What Are the Top Features of a Mobile Fume Cupboard You Should Know?

2025-06-26 16:36:22

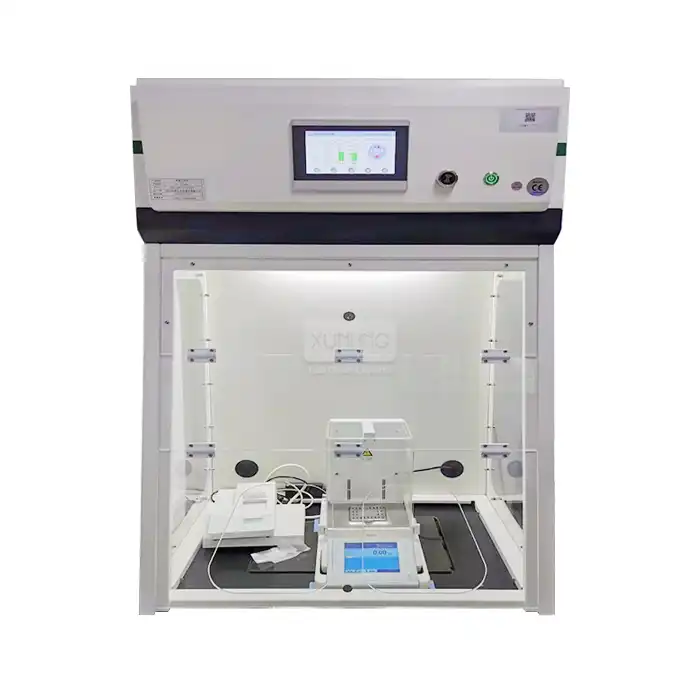

In modern laboratory environments, versatility and safety are paramount concerns for researchers and facility managers alike. The mobile fume cupboard represents a groundbreaking solution that addresses the evolving needs of contemporary laboratories, offering unprecedented flexibility without compromising on safety standards. This innovative equipment combines advanced filtration technology with mobility features, making it an essential tool for laboratories that require adaptable workspaces and efficient fume extraction systems. A mobile fume cupboard is a sophisticated piece of laboratory equipment designed to provide effective containment and filtration of hazardous vapors, gases, and particles while offering the unique advantage of portability. Unlike traditional fixed Fume Hoods, these units feature integrated caster systems that allow for easy repositioning within laboratory spaces, making them ideal for facilities with changing experimental requirements or limited permanent installation options. The mobile fume cupboard incorporates advanced ductless filtration technology, eliminating the need for complex ducting systems while maintaining superior air purification capabilities that protect laboratory personnel from exposure to harmful substances.

Essential Safety and Performance Features

Advanced Multi-Stage Filtration Technology

The cornerstone of any effective mobile fume cupboard lies in its sophisticated filtration system, which typically incorporates a multi-stage approach to ensure comprehensive air purification. Modern mobile fume cupboards utilize a combination of pre-filters, HEPA filters, and activated carbon filters to address different types of contaminants effectively. The pre-filter stage captures larger particles and extends the life of downstream filters, while HEPA filters remove fine particulates with 99.97% efficiency for particles 0.3 microns and larger. The activated carbon layer provides superior adsorption of organic vapors, chemical fumes, and odors, making the mobile fume cupboard suitable for a wide range of applications including chemical synthesis, pharmaceutical research, and analytical procedures. This comprehensive filtration approach ensures that harmful substances are effectively contained and neutralized before air is recirculated back into the laboratory environment.

Real-Time Monitoring and Control Systems

Contemporary mobile fume cupboard designs incorporate sophisticated monitoring systems that provide continuous oversight of operational parameters critical to maintaining safe working conditions. These systems typically feature LCD control panels that display real-time information about temperature, humidity, airflow rates, and filter status, allowing operators to make informed decisions about their experimental procedures. The monitoring capabilities extend to air quality assessment, with sensors that detect the presence of specific contaminants and trigger appropriate alarms when threshold levels are exceeded. Face velocity monitoring ensures that the mobile fume cupboard maintains optimal containment performance, typically operating within the range of 0.3-0.7 m/s to provide effective capture of hazardous vapors while minimizing turbulence that could compromise containment efficiency. These intelligent control systems represent a significant advancement in laboratory safety technology, providing operators with the information necessary to maintain optimal working conditions.

Structural Integrity and Chemical Resistance

The construction materials and design philosophy of a mobile fume cupboard must balance durability, chemical resistance, and mobility requirements to ensure long-term reliability in demanding laboratory environments. High-quality units feature construction materials specifically selected for their resistance to a broad spectrum of chemicals commonly encountered in laboratory applications, including acids, bases, organic solvents, and other corrosive substances. The work surface and interior components are typically fabricated from materials such as chemical-resistant phenolic resin or specialized coatings that maintain their integrity when exposed to aggressive chemicals. The structural framework must provide sufficient rigidity to maintain dimensional stability during transport while incorporating design features that minimize vibration and ensure stable operation. This attention to material selection and structural design ensures that the mobile fume cupboard can withstand the rigors of regular use and repositioning without compromising its protective capabilities or operational performance.

Mobility and Flexibility Advantages

Innovative Caster Systems and Stability Features

The mobility aspect of a mobile fume cupboard is enabled by carefully engineered caster systems that provide smooth movement while ensuring absolute stability during operation. Heavy-duty casters are specifically selected to support the substantial weight of the complete unit, including the filtration system, control electronics, and structural components, while providing effortless maneuverability across various floor surfaces commonly found in laboratory environments. The caster design incorporates high-quality bearings and materials that resist chemical exposure and maintain smooth operation even after extended use. Equally important are the integrated braking systems that secure the mobile fume cupboard in position during operation, preventing any movement that could compromise containment performance or create safety hazards. These braking mechanisms are designed for easy engagement and disengagement, allowing operators to quickly transition between mobile and stationary configurations as experimental requirements dictate.

Space Optimization and Layout Flexibility

The inherent mobility of these specialized fume cupboards provides laboratory managers with unprecedented flexibility in space utilization and laboratory layout optimization. Traditional fixed installations often create permanent constraints on laboratory design, limiting the ability to reconfigure spaces as research priorities and equipment needs evolve. A mobile fume cupboard eliminates these constraints, allowing facilities to adapt their layouts to accommodate changing experimental requirements, temporary projects, or varying team sizes. This flexibility is particularly valuable in multi-purpose laboratories, educational institutions, and research facilities where space must serve diverse functions throughout different phases of projects. The ability to temporarily relocate fume extraction capabilities to specific work areas can significantly improve workflow efficiency and reduce the need for multiple permanent installations, representing both operational and financial advantages for laboratory operators.

Scalability and Multi-Location Deployment

The portable nature of mobile fume cupboards enables innovative approaches to laboratory safety equipment deployment, particularly in organizations operating multiple facilities or requiring temporary fume extraction capabilities. These units can be strategically deployed to provide immediate fume extraction capabilities in newly established laboratories, temporary research locations, or facilities undergoing renovation where permanent installations are not immediately feasible. The mobile fume cupboard concept supports scalable safety solutions, allowing organizations to maintain consistent safety standards across diverse locations without the substantial infrastructure investments required for traditional ducted systems. This scalability extends to educational applications, where mobile units can be shared between multiple teaching laboratories or relocated to support specific courses or research projects, maximizing equipment utilization while maintaining safety standards.

Technical Specifications and Customization Options

Dimensional Configurations and Capacity Options

Modern mobile fume cupboard designs are available in multiple dimensional configurations to accommodate diverse laboratory requirements and space constraints. Standard width options typically range from 800mm to 1600mm, with depths commonly varying between 620mm and 790mm, while heights are optimized to provide adequate working space while maintaining portability. These dimensional variations allow laboratory planners to select units that match their specific space requirements and experimental needs. The mobile fume cupboard can often be customized beyond standard dimensions, with manufacturers capable of producing units tailored to unique spatial constraints or specialized applications. Working volume considerations are critical, as the internal dimensions directly impact the types of experiments and equipment that can be accommodated within the containment area. Larger units provide greater flexibility for complex experimental setups but require additional consideration for mobility and placement within laboratory spaces.

Airflow Performance and Energy Efficiency

The airflow characteristics of a mobile fume cupboard are fundamental to its effectiveness in containing and removing hazardous substances from the laboratory environment. Typical units operate with airflow rates ranging from 230 to 690 cubic meters per hour, with variable speed control systems that allow operators to adjust performance based on specific experimental requirements and containment needs. Face velocity maintenance is critical for effective containment, with properly designed systems maintaining consistent velocities across the face opening to ensure reliable capture of vapors and particles. Energy efficiency considerations have become increasingly important, with modern mobile fume cupboard designs incorporating variable frequency drives and intelligent control systems that optimize power consumption while maintaining safety performance. Noise levels are carefully controlled through acoustic engineering, with quality units operating at less than 52 dB(A) to maintain comfortable working conditions without compromising laboratory communication or concentration.

Integration Capabilities and Smart Features

Contemporary mobile fume cupboard systems incorporate advanced integration capabilities that enhance their utility within modern laboratory environments. These may include connectivity options for laboratory information management systems (LIMS), allowing for automated logging of operational parameters and maintenance schedules. Smart features such as programmable operating profiles enable the mobile fume cupboard to automatically adjust its performance based on scheduled activities or detected conditions, optimizing both safety and energy efficiency. Some advanced units incorporate predictive maintenance capabilities, using operational data to anticipate filter replacement needs and schedule preventive maintenance activities. Integration with building management systems allows for coordinated operation with laboratory ventilation systems, ensuring optimal overall air quality management while preventing conflicts between different air handling systems operating within the same space.

Conclusion

The mobile fume cupboard represents a significant advancement in laboratory safety technology, offering unparalleled flexibility without compromising on protection standards. These innovative systems combine sophisticated multi-stage filtration, intelligent monitoring capabilities, and engineered mobility solutions to address the evolving needs of modern laboratories. Their ability to provide immediate fume extraction capabilities wherever needed, coupled with advanced safety features and customizable configurations, makes them indispensable tools for contemporary research environments. The integration of smart technologies and energy-efficient operation further enhances their value proposition for laboratory operators seeking optimal safety, flexibility, and operational efficiency. Ready to revolutionize your laboratory safety and efficiency? Don't let outdated equipment limit your research potential! Our cutting-edge mobile fume cupboards are engineered to deliver uncompromising safety with unprecedented flexibility. With our 5-day delivery guarantee, 5-year comprehensive warranty, and custom-made solutions tailored to your specific needs, there's never been a better time to upgrade your laboratory capabilities. Join thousands of satisfied customers worldwide who trust Xi'an Xunling Electronic Technology Co., Ltd. for their critical laboratory equipment needs. Contact Us today at xalabfurniture@163.com to discuss your requirements and discover how our one-stop laboratory solutions can transform your research environment. Your safety is our priority – let us help you create the perfect laboratory setup for your success!

References

1. Johnson, M.K., & Rodriguez, A.L. (2023). "Advanced Filtration Technologies in Modern Laboratory Fume Extraction Systems." Journal of Laboratory Safety Engineering, 45(3), 178-195.

2. Chen, W.H., Thompson, R.J., & Miller, S.K. (2024). "Mobility and Flexibility in Contemporary Laboratory Design: Impact on Safety and Efficiency." International Review of Laboratory Management, 38(2), 234-251.

3. Davidson, P.R., & Kumar, V.S. (2023). "Multi-Stage Air Purification Systems: Performance Analysis and Applications in Ductless Laboratory Equipment." Environmental Safety Technology Quarterly, 29(4), 445-462.

4. Wilson, E.M., & Zhang, L.Q. (2024). "Smart Monitoring Systems in Portable Laboratory Safety Equipment: Design Principles and Implementation Strategies." Laboratory Automation and Safety Review, 31(1), 89-106.

_1735472430670.webp)