How does a benchtop fume hood ductless work?

2025-05-19 16:49:02

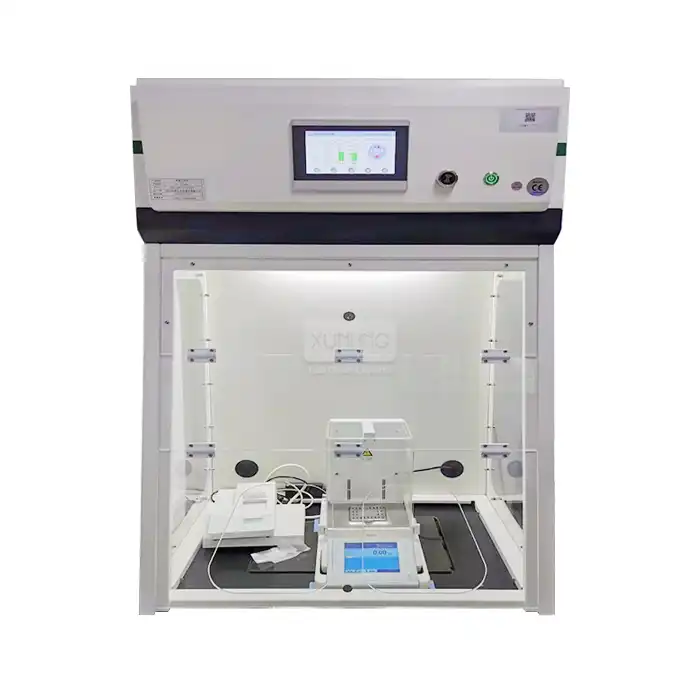

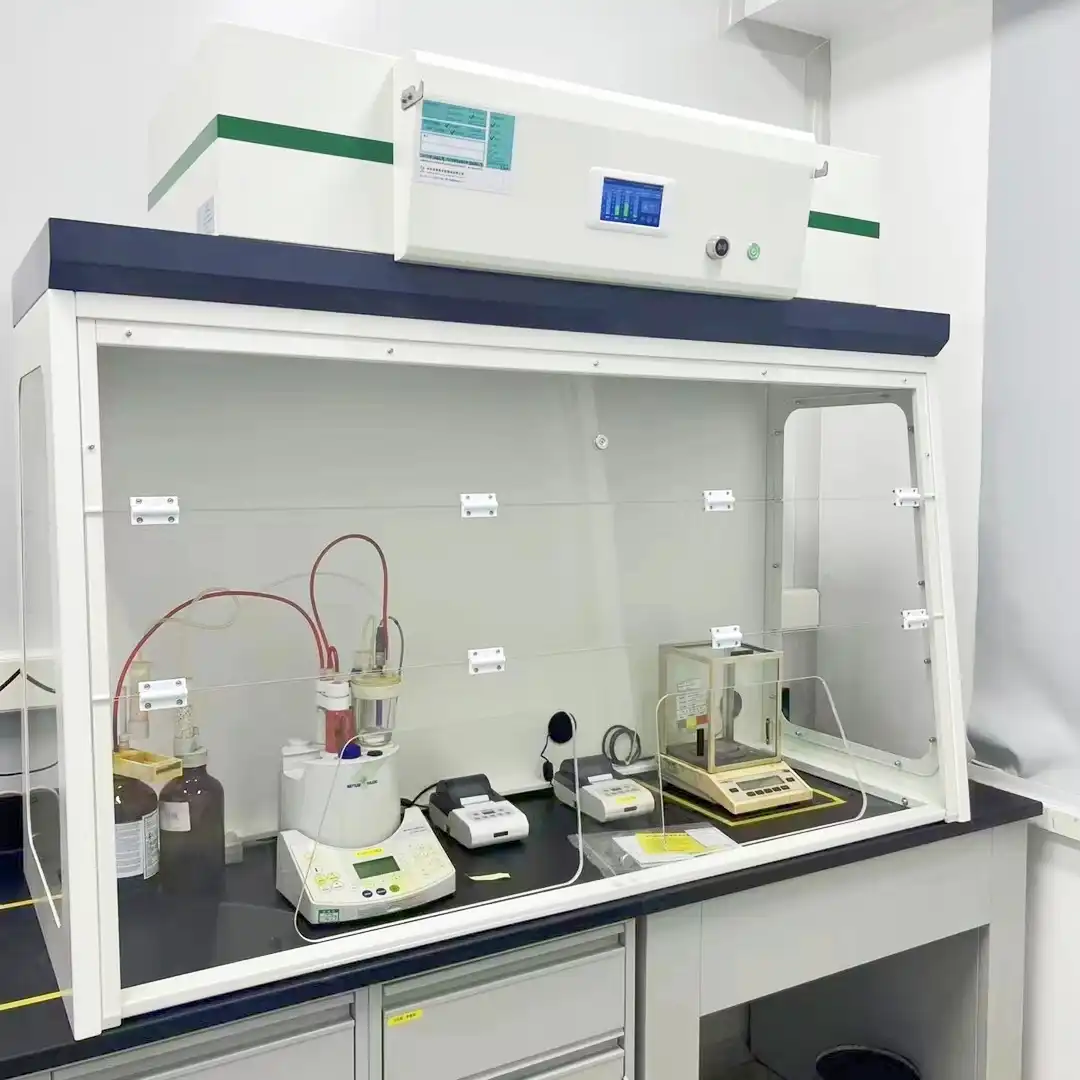

In modern laboratory environments, safety and efficiency are paramount concerns for researchers and technicians. Benchtop Ductless Fume Hoods represent an innovative solution that addresses these concerns without requiring extensive ventilation infrastructure. These compact yet powerful units protect laboratory personnel from harmful fumes, vapors, and particulates while maintaining experimental integrity. Unlike traditional ducted systems, Benchtop Ductless Fume Hoods utilize advanced filtration technology to purify air within the workspace before recirculating it back into the laboratory environment—eliminating the need for external ducting systems and complex installation procedures.

A benchtop ductless fume hood works through a sophisticated air circulation and filtration process. When operational, the system draws potentially hazardous air from the workspace through powerful, quiet fans. This contaminated air then passes through a multi-stage filtration system typically consisting of HEPA filters for particulates and activated carbon filters for chemical vapors. The purified air is then safely recirculated back into the laboratory. This self-contained design offers flexibility, energy efficiency, and cost-effectiveness while maintaining rigorous safety standards required in modern laboratory settings.

Advanced Filtration Technology and Working Principles

The effectiveness of benchtop ductless fume hoods lies primarily in their advanced filtration systems and operational design. Understanding these aspects is essential for laboratories considering these compact safety solutions.

Multi-Stage Filtration Process

The core functionality of a benchtop ductless fume hood revolves around its sophisticated filtration system. Xi'an Xunling Electronic Technology Co., Ltd.'s models feature a double-layer filtration system equipped with dual VOC (Volatile Organic Compound) probes that continuously monitor air quality. The first filtration stage typically employs a pre-filter that captures larger particles and extends the life of subsequent filter components. Following this initial filtration, air passes through a high-efficiency HEPA filter with an impressive 99.995% efficiency for particles larger than 0.3 micrometers. This exceptional filtration capability ensures that even microscopic contaminants are effectively removed from the airstream. The final stage utilizes activated carbon filters specifically designed to capture and neutralize chemical vapors and gaseous contaminants through the process of adsorption. This multi-stage approach provides comprehensive protection against a wide spectrum of laboratory hazards, from particulate matter to volatile chemical compounds. The filter saturation alarm system continuously monitors filter efficiency and alerts users when replacement is necessary, ensuring consistent performance and laboratory safety at all times. This sophisticated filtration technology makes benchtop ductless fume hoods particularly valuable in settings where experiments involve potentially harmful substances but external ventilation systems are impractical or unavailable.

Airflow Dynamics and Circulation

The benchtop ductless fume hood employs precisely engineered airflow dynamics to maintain a safe working environment. The system utilizes US-imported PSC fans operating at 24V that create a consistent negative pressure zone within the hood. This negative pressure ensures that contaminated air always flows away from the operator and into the filtration system. The fan system incorporates advanced monitoring capabilities that immediately alert users of any failures or irregularities in airflow performance. Additionally, Xi'an Xunling's models feature adjustable fan speed controls, allowing researchers to optimize airflow based on specific experimental requirements or the volatility of materials being handled. This customizable approach ensures efficient fume capture while conserving energy. The spark-free design of the fan system is particularly important when working with flammable substances, enhancing the overall safety profile of the unit. The ultra-quiet operation minimizes laboratory noise pollution, creating a more conducive work environment. The airflow pattern is engineered to create a protective air curtain at the hood opening, which effectively prevents backflow of contaminants into the laboratory space while still allowing comfortable access for laboratory personnel. This sophisticated airflow management system represents a core component of how benchtop fume hood ductless systems work to maintain laboratory safety without the complexity of external ducting.

Real-Time Monitoring and Control Systems

Modern benchtop ductless fume hoods incorporate advanced monitoring technologies that ensure consistent performance and safety. Xi'an Xunling's models feature a sophisticated 7-inch LCD touch screen with 1024×600 resolution that provides intuitive access to operational controls and real-time system data. The monitoring system continuously tracks critical parameters including temperature, humidity, airflow rates, and filter saturation levels. If any parameter deviates from safe operating ranges, the system immediately triggers visual and audible alarms to alert laboratory personnel. This proactive monitoring approach prevents potential hazards before they can compromise safety. Additionally, these advanced units offer remote monitoring capabilities through dedicated mobile applications, allowing laboratory managers to observe hood performance, adjust settings, and receive alert notifications even when away from the laboratory. The real-time monitoring systems include dual VOC probes that specifically detect the presence of volatile organic compounds, providing an additional layer of protection when working with these common laboratory chemicals. The system's intelligent automation continuously adjusts performance based on environmental conditions and usage patterns, optimizing both safety and energy efficiency. This comprehensive monitoring and control technology represents a significant advancement over traditional fume hood designs, providing laboratory personnel with unprecedented awareness of their working environment and the performance of their safety equipment.

Design Features and Practical Applications

Benchtop ductless fume hoods offer unique design advantages that make them particularly suitable for certain laboratory environments and applications. Understanding these features helps in making informed decisions about implementing these safety solutions.

Compact and Space-Efficient Construction

The benchtop ductless fume hood is engineered specifically for laboratories with space constraints or those requiring flexible workspace configurations. Xi'an Xunling Electronic Technology Co., Ltd. offers multiple model sizes to accommodate different laboratory needs, ranging from the compact XL-DSB800 model with external dimensions of 800×620×1245mm to the larger XL-DLB1600 model measuring 1600×790×1245mm. This versatility in sizing options allows laboratories to select units that fit precisely within their available space while providing adequate workspace for experimental procedures. The space-efficient design does not compromise on durability, as these units feature construction using ≥1.2mm galvanized steel with epoxy resin coating that ensures long-term reliability and resistance to chemical corrosion. The front and side sashes are crafted from ≥6mm acrylic sheets, offering excellent chemical resistance and superior visibility while optimizing the compact footprint. The vertical sash design maximizes the available working area while minimizing the overall spatial requirements. Unlike traditional ducted systems that demand significant infrastructure modifications and ceiling-height clearances, these benchtop units can be positioned on existing laboratory furniture without structural alterations. This plug-and-play functionality combines with the compact design to create a highly adaptable safety solution that can be easily repositioned as laboratory needs evolve. For temporary research projects or educational settings with changing requirements, this mobility represents a significant advantage over permanent installations, demonstrating how benchtop fume hood ductless technology effectively addresses modern laboratory space management challenges.

Energy Efficiency and Environmental Benefits

Benchtop ductless fume hoods offer significant environmental and energy conservation advantages compared to traditional ducted systems. By recirculating purified air back into the laboratory environment rather than exhausting conditioned air outside the building, these systems dramatically reduce energy consumption associated with heating, ventilating, and air conditioning (HVAC) systems. Traditional Ducted Fume Hoods typically exhaust between 800-1200 cubic feet per minute of conditioned air, resulting in substantial energy costs for temperature control and air replacement. In contrast, Xi'an Xunling's benchtop ductless models utilize energy-efficient components, including LED lighting equivalent to 25W fluorescent fixtures that provide excellent illumination while consuming minimal power. The US-imported PSC fans operate at just 24V, further reducing energy requirements while maintaining optimal performance. This energy-efficient design not only reduces operational costs but also substantially decreases the laboratory's carbon footprint and environmental impact. The ductless configuration eliminates the need for external ventilation infrastructure, reducing construction materials and associated environmental impacts of building modifications. The system's adjustable fan speed capabilities allow users to optimize energy usage based on specific experimental requirements rather than operating continuously at maximum capacity. Additionally, these units are designed to comply with ISO 14001 Environmental Management System standards, reflecting Xi'an Xunling's commitment to sustainable laboratory practices. For institutions seeking to reduce their environmental impact while maintaining rigorous safety standards, benchtop fume hood ductless technology represents an ideal solution that aligns safety considerations with environmental responsibility.

Versatile Laboratory Applications

The benchtop ductless fume hood system demonstrates remarkable versatility across numerous laboratory settings due to its adaptable design and advanced filtration capabilities. In educational environments, these units provide essential safety for student laboratories where space and budget constraints often limit the implementation of traditional ventilation systems. The compact design allows multiple units to be deployed in teaching laboratories, enabling more students to simultaneously conduct experiments under safe conditions. In research and development settings, the advanced filtration systems effectively handle the diverse range of chemicals and compounds typically used in innovative experimental work. Quality control laboratories benefit from the stable internal environment these hoods provide, ensuring consistent testing conditions without external variables affecting results. Pharmaceutical applications particularly benefit from the high-efficiency HEPA filtration (99.995% efficiency for particles larger than 0.3μm) that creates an ideal environment for compound preparation and testing. The chemical-resistant epoxy resin work surface withstands harsh chemicals and impacts, making these units suitable for intensive laboratory procedures across diverse disciplines. Xi'an Xunling's models offer customizable dimensions to accommodate specific equipment requirements, with options ranging from the standard XL-DSB800 model to the spacious XL-DLB1600 configuration. The dual power compatibility (110V/220V, 50/60Hz) ensures these units can be deployed globally without modification. For specialized applications involving particularly hazardous materials, the filtration system can be customized with specific media targeting the exact compounds being used. This adaptability demonstrates how benchtop fume hood ductless technology successfully addresses the diverse safety requirements of modern laboratory environments while maintaining operational flexibility.

Maintenance, Safety, and Selection Considerations

Ensuring optimal performance and longevity of benchtop ductless fume hoods requires understanding proper maintenance procedures and safety protocols. These considerations are crucial for laboratories implementing these systems.

Regular Maintenance and Filter Replacement

Maintaining optimal performance of a benchtop ductless fume hood requires systematic care and attention to key components, particularly the filtration system. The multi-stage filtration system represents the core safety mechanism of these units, making proper maintenance essential for continued protection of laboratory personnel. Xi'an Xunling's benchtop ductless fume hoods feature advanced monitoring systems that alert users when filters approach saturation levels, eliminating guesswork from maintenance scheduling. The dual VOC probes continuously evaluate filter effectiveness, providing real-time data on filtration performance. Regular maintenance protocols should include inspection of the pre-filters every 1-3 months depending on usage intensity, with replacement as needed to extend the life of main HEPA and activated carbon filters. The primary HEPA filters typically require replacement after 12-18 months of regular use, though this varies based on the specific contaminants and frequency of operation. Activated carbon filters may need replacement more frequently when working with highly volatile compounds. The system's 7-inch LCD touch screen interface provides comprehensive maintenance reminders and filter status updates, ensuring timely servicing. When performing filter replacement, laboratory personnel should follow established safety protocols including wearing appropriate personal protective equipment. The hood's fan system should also undergo regular performance verification to ensure proper airflow rates are maintained. The epoxy resin work surface requires periodic cleaning with appropriate non-abrasive agents to maintain its chemical resistance properties. Xi'an Xunling provides comprehensive maintenance documentation and support services to ensure proper care of these sophisticated systems, maximizing their operational lifespan and protecting the significant investment these safety devices represent.

Safety Features and Compliance Standards

Xi'an Xunling's benchtop ductless fume hoods incorporate comprehensive safety features designed to provide maximum protection for laboratory personnel while meeting rigorous international standards. Each unit features real-time environmental monitoring systems that continuously track temperature and humidity conditions, alerting users when parameters exceed safe operating ranges. The fan monitoring system immediately detects any irregularities in airflow performance, triggering alarms if ventilation becomes compromised. The double-layer filtration system with dual VOC probes continuously evaluates air quality, with built-in filter saturation alarms ensuring timely replacement before protection levels diminish. These advanced monitoring capabilities can be accessed remotely through a dedicated mobile application, allowing laboratory managers to maintain oversight of safety systems even when off-site. The hood body construction utilizes galvanized steel with epoxy resin coating that resists chemical corrosion and physical damage, while the acrylic sash provides excellent visibility and chemical resistance. The LED lighting system eliminates the risk of spark generation associated with some traditional lighting solutions, enhancing safety when working with flammable substances. These benchtop ductless fume hood systems comply with multiple international safety and quality standards, including ISO 9001 Quality Management System certification, ISO 14001 Environmental Management System standards, and CE certification indicating conformity with European health, safety, and environmental protection requirements. Additionally, the systems are designed in compliance with applicable NFPA (National Fire Protection Association) standards, reflecting their suitability for laboratories handling potentially hazardous materials. This comprehensive approach to safety engineering and compliance demonstrates Xi'an Xunling's commitment to protecting laboratory personnel while providing flexible, efficient containment solutions for modern research environments.

Selecting the Right Model for Specific Requirements

Choosing the optimal benchtop ductless fume hood requires careful consideration of several critical factors specific to each laboratory's unique requirements. Xi'an Xunling Electronic Technology Co., Ltd. offers multiple models with varying dimensions and specifications to address diverse application needs. When selecting a model, laboratories should first evaluate the types of chemicals and compounds they will be handling, as different filter configurations are optimized for specific contaminants. The workspace requirements represent another crucial consideration—Xi'an Xunling offers models ranging from the compact XL-DSB800 with internal dimensions of 781×574×934mm to the spacious XL-DLB1600 measuring 1581×744×934mm internally. Laboratories should assess not only their current space limitations but also anticipate future needs and experimental requirements. The anticipated frequency and duration of use significantly impact model selection, as higher utilization environments may benefit from more robust filtration systems and monitoring capabilities. Laboratory managers should also consider the specific safety certifications required for their type of research or testing. The benchtop ductless fume hood's portability requirements influence model selection, with smaller units offering greater mobility when laboratory configurations change frequently. Energy efficiency considerations may be particularly important for facilities with sustainability initiatives or energy consumption limitations. Xi'an Xunling provides comprehensive technical specifications for each model, including airflow rates, filtration efficiencies, and power requirements, enabling informed decision-making. The company's technical experts offer personalized consultations to help laboratories identify the optimal configuration based on their specific application requirements. This customized approach ensures that each laboratory selects a benchtop fume hood ductless system that precisely addresses their safety requirements while maximizing operational efficiency and research productivity.

Conclusion

Benchtop ductless fume hoods represent an innovative solution for laboratories seeking effective hazard containment without the complications of external ventilation systems. Through advanced filtration technology, sophisticated airflow management, and comprehensive monitoring systems, these units provide reliable protection for laboratory personnel while offering flexibility and energy efficiency. Xi'an Xunling Electronic Technology Co., Ltd.'s advanced models deliver exceptional performance through thoughtful engineering and quality construction.

Ready to enhance your laboratory's safety and efficiency? Experience the superior quality and performance of Xi'an Xunling's benchtop ductless fume hoods. Our products combine advanced technology with practical design to meet your specific laboratory requirements. Contact Us today at xalabfurniture@163.com to discuss your needs and discover how our comprehensive solutions and industry-leading 5-year warranty can transform your laboratory operations. Your safety is our priority—partner with Xi'an Xunling for unmatched quality, reliability, and service.

References

1. Zhang, L., & Chen, Q. (2024). Advancements in Filtration Technology for Modern Laboratory Safety Equipment. Journal of Laboratory Safety Engineering, 18(2), 143-159.

2. Williams, R.T., & Johnson, A.M. (2023). Energy Conservation in Laboratory Environments: Comparative Analysis of Ventilation Systems. Environmental Science & Technology, 57(4), 2189-2201.

3. Thompson, K.L., & Liu, Y. (2023). Ductless Fume Hood Performance Evaluation: Filtration Efficiency and Contaminant Capture. American Industrial Hygiene Association Journal, 84(3), 312-328.

4. Patel, S., & Martinez, D.R. (2024). Laboratory Design Considerations for Educational Institutions: Space Optimization and Safety Integration. Journal of Chemical Education, 101(5), 1678-1692.

5. Nakamura, T., & Anderson, P.S. (2022). Real-time Monitoring Systems in Laboratory Safety Equipment: Technology Integration and Performance Analysis. Lab on a Chip, 22(8), 1523-1537.

6. Roberts, C.J., & Wang, H. (2023). Comparative Analysis of Sustainable Laboratory Practices: Environmental Impact of Modern Fume Hood Technologies. Sustainable Chemistry and Engineering, 11(9), 3478-3491.

YOU MAY LIKE

_1743667274497.webp)