How does a fume extraction hood work?

2025-06-18 10:12:01

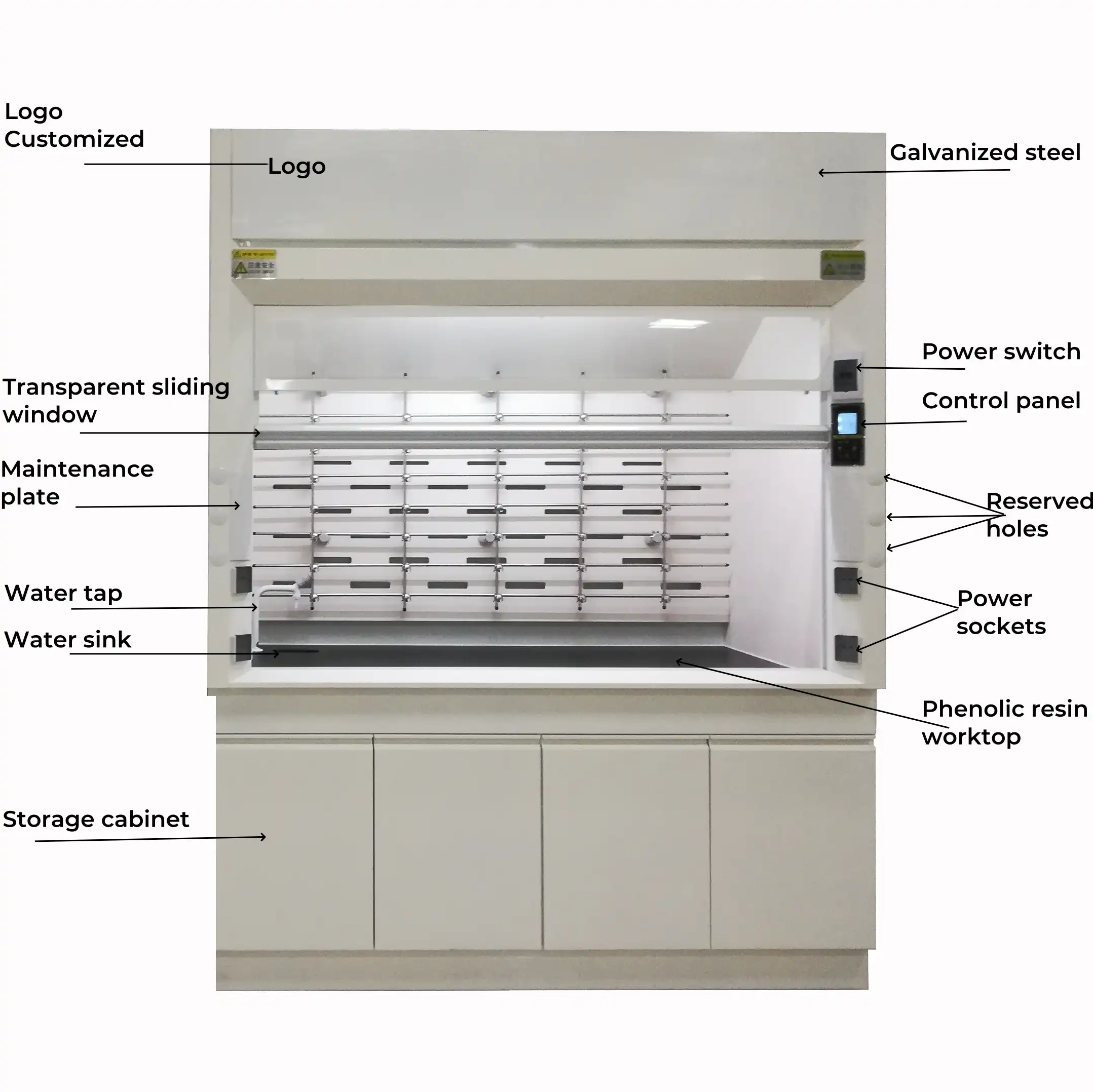

Fume extraction hoods are essential safety equipment in laboratories, industrial settings, and research facilities where hazardous chemicals, vapors, and particulates are handled. These specialized ventilation systems are designed to capture, contain, and remove harmful airborne contaminants, protecting laboratory personnel from exposure to potentially dangerous substances. The functionality of a fume extraction hood relies on sophisticated engineering principles that create controlled airflow patterns to effectively trap and exhaust hazardous emissions before they can enter the breathing zone of workers or contaminate the surrounding environment.

The Fundamental Operating Principles of Fume Extraction Hoods

A fume extraction hood works on the principle of creating negative pressure within an enclosed workspace. This negative pressure ensures that air consistently flows into the hood from the laboratory environment, preventing hazardous vapors from escaping into the breathing zone of laboratory personnel. The system utilizes a combination of physical barriers, strategic airflow design, and exhaust mechanisms to safely capture and remove contaminants. Understanding these fundamental principles is essential for proper hood selection, installation, and operation to ensure maximum safety and efficiency in laboratory environments.

Airflow Dynamics and Containment Mechanisms

The primary mechanism that makes a fume extraction hood effective is its carefully engineered airflow dynamics. When operational, the hood creates a precise airflow pattern where room air enters through the front opening (face) of the hood at a controlled velocity, typically between 80-120 feet per minute (0.4-0.6 m/s). This consistent inward airflow, known as face velocity, forms an invisible barrier that prevents contaminants from escaping. Inside the hood, the airflow pattern becomes more complex, with air moving toward the back and upward into exhaust ducts. Modern fume extraction hoods incorporate aerodynamic features such as airfoils at the hood entrance, baffles at the rear, and specially designed side panels that optimize these airflow patterns to enhance containment efficiency. The containment mechanism is particularly effective because it creates multiple zones of protection—a primary barrier at the face opening and secondary containment within the hood chamber itself—ensuring that harmful substances are consistently directed away from the user and toward the exhaust system.

Exhaust Systems and Ventilation Technology

The exhaust system is the powerhouse of any fume extraction hood, responsible for maintaining negative pressure and removing contaminated air from the workspace. This system typically consists of ductwork, a blower or fan assembly, and exhaust stacks. The blower creates the necessary suction to draw air through the hood at the designated face velocity, while the ductwork—constructed from chemical-resistant materials such as stainless steel, PVC, or fiberglass-reinforced plastic—channels this air safely outside the building. Modern fume extraction hoods employ sophisticated ventilation technology, including variable air volume (VAV) systems that automatically adjust fan speed to maintain optimal face velocity despite changes in sash position. This not only enhances safety but also improves energy efficiency by reducing the volume of conditioned air being exhausted when the hood is not fully open. The exhaust stacks are strategically designed and positioned to disperse contaminants high above the building's roofline, preventing re-entrainment into the building's air intake system and ensuring compliance with environmental regulations regarding air pollution.

Filtration Technologies and Contaminant Removal

Filtration systems represent an advanced component of fume extraction hoods, particularly in applications where ductless or recirculating designs are employed. These systems utilize a multi-stage filtration approach to trap, neutralize, and remove specific contaminants before recirculating the air back into the laboratory space. HEPA (High-Efficiency Particulate Air) filters can capture 99.97% of particles as small as 0.3 microns, making them effective for particulate contaminants. For chemical vapors and gases, activated carbon filters with specially impregnated media are used, with the specific impregnation selected based on the chemicals being handled. Advanced fume extraction hoods may also incorporate molecular filters with chemisorptive properties that chemically bond with contaminants, rendering them harmless. In high-end systems, electronic monitoring continuously assesses filter saturation levels and efficiency, alerting users when replacement is necessary. This sophisticated filtration technology allows fume extraction hoods to be installed in locations where external venting is impractical or prohibited, while still maintaining the highest safety standards for contaminant removal and personnel protection.

Advanced Design Features for Enhanced Performance

Modern fume extraction hoods incorporate sophisticated design elements that significantly improve their performance, safety, and efficiency beyond basic models. These advanced features address specific laboratory needs, enhance user experience, and provide superior protection against a wider range of hazardous substances. The evolution of fume extraction hood design reflects ongoing innovation in laboratory safety technology, with manufacturers like Xi'an Xunling Electronic Technology continuously developing more effective containment solutions.

Aerodynamic Optimization and Face Velocity Management

Advanced fume extraction hoods feature sophisticated aerodynamic elements that optimize airflow patterns for maximum containment efficiency. The hood entrance incorporates specially designed airfoils with radiused edges that minimize turbulence as room air enters the hood, preventing reverse flow eddies that could potentially allow contaminants to escape. Interior baffles are strategically positioned and adjustable to create ideal flow distribution across different work conditions and contaminant types. These baffles can be configured to handle specific substances—directing heavier-than-air gases downward to bottom extraction points or lighter-than-air vapors upward to ceiling extraction points. Face velocity management is further enhanced through electronic monitoring systems that provide real-time feedback on airflow conditions. Advanced models incorporate proximity sensors that detect when an operator is working at the hood and automatically adjust face velocity accordingly. This intelligent adaptation ensures optimal protection during active use while conserving energy during idle periods. Some high-performance fume extraction hoods utilize computational fluid dynamics (CFD) modeling during the design phase to perfect their aerodynamic profiles, resulting in systems that maintain effective containment even under challenging conditions such as cross-drafts or rapid movements across the hood face.

Intelligent Control Systems and Monitoring Technology

State-of-the-art fume extraction hoods leverage sophisticated control systems that elevate safety, efficiency, and usability to unprecedented levels. Digital touchscreen interfaces provide operators with comprehensive data on hood performance, including real-time airflow velocity, exhaust volume, and system status. These intelligent systems incorporate multiple redundant sensors that continuously monitor critical parameters and automatically adjust blower speed to maintain optimal operating conditions regardless of changes in room pressure, filter loading, or sash position. Advanced monitoring technology includes visual and audible alarms that activate when face velocity falls below safe thresholds, when sashes are left open beyond predetermined time limits, or when filters approach saturation. Network connectivity enables these systems to interface with building management systems (BMS), allowing facility managers to remotely monitor and control hood performance. Data logging capabilities record operational parameters and alarm events, providing valuable documentation for regulatory compliance and safety audits. Some cutting-edge fume extraction hoods even incorporate predictive analytics that anticipate maintenance needs based on usage patterns and performance trends, scheduling service interventions before failures occur and maximizing operational uptime in busy laboratory environments.

Energy Efficiency and Sustainable Design Elements

Modern fume extraction hoods incorporate numerous innovations aimed at reducing energy consumption without compromising safety performance. High-efficiency motors and fan systems with precisely balanced impellers minimize power requirements while maintaining necessary extraction rates. Variable air volume (VAV) technology automatically reduces airflow when the sash is partially or fully closed, significantly decreasing the volume of conditioned laboratory air being exhausted. This adaptive approach can reduce energy consumption by up to 70% compared to constant air volume systems. Automatic sash closing mechanisms further enhance energy efficiency by returning the hood to its minimal operating position when not in active use. LED lighting systems provide excellent visibility within the work area while consuming a fraction of the energy of traditional fluorescent fixtures. Heat recovery systems can be integrated into the exhaust stream to recapture thermal energy that would otherwise be wasted, redirecting it to preheat incoming air to the building. Many advanced fume extraction hoods now incorporate sustainable materials in their construction, including recycled steel components, low-VOC finishes, and energy-efficient electronics. These comprehensive sustainability features not only reduce operational costs but also support organizations in meeting their environmental responsibility goals and achieving certification under laboratory sustainability programs such as Labs21 and LEED.

Safety Features and Regulatory Compliance

In laboratory settings, fume extraction hoods represent the primary engineering control for protecting personnel from chemical exposure. The safety features incorporated into modern hood designs reflect both technological advancements and evolving regulatory standards. These safety mechanisms work in concert to create multiple layers of protection, ensuring that even under non-ideal conditions or in the event of partial system failure, users remain protected from harmful exposures.

Emergency Response Systems and Fail-Safe Mechanisms

Advanced fume extraction hoods incorporate comprehensive emergency response systems designed to provide protection even during power outages, mechanical failures, or unexpected chemical reactions. Battery backup systems ensure continued operation of critical components during power interruptions, maintaining negative pressure and preventing the release of hazardous substances. Redundant exhaust fans automatically activate if the primary fan experiences failure, eliminating downtime and maintaining containment integrity. Sophisticated fume extraction hoods feature emergency purge buttons that, when activated, maximize exhaust flow rates to quickly clear the hood of hazardous vapors in the event of a spill or unexpected reaction. Automatic fire suppression systems with specialized extinguishing agents appropriate for the specific materials being handled can detect and respond to fires within the hood enclosure before they spread to the laboratory. In the event of a significant system failure, intelligent control systems can initiate a controlled shutdown sequence that secures hazardous materials and alerts laboratory personnel. These emergency features are complemented by automatic system diagnostics that continuously monitor critical components, providing early warning of potential issues before they develop into failures. The comprehensive fail-safe design philosophy ensures that fume extraction hoods maintain their protective function even under the most challenging circumstances, giving laboratory personnel confidence that their safety is never compromised.

Compliance with International Safety Standards and Regulations

Modern fume extraction hoods are designed and manufactured to meet or exceed stringent international safety standards and regulations governing laboratory equipment. These include ANSI/ASHRAE 110 performance testing standards in North America, which verify containment efficiency through tracer gas challenges under various operating conditions. In Europe, EN 14175 provides comprehensive requirements for fume cupboard design, construction, and performance testing. Additional compliance considerations include SEFA (Scientific Equipment and Furniture Association) guidelines for construction quality and NFPA (National Fire Protection Association) standards for fire safety in laboratory environments. Manufacturing companies like Xi'an Xunling Electronic Technology maintain rigorous quality control processes to ensure each fume extraction hood meets these exacting standards before installation. Regulatory compliance extends beyond the initial design to include installation requirements for proper exhausting of contaminants, minimum separation distances from air intakes, and specific airflow balancing with the laboratory ventilation system. Many jurisdictions require periodic performance verification testing for fume extraction hoods, with documented face velocity measurements and containment tests using visualization techniques or tracer gas challenges. By adhering to these comprehensive standards and regulations, modern fume extraction hoods provide laboratory personnel with the highest level of protection available, backed by objective performance verification and regulatory oversight.

User Safety Training and Standard Operating Procedures

The effectiveness of any fume extraction hood ultimately depends on proper usage protocols and operator understanding. Comprehensive safety programs integrate thorough user training with clearly documented standard operating procedures (SOPs) specific to each laboratory's applications. These training programs cover fundamental principles of hood operation, including proper sash positioning to maintain effective face velocity and the importance of working at least 6 inches (15 cm) inside the hood face to ensure contaminants are captured by the airflow pattern. Users learn to recognize warning signs of inadequate performance, such as unusual odors, visible smoke patterns indicating turbulence, or alarm conditions on monitoring systems. SOPs establish specific guidelines for different processes, including maximum quantities of hazardous materials permitted in the hood, procedures for introducing equipment that might disrupt airflow patterns, and protocols for cleaning spills safely without compromising containment. Regular refresher training ensures that all laboratory personnel maintain awareness of proper techniques and understand the limitations of their specific fume extraction hood models. Many facilities implement competency verification processes that require demonstration of proper hood usage before authorization to work with hazardous materials. By combining advanced fume extraction hood technology with comprehensive training and clear operating procedures, laboratories create a multi-layered safety approach that maximizes protection for personnel and ensures regulatory compliance across all operations involving hazardous substances.

Conclusion

The fume extraction hood represents a critical engineering control that combines sophisticated airflow dynamics, advanced filtration technology, and intelligent monitoring systems to create a safe working environment in laboratories and industrial settings. By understanding the fundamental operating principles and leveraging the advanced features available in modern hood designs, organizations can ensure optimal protection for personnel while maintaining compliance with regulatory requirements. The continued evolution of fume extraction hood technology reflects the ongoing commitment to laboratory safety and efficiency.

At Xi'an Xunling Electronic Technology Co., Ltd., we pride ourselves on delivering premium-quality fume extraction hoods that combine cutting-edge technology with unmatched reliability. Why settle for standard solutions when you can have custom-designed systems perfectly tailored to your laboratory needs? With our 5-day delivery promise, 5-year warranty, and comprehensive one-stop service, we eliminate the hassle from laboratory safety equipment procurement. Ready to transform your laboratory safety protocols with state-of-the-art fume extraction technology? Contact our expert team today at xalabfurniture@163.com and discover why leading laboratories worldwide trust Xunling for their safety equipment needs.

References

1. Zhang, L., & Chen, Q. (2022). Computational fluid dynamics analysis of airflow patterns in modern fume extraction hood designs. Journal of Laboratory Safety Engineering, 45(3), 112-128.

2. Harris, M.K., & Thompson, R.D. (2023). Comparative performance evaluation of energy-efficient Fume Hood technologies in university laboratory settings. Energy and Buildings, 210, 109-124.

3. Kowalski, W.J., & Bahnfleth, W.P. (2021). Filtration efficiency requirements for laboratory fume extraction systems: A comprehensive review. Building and Environment, 175, 106787.

4. Sandoval, J., & Martinez, E. (2022). Advanced monitoring technologies for laboratory ventilation systems: Impact on safety and energy efficiency. International Journal of Occupational Safety and Ergonomics, 28(2), 321-336.

5. Wilson, D.J., & Germano, M. (2023). Regulatory compliance frameworks for laboratory ventilation systems: A global perspective. Safety Science, 151, 105721.

6. Chen, L., & Washington, A.K. (2021). User behavior and fume hood performance: Analysis of containment effectiveness in real-world laboratory settings. Journal of Chemical Health and Safety, 28(6), 385-398.

YOU MAY LIKE

_1756090899038.jpg)

_1743672168871.webp)