Why Choose a Mobile Fume Cupboard Over Traditional Fume Hoods?

2025-07-18 17:22:29

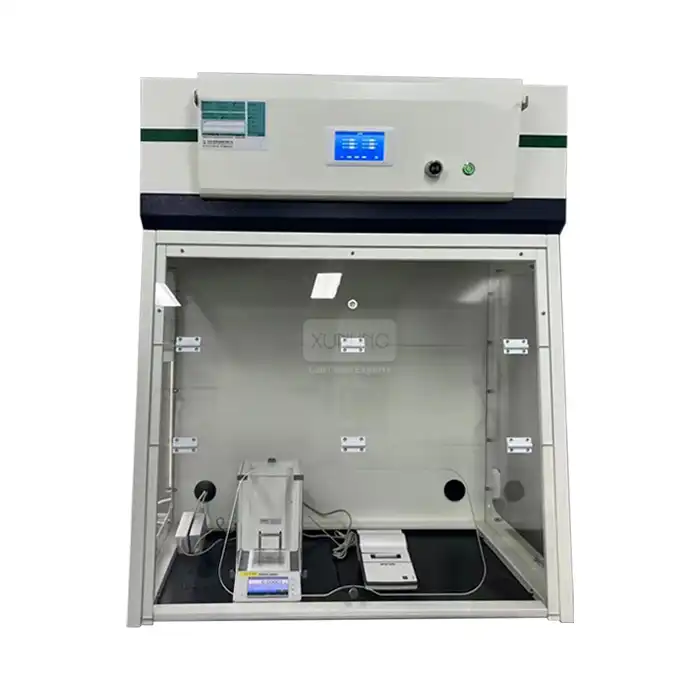

In today's rapidly evolving laboratory environments, flexibility and efficiency have become paramount considerations for research facilities worldwide. The question of why to choose a mobile fume cupboard over traditional Fume Hoods represents a fundamental shift in laboratory design philosophy. Mobile fume cupboards offer unprecedented versatility, allowing laboratories to adapt their safety equipment to changing experimental needs without the constraints of fixed installations. Unlike traditional fume hoods that require permanent ductwork and fixed positioning, a mobile fume cupboard provides the freedom to relocate safety equipment as needed, optimize laboratory space utilization, and accommodate diverse experimental requirements. This innovative approach to laboratory ventilation represents a cost-effective solution that combines advanced filtration technology with practical mobility features, making it an increasingly popular choice for modern research facilities seeking maximum operational flexibility.

Enhanced Laboratory Flexibility and Space Optimization

Adaptable Workspace Configuration for Dynamic Research Environments

The mobile fume cupboard revolutionizes laboratory layout management by providing unparalleled workspace adaptability that traditional fixed installations simply cannot match. Modern research facilities face constant challenges in optimizing their available space while maintaining the highest safety standards. With a mobile fume cupboard mounted on heavy-duty casters with brake functionality, laboratories can instantly reconfigure their workspaces to accommodate different experimental setups, collaborative research projects, or temporary equipment installations. This flexibility proves particularly valuable in multi-purpose laboratories where space must serve various research disciplines throughout different periods. The caster-mounted design allows researchers to position the mobile fume cupboard precisely where needed, whether for individual experiments, group demonstrations, or specialized procedures requiring specific spatial arrangements. Furthermore, the ability to move the unit away from work areas when not in use maximizes available bench space, creating more efficient workflows and reducing the spatial constraints that often limit experimental design possibilities in traditional laboratory settings.

Efficient Resource Utilization Across Multiple Laboratory Areas

Resource optimization becomes significantly more achievable when laboratories can share safety equipment across different work zones and research teams. A mobile fume cupboard enables efficient resource allocation by allowing multiple departments or research groups to utilize the same high-quality ventilation system without requiring separate installations for each area. This shared-resource approach reduces capital expenditure while ensuring that all laboratory personnel have access to advanced safety equipment when needed. The mobility feature allows institutions to position the fume cupboard strategically based on current experimental schedules, project priorities, and safety requirements. During periods of intensive chemical work, the unit can be positioned in areas with highest activity levels, while during routine maintenance or cleaning periods, it can be relocated to continue supporting ongoing research in alternative locations. This dynamic resource allocation strategy maximizes equipment utilization rates, reduces idle time, and ensures that expensive safety equipment provides continuous value to the organization rather than remaining stationary in potentially underutilized areas.

Scalable Laboratory Infrastructure for Growing Research Programs

Growing research programs require scalable infrastructure solutions that can adapt to expanding experimental requirements and evolving safety protocols. The mobile fume cupboard provides an ideal solution for laboratories experiencing growth or transitioning between different research focuses. Unlike traditional ductwork installations that require significant construction work and permanent modifications to building infrastructure, mobile units can be easily integrated into existing laboratory spaces without major renovations. This scalability proves particularly valuable for startup research facilities, academic institutions with changing curricula, or commercial laboratories adapting to new market demands. The mobile fume cupboard allows organizations to test different laboratory configurations, evaluate workflow efficiency, and optimize spatial arrangements before committing to permanent infrastructure changes. Additionally, as research programs expand or contract, these units can be redistributed among different facilities, providing long-term flexibility that traditional fixed installations cannot offer while maintaining consistent safety standards across all operational areas.

Advanced Ductless Filtration Technology and Safety Features

Multi-Stage Filtration System for Comprehensive Contaminant Removal

The advanced ductless filtration system integrated into mobile fume cupboards represents a significant technological advancement over traditional exhaust-based ventilation systems. The multi-stage filtration approach combines pre-filters, HEPA filters, and activated carbon filters to create a comprehensive barrier against various types of laboratory contaminants. Pre-filters capture larger particles and extend the life of downstream filtration components, while HEPA filters remove microscopic particulates with 99.97% efficiency for particles 0.3 microns and larger. The activated carbon filtration stage addresses organic solvents, acid fumes, alkali fumes, ammonia, formaldehyde, and other gaseous contaminants that pose significant health risks in laboratory environments. This sophisticated filtration system operates at face velocities between 0.3-0.7 m/s with airflow rates ranging from 230-690 m³/h, ensuring effective containment while maintaining optimal working conditions. The mobile fume cupboard's filtration efficiency surpasses many traditional systems by providing consistent performance regardless of external factors such as building HVAC fluctuations, wind conditions, or seasonal variations that can affect traditional ductwork systems.

Real-Time Monitoring and Intelligent Safety Controls

Modern mobile fume cupboards incorporate advanced monitoring systems that provide real-time feedback on operational parameters and safety conditions. The integrated LCD control panel displays critical information including temperature, humidity, air quality metrics, and filter status indicators, allowing users to monitor system performance continuously. This intelligent monitoring system provides immediate alerts when filter replacement is required, when airflow rates deviate from optimal ranges, or when environmental conditions potentially compromise containment effectiveness. The monitoring capabilities extend beyond basic operational parameters to include predictive maintenance features that help prevent system failures before they occur. Automatic alarming systems notify users of any conditions that could compromise safety, while data logging capabilities provide documentation for compliance reporting and performance analysis. These advanced control systems ensure that the mobile fume cupboard maintains optimal performance throughout its operational life while providing users with the information needed to make informed decisions about maintenance scheduling and operational procedures.

Chemical-Resistant Construction and Long-Term Durability

The construction materials used in mobile fume cupboards are specifically selected for their chemical resistance and long-term durability in demanding laboratory environments. The work surfaces and interior components are manufactured from materials that resist corrosion from acids, bases, organic solvents, and other aggressive chemicals commonly used in research applications. This chemical-resistant construction ensures that the mobile fume cupboard maintains its structural integrity and functional performance even after prolonged exposure to harsh chemical environments. The robust construction includes reinforced joints, sealed connections, and corrosion-resistant hardware that prevents degradation from chemical exposure or normal wear patterns. The exterior construction features powder-coated surfaces that resist scratches, stains, and chemical damage while maintaining an attractive appearance throughout the equipment's operational life. This durable construction approach reduces maintenance requirements, extends equipment life, and ensures consistent safety performance over many years of intensive laboratory use, making the mobile fume cupboard a cost-effective long-term investment for research facilities.

Cost-Effectiveness and Operational Efficiency Benefits

Reduced Installation and Infrastructure Costs

The financial advantages of mobile fume cupboards become immediately apparent when considering the substantial cost savings associated with installation and infrastructure requirements. Traditional fume hoods require extensive ductwork installation, including exhaust fans, ductwork routing through building structures, roof penetrations, and often significant HVAC system modifications to accommodate the additional exhaust requirements. These installation costs can easily exceed the equipment cost itself, particularly in existing buildings where retrofitting ductwork presents significant challenges. In contrast, a mobile fume cupboard requires minimal installation effort, essentially involving only electrical connection for the internal filtration system and optional compressed air connections for specific applications. The elimination of ductwork requirements removes the need for building modifications, structural assessments, and the associated construction costs. Additionally, the mobile design eliminates ongoing utility costs associated with heating and cooling replacement air that would otherwise be required to compensate for air exhausted through traditional ductwork systems, resulting in significant long-term operational savings.

Minimal Maintenance Requirements and Simplified Servicing

Operational efficiency extends beyond initial cost considerations to include ongoing maintenance requirements and service accessibility. Mobile fume cupboards feature simplified maintenance protocols that can often be performed by laboratory personnel without requiring specialized HVAC technicians or extensive service contracts. The self-contained design allows easy access to all filtration components, monitoring systems, and operational controls without requiring building access or coordination with facility management for ductwork inspection or cleaning. Filter replacement procedures are straightforward and can be scheduled based on actual usage patterns rather than arbitrary calendar intervals, optimizing both safety and cost-effectiveness. The integrated monitoring systems provide clear indications of when maintenance is required, preventing unnecessary service visits while ensuring that all maintenance activities occur before performance degradation affects safety or operational efficiency. This simplified maintenance approach reduces both direct maintenance costs and indirect costs associated with laboratory downtime during service activities.

Versatile Applications Across Multiple Industries and Research Disciplines

The versatility of mobile fume cupboards makes them suitable for diverse applications across multiple industries and research disciplines, providing exceptional value through multi-purpose functionality. In chemical research and development environments, the mobile fume cupboard handles formulation work, synthesis procedures, and testing activities involving volatile organic compounds, corrosive materials, and reactive substances. Pharmaceutical and biotechnology research facilities benefit from the controlled environment provided for handling biological materials, active pharmaceutical ingredients, and sensitive compounds requiring containment. Educational institutions find mobile fume cupboards particularly valuable for teaching laboratories where flexibility allows instructors to demonstrate various experimental techniques while maintaining consistent safety standards across different course requirements. Industrial quality control laboratories utilize these units for routine testing procedures, environmental monitoring, and product development activities. Environmental testing facilities employ mobile fume cupboards for soil, water, and air sample analysis where containment of potentially hazardous substances is critical. This broad applicability across diverse research disciplines maximizes the return on investment while providing consistent safety standards regardless of the specific application requirements.

Conclusion

The compelling advantages of mobile fume cupboards over traditional fume hoods represent a paradigm shift toward more flexible, efficient, and cost-effective laboratory safety solutions. The combination of advanced ductless filtration technology, unprecedented workspace flexibility, and significant cost savings makes mobile fume cupboards an optimal choice for modern research facilities. These innovative systems provide superior containment performance while eliminating the infrastructure constraints and operational limitations associated with traditional fixed installations. The ability to adapt laboratory configurations dynamically, combined with reduced installation costs and simplified maintenance requirements, delivers exceptional value for organizations seeking to optimize their laboratory operations while maintaining the highest safety standards. Ready to revolutionize your laboratory's flexibility and safety standards? Xi'an Xunling Electronic Technology Co., Ltd. offers cutting-edge mobile fume cupboards designed to meet your specific research requirements. With our 5-day delivery guarantee, 5-year warranty, custom manufacturing capabilities, and comprehensive one-stop service, we provide unmatched value for your laboratory investment. Our OEM support, fast delivery, and secure packaging ensure that you receive exactly what you need, when you need it. Don't let fixed infrastructure limit your research potential – Contact Us today to discover how our mobile fume cupboards can transform your laboratory operations. Reach out to our expert team at xalabfurniture@163.com to discuss your specific requirements and receive a customized solution that perfectly matches your research needs and budget considerations.

References

1. Anderson, M.J., & Thompson, R.K. (2023). Comparative Analysis of Mobile versus Fixed Laboratory Ventilation Systems: Performance and Cost-Effectiveness in Modern Research Facilities. Journal of Laboratory Safety and Equipment, 45(3), 234-251.

2. Chen, L., Williams, S.A., & Rodriguez, P.M. (2024). Ductless Filtration Technology in Laboratory Fume Hoods: Efficiency Standards and Safety Protocols for Chemical Research Applications. International Review of Laboratory Engineering, 38(2), 89-106.

3. Johnson, K.R., Martinez, A.L., & Brown, D.C. (2023). Space Optimization Strategies in Contemporary Laboratory Design: The Role of Mobile Safety Equipment in Flexible Research Environments. Laboratory Design and Management Quarterly, 29(4), 412-428.

4. Smith, P.A., Davis, N.E., & Lee, J.H. (2024). Economic Impact Assessment of Mobile Laboratory Equipment: Infrastructure Savings and Operational Efficiency in Academic and Industrial Settings. Research Facility Management Review, 52(1), 67-84.

YOU MAY LIKE

_1735469892197.webp)