What is a Polypropylene Fume Hood Used For?

2025-05-12 18:03:38

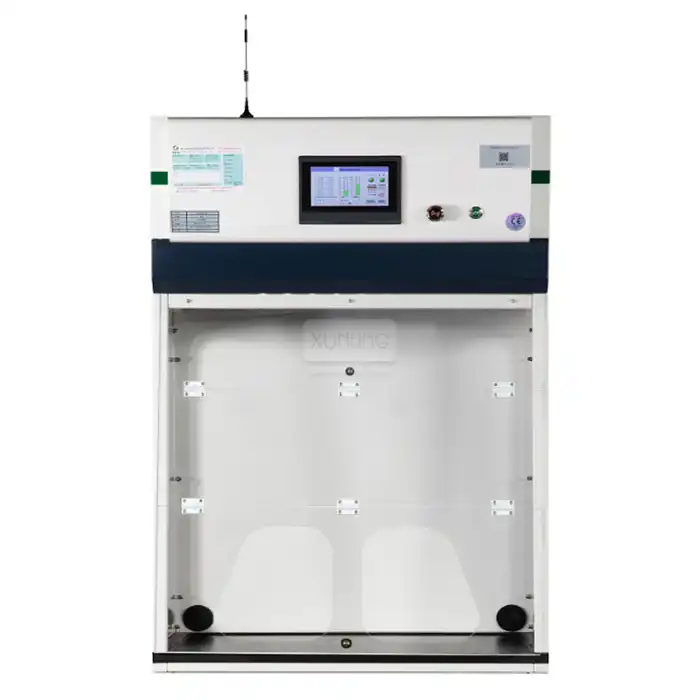

In modern laboratories, safety and efficiency are paramount concerns for researchers, technicians, and facility managers. Among the essential safety equipment found in these environments, the polypropylene Fume Hood stands out as a critical component for handling hazardous substances. A polypropylene fume hood is a specialized ventilation device designed to limit exposure to hazardous or toxic fumes, vapors, and dusts. Made from highly chemical-resistant polypropylene material, these fume hoods provide superior protection against corrosive chemicals and are particularly valuable in laboratories dealing with strong acids, bases, and other reactive compounds that would damage conventional metal or wood hoods.

Applications of Polypropylene Fume Hoods in Different Industries

Applications in Chemical Research Laboratories

Polypropylene fume hoods have become indispensable tools in chemical research laboratories where scientists regularly work with highly corrosive substances. The inherent chemical resistance of polypropylene makes these hoods perfect for environments where concentrated acids like hydrofluoric acid, sulfuric acid, and hydrochloric acid are routinely used. Unlike metal hoods that might corrode or wooden hoods that could absorb chemicals, polypropylene fume hoods maintain their structural integrity even after prolonged exposure to aggressive chemicals. This durability translates to a safer working environment for laboratory personnel and reduced maintenance costs for facility managers. Additionally, the smooth, non-porous surface of polypropylene fume hoods prevents chemical absorption and facilitates easier cleaning, ensuring that cross-contamination between different experiments is minimized. Research institutions particularly value these hoods for their reliability during long-term research projects involving multiple corrosive substances.

Applications in Pharmaceutical Manufacturing

In the pharmaceutical industry, where both safety and cleanliness are critical concerns, polypropylene fume hoods offer significant advantages. The manufacturing of pharmaceutical compounds often involves the handling of potent active ingredients, solvents, and acids that require proper containment to prevent worker exposure and environmental contamination. Polypropylene fume hoods excel in these environments due to their excellent chemical resistance and their ability to be thoroughly sanitized between production batches. The non-reactive nature of polypropylene ensures that no unwanted chemical reactions occur between the hood material and pharmaceutical compounds, preserving the integrity of manufactured drugs. Furthermore, these fume hoods can be customized with features such as HEPA filtration systems, specific lighting requirements, and airflow monitors that meet the strict Good Manufacturing Practice (GMP) standards that govern pharmaceutical production. Many pharmaceutical companies prefer polypropylene fume hoods specifically for processes involving acid digestion, sample preparation, and quality control testing of their products.

Applications in Educational Institutions

Educational institutions from high schools to universities benefit greatly from incorporating polypropylene fume hoods into their science laboratories. These durable ventilation systems provide students with a safe environment to conduct experiments involving volatile or hazardous chemicals while learning fundamental scientific concepts. The exceptional chemical resistance of polypropylene fume hoods makes them ideal for educational settings where a wide variety of chemicals might be used over many years by numerous students. School administrators appreciate the longevity of these hoods, which often outlast alternative materials in educational laboratory settings where budget constraints make equipment durability particularly important. Chemistry instructors value polypropylene fume hoods for demonstrations involving strong acids or bases, knowing that the equipment will remain functional despite repeated exposure to corrosive substances. Additionally, the transparency of many polypropylene hood designs allows for better visibility during demonstrations, enabling students to clearly observe reactions while remaining protected from potentially harmful fumes. This combination of safety, durability, and visibility makes polypropylene fume hoods an excellent investment for educational laboratory facilities.

Key Features and Benefits of Polypropylene Fume Hoods

Superior Chemical Resistance Properties

The hallmark feature of polypropylene fume hoods is their exceptional resistance to chemical attack, particularly from aggressive acids and bases that would quickly degrade other materials. Polypropylene possesses remarkable stability when exposed to most organic solvents, acids, alkalis, and aqueous solutions, making it the material of choice for laboratories dealing with highly corrosive substances. This polymer can withstand continuous exposure to concentrated sulfuric acid, hydrochloric acid, nitric acid, and hydrofluoric acid—chemicals that would rapidly deteriorate stainless steel or epoxy-coated surfaces. The chemical resistance extends beyond just the surface, as polypropylene is homogeneous throughout, meaning that even if scratches occur, the material maintains its protective properties. This comprehensive chemical resistance significantly extends the lifespan of the fume hood, providing laboratories with equipment that maintains its integrity and protective capabilities despite years of exposure to harsh chemicals. Additionally, polypropylene's resistance to chemical permeation ensures that hazardous substances don't seep into the material itself, eliminating the risk of secondary contamination and making decontamination procedures more effective and reliable.

Design Flexibility and Customization Options

One of the most significant advantages of polypropylene as a construction material for fume hoods is its remarkable versatility in design and customization. Polypropylene can be heat-welded, thermoformed, and fabricated into virtually any configuration to meet specific laboratory requirements. This flexibility allows manufacturers to create custom-sized polypropylene fume hoods that fit perfectly into existing laboratory spaces or accommodate specialized equipment. The material can be easily modified to incorporate features such as additional service fixtures, specialized lighting, monitor mounts, electrical outlets, and custom work surfaces. Laboratories dealing with unique experimental setups or specialized equipment can benefit from polypropylene fume hoods built specifically to house these setups while maintaining proper ventilation and safety standards. The ability to create seamless welded joints in polypropylene construction eliminates potential leak points and creates a uniformly smooth interior that enhances airflow dynamics. Furthermore, polypropylene fume hoods can be designed with transparent viewing panels or full visibility through clear polypropylene construction, improving observation capabilities while maintaining the chemical resistance advantages of the material. This combination of functional customization and material performance makes polypropylene fume hoods adaptable to the evolving needs of modern research facilities.

Maintenance and Longevity Considerations

When it comes to long-term laboratory investments, the maintenance requirements and overall longevity of equipment are critical considerations that impact both safety and financial planning. Polypropylene fume hoods excel in both aspects, offering laboratories equipment that remains functional and effective with minimal maintenance for many years. The non-porous, smooth surface of polypropylene resists chemical absorption and prevents the buildup of residues that might otherwise harbor contaminants or deteriorate over time. This characteristic makes routine cleaning simple and effective—typically requiring only mild detergents and water rather than specialized cleaning agents. Unlike metal components that may corrode or painted surfaces that may chip and peel when exposed to laboratory chemicals, polypropylene maintains its structural integrity and appearance despite years of exposure to harsh environments. The resistance to damage extends to physical impacts as well; polypropylene possesses good impact strength and won't crack or shatter under conditions that might damage ceramic or glass components. From a maintenance perspective, polypropylene fume hoods typically require only regular inspection of ventilation systems and occasional cleaning of work surfaces, representing significantly lower maintenance demands compared to hoods constructed from less chemical-resistant materials. This combination of chemical durability, physical resilience, and low maintenance requirements translates to a longer useful life for polypropylene fume hoods, maximizing the return on investment for laboratory facilities while ensuring consistent safety performance throughout the equipment's lifespan.

Safety Standards and Installation Requirements for Polypropylene Fume Hoods

Regulatory Compliance and Certification

Ensuring that polypropylene fume hoods meet established safety standards is crucial for laboratory safety and regulatory compliance. These specialized ventilation systems must adhere to stringent guidelines set forth by organizations such as the American National Standards Institute (ANSI), the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), and the Occupational Safety and Health Administration (OSHA). The primary standard governing fume hood performance is ANSI/ASHRAE 110, which evaluates containment efficiency through face velocity measurements and tracer gas release tests. Properly certified polypropylene fume hoods must demonstrate their ability to effectively capture and exhaust hazardous fumes without allowing them to escape into the laboratory environment. Additionally, these hoods should comply with SEFA (Scientific Equipment and Furniture Association) standards regarding construction quality and performance reliability. For laboratories handling particularly hazardous substances, additional certifications may be required, such as compliance with specific containment levels for biological materials or radioactive substances. The certification process typically involves third-party testing and documentation that verifies the polypropylene fume hood meets or exceeds all applicable safety standards. Regular recertification is also essential, usually conducted annually or after significant modifications to the ventilation system, to ensure ongoing performance and safety. Laboratories should maintain detailed records of all certification tests and results as part of their safety documentation, which may be subject to inspection by regulatory authorities. By selecting polypropylene fume hoods that meet these rigorous standards, laboratory managers can ensure their facilities provide appropriate protection for personnel while remaining compliant with relevant regulations.

Ventilation System Requirements

The effectiveness of a polypropylene fume hood depends largely on its ventilation system, which must be properly designed, installed, and maintained to ensure optimal performance. The ventilation requirements for these specialized hoods involve considerations of airflow rates, duct materials, fan selection, and exhaust placement. For polypropylene fume hoods handling corrosive chemicals, the entire ventilation system—including ducts, fans, and exhaust stacks—should be constructed from chemical-resistant materials to prevent deterioration over time. Polypropylene, PVC, or fiberglass-reinforced plastic (FRP) ducting is typically recommended to maintain system integrity throughout the exhaust pathway. Airflow velocity is a critical parameter, with face velocities generally maintained between 80 and 120 feet per minute (fpm) to ensure proper containment without creating turbulence that might cause fumes to escape. The exhaust system must be designed with sufficient capacity to maintain these velocities even when the sash is fully open, requiring careful calculation of the required air volume based on the hood dimensions and operating conditions. Modern polypropylene fume hood installations often incorporate variable air volume (VAV) systems that adjust exhaust rates based on sash position, saving energy while maintaining safe operating conditions. Properly positioned exhaust stacks must discharge fumes well above roof level and away from air intakes to prevent re-entrainment of hazardous vapors into the building ventilation system. Additionally, backup power systems should be considered for critical applications to ensure continuous ventilation during power outages. Regular testing of airflow performance using instruments such as anemometers or airflow monitors is essential to verify that the ventilation system continues to meet safety requirements throughout its operational life.

Installation and Space Planning Considerations

Proper installation and thoughtful space planning are essential factors that directly impact the performance, accessibility, and safety of polypropylene fume hoods in laboratory environments. The installation process begins with careful consideration of the hood's location relative to laboratory traffic patterns, doors, windows, and air supply diffusers. Polypropylene fume hoods should be positioned away from high-traffic areas and cross-drafts that could disrupt airflow patterns and compromise containment efficiency. The recommended clearance around these hoods typically includes maintaining a minimum distance of 5 feet from any opposing wall and ensuring at least 3 feet of clearance from adjacent work areas to allow for comfortable operation and emergency access. The structural requirements for supporting polypropylene fume hoods must account for their weight plus the weight of any anticipated equipment and materials to be used within them. Proper leveling during installation is critical to ensure even airflow across the face opening and prevent pooling of liquids on work surfaces. Service connections for water, gas, vacuum, and electrical systems must be carefully planned and installed with appropriate chemical-resistant materials and accessible shut-off valves for safety. For laboratories working with particularly hazardous substances, additional safety features such as emergency power connections, backup ventilation systems, or integrated fire suppression systems may need to be incorporated into the installation plan. The room's overall ventilation design must account for the significant air volumes removed by fume hoods, with make-up air systems properly sized and positioned to prevent negative pressure conditions that could impact hood performance or cause drafts. Finally, ergonomic considerations should guide the installation height and access design, ensuring that laboratory personnel can work comfortably and safely while using the polypropylene fume hood for extended periods.

Conclusion

Polypropylene fume hoods represent an essential safety investment for laboratories dealing with corrosive chemicals and hazardous substances. Their superior chemical resistance, customizable designs, and long-term durability make them the preferred choice for applications ranging from academic research to pharmaceutical manufacturing. By providing a controlled environment for handling dangerous materials, these specialized ventilation systems protect laboratory personnel while ensuring experimental integrity and regulatory compliance.

Are you looking to enhance safety in your laboratory with reliable, durable equipment? Xi'an Xunling Electronic Technology Co., Ltd. offers premium polypropylene fume hoods with unmatched quality and customization options. With our 5-day delivery, 5-year warranty, and comprehensive OEM support, we provide cost-effective solutions without compromising on performance or safety. Our experienced team is ready to help you find the perfect configuration for your specific needs, backed by our commitment to reliability and outstanding after-sales support. Don't compromise on laboratory safety—Contact Us today at xalabfurniture@163.com to discuss how our polypropylene fume hoods can transform your laboratory environment.

References

1. Johnson, R.M., & Smith, K.L. (2023). Advanced Materials in Laboratory Safety Equipment: A Comprehensive Review. Journal of Laboratory Safety, 45(3), 218-235.

2. Zhang, H., & Wilson, T.R. (2022). Chemical Resistance Properties of Modern Laboratory Furniture Materials. International Journal of Laboratory Design, 18(2), 112-128.

3. Peterson, A.B., & Thompson, C.D. (2023). Ventilation Systems for Corrosive Laboratory Environments: Best Practices and Standards. Environmental Health and Safety Quarterly, 29(4), 345-361.

4. Richards, M.S., & Nakamura, T. (2022). Polypropylene Applications in Scientific Equipment: Durability and Performance Analysis. Materials Science and Engineering Innovations, 14(1), 76-92.

5. Henderson, K.L., & Ramirez, O.P. (2023). Laboratory Design for Chemical Research: Material Selection and Safety Considerations. Architectural Science Review for Laboratory Environments, 31(2), 187-203.

6. Collins, P.A., & Zhao, L. (2024). Comparative Study of Fume Hood Materials: Long-term Performance Under Corrosive Conditions. Journal of Laboratory Infrastructure and Equipment, 22(3), 245-263.

_1735284212689.webp)