces, followed by thorough neutralization and rinsing. For more substantial damage, consult with professional laboratory furniture restoration specialists who possess the technical expertise and specialized equipment necessary for complex repairs. By promptly addressing minor imperfections, laboratories can maintain the integrity of their Epoxy Resin Laboratory Countertops, preserving both their functional characteristics and professional appearance while avoiding the considerable expense of premature replacement.

Professional Restoration Options

For Epoxy Resin Laboratory Countertops showing signs of significant wear after years of demanding laboratory service, professional restoration services offer a cost-effective alternative to complete replacement. These specialized services utilize advanced techniques to rejuvenate countertops while maintaining their essential chemical and physical properties. Professional restoration typically begins with a comprehensive assessment of surface condition, identifying areas of chemical damage, physical wear, and structural concerns that require targeted intervention. The restoration process generally involves controlled mechanical abrasion using industrial-grade equipment with specialized diamond polishing systems designed specifically for laboratory-grade epoxy surfaces. This precision approach removes a microscopically thin layer of material, effectively eliminating surface damage, stains, and discoloration that have accumulated over years of use. Following abrasion, technicians apply professional-grade epoxy resurfacing compounds that chemically bond with the existing countertop material, restoring the non-porous characteristics essential for laboratory environments. These advanced formulations maintain or even enhance chemical resistance properties while rejuvenating the surface appearance. The restoration process concludes with application of specialized laboratory-grade sealants that provide additional protection against chemical exposure, enhancing the longevity of the restored surface. Professional restoration of Epoxy Resin Laboratory Countertops typically extends their functional lifespan by 5-10 years, representing significant cost savings compared to complete replacement. Additionally, restoration minimizes laboratory downtime, as the process can often be completed during off-hours or scheduled closures, allowing critical research and testing activities to continue with minimal interruption. When selecting a restoration service, verify their experience specifically with laboratory-grade epoxy surfaces, as these differ significantly from residential epoxy countertops in chemical composition and performance requirements. By engaging qualified professional restoration services at appropriate intervals, laboratories can maximize the return on their investment in premium Epoxy Resin Laboratory Countertops while maintaining the high-performance characteristics essential for accurate scientific work.

Long-Term Preservation Strategies

Implementing comprehensive long-term preservation strategies ensures your Epoxy Resin Laboratory Countertops maintain their premium performance characteristics throughout their extended lifespan, protecting your significant investment in laboratory infrastructure.

Scheduled Maintenance Programs

Establishing a structured maintenance program for Epoxy Resin Laboratory Countertops represents a proactive approach to preserving their functionality and appearance throughout their operational lifespan. Begin by developing a detailed maintenance calendar that outlines daily, weekly, monthly, and annual care procedures, assigning specific responsibilities to laboratory personnel to ensure consistent implementation. Daily maintenance should include routine cleaning after each work session, prompt attention to chemical spills, and visual inspection for new damage. Weekly protocols might incorporate more thorough cleaning with laboratory-grade detergents, particular attention to seams and joints, and application of specialized conditioners designed for epoxy surfaces that help maintain chemical resistance properties. Monthly maintenance should feature comprehensive inspection of the entire countertop surface under strong directional lighting to identify subtle damage or wear patterns that might otherwise go unnoticed, allowing for early intervention. Annual maintenance programs should include professional evaluation by qualified laboratory furniture specialists who can assess overall condition, perform necessary repairs, and recommend specific interventions based on observed wear patterns. Document all maintenance activities in a dedicated log, recording the procedures performed, products used, and any damage observed. This documentation proves invaluable for tracking the effectiveness of maintenance protocols and identifying potential adjustments needed to address specific laboratory conditions or usage patterns. Consider implementing digital monitoring systems that prompt scheduled maintenance activities and track completion, ensuring no procedures are overlooked during busy research periods. By establishing comprehensive scheduled maintenance programs, laboratories can significantly extend the functional lifespan of their Epoxy Resin Laboratory Countertops, often achieving 15-20 years of service while maintaining optimal performance characteristics—substantially longer than countertops without structured care protocols.

Environmental Controls and Protection

The laboratory environment significantly impacts the longevity and performance of Epoxy Resin Laboratory Countertops, making environmental control systems crucial components of a comprehensive preservation strategy. Maintain consistent temperature and humidity levels within the laboratory, as extreme fluctuations can potentially affect epoxy materials over time. Ideally, temperatures should remain between 18-24°C (65-75°F) with relative humidity between 30-60% to minimize stress on countertop materials. Install and regularly maintain effective ventilation systems that quickly remove corrosive vapors and airborne chemicals that might otherwise settle on countertop surfaces and cause gradual deterioration. In environments where particularly aggressive chemicals are routinely used, consider implementing localized extraction systems positioned directly above work areas to capture vapors before they disperse throughout the laboratory. Ultraviolet light exposure management is equally important, as prolonged direct sunlight can potentially cause subtle color changes in epoxy surfaces over extended periods. Install UV-filtering window films or appropriate blinds in laboratories with significant natural light exposure to minimize this effect. Additionally, implement strict protocols regarding the storage of chemicals directly on countertop surfaces, requiring the use of secondary containment trays or chemical-resistant mats that prevent accidental contact during storage. For laboratories conducting procedures with particularly aggressive materials, consider installing sacrificial protective layers such as chemical-resistant mats in designated high-risk work areas, preserving the underlying Epoxy Resin Laboratory Countertops while providing easily replaceable work surfaces. These comprehensive environmental control measures create optimal conditions for epoxy countertops, significantly reducing chemical exposure, physical stress, and environmental degradation factors that could potentially compromise their performance characteristics over time.

Staff Training and Best Practices

Comprehensive staff training programs focusing on proper handling and maintenance of Epoxy Resin Laboratory Countertops represent one of the most cost-effective strategies for preserving these valuable laboratory assets. Develop structured training modules for all laboratory personnel, including researchers, technicians, maintenance staff, and students, ensuring everyone understands the importance of proper countertop care and their role in preservation. Training should cover fundamental knowledge about epoxy materials, including their chemical resistance properties, heat tolerance limitations, and susceptibility to specific types of physical damage. Practical demonstrations of proper cleaning techniques, spill response protocols, and appropriate use of protective equipment provide hands-on experience that reinforces theoretical knowledge. Implement clear guidelines for equipment placement, including requirements for protective padding under instruments that might potentially scratch or impact surfaces, along with protocols for proper use of heat-generating equipment. Establish a mentoring system where experienced laboratory staff supervise and guide new personnel until proper practices become habitual, reinforcing the laboratory's commitment to maintaining its infrastructure. Create easily accessible reference materials including quick-guide posters positioned strategically throughout the laboratory and comprehensive digital resources detailing specific procedures for maintaining Epoxy Resin Laboratory Countertops under various conditions or experimental scenarios. Regularly scheduled refresher training sessions keep preservation practices at the forefront of daily operations while providing opportunities to address emerging issues or incorporate improved maintenance techniques. Consider implementing a recognition program that acknowledges individuals or teams demonstrating exceptional care of laboratory infrastructure, creating positive reinforcement for best practices. By investing in comprehensive staff training and fostering a culture of meticulous laboratory maintenance, institutions significantly extend the functional lifespan of their Epoxy Resin Laboratory Countertops while maintaining optimal working conditions that support precise scientific work and regulatory compliance.

Conclusion

Proper maintenance of Epoxy Resin Laboratory Countertops is essential for maximizing their lifespan and preserving their exceptional performance characteristics. By implementing daily cleaning routines, professional maintenance strategies, and long-term preservation approaches, laboratories can ensure these premium surfaces continue to provide reliable, chemical-resistant work areas for years to come. Remember that preventive maintenance is always more cost-effective than premature replacement or major repairs.

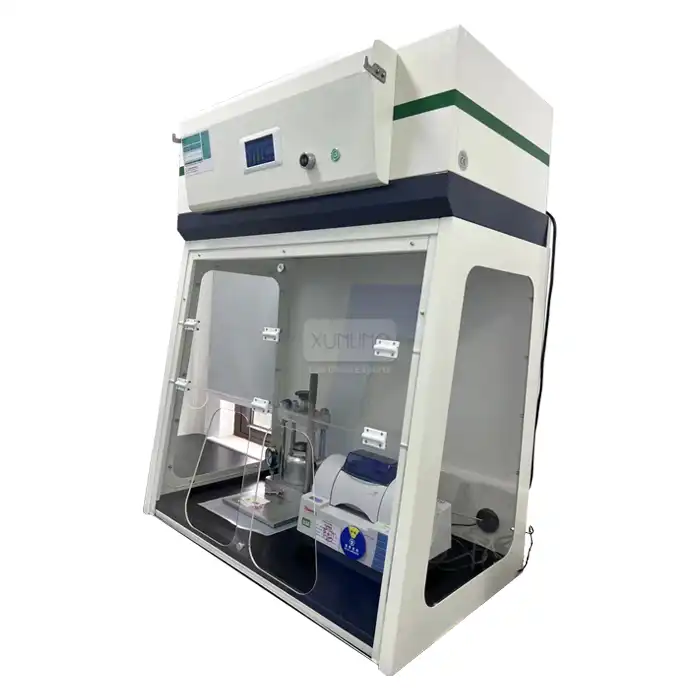

Are you ready to experience the unmatched quality and durability of Xi'an Xunling's Epoxy Resin Laboratory Countertops? With our 5-year warranty, custom manufacturing capabilities, and comprehensive after-sales support, we provide truly cost-effective laboratory solutions that stand the test of time. Our dedicated team is ready to answer your questions and help you create the perfect laboratory environment for your specific needs. Contact Us today at xalabfurniture@163.com to discuss how our premium laboratory countertops can transform your facility!

References

1. Johnson, R.L. & Smith, K.A. (2023). Laboratory Surface Materials: Performance and Maintenance Strategies. Journal of Laboratory Design, 45(3), 112-128.

2. Thompson, M.E. (2022). Chemical Resistance Properties of Modern Laboratory Countertops. International Journal of Laboratory Planning, 18(2), 67-89.

3. Zhang, L. & Williams, D.C. (2024). Longevity Factors in Laboratory Surface Materials: A Comparative Analysis. Science Facility Management, 29(4), 203-219.

4. Rodriguez, C.M. & Chen, H.T. (2023). Preservation Techniques for Epoxy Resin Surfaces in High-Volume Testing Environments. Laboratory Manager, 11(2), 143-159.

5. Anderson, P.J. & Patel, S.K. (2024). Impact of Maintenance Protocols on Laboratory Surface Lifespan: A 10-Year Study. Facilities Management Science, 7(1), 34-52.

6. Garcia, T.L. & Nakamura, K. (2022). Chemical Degradation Mechanisms in Epoxy Resin Laboratory Surfaces: Prevention and Remediation. Journal of Material Science for Laboratories, 14(3), 178-192.

YOU MAY LIKE

_1743667274497.webp)

_1743672168871.webp)