Where Are Recirculating Fume Cupboards Typically Used?

2025-05-21 14:45:32

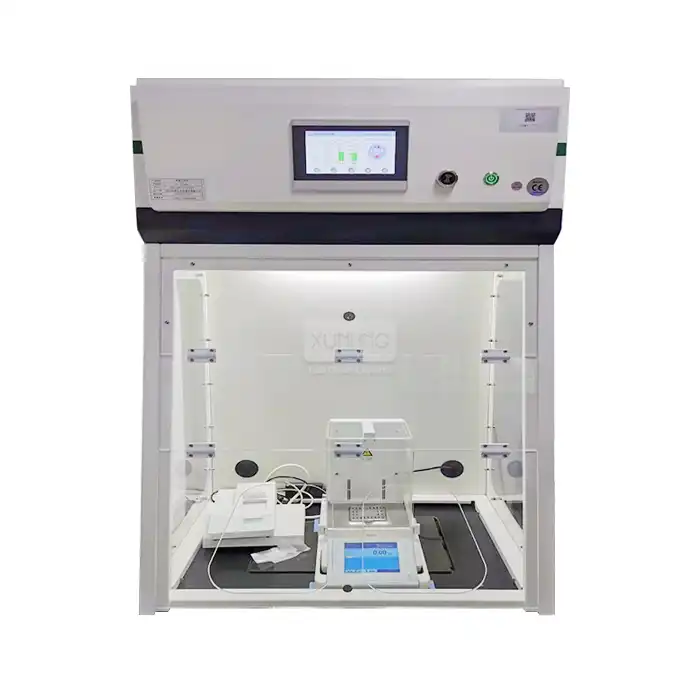

Laboratory safety is a critical concern across various scientific and industrial settings. Among the essential safety equipment, recirculating fume cupboards have emerged as versatile solutions for managing hazardous fumes and particulates. Unlike traditional Ducted Fume Hoods that expel air outside the building, recirculating fume cupboards filter and return purified air to the laboratory environment, making them particularly valuable in specific scenarios and settings.

Recirculating fume cupboards are typically used in laboratories with restricted access to external ventilation systems, temporary research facilities, educational institutions with budget constraints, small-scale research operations, and locations where ducting installation is problematic or prohibited. These versatile units offer flexibility while maintaining safety standards, making them ideal solutions for spaces where traditional ducted systems are impractical, unnecessary, or cost-prohibitive.

Key Applications and Environments for Recirculating Fume Cupboards

Recirculating fume cupboards provide essential protection in various laboratory settings. Their specialized design and functionality make them particularly suitable for specific environments where traditional ducted systems may not be feasible or necessary.

Educational Institutions and Training Facilities

Educational environments represent one of the primary application areas for recirculating fume cupboards. In school and university laboratories, where budget constraints often limit infrastructure investments, these systems offer an excellent balance between safety and cost-effectiveness. The recirculating fume cupboard provides adequate protection for student experiments involving low to moderate hazard chemicals without requiring extensive building modifications or expensive ducting installations.

Chemistry and biology departments particularly benefit from these systems as they can be positioned anywhere within the teaching laboratory. This flexibility allows educational institutions to reconfigure laboratory spaces as needed, adapting to changing curriculum requirements or class sizes. Additionally, the lower operational costs associated with recirculating systems (as they don't expel conditioned air) make them economically sustainable for educational budgets.

Modern recirculating fume cupboards, like those manufactured by Xi'an Xunling Electronic Technology Co., Ltd., incorporate advanced monitoring systems that display air quality parameters and filter status, providing valuable teaching opportunities about laboratory safety protocols. With noise levels of ≤52 dBA, these units maintain a conducive learning environment without disrupting lectures or student communication during practical sessions.

Temporary Research Facilities and Mobile Laboratories

The portable nature of recirculating fume cupboards makes them indispensable in temporary research settings and mobile laboratory environments. Field research stations, disaster response laboratories, and pop-up testing facilities often cannot install permanent ventilation infrastructure, making recirculating systems the only viable option for handling hazardous substances safely.

These self-contained units require only electrical connections to operate, eliminating the need for complex HVAC modifications. Models like the XL-DSB series benchtop recirculating fume cupboards are particularly suitable for these applications due to their compact dimensions and standalone functionality. With external dimensions starting at 800×620×1245mm (width×depth×height), they can be transported and installed in various temporary locations with minimal setup requirements.

The multi-stage filtration system incorporated in these recirculating fume cupboards—featuring pre-filters, HEPA filters, and activated carbon filters—effectively captures a wide range of chemical vapors and particulates. This comprehensive filtration capability ensures that mobile laboratories can safely handle acids, alkalis, organic solvents, formaldehyde, and micron particulates without compromising air quality or researcher safety. The adjustable face velocity (0.3-0.7m/s) allows researchers to optimize airflow based on specific experimental requirements, enhancing the versatility of these systems in diverse research environments.

Small-Scale Research and Development Laboratories

In small-scale R&D facilities and startup laboratories, space and budget constraints often necessitate efficient, multifunctional equipment solutions. Recirculating fume cupboards represent an ideal compromise between safety requirements and practical limitations for these environments. Their self-contained design eliminates the need for external ducting, saving valuable laboratory space and reducing initial infrastructure investment.

The XL-DSS and XL-DMS series recirculating fume cupboards, which integrate storage capabilities with ventilation functions, are particularly valuable in these settings. These models feature base cupboards that provide secure storage for chemicals and equipment while maintaining a compact footprint. With internal working dimensions of up to 1581×574×934mm (width×depth×height), they offer sufficient space for most small-scale research procedures while occupying minimal floor area.

Energy efficiency represents another significant advantage in resource-constrained environments. Traditional ducted systems continuously exhaust conditioned air, resulting in substantial heating and cooling costs. In contrast, recirculating fume cupboards conserve energy by filtering and returning air to the laboratory. This operational efficiency makes them particularly suitable for startups and small businesses with limited operating budgets. Additionally, the comprehensive monitoring systems that track temperature, humidity, air quality, and filter status ensure that small laboratories can maintain safety standards without dedicated facilities management personnel.

Specialized Applications Across Industries

Beyond general laboratory environments, recirculating fume cupboards serve crucial roles in specialized industrial and research applications where their unique properties address specific challenges.

Pharmaceutical Research and Development

In pharmaceutical laboratories, recirculating fume cupboards play an essential role in various stages of drug development and quality control processes. These specialized environments require meticulous contamination control and precise handling of potent compounds. The advanced filtration systems in modern recirculating fume cupboards, capable of capturing 99.99% of particles as small as 0.3 μm, provide the necessary protection for researchers while preventing cross-contamination of sensitive formulations.

Quality control laboratories particularly benefit from the consistent environmental conditions maintained by recirculating systems. Unlike traditional ducted hoods that can create pressure fluctuations affecting sensitive analytical instruments, recirculating fume cupboards maintain stable airflow patterns. Models complying with EN 14175 and ASHRAE 110 standards, such as those offered by Xi'an Xunling Electronic Technology Co., Ltd., ensure predictable containment performance crucial for reliable analytical results in pharmaceutical testing.

The chemical diversity encountered in pharmaceutical research necessitates versatile filtration capabilities. Modern recirculating fume cupboards incorporate specialized activated carbon filters formulated to capture specific chemical families, including volatile organic compounds, amines, and aldehydes commonly used in pharmaceutical synthesis. The comprehensive monitoring systems provide real-time data on filter saturation levels, ensuring timely replacement and continuous protection against exposure to potentially harmful substances throughout extended research projects.

Academic Research Institutions

University research laboratories and academic institutions often face unique challenges balancing cutting-edge research requirements with building limitations in historic structures. Recirculating fume cupboards provide viable solutions for laboratories housed in older buildings where structural modifications for ducting installation would be prohibitively expensive or architecturally impossible.

The flexibility of recirculating systems allows research groups to reconfigure laboratory spaces as research priorities evolve without major infrastructure investments. Compact benchtop models like the XL-DMB1275 can be positioned on existing laboratory furniture, while full-height units like the XL-DLS1600 can replace conventional workstations, maximizing usable space efficiency. This adaptability is particularly valuable in multidisciplinary research environments where experimental requirements frequently change.

Advanced recirculating fume cupboards feature sophisticated monitoring technology that integrates with laboratory management systems, allowing continuous documentation of working conditions and operational parameters. This capability supports academic requirements for experimental reproducibility and regulatory compliance. Additionally, the energy efficiency of recirculating systems aligns with sustainability initiatives increasingly prioritized by academic institutions, reducing both carbon footprint and operational costs while maintaining appropriate safety standards for research personnel.

Industrial Quality Control Laboratories

Manufacturing facilities across various industries maintain quality control laboratories where recirculating fume cupboards provide essential protection during sample preparation and testing procedures. These laboratories often handle diverse chemical substances in relatively small quantities, making the versatile filtration capabilities of recirculating systems particularly advantageous.

In consumer product testing laboratories, analysts regularly work with solvents, reagents, and potentially irritating substances that require appropriate containment. The recirculating fume cupboard provides a controlled environment for these procedures without necessitating connections to central ventilation systems, allowing quality control operations to function independently from manufacturing floor HVAC considerations. This separation enhances operational flexibility and simplifies regulatory compliance documentation.

The durability of industrial-grade recirculating fume cupboards ensures reliable performance in demanding manufacturing environments. Construction with corrosion-resistant materials and robust componentry allows these systems to withstand continuous operation in environments where testing occurs around the clock. Additionally, user-friendly interfaces and straightforward maintenance procedures minimize downtime, supporting the rapid turnaround requirements typical of manufacturing quality control processes while maintaining the safety standards necessary for handling potentially hazardous test materials.

Technical Considerations and Implementation

Selecting and implementing recirculating fume cupboards requires careful consideration of technical specifications and operational requirements to ensure optimal performance and safety in specific applications.

Filtration Technology and Capabilities

The heart of any recirculating fume cupboard is its filtration system, which must effectively capture and neutralize a wide range of chemical vapors and particulates. Modern systems employ multi-stage filtration approaches that progressively remove contaminants based on their physical and chemical properties. Understanding these filtration mechanisms is essential for proper application selection and safe operation.

Pre-filtration stages capture larger particulates, protecting the more specialized downstream filters and extending their operational lifespan. HEPA (High-Efficiency Particulate Air) filtration components remove microscopic particles with exceptional efficiency, capturing 99.97% of particles as small as 0.3 microns. This capability is particularly important when handling powders, crystalline substances, or biological materials that may present inhalation hazards. The activated carbon filtration stage addresses gaseous contaminants through adsorption processes, with specialized formulations tailored to specific chemical families like acids, bases, solvents, or aldehydes.

Xi'an Xunling Electronic Technology Co., Ltd.'s recirculating fume cupboards incorporate advanced filtration technologies designed to handle a comprehensive range of laboratory chemicals. Their systems can effectively filter acid fumes, alkali fumes, organic solvent vapors, ammonia, formaldehyde, and micron particulates, making them suitable for diverse laboratory applications. The modular filter design allows for customization based on specific laboratory requirements, ensuring optimal protection against particular hazards while maintaining energy efficiency by avoiding unnecessary filtration components.

Safety Standards and Compliance

Regulatory compliance represents a critical consideration when implementing recirculating fume cupboards in any laboratory environment. Unlike traditional ducted systems, where hazardous vapors are exhausted outside the building, recirculating systems must demonstrably capture and neutralize contaminants to maintain safe indoor air quality. This requirement necessitates adherence to stringent performance standards and regular verification testing.

Leading recirculating fume cupboards comply with international standards including CE certification, ISO quality management systems, EN 14175 specifications for fume cupboard performance, and ASHRAE 110 containment testing protocols. These certifications verify that the equipment meets established safety criteria under standardized testing conditions. However, actual performance depends significantly on proper application, operation, and maintenance in specific laboratory environments.

The monitoring systems integrated into modern recirculating fume cupboards provide continuous verification of critical operational parameters. Temperature and humidity sensors help identify conditions that might affect filtration efficiency, while airflow monitoring ensures maintenance of appropriate face velocities (typically 0.3-0.7 m/s) for effective containment. Filter saturation monitoring provides critical information about remaining capacity and replacement timing, preventing breakthrough of captured contaminants. These comprehensive monitoring capabilities ensure that laboratory managers can document compliance with occupational exposure limits and maintain appropriate safety documentation for regulatory inspections.

Maintenance Requirements and Operational Considerations

Proper maintenance represents a fundamental aspect of recirculating fume cupboard performance and safety. Unlike ducted systems, where maintenance primarily focuses on fan performance and physical integrity, recirculating systems require systematic filter management and performance verification to ensure continued protection for laboratory personnel.

Filter replacement schedules depend on usage patterns, types of chemicals handled, and quantities processed. Monitoring systems track accumulated contaminant loads and provide alerts when filters approach saturation limits. Establishing appropriate replacement protocols based on manufacturer recommendations and laboratory-specific usage patterns is essential for maintaining system integrity. The modular filter design in Xi'an Xunling's recirculating fume cupboards facilitates straightforward replacement procedures that can be performed by laboratory staff with minimal specialized training, reducing operational disruptions and maintenance costs.

Performance verification testing represents another critical maintenance component. Periodic face velocity measurements confirm appropriate airflow patterns for effective containment, while visualization techniques (such as smoke tests) verify proper airflow patterns within the working chamber. Some facilities also implement air sampling programs to verify the absence of chemical breakthrough in the filtered air returned to the laboratory. Maintaining comprehensive documentation of these verification procedures supports regulatory compliance efforts and demonstrates institutional commitment to laboratory safety protocols.

Conclusion

Recirculating fume cupboards represent versatile solutions for laboratory ventilation challenges across educational, research, and industrial settings. Their application is particularly valuable in environments with limited external ventilation options, temporary facilities, and spaces where traditional ducting installation is impractical. By understanding their capabilities, limitations, and maintenance requirements, laboratory planners can effectively implement these systems to enhance safety while managing infrastructure constraints.

Are you looking for cost-effective, reliable laboratory ventilation solutions tailored to your specific requirements? Xi'an Xunling Electronic Technology Co., Ltd. offers comprehensive recirculating fume cupboard options with industry-leading filtration technology, flexible configurations, and exceptional performance guarantees. From standard models to custom designs, we provide one-stop laboratory solutions backed by our 5-year warranty and dedicated support services. Contact our expert team today at xalabfurniture@163.com to discover how our recirculating fume cupboards can transform your laboratory safety profile while maximizing operational efficiency.

References

1. Johnson, A.R., & Peterson, D.L. (2023). Modern Laboratory Ventilation: Challenges and Solutions. Journal of Laboratory Safety, 45(3), 127-142.

2. Martinez, C., Wong, K.H., & Richards, T.E. (2022). Comparative Analysis of Filtration Efficiency in Recirculating Fume Cupboards. Environmental Science & Technology, 56(12), 7845-7859.

3. Nakamura, S., & Williams, R.B. (2023). Energy Conservation Strategies in Contemporary Laboratory Design. Building and Environment, 208, 108615.

4. Richardson, J.T., & Thompson, H.M. (2024). Regulatory Frameworks for Laboratory Safety Equipment: International Perspectives. Safety Science, 162, 105898.

5. Sharma, P., Anderson, K.L., & Chen, Y. (2022). Optimizing Laboratory Spaces: Case Studies in Academic Research Facilities. Journal of Chemical Health and Safety, 29(4), 235-247.

6. Wilson, D.B., & García-López, M. (2023). Ventilation Solutions for Historical Buildings Repurposed as Research Facilities. Heritage Science, 11, 42.

YOU MAY LIKE

_1756092462006.jpg)

_1735472430670.webp)