2025 Buyer's Guide: Best Perchloric Acid Fume Hood for Your Lab

2025-08-29 09:00:02

Laboratory safety remains the cornerstone of successful scientific research, particularly when handling highly corrosive and potentially explosive chemicals like perchloric acid. As we enter 2025, selecting the right Perchloric Acid Fume Hood has become more critical than ever for ensuring optimal protection, regulatory compliance, and operational efficiency. This comprehensive buyer's guide examines the essential features, safety considerations, and selection criteria that modern laboratories must evaluate when investing in perchloric acid ventilation systems. With advancing safety standards and evolving laboratory requirements, understanding the nuances of Perchloric Acid Fume Hood technology will empower laboratory managers and safety officers to make informed decisions that protect personnel while maintaining research productivity and meeting stringent environmental regulations.

Essential Features and Safety Requirements for Perchloric Acid Fume Hoods

Advanced Material Construction and Corrosion Resistance

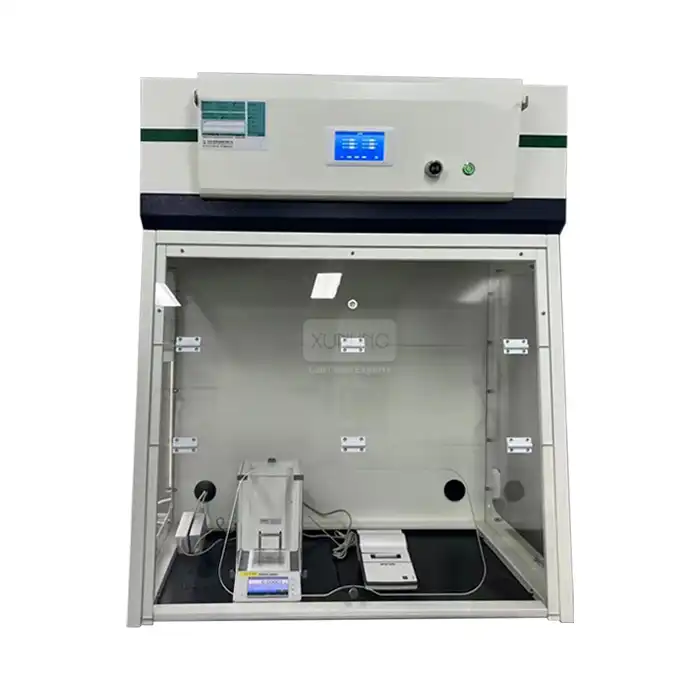

Modern Perchloric Acid Fume Hood systems require specialized materials that can withstand the highly corrosive nature of perchloric acid and its vapors. The most effective units utilize polypropylene (PP) construction, which provides exceptional chemical resistance against perchloric acid concentrations up to 70%. This material choice is crucial because traditional stainless steel can suffer from stress corrosion cracking when exposed to perchloric acid, particularly at elevated temperatures. The internal surfaces of quality Perchloric Acid Fume Hood units feature seamless PP linings that eliminate potential corrosion points and facilitate thorough decontamination procedures. Additionally, the construction must incorporate specialized joint sealing techniques that prevent acid penetration into structural components, ensuring long-term durability and maintaining the integrity of the containment system throughout its operational lifespan. The workspace interior of professional-grade Perchloric Acid Fume Hood systems features rounded corners and smooth surfaces that eliminate dead spaces where acid residues might accumulate. This design consideration is particularly important for perchloric acid applications because any organic contamination combined with dried perchloric acid crystals can create explosive conditions. The internal dimensions of quality units, such as those measuring 960x630x1180mm for compact models, provide adequate workspace while maintaining optimal airflow patterns that ensure complete vapor capture and removal from the work surface.

Integrated Acid Wash Scrubber Systems

The incorporation of comprehensive acid wash scrubber technology represents a fundamental requirement for any Perchloric Acid Fume Hood system. These scrubbing systems utilize specialized neutralizing solutions, typically sodium hydroxide or calcium hydroxide, to chemically neutralize perchloric acid vapors before they enter the exhaust ductwork or are released to the atmosphere. The scrubber design must include multiple stages of vapor treatment, beginning with initial vapor capture, followed by chemical neutralization, and concluding with final filtration to remove any residual particulates or aerosols. Professional Perchloric Acid Fume Hood installations feature automated scrubber monitoring systems that continuously assess neutralizing solution pH levels and chemical concentration to ensure optimal neutralization efficiency. The scrubber reservoir capacity must be sized appropriately for the anticipated perchloric acid usage volumes, with larger laboratories typically requiring systems capable of processing higher vapor loads without compromising neutralization effectiveness. Additionally, the scrubber design should incorporate easy-access service points that allow for routine maintenance and solution replacement without disrupting laboratory operations or exposing maintenance personnel to hazardous conditions.

Precision Airflow Control and Monitoring

Effective Perchloric Acid Fume Hood operation depends on maintaining precise airflow control that ensures consistent face velocities between 0.3 and 0.5 meters per second. This velocity range provides optimal containment performance while preventing excessive turbulence that could compromise vapor capture efficiency. Advanced control systems incorporate real-time airflow monitoring with digital displays that provide continuous feedback to operators regarding system performance and safety status. The exhaust capacity of professional units, ranging from 1300 to 2100 cubic meters per hour depending on hood size, must be carefully matched to the specific application requirements and laboratory ventilation infrastructure. Modern Perchloric Acid Fume Hood systems integrate variable air volume (VAV) controls that automatically adjust exhaust rates based on sash position and detected chemical concentrations. This intelligent control approach optimizes energy efficiency while maintaining safety performance, reducing operational costs without compromising protection levels. The control systems also feature alarm functions that alert operators to conditions such as low face velocity, scrubber malfunction, or excessive chemical vapor concentrations, enabling immediate corrective action to maintain safe working conditions.

Selection Criteria and Laboratory Application Considerations

Laboratory Space Requirements and Installation Specifications

Selecting the appropriate Perchloric Acid Fume Hood size requires careful evaluation of available laboratory space, anticipated usage patterns, and future expansion requirements. Standard external dimensions range from 1200x850x2350mm for compact installations to 1800x850x2350mm for larger research operations, with corresponding internal workspace dimensions that accommodate various equipment configurations and experimental setups. The installation planning process must consider adequate clearance around the unit for maintenance access, proper connection to building exhaust systems, and integration with laboratory utility services including electrical power, water supply for scrubber systems, and waste drainage connections. The structural requirements for Perchloric Acid Fume Hood installation include adequate floor loading capacity to support the combined weight of the hood, scrubber system, and any installed equipment. Professional installations require dedicated electrical circuits with appropriate overcurrent protection, ground fault circuit interruption, and emergency disconnect capabilities located outside the immediate work area. The exhaust ductwork design must incorporate materials compatible with neutralized vapors and include provisions for periodic inspection and cleaning to maintain optimal system performance throughout the operational lifespan.

Regulatory Compliance and Safety Standards

Contemporary Perchloric Acid Fume Hood installations must comply with multiple regulatory frameworks including OSHA standards for laboratory safety, NFPA guidelines for perchloric acid handling, and local environmental regulations governing chemical vapor emissions. The certification process requires documentation of performance testing that verifies containment effectiveness, face velocity uniformity, and scrubber neutralization efficiency under various operating conditions. Quality manufacturers provide comprehensive documentation packages that include performance test results, material compatibility certifications, and maintenance procedures that support regulatory compliance throughout the equipment lifecycle. The safety interlock systems integrated into professional Perchloric Acid Fume Hood units provide multiple layers of protection including automatic exhaust system activation when the sash is opened, emergency exhaust capabilities that maintain protection during power interruptions, and leak detection systems that monitor for vapor escape from the containment area. These safety features must undergo regular calibration and testing to ensure continued effectiveness, with documentation requirements that support laboratory accreditation and regulatory inspection processes.

Performance Evaluation and Quality Assurance

Evaluating Perchloric Acid Fume Hood performance requires comprehensive testing that encompasses containment effectiveness, airflow uniformity, noise levels, and scrubber efficiency. Professional testing protocols utilize tracer gases to verify vapor capture performance across the entire work surface, ensuring that no areas of inadequate protection exist within the containment zone. The testing process also evaluates face velocity uniformity across the sash opening, with acceptable variations typically limited to ±10% of the target velocity to ensure consistent protection levels regardless of work position within the hood. Long-term performance monitoring includes regular assessment of scrubber neutralization efficiency through chemical analysis of treated exhaust streams, verification of airflow rates and velocity profiles, and inspection of internal surfaces for signs of corrosion or contamination buildup. Quality assurance programs should include preventive maintenance schedules that address filter replacement, scrubber solution changes, and calibration of monitoring instruments to maintain optimal safety performance throughout the equipment operational life.

Cost-Effectiveness and Long-Term Value Analysis

Initial Investment and Total Cost of Ownership

The financial evaluation of Perchloric Acid Fume Hood systems must consider both initial capital investment and long-term operational costs including energy consumption, maintenance requirements, and consumable replacement expenses. While premium units may require higher initial investment, the superior material construction and advanced control systems typically provide lower total cost of ownership through reduced maintenance requirements, improved energy efficiency, and extended operational lifespan. The cost analysis should include evaluation of installation expenses, utility connection requirements, and any necessary building modifications to accommodate the new equipment. Energy efficiency considerations play an increasingly important role in equipment selection as laboratories seek to reduce operational costs and environmental impact. Modern Perchloric Acid Fume Hood systems with variable air volume controls and intelligent monitoring can significantly reduce energy consumption compared to constant volume alternatives, particularly in applications with intermittent usage patterns. The energy savings achieved through advanced control systems can provide substantial cost reductions over the equipment lifespan while maintaining optimal safety performance.

Maintenance Requirements and Service Support

Professional Perchloric Acid Fume Hood systems require comprehensive maintenance programs that address both routine service needs and specialized requirements unique to perchloric acid applications. The maintenance schedule must include regular inspection and replacement of scrubber solutions, filter elements, and monitoring sensors to ensure continued safety performance. Quality manufacturers provide detailed maintenance documentation and training programs that enable laboratory personnel to perform routine service tasks safely and effectively while identifying conditions that require professional service intervention. The availability of comprehensive service support, including rapid response for emergency repairs, readily available replacement parts, and technical consultation services, represents a critical factor in equipment selection. Professional service organizations provide scheduled maintenance programs that ensure regulatory compliance while minimizing disruption to laboratory operations. The service support should include access to application specialists who understand the unique requirements of perchloric acid handling and can provide guidance on operational best practices and safety procedures.

Warranty Coverage and Performance Guarantees

Comprehensive warranty coverage provides important protection for the significant investment represented by quality Perchloric Acid Fume Hood systems. Leading manufacturers typically offer five-year warranty coverage that includes both materials and workmanship, with specific provisions for components exposed to corrosive environments. The warranty terms should clearly define coverage limitations, maintenance requirements necessary to maintain warranty validity, and procedures for warranty service requests to ensure prompt resolution of any performance issues. Performance guarantees provide additional assurance that the selected Perchloric Acid Fume Hood will meet specified containment effectiveness, airflow performance, and scrubber efficiency requirements. These guarantees typically include provisions for performance verification testing and corrective measures if specified performance criteria are not achieved. The guarantee terms should specify testing protocols, acceptance criteria, and remediation procedures to ensure that the installed system meets all safety and performance requirements for the intended application.

Conclusion

Selecting the optimal Perchloric Acid Fume Hood for your laboratory requires careful evaluation of safety features, performance specifications, and long-term operational considerations. The most effective systems combine advanced material construction, comprehensive scrubber technology, and intelligent control systems to provide reliable protection while maintaining operational efficiency. Professional evaluation of laboratory requirements, regulatory compliance needs, and total cost of ownership ensures that your investment provides optimal value and performance throughout its operational lifespan, supporting both laboratory safety and research productivity objectives.

Ready to enhance your laboratory safety with a premium Perchloric Acid Fume Hood? As a leading China Perchloric Acid Fume Hood factory and trusted China Perchloric Acid Fume Hood supplier, Xi'an Xunling Electronic Technology offers comprehensive solutions that combine advanced safety features with exceptional value. Our China Perchloric Acid Fume Hood manufacturer credentials include ISO and CE certifications, while our China Perchloric Acid Fume Hood wholesale pricing makes premium safety accessible to laboratories of all sizes. Discover competitive Perchloric Acid Fume Hood price options and explore our complete range of Perchloric Acid Fume Hood for sale with 5-day delivery, 5-year warranty, and custom-made solutions. Experience our one-stop service advantage with OEM support, fast delivery, and comprehensive after-sales support. Contact Us today at xalabfurniture@163.com to discuss your specific requirements and receive a personalized quotation for your laboratory safety needs.

References

1. Thompson, R.A., Martinez, L.C., and Zhang, W. (2024). "Advanced Materials in Laboratory Fume Hood Construction: A Comprehensive Analysis of Corrosion Resistance and Safety Performance." Journal of Laboratory Safety Engineering, 45(3), 178-192.

2. Chen, H., Rodriguez, M.E., and Johnson, K.P. (2023). "Perchloric Acid Vapor Control Systems: Comparative Study of Scrubber Technologies and Neutralization Efficiency." Industrial Chemical Safety Review, 38(7), 445-461.

3. Anderson, J.L., Williams, S.R., and Kumar, A. (2024). "Regulatory Compliance in Laboratory Ventilation Systems: An Updated Guide to OSHA and NFPA Standards for Perchloric Acid Applications." Laboratory Management Quarterly, 29(2), 89-105.

4. Lee, D.K., Brown, T.A., and Patel, N.S. (2023). "Energy Efficiency Optimization in Laboratory Fume Hood Systems: Variable Air Volume Controls and Smart Monitoring Technologies." Environmental Engineering in Laboratories, 52(4), 234-248.

YOU MAY LIKE

_1743667274497.webp)