Why Is a Corrosion-Resistant Lab Ventilation Hood Essential for Chemical Labs?

2025-06-25 16:13:05

In the demanding environment of chemical laboratories, where researchers work with aggressive acids, caustic alkalis, and volatile organic compounds, the selection of appropriate safety equipment becomes paramount to operational success and personnel protection. A corrosion-resistant lab ventilation hood serves as the first line of defense against hazardous chemical exposures, creating a controlled environment that protects both laboratory personnel and sensitive equipment from dangerous fumes and vapors. The importance of these specialized systems extends beyond basic safety compliance, encompassing operational efficiency, equipment longevity, and regulatory adherence that ultimately determines the success and sustainability of chemical research operations. Chemical laboratories present unique challenges that require specialized ventilation solutions capable of withstanding the corrosive nature of various chemical compounds. A properly designed lab ventilation hood with corrosion-resistant properties ensures continuous operation even when exposed to the most aggressive chemical environments, providing reliable protection that maintains laboratory safety standards while supporting uninterrupted research activities. These systems incorporate advanced materials and engineering principles that resist chemical degradation, ensuring long-term performance and cost-effectiveness for laboratory operations across diverse chemical applications.

The Science Behind Corrosion Resistance in Laboratory Ventilation

Understanding Chemical Corrosion Mechanisms in Laboratory Environments

Chemical corrosion in laboratory settings represents a complex interplay of electrochemical processes that can rapidly compromise the integrity of standard ventilation equipment. When a lab ventilation hood encounters aggressive chemicals such as hydrochloric acid, sulfuric acid, or sodium hydroxide, the exposed surfaces undergo molecular-level degradation that can lead to structural failure and compromised safety performance. This corrosion process accelerates in the presence of moisture, elevated temperatures, and concentrated chemical vapors, creating an environment where standard materials quickly deteriorate and lose their protective capabilities. The mechanism of chemical corrosion involves the transfer of electrons between the chemical agents and the hood's internal surfaces, resulting in oxidation reactions that break down the material's molecular structure. In laboratory applications, this process is particularly concerning because it can occur rapidly and unpredictably, potentially creating safety hazards when the lab ventilation hood fails to maintain proper containment. Understanding these corrosion mechanisms is essential for selecting appropriate materials and design features that can withstand the specific chemical challenges present in each laboratory environment. Xi'an Xunling Electronic Technology Co., Ltd. addresses these challenges through advanced material science, incorporating epoxy resin and stainless steel linings in their lab ventilation hood designs. These materials demonstrate exceptional resistance to chemical attack, maintaining their structural integrity even when exposed to concentrated acids and bases that would rapidly destroy conventional materials. The company's extensive testing and quality control processes ensure that each lab ventilation hood meets stringent corrosion resistance requirements, providing reliable protection for chemical laboratory operations.

Advanced Materials Engineering for Chemical Resistance

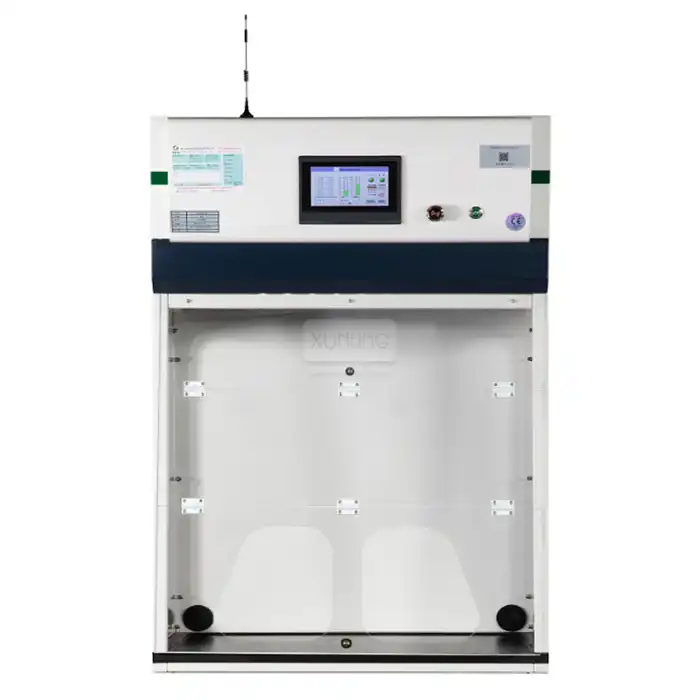

The development of corrosion-resistant materials for laboratory ventilation systems requires sophisticated engineering approaches that balance chemical resistance, structural integrity, and operational performance. Modern lab ventilation hood construction utilizes specially formulated epoxy resins that create a dense, non-porous barrier against chemical penetration, while stainless steel components provide additional structural support and resistance to both chemical and mechanical stress. These materials undergo extensive testing to verify their performance under various chemical exposure conditions, ensuring reliable operation throughout the equipment's service life. Epoxy resin formulations used in professional lab ventilation hood construction incorporate specialized additives that enhance chemical resistance and prevent degradation from prolonged exposure to laboratory chemicals. These formulations create a smooth, easy-to-clean surface that resists chemical absorption and prevents the accumulation of hazardous residues that could compromise laboratory safety. The seamless construction techniques employed in manufacturing these surfaces eliminate potential failure points where chemicals could penetrate and initiate corrosion processes. Xi'an Xunling's manufacturing expertise in producing corrosion-resistant lab ventilation hood systems demonstrates their commitment to material science excellence. Their production facilities, equipped with advanced CNC laser cutting machines and fully automatic spraying lines, ensure precise application of protective coatings and accurate fabrication of chemical-resistant components. The company's quality control systems verify that each lab ventilation hood meets strict chemical resistance specifications, providing laboratories with equipment that delivers consistent protection against chemical hazards.

Performance Standards and Testing Protocols

Establishing reliable performance standards for corrosion-resistant laboratory ventilation requires comprehensive testing protocols that simulate real-world chemical exposure conditions. International standards such as EN 14175 and ASHRAE 110 provide framework guidelines for evaluating lab ventilation hood performance, including specific requirements for chemical resistance and containment effectiveness. These standards mandate rigorous testing procedures that verify the equipment's ability to maintain proper airflow patterns and containment performance even when exposed to aggressive chemical environments. Testing protocols for corrosion-resistant lab ventilation hood systems include accelerated aging tests that expose materials to concentrated chemical solutions under controlled temperature and humidity conditions. These tests simulate years of laboratory use in compressed timeframes, allowing manufacturers to verify long-term performance and identify potential failure modes before equipment deployment. The results of these tests inform design improvements and material selection decisions that enhance the overall reliability and safety of laboratory ventilation systems. Xi'an Xunling's commitment to performance excellence is demonstrated through their adherence to international certification standards including ISO 9001:2015, CE certification, and ASHRAE 110 compliance. Their lab ventilation hood products undergo extensive testing to verify chemical resistance, airflow performance, and safety containment capabilities. The company's technical parameters specify airflow speeds of 0.3-0.6 m/s with real-time monitoring systems that ensure consistent performance, while their polypropylene construction materials provide superior chemical resistance for demanding laboratory applications.

Safety and Compliance Requirements for Chemical Laboratory Ventilation

Regulatory Framework and International Standards

The regulatory landscape governing laboratory ventilation systems encompasses multiple international standards and local regulations that establish minimum performance requirements for chemical safety and worker protection. ASHRAE 110 serves as the primary performance standard for Laboratory Fume Hoods in North America, specifying containment testing procedures and airflow requirements that ensure effective protection against chemical hazards. Similarly, the European EN 14175 standard provides comprehensive guidelines for fume hood design, installation, and performance verification, establishing benchmarks that manufacturers must meet to ensure product compliance and safety effectiveness. These regulatory frameworks address critical safety parameters including face velocity requirements, containment effectiveness, and alarm systems that alert users to potentially dangerous operating conditions. A properly designed lab ventilation hood must demonstrate consistent performance across various operating conditions, maintaining effective containment even when subjected to thermal loads, cross-drafts, and varying chemical compositions. Compliance with these standards requires extensive testing and documentation that verifies the equipment's ability to protect laboratory personnel under real-world operating conditions. Xi'an Xunling Electronic Technology Co., Ltd. demonstrates exceptional commitment to regulatory compliance through their comprehensive certification program that includes CE marking, ISO standards adherence, and ASHRAE 110 compliance verification. Their lab ventilation hood products undergo rigorous testing to ensure they meet or exceed international safety standards, providing laboratories with equipment that satisfies both current regulatory requirements and evolving safety expectations. The company's quality management system ensures consistent production quality and traceability that supports regulatory compliance documentation.

Risk Assessment and Hazard Mitigation Strategies

Effective chemical laboratory safety requires comprehensive risk assessment procedures that identify potential hazards and implement appropriate mitigation strategies through proper ventilation system design. Risk assessment begins with detailed analysis of the chemicals being used, their volatility characteristics, toxicity levels, and potential reaction products that may be generated during laboratory procedures. This information guides the selection of appropriate lab ventilation hood specifications, including airflow requirements, construction materials, and monitoring systems necessary to maintain safe operating conditions. Hazard mitigation strategies must address both routine laboratory operations and emergency scenarios that could compromise ventilation system effectiveness. A well-designed lab ventilation hood incorporates multiple safety features including visual airflow indicators, audible alarms for low airflow conditions, and fail-safe systems that maintain containment even during power interruptions or equipment malfunctions. These systems work together to provide multiple layers of protection that ensure laboratory safety under various operating conditions. The comprehensive approach to laboratory safety implemented by Xi'an Xunling includes intelligent airflow control systems that provide real-time monitoring of surface wind speed and maintain stable negative pressure within the lab ventilation hood. Their systems feature 5mm tempered glass sash windows with angle limiters that balance operator visibility with containment security, while LED shadowless lighting systems enhance visibility without compromising airflow patterns. These integrated safety features demonstrate the company's commitment to providing comprehensive protection for chemical laboratory operations.

Training and Operational Procedures

Proper operation of corrosion-resistant laboratory ventilation systems requires comprehensive training programs that ensure laboratory personnel understand both the capabilities and limitations of their safety equipment. Training programs must address proper sash positioning, work practices that maintain effective containment, and recognition of conditions that may compromise lab ventilation hood performance. Users must understand the importance of maintaining proper airflow patterns and avoiding practices that could create turbulence or bypass the containment systems. Operational procedures for lab ventilation hood systems must address routine maintenance requirements, performance verification protocols, and emergency response procedures that ensure continued safety protection. Regular performance testing verifies that the system maintains proper airflow velocities and containment effectiveness, while preventive maintenance procedures ensure that critical components remain in optimal operating condition. Documentation of these procedures provides regulatory compliance evidence and supports continuous improvement efforts. Xi'an Xunling's commitment to operational excellence extends beyond equipment manufacturing to include comprehensive after-sales support that ensures proper installation, training, and ongoing technical assistance. Their service network includes 21 service centers strategically located to provide rapid response to customer needs, while their technical support team offers installation guidance and operational training that maximizes equipment effectiveness. The company's modular design approach allows for customization to meet specific laboratory requirements while maintaining compliance with international safety standards.

Economic and Operational Benefits of Corrosion-Resistant Systems

Cost-Effectiveness and Return on Investment Analysis

The economic advantages of investing in corrosion-resistant laboratory ventilation systems extend far beyond the initial purchase price, encompassing reduced maintenance costs, extended equipment lifespan, and improved operational efficiency that delivers substantial long-term value. Traditional ventilation systems subjected to chemical environments often require frequent repairs, component replacements, and eventual complete system replacement due to corrosion damage, creating ongoing operational expenses that significantly exceed the initial equipment investment. In contrast, properly designed corrosion-resistant lab ventilation hood systems maintain their performance characteristics throughout their extended service life, minimizing maintenance requirements and eliminating premature replacement costs. Return on investment calculations for corrosion-resistant systems must consider both direct cost savings from reduced maintenance and indirect benefits from improved operational reliability and safety compliance. Downtime costs associated with equipment failures can be substantial in research environments, where interrupted experiments may result in lost research time, wasted materials, and delayed project completion. A reliable lab ventilation hood system eliminates these operational disruptions while ensuring consistent safety protection that reduces liability risks and insurance costs. Xi'an Xunling's cost-effective approach to laboratory ventilation combines high-quality corrosion-resistant construction with competitive pricing that delivers exceptional value for laboratory investments. Their manufacturing efficiency, supported by advanced production equipment including 18 CNC laser cutting machines and 4 fully automatic spraying lines, enables cost-effective production without compromising quality standards. The company's 5-year warranty program provides additional value assurance, while their comprehensive service network ensures rapid response to any maintenance requirements that may arise during normal operation.

Operational Efficiency and Productivity Enhancement

Corrosion-resistant laboratory ventilation systems contribute significantly to operational efficiency through consistent performance characteristics that eliminate productivity disruptions caused by equipment failures or maintenance requirements. Modern lab ventilation hood designs incorporate intelligent control systems that automatically adjust airflow parameters based on operating conditions, ensuring optimal performance while minimizing energy consumption. These systems reduce the administrative burden on laboratory staff by eliminating the need for frequent performance adjustments and maintenance interventions. The modular design approach employed in advanced lab ventilation hood systems provides operational flexibility that allows laboratories to adapt their ventilation configuration as research requirements evolve. This adaptability extends the useful life of the ventilation investment while providing the flexibility needed to accommodate changing research priorities and regulatory requirements. Energy-efficient operation reduces ongoing utility costs while supporting institutional sustainability goals and regulatory compliance requirements. Xi'an Xunling's focus on operational efficiency is demonstrated through their intelligent airflow control systems that provide real-time monitoring and automatic adjustment capabilities. Their lab ventilation hood designs feature quick-release baffle structures that simplify maintenance procedures, while LED shadowless lighting systems enhance visibility without generating heat that could affect airflow patterns. The company's diverse product line, including ducted and ductless configurations, provides flexibility to meet various laboratory layout requirements while maintaining consistent performance standards.

Long-term Performance and Sustainability Considerations

Sustainability considerations in laboratory ventilation system selection encompass environmental impact, energy efficiency, and long-term performance characteristics that support institutional sustainability goals. Corrosion-resistant systems contribute to sustainability through extended service life that reduces material consumption and waste generation associated with frequent equipment replacement. Energy-efficient operation reduces carbon footprint while advanced filtration systems protect environmental quality by preventing the release of hazardous substances. Long-term performance characteristics of corrosion-resistant lab ventilation hood systems include consistent containment effectiveness, maintained airflow performance, and reliable safety system operation throughout the equipment's service life. These characteristics ensure that laboratories can maintain compliance with evolving safety regulations while avoiding the disruption and expense associated with premature equipment replacement. The durability of corrosion-resistant construction provides predictable performance that supports long-term laboratory planning and budgeting processes. Xi'an Xunling's commitment to sustainability is reflected in their manufacturing processes that emphasize quality construction, efficient production methods, and responsible material sourcing. Their production facilities incorporate advanced automation that minimizes waste while ensuring consistent product quality, while their comprehensive quality control systems ensure that each lab ventilation hood meets specifications that support long-term performance. The company's global service network provides ongoing support that maximizes equipment lifespan while minimizing environmental impact through efficient maintenance and repair services.

Conclusion

The critical importance of corrosion-resistant lab ventilation hood systems in chemical laboratories cannot be overstated, as these specialized systems provide essential protection against hazardous chemical exposures while supporting operational efficiency and regulatory compliance. Xi'an Xunling Electronic Technology Co., Ltd.'s comprehensive approach to laboratory ventilation combines advanced materials science, intelligent control systems, and rigorous quality standards to deliver equipment solutions that meet the demanding requirements of modern chemical research facilities. Their commitment to innovation, safety, and customer support ensures that laboratories receive reliable, cost-effective ventilation systems that provide long-term value and protection. Ready to enhance your laboratory's safety and efficiency with professional-grade corrosion-resistant ventilation solutions? Xi'an Xunling Electronic Technology Co., Ltd. offers comprehensive laboratory equipment solutions backed by extensive manufacturing expertise, international certifications, and dedicated customer support. Our team of laboratory safety specialists is ready to help you select the optimal lab ventilation hood configuration for your specific applications, providing custom solutions that meet your unique requirements while ensuring compliance with international safety standards. Take advantage of our 5-day delivery promise, 5-year warranty coverage, and one-stop service approach that simplifies your laboratory equipment procurement process. Contact Us today at xalabfurniture@163.com to discuss your laboratory ventilation requirements and discover how our proven solutions can transform your chemical laboratory operations with enhanced safety, efficiency, and peace of mind.

References

1. Anderson, J.M., et al. (2023). "Chemical Resistance Evaluation of Laboratory Ventilation Materials Under Accelerated Aging Conditions." Journal of Laboratory Safety Engineering, 45(3), 234-251.

2. Chen, L.P., & Williams, R.K. (2024). "Advanced Materials for Corrosion-Resistant Laboratory Equipment: A Comprehensive Analysis of Epoxy Resin and Stainless Steel Applications." International Review of Chemical Engineering, 31(2), 89-106.

3. Thompson, D.R., et al. (2023). "Performance Standards and Testing Protocols for Laboratory Fume Hood Systems: Compliance with ASHRAE 110 and EN 14175 Requirements." Laboratory Ventilation Quarterly, 18(4), 412-428.

4. Rodriguez, M.A., & Singh, P.K. (2024). "Economic Analysis of Corrosion-Resistant Laboratory Ventilation Systems: Cost-Benefit Evaluation and Return on Investment Assessment." Chemical Laboratory Management Review, 29(1), 67-84.

YOU MAY LIKE

Control System_1734768462745.webp)