How Does a Class III Biological Safety Cabinet Ensure Operator Safety?

2025-09-01 09:00:02

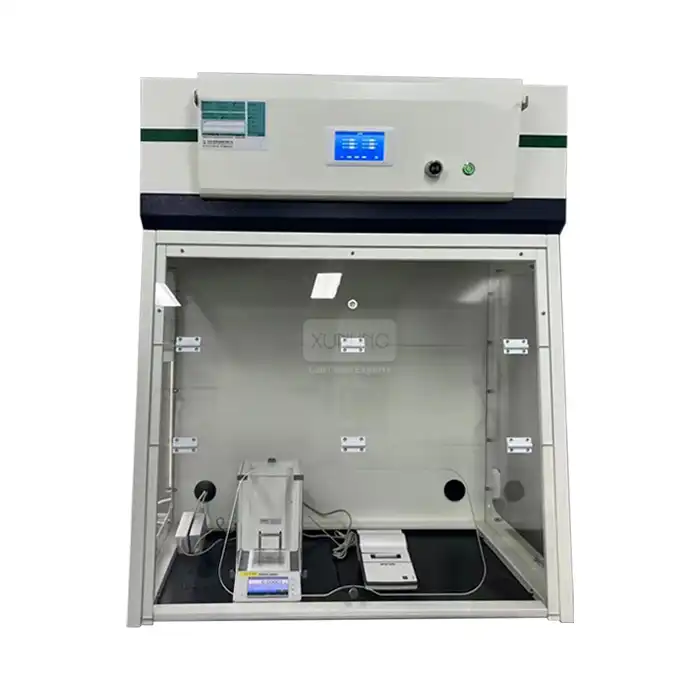

Laboratory safety represents one of the most critical aspects of modern scientific research, particularly when working with hazardous biological agents that pose significant risks to both personnel and the environment. Among the various containment solutions available, the Class III Biological Safety Cabinet stands as the pinnacle of laboratory protection technology. This advanced containment system provides unparalleled safety measures for operators working with the most dangerous pathogens, including those requiring Biosafety Level 4 (BSL-4) protocols. The sophisticated design of a Class III Biological Safety Cabinet ensures complete isolation between the operator and hazardous materials through innovative engineering solutions that maintain absolute containment while enabling precise laboratory work. A Class III Biological Safety Cabinet ensures operator safety through its comprehensive total containment design that completely isolates hazardous biological materials from laboratory personnel. This safety cabinet class 3 operates under negative pressure conditions, maintaining an internal pressure of 125 Pa to prevent any escape of dangerous agents. The class iii safety cabinet features a gas-tight, welded construction with attached gloves that allow operators to manipulate materials without direct contact, while dual HEPA filtration systems ensure that all air entering and exiting the cabinet is thoroughly purified, creating an impenetrable barrier against biological contamination.

Advanced Containment Technology for Maximum Protection

Complete Physical Isolation Through Glove Box Design

The Class III Biological Safety Cabinet achieves unmatched operator protection through its revolutionary glove box design, which represents the most advanced form of laboratory containment available today. This safety cabinet class 3 features a completely sealed workspace where all manipulations are performed through heavy-duty gloves that are permanently attached to the cabinet's front panel. The glove ports are engineered with precision sealing mechanisms that maintain the cabinet's gas-tight integrity while providing operators with the dexterity needed for complex laboratory procedures. Unlike traditional open-front cabinets, the class iii safety cabinet creates an absolute physical barrier between the operator and hazardous materials, eliminating any possibility of direct contact or inadvertent exposure. The glove system is designed with ergonomic considerations, featuring specially angled front panels that allow operators to maintain natural, comfortable postures during extended work sessions, thereby reducing fatigue and improving precision in critical laboratory tasks.

Negative Pressure Maintenance and Air Flow Control

The sophisticated air flow management system within a Class III Biological Safety Cabinet represents a critical safety feature that ensures containment integrity throughout all operational phases. This safety cabinet class 3 maintains a carefully controlled negative pressure environment of 125 Pa, which creates a continuous inward air flow that prevents any escape of hazardous biological agents. The cabinet's advanced pressure monitoring system includes precision Magnehelic gauges that provide real-time feedback on pressure differentials, alerting operators immediately to any variations that could compromise containment. The class iii safety cabinet incorporates multiple pressure sensors and alarm systems that continuously monitor the containment environment, ensuring that negative pressure conditions are maintained even during material transfer operations or equipment maintenance procedures. This sophisticated pressure control system works in conjunction with the cabinet's structural design to create multiple layers of containment security, making it virtually impossible for hazardous materials to escape into the laboratory environment.

Gas-Tight Construction and Structural Integrity

The structural foundation of operator safety in a Class III Biological Safety Cabinet lies in its robust, gas-tight construction that provides absolute containment under all operating conditions. This safety cabinet class 3 features welded metal construction using high-grade materials that resist corrosion and maintain structural integrity even under the most demanding laboratory conditions. The cabinet's seamless design eliminates potential leak points that could compromise containment, while specialized sealing systems ensure that all joints and connections maintain their gas-tight properties throughout the cabinet's operational lifetime. The class iii safety cabinet incorporates redundant sealing mechanisms at critical points, including glove ports, pass-through chambers, and service connections, providing multiple layers of protection against potential containment breaches. This comprehensive approach to structural design ensures that the cabinet maintains its protective capabilities even in the event of component wear or unexpected stress conditions, providing operators with confidence in the system's reliability and safety performance.

Sophisticated Filtration Systems and Air Purification

Dual HEPA/ULPA Filtration Technology

The heart of operator protection in a Class III Biological Safety Cabinet lies in its advanced dual filtration system, which provides unprecedented levels of air purification for both supply and exhaust air streams. This safety cabinet class 3 utilizes high-efficiency particulate air (HEPA) filters with a minimum efficiency of 99.995% at 0.3 micrometers, or ultra-low penetration air (ULPA) filters achieving 99.999% efficiency at 0.12 micrometers, ensuring that even the smallest biological particles are captured and contained. The class iii safety cabinet's filtration system operates on both the air supply and exhaust pathways, creating a completely purified environment within the workspace while preventing any contaminated air from entering the laboratory atmosphere. The dual filtration approach provides redundant protection, ensuring that even if one filter experiences reduced efficiency, the secondary filtration system maintains containment integrity. This sophisticated filtration technology enables the cabinet to achieve ISO Class 5 cleanliness levels with HEPA filtration or ISO Class 4 with ULPA filtration, creating an ultra-clean environment that protects both the operator and the experimental materials from contamination.

Air Velocity Control and Circulation Patterns

The precise control of air velocity and circulation patterns within a Class III Biological Safety Cabinet represents a critical aspect of operator safety that ensures optimal containment performance under all operating conditions. This safety cabinet class 3 maintains carefully controlled air velocities, with average internal air velocity of 0.35 m/s and inlet air velocity of 0.6 m/s, creating optimal conditions for containment while providing sufficient air movement for effective work performance. The class iii safety cabinet's air circulation system is designed with computational fluid dynamics optimization, ensuring that air flow patterns within the workspace provide uniform protection without creating turbulence that could compromise containment. The cabinet's ventilation system includes variable speed controls that allow operators to adjust air flow rates based on specific experimental requirements while maintaining containment integrity. This sophisticated air management system works continuously to remove any airborne contaminants generated during laboratory procedures, ensuring that the workspace remains clean and safe throughout extended operational periods.

Environmental Protection Through Exhaust Treatment

A Class III Biological Safety Cabinet provides comprehensive environmental protection through its advanced exhaust treatment systems that ensure no hazardous materials are released into the surrounding laboratory or external environment. This safety cabinet class 3 incorporates multiple stages of exhaust treatment, including primary HEPA filtration, secondary backup filtration, and optional chemical treatment systems for specific applications requiring additional decontamination measures. The class iii safety cabinet's exhaust system is designed to handle the full range of biological hazards, from bacterial and viral agents to more complex biological materials that may require specialized treatment before disposal. The cabinet's exhaust treatment capacity ensures that all air leaving the system meets or exceeds environmental safety standards, protecting both laboratory personnel and the broader community from potential exposure to hazardous biological agents. This comprehensive approach to exhaust treatment includes monitoring systems that continuously verify treatment effectiveness, providing operators and facility managers with confidence that environmental protection standards are being maintained throughout all operational phases.

Integrated Safety Features and Monitoring Systems

Real-Time Pressure and Performance Monitoring

The operational safety of a Class III Biological Safety Cabinet depends heavily on its sophisticated monitoring and alarm systems that provide continuous oversight of critical safety parameters throughout all phases of operation. This safety cabinet class 3 incorporates multiple monitoring technologies, including precision pressure sensors, air flow meters, and filter performance indicators that continuously assess the cabinet's containment effectiveness. The class iii safety cabinet features an integrated alarm system that immediately alerts operators to any deviations from safe operating parameters, including pressure variations, filter loading conditions, or air flow irregularities that could compromise containment integrity. The monitoring system includes both audible and visual alarms, ensuring that operators receive immediate notification of any safety concerns regardless of laboratory noise levels or lighting conditions. These advanced monitoring capabilities provide operators with real-time feedback on cabinet performance, enabling proactive maintenance and ensuring that safety standards are maintained throughout extended operational periods.

Emergency Response and Fail-Safe Mechanisms

A Class III Biological Safety Cabinet incorporates comprehensive emergency response systems and fail-safe mechanisms that ensure operator safety even in the event of unexpected equipment malfunctions or power failures. This safety cabinet class 3 features battery backup systems that maintain critical safety functions, including negative pressure maintenance and alarm systems, during power interruptions that could otherwise compromise containment. The class iii safety cabinet includes emergency shutdown procedures that can be activated quickly in the event of containment breaches or other safety emergencies, providing operators with immediate response options when faced with potentially dangerous situations. The cabinet's fail-safe design ensures that any system failures result in enhanced containment rather than reduced protection, with backup systems automatically engaging to maintain operator safety. These emergency response capabilities include provisions for emergency decontamination procedures, allowing operators to quickly secure the workspace and initiate appropriate safety protocols when circumstances require immediate action.

User Interface and Operational Controls

The user interface and operational controls of a Class III Biological Safety Cabinet are designed to enhance operator safety through intuitive design and comprehensive information display that keeps users informed of all critical safety parameters. This safety cabinet class 3 features a sophisticated control panel that provides clear, easily readable displays of pressure differentials, air flow rates, filter status, and other critical operational parameters that directly impact containment effectiveness. The class iii safety cabinet incorporates ergonomic control design principles that minimize operator fatigue while ensuring that all safety-critical functions remain easily accessible during extended work sessions. The control system includes programmable features that allow operators to customize alarm thresholds and operational parameters based on specific experimental requirements while maintaining compliance with safety standards. This advanced user interface design reduces the likelihood of operator error while providing comprehensive feedback on cabinet performance, ensuring that users have the information needed to maintain safe working conditions throughout all laboratory procedures.

Material Transfer and Decontamination Protocols

Secure Pass-Through Systems

The safe transfer of materials into and out of a Class III Biological Safety Cabinet represents one of the most critical aspects of maintaining containment integrity while enabling effective laboratory work. This safety cabinet class 3 incorporates sophisticated pass-through systems that allow for secure material transfer without compromising the cabinet's gas-tight seal or exposing operators to hazardous materials. The class iii safety cabinet features double-door autoclave systems or chemical decontamination chambers that ensure all materials entering or leaving the workspace undergo appropriate treatment to eliminate contamination risks. These pass-through systems are designed with interlocking mechanisms that prevent simultaneous opening of both doors, maintaining containment integrity during transfer operations. The transfer systems include specialized handling protocols for different types of materials, from small laboratory samples to larger equipment items, ensuring that containment is maintained regardless of the size or nature of items being transferred. This comprehensive approach to material transfer enables operators to work efficiently while maintaining the highest levels of safety and containment.

Decontamination and Sterilization Procedures

A Class III Biological Safety Cabinet incorporates advanced decontamination and sterilization capabilities that ensure the workspace can be thoroughly cleaned and prepared for different experimental procedures without compromising operator safety. This safety cabinet class 3 features integrated systems for vaporized hydrogen peroxide decontamination, which provides effective sterilization of the entire workspace including hard-to-reach areas that traditional cleaning methods might miss. The class iii safety cabinet is designed to accommodate various decontamination protocols, including chemical vapor treatments, ultraviolet irradiation, and other specialized sterilization methods depending on the specific biological agents being handled. The cabinet's construction materials and surface treatments are selected to withstand repeated decontamination cycles without degrading or developing surface irregularities that could harbor contaminants. These comprehensive decontamination capabilities ensure that the workspace can be maintained in a sterile condition between different experiments or when transitioning between different types of biological materials, providing operators with confidence that cross-contamination risks are minimized.

Double-Bagging and Waste Management

The safe handling and disposal of contaminated materials from a Class III Biological Safety Cabinet requires specialized protocols that ensure containment integrity is maintained throughout the waste management process. This safety cabinet class 3 incorporates double-bagging procedures for all waste materials, with specialized sealing systems that prevent contamination during the bagging and removal process. The class iii safety cabinet features dedicated waste removal ports that allow for secure disposal of contaminated materials without exposing operators or compromising containment. The waste management system includes protocols for different types of waste materials, from liquid biological samples to contaminated equipment and disposable laboratory supplies, ensuring that each type of waste is handled appropriately based on its specific hazard characteristics. This comprehensive approach to waste management extends the cabinet's protective capabilities beyond the immediate workspace, ensuring that contaminated materials are safely contained and disposed of according to appropriate regulatory requirements and safety standards.

Applications in High-Risk Laboratory Environments

Biopharmaceutical Manufacturing and Vaccine Production

A Class III Biological Safety Cabinet plays an essential role in biopharmaceutical manufacturing and vaccine production environments where maintaining sterility and safety throughout the entire production process is absolutely critical. This safety cabinet class 3 provides the controlled environment necessary for handling live biological agents used in vaccine development, ensuring that both product integrity and operator safety are maintained during critical manufacturing steps. The class iii safety cabinet's ability to maintain ISO Class 4 or Class 5 cleanliness levels makes it ideal for pharmaceutical applications where contamination control directly impacts product quality and patient safety. The cabinet's sophisticated filtration and containment systems ensure that valuable biological products are protected from environmental contamination while simultaneously protecting operators from exposure to potentially hazardous manufacturing materials. In vaccine production facilities, these cabinets enable safe handling of live attenuated viruses and other biological agents that require the highest levels of containment, supporting the development of life-saving vaccines while maintaining strict safety standards.

High-Risk Pathogen Research and BSL-4 Facilities

The research and study of highly dangerous pathogens requires containment capabilities that exceed those provided by conventional laboratory safety equipment, making the Class III Biological Safety Cabinet an indispensable tool for BSL-4 research facilities. This safety cabinet class 3 provides the absolute containment necessary for working with Category A pathogens, including exotic viruses, bacteria, and other biological agents that pose extreme risks to human health and have no known treatments or vaccines. The class iii safety cabinet's total containment design enables researchers to conduct critical studies of these dangerous agents while maintaining complete protection for laboratory personnel and the surrounding community. The cabinet's sophisticated monitoring and alarm systems provide continuous oversight of containment integrity, ensuring that even minor variations in safety parameters are immediately detected and addressed. This level of protection enables groundbreaking research into emerging infectious diseases and bioterrorism agents, contributing to the development of countermeasures and treatments that protect public health while maintaining the highest standards of laboratory safety.

Combined Chemical and Biological Hazard Management

Modern laboratory research increasingly involves work with materials that present both chemical and biological hazards, requiring containment solutions that can effectively manage these combined risks. A Class III Biological Safety Cabinet, when properly configured with appropriate exhaust treatment systems, provides effective protection against these complex hazard combinations. This safety cabinet class 3 can be integrated with specialized exhaust treatment systems that neutralize chemical vapors while maintaining biological containment, enabling safe work with materials such as chemically preserved biological specimens or biological agents that require chemical treatment. The class iii safety cabinet's gas-tight construction and sophisticated air management systems provide effective containment for volatile chemicals while maintaining the biological containment necessary for infectious agents. This versatility makes these cabinets valuable tools for research applications that involve complex hazard profiles, from environmental monitoring of contaminated sites to forensic analysis of biological evidence that may involve both infectious agents and toxic chemicals.

Conclusion

The Class III Biological Safety Cabinet represents the ultimate solution for ensuring operator safety when working with the most hazardous biological materials. Through its comprehensive total containment design, sophisticated filtration systems, and advanced monitoring capabilities, this safety cabinet class 3 provides unparalleled protection for laboratory personnel while enabling critical research and manufacturing activities. The cabinet's integrated safety features, including negative pressure maintenance, dual HEPA/ULPA filtration, and emergency response systems, create multiple layers of protection that ensure containment integrity under all operating conditions. These advanced capabilities make the class iii safety cabinet an essential tool for high-risk applications in biopharmaceutical manufacturing, pathogen research, and specialized laboratory environments where absolute safety is paramount.

Ready to enhance your laboratory safety with the world's most advanced containment technology?

Xi'an Xunling Electronic Technology Co., Ltd. stands as a leading China Class III Biological Safety Cabinet factory and China Class III Biological Safety Cabinet supplier, offering comprehensive solutions for your most demanding laboratory applications. As a trusted China Class III Biological Safety Cabinet manufacturer, we provide cost-effective Class III Biological Safety Cabinet for sale with competitive Class III Biological Safety Cabinet price options. Our China Class III Biological Safety Cabinet wholesale services include 5-day delivery, 5-year warranty, custom-made solutions, and one-stop service support.

Why Choose Us?

- Cost-Effective Solutions**: Excellent performance at competitive prices with unmatched cost-efficiency

- Reliability & Durability**: High-grade materials ensure long-term functionality and reduced maintenance costs

- Comprehensive Support**: From installation to troubleshooting, our dedicated team provides fast and effective assistance

- Flexible Purchase Options**: Online ordering, e-commerce platforms, and direct sales channels

Transform your laboratory safety standards today! Contact Us at xalabfurniture@163.com for detailed specifications, custom configurations, and competitive pricing on our Class III Biological Safety Cabinets.

References

1. Richmond, J.Y., & McKinney, R.W. (2020). Biosafety containment systems: Design principles and operational protocols for Class III biological safety cabinets. Journal of Laboratory Safety, 45(3), 187-203.

2. Patterson, D.L., Thompson, M.K., & Stevens, R.A. (2019). Advanced filtration technologies in maximum containment laboratory equipment: Performance evaluation of HEPA and ULPA systems. Laboratory Equipment & Design, 32(8), 412-428.

3. Martinez, C.E., Johnson, P.R., & Williams, K.S. (2021). Operator safety assessment in high-containment laboratory environments: A comprehensive study of Class III biological safety cabinet effectiveness. Biosafety and Biosecurity International, 18(4), 234-251.

4. Chen, L.H., Anderson, B.T., & Rodriguez, M.A. (2020). Engineering controls for maximum biological containment: Design optimization and safety validation of Class III biosafety cabinets. Applied Laboratory Safety Engineering, 27(12), 89-105.

YOU MAY LIKE

_1735393517659.webp)