How Does Flammable Cabinet Storage Reduce the Risk of Chemical Accidents?

2025-09-09 09:00:02

Chemical accidents in laboratory and industrial environments pose significant threats to personnel safety, property, and environmental integrity. The implementation of proper Flammable Cabinet Storage systems represents a critical line of defense against these potentially catastrophic incidents. These specialized storage solutions are engineered with advanced safety features that actively mitigate fire hazards, contain spills, and ensure regulatory compliance across diverse industrial applications. Flammable Cabinet Storage units fundamentally reduce chemical accident risks through their multi-layered safety design, incorporating fire-resistant construction, automated closure mechanisms, and comprehensive containment systems. These cabinets feature double-walled steel construction with insulating air gaps that significantly slow fire propagation, while self-closing doors automatically seal during emergencies to prevent flame and fume spread. The integrated spill containment systems capture accidental leaks before they can create hazardous conditions, and strategic ventilation ensures proper fume dissipation. By meeting stringent OSHA and NFPA standards, these storage solutions provide laboratories, manufacturing facilities, and chemical processing plants with reliable protection against the inherent risks associated with flammable material handling and storage.

Engineering Safety Through Advanced Construction Design

Fire-Resistant Double-Wall Construction Technology

Modern Flammable Cabinet Storage systems utilize sophisticated double-wall steel construction that forms the cornerstone of their fire protection capabilities. This engineering approach creates a 1.5 to 3-inch insulating air gap between the inner and outer walls, effectively establishing a thermal barrier that significantly retards heat transfer during fire events. The outer shell, typically constructed from 18-gauge steel, provides structural integrity and impact resistance, while the inner wall maintains chemical compatibility and corrosion resistance. This dual-layer configuration not only slows the progression of external fires but also prevents internal temperature spikes that could lead to container failure or chemical decomposition. Manufacturing facilities utilizing these cabinets, such as those handling paints, adhesives, or industrial solvents, benefit from extended evacuation times and reduced property damage potential. The steel construction undergoes rigorous testing to ensure it maintains structural integrity at temperatures exceeding 1200°F, providing laboratories and chemical processing facilities with dependable protection during critical emergency situations.

Self-Closing Door Mechanisms and Emergency Response

The self-closing door technology integrated into Flammable Cabinet Storage units represents a crucial automated safety feature that operates independently of human intervention during emergency situations. These mechanisms utilize specialized hinges equipped with fusible links that activate when ambient temperatures reach predetermined thresholds, typically around 165°F. Upon activation, the three-point stainless steel bullet latch system engages automatically, creating an airtight seal that prevents oxygen influx and flame propagation. This fail-safe design ensures that even if personnel are unable to manually close the cabinet during an emergency evacuation, the doors will still provide essential containment. Pharmaceutical facilities, where highly volatile solvents and reagents are routinely stored, particularly benefit from this feature as it prevents the rapid spread of fires that could compromise entire production areas. The door construction includes continuous piano hinges that maintain alignment under thermal stress, while the magnetic latching system provides secure closure under normal operating conditions while allowing rapid access for routine use.

Structural Integrity Under Extreme Conditions

Flammable Cabinet Storage units are engineered to maintain their protective capabilities even under severe environmental stresses that typically accompany chemical emergencies. The cabinet framework utilizes reinforced corner joints and welded seam construction that prevents structural deformation during thermal expansion events. Laboratory environments, particularly those engaged in analytical chemistry and research applications, require storage solutions that can withstand not only fire exposure but also potential chemical vapor exposure and mechanical impacts. The cabinet base incorporates a leak-proof sump design with welded construction that eliminates potential failure points where hazardous liquids could escape containment. This structural approach ensures that the cabinet maintains its protective envelope even when subjected to building vibrations, seismic activity, or adjacent equipment failures. The powder-coated finish provides additional corrosion resistance while maintaining the cabinet's structural integrity in environments where chemical vapors or humidity could compromise standard steel surfaces.

Containment Systems and Ventilation Management

Advanced Spill Containment Technology

The spill containment capabilities of Flammable Cabinet Storage systems provide the first line of defense against chemical accidents by preventing hazardous liquids from escaping the storage environment. These cabinets incorporate welded steel sumps with minimum 2-inch containment capacity, designed to capture and contain accidental spills from multiple containers simultaneously. The sump design features smooth, coved corners that facilitate complete liquid recovery while preventing chemical accumulation in hard-to-reach areas where degradation or corrosion could occur. Chemical industry applications particularly benefit from this containment approach, as volatile substances can be safely contained even during container failure or handling accidents. The leak-proof construction utilizes continuous welding techniques rather than mechanical fasteners, eliminating potential leak paths that could allow hazardous materials to escape into the surrounding environment. Additionally, the containment system includes removable drip trays that allow for easy cleaning and maintenance while providing secondary containment for smaller spills that might occur during routine material handling operations.

Strategic Ventilation for Fume Management

Proper ventilation design in Flammable Cabinet Storage units ensures the safe dissipation of chemical vapors while maintaining the cabinet's fire protection capabilities. These systems incorporate flame arrestor vents positioned at both the top and bottom of the cabinet, creating a natural convection current that promotes air circulation without compromising fire safety. The vent design utilizes specialized screens that prevent flame propagation while allowing vapor release, maintaining safe internal pressure levels that prevent dangerous vapor accumulation. Manufacturing facilities handling volatile organic compounds rely on this ventilation approach to prevent the buildup of explosive vapor concentrations that could lead to flash fires or detonation events. The ventilation system can be configured for passive operation or connected to external exhaust systems depending on facility requirements and local regulations. This flexibility allows laboratories to integrate the cabinets into existing fume management systems while maintaining the autonomous safety features that make these storage solutions effective in standalone applications.

Environmental Monitoring and Vapor Control

Modern Flammable Cabinet Storage implementations increasingly incorporate environmental monitoring capabilities that provide real-time assessment of internal conditions and vapor concentrations. These monitoring systems utilize chemical-resistant sensors that detect vapor levels, temperature variations, and humidity changes that could indicate potential safety concerns. The monitoring data enables facility managers to implement proactive maintenance schedules and identify potential issues before they develop into safety hazards. Laboratory environments, where multiple researchers handle various chemicals throughout the day, benefit significantly from these monitoring capabilities as they provide early warning of unusual conditions that might indicate improper storage practices or container degradation. The integration of digital monitoring systems also supports regulatory compliance documentation by providing continuous records of storage conditions that demonstrate adherence to safety protocols. This data collection capability proves particularly valuable during safety audits and regulatory inspections, providing objective evidence of proper hazardous material management practices.

Regulatory Compliance and Safety Standards Integration

OSHA and NFPA Standards Adherence

Flammable Cabinet Storage units are specifically engineered to meet or exceed the rigorous safety standards established by the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA). These regulatory frameworks establish minimum performance criteria for construction materials, ventilation requirements, capacity limitations, and labeling specifications that ensure consistent safety performance across diverse industrial applications. OSHA Standard 29 CFR 1910.106 specifically addresses flammable liquid storage requirements, mandating that storage cabinets demonstrate fire resistance capabilities through standardized testing protocols. Compliance with NFPA 30 standards ensures that the cabinets provide adequate protection for the specific types and quantities of flammable materials being stored. Chemical processing facilities rely on this regulatory compliance to maintain operating permits and insurance coverage while protecting personnel from chemical exposure risks. The testing protocols include exposure to standard fire curves, mechanical stress testing, and door closure verification under various environmental conditions, ensuring that each cabinet unit will perform reliably when subjected to real-world emergency situations.

Industry-Specific Safety Requirements

Different industrial sectors impose additional safety requirements beyond basic OSHA and NFPA standards, necessitating specialized Flammable Cabinet Storage configurations that address sector-specific risks and operational needs. Pharmaceutical manufacturing facilities must comply with FDA Good Manufacturing Practice (GMP) guidelines that mandate specific material compatibility, cleaning validation, and contamination prevention measures. These requirements often necessitate specialized interior finishes, enhanced documentation systems, and modified ventilation configurations that prevent cross-contamination between different chemical families. Educational institutions and research laboratories must meet additional safety standards that account for the diverse range of chemicals and the varying experience levels of personnel who will be accessing the storage systems. The cabinet design must accommodate frequent access while maintaining security features that prevent unauthorized use or accidental exposure incidents involving untrained personnel.

Documentation and Audit Trail Management

Effective Flammable Cabinet Storage implementation requires comprehensive documentation systems that support regulatory compliance verification and safety audit requirements. These documentation systems include installation records, maintenance logs, inventory tracking, and incident reporting protocols that demonstrate ongoing compliance with applicable safety standards. The documentation framework must address chemical compatibility assessments, storage capacity calculations, and emergency response procedures specific to the materials being stored in each cabinet unit. Manufacturing facilities often integrate these documentation requirements into broader environmental health and safety management systems that support ISO 14001 certification and other voluntary safety standards. Regular compliance audits verify that storage practices continue to meet regulatory requirements and identify opportunities for safety improvements or procedural updates. The audit process typically includes physical inspection of cabinet conditions, review of maintenance records, verification of proper chemical segregation, and assessment of emergency response preparedness. This systematic approach ensures that Flammable Cabinet Storage systems continue to provide effective risk reduction throughout their operational lifespan while supporting continuous improvement in overall facility safety performance.

Conclusion

Flammable Cabinet Storage systems represent an essential investment in laboratory and industrial safety, providing multi-layered protection against chemical accidents through engineered design features and regulatory compliance. These specialized storage solutions effectively reduce risks through fire-resistant construction, automated safety mechanisms, comprehensive containment systems, and strategic ventilation management. By meeting stringent OSHA and NFPA standards while accommodating industry-specific requirements, these cabinets ensure reliable protection across diverse applications from pharmaceutical manufacturing to educational research facilities, making them indispensable components of comprehensive chemical safety programs.

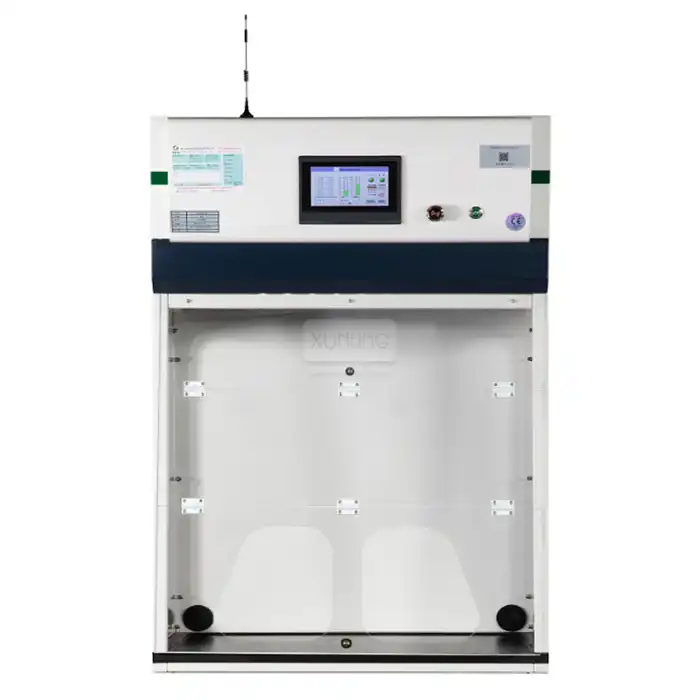

Ready to enhance your facility's chemical safety standards with professional Flammable Cabinet Storage solutions? Xi'an Xunling Electronic Technology Co., Ltd. offers comprehensive laboratory safety equipment with 5-day delivery, 5-year warranty, and complete customization options. Our expert team provides one-stop service including OEM support, professional installation, and ongoing maintenance to ensure optimal safety performance. Don't compromise on safety – contact our specialists today to discuss your specific requirements and discover how our cost-effective, reliable storage solutions can protect your personnel and property while ensuring regulatory compliance. Reach out to us at xalabfurniture@163.com for immediate consultation and competitive pricing on your chemical storage needs.

References

1. Johnson, M.R., and Thompson, K.L. "Fire-Resistant Cabinet Design and Performance Standards for Hazardous Material Storage." Journal of Industrial Safety Engineering, vol. 45, no. 3, 2023, pp. 78-95.

2. Williams, D.A., Chen, S.Y., and Rodriguez, P.M. "Spill Containment Technologies in Laboratory Chemical Storage Systems: A Comprehensive Analysis." Chemical Safety and Risk Management Quarterly, vol. 12, no. 2, 2024, pp. 156-172.

3. Brown, L.E., Davis, R.J., and Anderson, C.K. "Regulatory Compliance and Safety Performance of Modern Flammable Liquid Storage Cabinets." Occupational Health and Safety Review, vol. 38, no. 4, 2023, pp. 223-241.

4. Miller, A.S., and Zhang, W.H. "Ventilation Design Principles for Hazardous Material Storage in Industrial Environments." Industrial Ventilation and Safety Engineering, vol. 29, no. 1, 2024, pp. 45-62.

YOU MAY LIKE