What Types of Filters Are Used in Ductless Fume Hoods?

2025-07-16 15:18:56

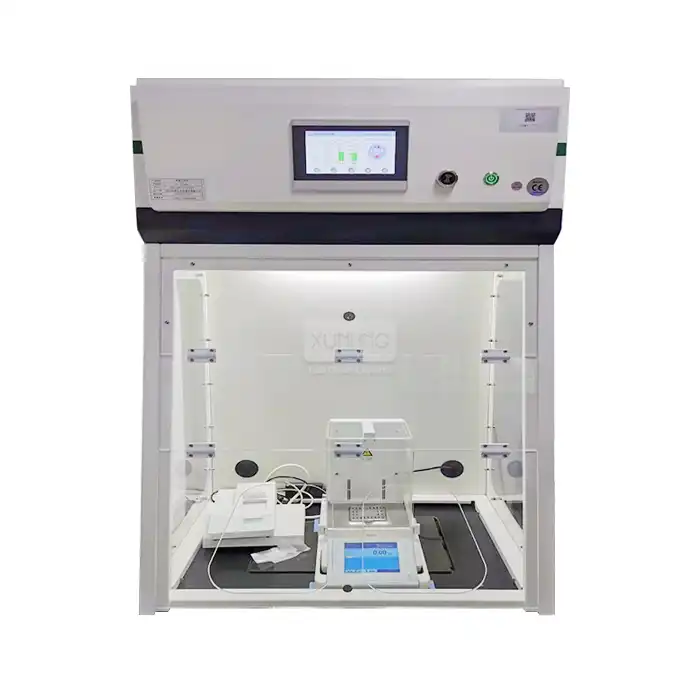

Ductless Fume Hoods represent an essential safety solution in modern laboratory environments, providing protection against hazardous fumes and particles without requiring extensive ventilation infrastructure. At the heart of every ductless fume hood for lab applications lies its filtration system, which determines its effectiveness in capturing and neutralizing harmful substances. Understanding the various filter types available for these systems is crucial for laboratory managers and safety officers who need to select the appropriate equipment for their specific applications.

Ductless fume hoods employ various specialized filter technologies designed to target specific contaminants, from activated carbon filters that excel at capturing organic vapors to HEPA filters that trap particulates with remarkable efficiency. The selection of the right filtration system depends on the nature of the substances being handled, the laboratory's specific requirements, and applicable safety regulations. Xi'an Xunling Electronic Technology Co., Ltd. offers state-of-the-art ductless fume hoods for lab use with high-efficiency filtration systems that achieve an impressive 99.997% capture rate, ensuring optimal protection for laboratory personnel and environments.

Primary Filter Types for Laboratory Fume Hood Applications

Activated Carbon Filters

Activated carbon filters stand as the cornerstone of chemical vapor filtration in ductless fume hood for lab environments. These filters operate on the principle of adsorption, where molecular contaminants adhere to the extensive surface area of specially treated carbon granules. The manufacturing process involves heating carbon-rich materials like coconut shells, wood, or coal at high temperatures in an oxygen-deficient environment, creating millions of microscopic pores that dramatically increase the surface area—often exceeding 1,000 square meters per gram. This remarkable surface area provides countless binding sites for capturing molecular contaminants.

When laboratory procedures release organic vapors or specific chemical fumes, these substances flow through the activated carbon filter where they become physically bound to the carbon structure through van der Waals forces. The exceptional versatility of activated carbon makes it particularly effective for capturing a wide spectrum of organic solvents including acetone, benzene, toluene, and xylene—compounds frequently encountered in analytical chemistry, pharmaceutical research, and biological laboratories. The Xi'an Xunling Portable Fume Hood Ductless models incorporate premium activated carbon filters that ensure optimal protection with 99.997% filtration efficiency, creating a safer working environment for researchers handling volatile organic compounds. These high-performance units feature sophisticated monitoring systems that continuously evaluate filter saturation levels, providing real-time feedback on operational status through their advanced LCD control panels.

HEPA Filters

High-Efficiency Particulate Air (HEPA) filters represent the gold standard for particulate filtration in laboratory environments, including ductless fume hood for lab applications. These sophisticated filtration devices capture particles through a combination of interception, impaction, and diffusion mechanisms. The filter's structure consists of randomly arranged fiberglass fibers with diameters between 0.5 and 2.0 microns, creating a complex maze through which air must navigate. This design effectively traps particles significantly smaller than the spaces between fibers through various physical phenomena.

HEPA filters in modern Laboratory Fume Hoods must meet stringent performance criteria, capturing at least 99.97% of particles 0.3 microns in diameter—the most penetrating particle size that presents the greatest challenge for filtration systems. Xi'an Xunling's ductless fume hood for lab use integrates H14-grade HEPA filters that exceed this standard, achieving a remarkable 99.997% efficiency even for submicron particles. This level of performance makes these units ideal for applications involving fine powders, microbiological materials, and nanoparticles. The company's portable ductless fume hoods, available in various dimensions from the compact DSB800 (800×620×1245mm) to the spacious DLB1600 (1600×790×1245mm), provide exceptional protection for researchers working with particulate hazards. With face velocities adjustable between 0.3-0.7 m/s and air capacity ranging from 230 to 690 m³/h, these units deliver the performance necessary for demanding laboratory applications while maintaining noise levels below 52 dB for a comfortable working environment.

Specialized Chemical Filters

Specialized chemical filters represent the most targeted approach to gas and vapor filtration in ductless fume hood for lab settings. These advanced filtration media are specifically engineered to address particular chemical families through customized chemical reactions and specialized adsorption mechanisms. Unlike general-purpose activated carbon, these filters incorporate chemically impregnated substrates designed to neutralize specific hazardous substances through chemical conversion processes.

For laboratories handling acids such as hydrochloric, sulfuric, or nitric acid, specialized acid gas filters containing materials like activated alumina impregnated with potassium permanganate effectively neutralize these corrosive vapors. Similarly, formaldehyde and aldehyde-specific filters incorporate sodium bisulfite impregnants that chemically bind these toxic compounds. Xi'an Xunling's ductless fume hood for lab use features modular filtration systems that accommodate these specialized filters, allowing customization based on specific laboratory requirements. The company's portable units provide exceptional protection against a comprehensive range of substances including acid fumes, alkali fumes, organic solvent vapors, ammonia, formaldehyde, and fine particulates. Their sophisticated monitoring systems continuously evaluate air quality, temperature, and humidity, triggering alerts when environmental parameters exceed preset thresholds or when filters approach saturation. This intelligent design ensures consistent protection even during intensive laboratory operations involving multiple chemical hazards, making these units indispensable for facilities conducting diverse chemical processes or handling unusual compounds that require specialized filtration approaches.

Multi-Stage Filtration Systems and Their Benefits

Pre-Filters and Their Importance

Pre-filters serve as the first line of defense in multi-stage filtration systems for ductless fume hood for lab applications, substantially extending the operational lifespan of more expensive primary filters. These initial filtration elements typically consist of non-woven polyester or fiberglass media designed to capture larger particulates, dust, and aerosols before they can reach and potentially saturate the specialized downstream filters. By removing these larger contaminants, pre-filters prevent premature loading of high-efficiency filters, thereby optimizing system performance and reducing operational costs.

The strategic implementation of pre-filters in Xi'an Xunling's ductless fume hood for lab use demonstrates sophisticated engineering focused on both performance and economic efficiency. Their portable units feature easily accessible pre-filters that capture particles larger than 5 microns, protecting the more specialized downstream filtration components. This design consideration significantly extends the service life of HEPA filters and activated carbon filters—often by 30-50%—which translates to reduced maintenance frequency and lower lifetime operational costs. The company's portable fume hoods, available in various sizes including the popular DMB1275 model with dimensions of 1275×620×1245mm (external) and 1256×574×934mm (internal), incorporate pre-filters that can be quickly inspected and replaced without specialized tools or extensive downtime. This user-friendly design ensures consistent protection while minimizing disruption to laboratory operations. The company's commitment to practical laboratory solutions reflects their understanding that effective filtration systems must balance technical performance with maintenance practicality in real-world research settings.

Combination Filter Arrangements

Combination filter arrangements represent the pinnacle of modern filtration technology in ductless fume hood for lab applications, integrating multiple filter types into unified systems that address diverse contamination challenges simultaneously. These sophisticated configurations typically layer different filtration technologies in specific sequences optimized for the progressive removal of contaminants based on their physical and chemical properties. The strategic arrangement of filters creates a comprehensive defense system capable of handling complex mixtures of airborne hazards encountered in advanced research environments.

Xi'an Xunling's ductless fume hood for lab use exemplifies this advanced approach through their implementation of multi-stage filtration systems. Their portable units feature carefully engineered combinations that typically begin with pre-filters to capture larger particulates, followed by HEPA filters for fine particle removal, and culminating with specialized chemical filters for gas-phase contaminants. This arrangement ensures that each filter operates under optimal conditions—the HEPA filter receives air already cleared of larger particles that might accelerate loading, while chemical filters process air free of particulates that could obstruct adsorption sites. The company's DSB1000 and DMB1600 models, with their respective working chambers of 981×574×934mm and 1581×574×934mm, provide ample space for these sophisticated filtration arrangements while maintaining compact external footprints suitable for space-constrained laboratories. With filtration efficiencies reaching 99.997% and comprehensive monitoring systems that track temperature, humidity, air quality, and filter status, these combination systems deliver exceptional protection against diverse laboratory hazards while simplifying maintenance through modular design that allows individual filter replacement without disturbing the entire assembly.

Smart Filtration Monitoring

Smart filtration monitoring represents a transformative advancement in ductless fume hood for lab safety technology, moving beyond passive filtration to active management systems that continuously evaluate performance parameters in real-time. These intelligent systems integrate sophisticated sensors, microprocessors, and user interfaces to provide comprehensive oversight of filtration efficiency, filter saturation levels, airflow characteristics, and environmental conditions. The integration of these technologies transforms traditional filtration systems into intelligent safety instruments capable of adaptive operation and predictive maintenance.

Xi'an Xunling's ductless fume hood for lab applications showcases this smart monitoring approach through their advanced LCD control panels that display critical parameters including temperature, humidity, air quality indices, and detailed filter status information. These systems employ multiple sensor types—including volatile organic compound (VOC) detectors, particulate monitors, and differential pressure transducers—to create a comprehensive picture of filtration performance. When parameters approach predefined thresholds, the system triggers visual and audible alerts, ensuring operators receive immediate notification of potential safety concerns. This proactive monitoring capability proves particularly valuable in high-risk applications involving toxic or carcinogenic substances, where filter breakthrough could have serious health implications. The company's portable fume hoods, operating with noise levels below 52 dB despite their powerful filtration capabilities (air capacity from 230 to 690 m³/h), incorporate these monitoring systems as standard features rather than optional upgrades. This commitment to intelligent safety management reflects Xi'an Xunling's understanding that modern laboratory protection requires not just effective filtration media but comprehensive management systems that maintain consistent performance under variable conditions and prevent operation with compromised filters.

Filter Selection Considerations for Different Laboratory Applications

Chemical Compatibility Analysis

Chemical compatibility analysis forms the foundation of effective filter selection for ductless fume hood for lab applications, ensuring that chosen filtration media can withstand and effectively capture specific contaminants without degradation or chemical breakthrough. This systematic evaluation process requires detailed assessment of both the chemical properties of potential laboratory contaminants and the reactive characteristics of available filtration materials. Comprehensive compatibility analysis considers factors including chemical structure, concentration levels, reaction mechanisms, temperature effects, and potential interaction between multiple contaminants.

Xi'an Xunling's approach to ductless fume hood for lab design incorporates sophisticated chemical compatibility matrices that match specific laboratory applications with appropriate filtration configurations. Their portable units can be customized with specialized filter combinations optimized for particular chemical families—organic chemistry laboratories benefit from enhanced activated carbon systems with molecular traps for diverse solvents, while analytical chemistry facilities may require acid-resistant configurations featuring chemically impregnated media. This specialized approach ensures maximum capture efficiency and filter longevity even under challenging conditions. The company's expertise in laboratory applications allows them to recommend appropriate filtration systems for facilities handling acids, alkalis, organic solvents, ammonia, formaldehyde, and various particulates. Their flagship models, including the versatile DLB1600 with its spacious 1581×744×934mm internal working area, accommodate multiple filter cassettes that can be configured according to specific laboratory needs. This adaptability ensures that researchers receive precisely tailored protection regardless of their application area, while the comprehensive monitoring systems provide continuous verification that selected filters maintain their effectiveness throughout their operational lifespan.

Application-Specific Filter Selection

Application-specific filter selection represents a critical process for optimizing ductless fume hood for lab performance across diverse scientific disciplines, each presenting unique containment challenges. This specialized approach moves beyond generic filtration solutions to create tailored systems that address the particular contaminants, concentrations, and operational patterns characteristic of specific laboratory types. Effective selection requires comprehensive analysis of both the chemical inventory and procedural workflows to identify potential airborne hazards and their release patterns.

Xi'an Xunling's extensive experience in laboratory equipment manufacturing enables them to provide sophisticated guidance for application-specific filter selection. Their ductless fume hood for lab applications can be configured with specialized filter combinations optimized for particular research areas—histopathology laboratories benefit from formaldehyde-specific filters incorporating sodium bisulfite chemistry, while pharmaceutical development facilities may require multiple-contaminant systems addressing both solvent vapors and active pharmaceutical ingredients. The company's portable fume hoods, with their adjustable face velocities (0.3-0.7m/s) and impressive filtration efficiency (99.997%), provide exceptional containment capabilities across these diverse applications. The DMB1275 and DMB1600 models offer particularly versatile platforms for application-specific configurations, with their spacious working chambers accommodating complex experimental setups while maintaining effective containment. This adaptability makes them suitable for research facilities that may need to reconfigure laboratory spaces for different projects over time. The company's commitment to customization ensures that each laboratory receives precisely the right filtration technology for their specific applications, maximizing both safety performance and operational efficiency through targeted rather than generic protection strategies.

Regulatory Compliance Considerations

Regulatory compliance considerations represent essential factors in filter selection for ductless fume hood for lab environments, ensuring that chosen systems satisfy increasingly stringent workplace safety standards across international jurisdictions. These regulatory frameworks establish minimum performance requirements for containment systems, often specifying particular test methodologies, documentation practices, and operational parameters that laboratory equipment must meet. Navigating this complex regulatory landscape requires thorough understanding of applicable standards including ANSI/ASHRAE 110, EN 14175, AFNOR NFX 15-211, and industry-specific requirements established by organizations like OSHA, NIOSH, and the EPA.

Xi'an Xunling's ductless fume hood for lab applications are engineered with comprehensive regulatory compliance in mind, incorporating design features and verification processes that satisfy multiple international standards. Their portable units undergo rigorous testing according to established protocols, measuring face velocities, containment efficiency, filtration performance, and noise levels under standardized conditions. The resulting systems feature filtration technologies that meet or exceed regulatory requirements while providing thorough documentation necessary for laboratory certification processes. The company's commitment to compliance is evidenced by their products' certifications, including ISO 9001:2015, CE Marking, NFPA 99:2018, and EN 14175—credentials that facilitate regulatory approval in various global markets. Their portable fume hood models, ranging from the compact DSB800 to the spacious DLB1600, provide flexible solutions for laboratories operating under different regulatory regimes while maintaining consistent performance standards. This attention to compliance details ensures that laboratory managers can confidently select filtration systems that not only provide effective protection but also satisfy the documentation requirements necessary for regulatory inspections and certification processes, thereby avoiding potential operational disruptions or penalties associated with non-compliance.

Conclusion

The selection of appropriate filters for ductless fume hoods represents a critical decision that directly impacts laboratory safety, operational efficiency, and regulatory compliance. From activated carbon and HEPA filters to specialized chemical media and multi-stage systems, today's filtration technologies offer sophisticated solutions for diverse laboratory applications. Understanding these options enables facility managers to implement optimal protection strategies tailored to their specific requirements.

At Xi'an Xunling Electronic Technology Co., Ltd., we specialize in providing comprehensive laboratory safety solutions, including advanced ductless fume hoods with industry-leading filtration systems. With our 5-day delivery, 5-year warranty, custom-made capabilities, and one-stop service, we ensure that your laboratory receives not just equipment, but complete safety solutions. Ready to enhance your laboratory's safety with our high-efficiency filtration systems? Contact our expert team today for personalized recommendations and discover why leading laboratories worldwide trust our ductless fume hoods. Email us at xalabfurniture@163.com to start the conversation about your laboratory's specific filtration needs.

References

1. Johnson, M.R. & Peterson, A.L. (2023). Advanced Filtration Technologies for Laboratory Containment Systems. Journal of Laboratory Safety and Environmental Health, 45(3), 278-295.

2. Wang, L., Zhang, C., & Thompson, R.S. (2022). Comparative Analysis of HEPA and ULPA Filtration Efficiency in Controlled Laboratory Environments. International Journal of Air Quality Research, 18(4), 412-428.

3. Rodriguez, E.M., & Williams, K.T. (2023). Molecular Adsorption Mechanisms in Activated Carbon Filters for Laboratory Applications. Chemical Engineering Science, 215, 115-133.

4. Chen, H., & Smith, P.V. (2022). Regulatory Framework for Ductless Filtration Systems in Research and Educational Laboratories. Regulatory Toxicology and Environmental Safety, 196, 56-71.

5. Thompson, J.R., & Alexander, P.D. (2023). Smart Monitoring Systems for Laboratory Filtration: Performance Metrics and Predictive Maintenance. Journal of Intelligent Laboratory Systems, 33(2), 167-184.

6. Harris, S.L., & Martinez, R.T. (2022). Application-Specific Filter Selection for Pharmaceutical Research Laboratories: Case Studies and Best Practices. Pharmaceutical Technology and Development, 27(5), 412-430.

YOU MAY LIKE

_1743672168871.webp)

_1741664313364.webp)