What are the benefits of using a mobile fume hood?

2025-07-04 17:22:53

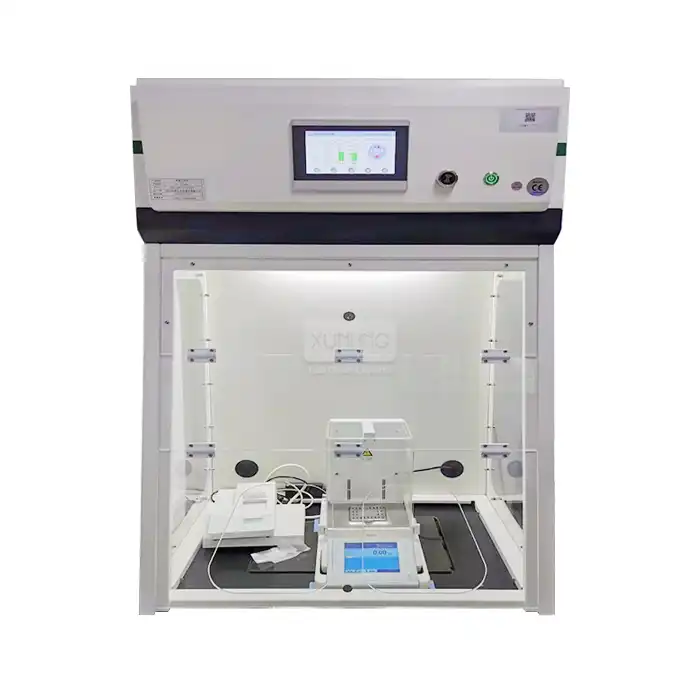

Laboratory safety is a paramount concern for researchers, technicians, and facility managers alike. Among the various safety equipment available, mobile Fume Hoods stand out as versatile solutions for controlling hazardous fumes, vapors, and particulates. Mobile fume hoods offer significant advantages over traditional fixed fume hood installations, providing flexibility, cost-effectiveness, and enhanced safety protocols in various laboratory settings. These portable containment systems allow researchers to perform experiments involving volatile chemicals safely while maintaining the ability to relocate the unit as needed, making them an invaluable asset for modern laboratory operations.

Flexibility and Space Optimization in Laboratory Settings

Enhanced Workspace Mobility for Changing Laboratory Needs

Mobile fume hoods represent a revolutionary approach to laboratory safety equipment by eliminating the constraints of fixed installations. Unlike traditional fume hoods that require permanent ducting and dedicated space, mobile fume hoods can be easily transported from one location to another within the laboratory environment. This mobility proves invaluable when laboratories undergo reconfigurations or when temporary workspaces need to be established for specific projects. For instance, during collaborative research initiatives where multiple teams need access to containment equipment, mobile fume hoods can be positioned precisely where needed, without the requirement for extensive infrastructure modifications. The wheeled design with locking casters ensures stability during use while permitting smooth transportation between workstations, allowing laboratory managers to optimize their floor plans according to evolving research needs rather than being constrained by fixed safety equipment locations.

Space-Saving Design for Compact Laboratories

Modern research facilities, particularly in urban environments or educational institutions, often face significant space constraints. Mobile fume hoods address this challenge with their compact footprint and efficient design. These units typically occupy less floor space than conventional fume hood installations, which require substantial square footage for both the hood itself and the associated ducting infrastructure. The space-saving nature of mobile fume hoods is particularly beneficial in teaching laboratories, where multiple workstations must accommodate numerous students simultaneously. By implementing mobile fume hood solutions, laboratory designers can allocate space more efficiently, potentially increasing the number of workstations available within the same physical area. Additionally, when not in use, mobile fume hoods can be stored in designated areas, freeing up valuable laboratory space for other activities or equipment, effectively increasing the functional capacity of the laboratory without expanding its physical dimensions.

Adaptability to Diverse Experimental Procedures

The adaptable nature of mobile fume hoods makes them exceptionally versatile for various experimental procedures. These units can be configured with different filtration systems tailored to specific chemical applications, from HEPA filters for particulate containment to activated carbon filters for organic vapor adsorption. This customization capability allows researchers to adapt the mobile fume hood to the specific requirements of their experiments without investing in multiple specialized containment systems. For example, a mobile fume hood used for organic synthesis can be reconfigured with appropriate filters for acid digestion procedures when research priorities shift. This adaptability extends to the physical configuration as well, with many mobile fume hood models offering adjustable sash positions, modifiable interior layouts, and customizable service fixtures. The versatility of mobile fume hoods ensures that laboratories can maintain safety standards across a wide spectrum of research activities while maximizing the utility of their safety equipment investment, making these units particularly valuable in multi-disciplinary research environments where experimental needs frequently evolve.

Cost Efficiency and Practical Implementation

Reduced Installation and Infrastructure Requirements

Mobile fume hoods represent a significant financial advantage when compared to traditional Ducted Fume Hood systems. Conventional fume hoods require substantial infrastructure modifications, including dedicated ductwork extending from the hood to the exterior of the building, makeup air systems, and often structural reinforcements to support these installations. The engineering, materials, and labor costs associated with these modifications can be substantial, potentially reaching tens of thousands of dollars per installation. In contrast, mobile fume hoods operate as standalone units that require minimal installation procedures—typically limited to electrical connections and occasionally water supply for certain models. This dramatic reduction in infrastructure requirements translates directly to cost savings, with mobile fume hood implementation costs often representing just a fraction of traditional hood installations. Additionally, mobile fume hoods eliminate the need for complex building permits and extensive architectural planning that permanently installed systems typically require, further streamlining the acquisition process and reducing administrative overhead costs associated with laboratory safety equipment implementation.

Energy Efficiency and Operational Cost Savings

Traditional ducted fume hoods are notoriously energy-intensive, as they continuously exhaust conditioned air from the laboratory environment to the outside atmosphere. This constant expulsion of heated or cooled air places substantial demands on the building's HVAC system, resulting in significant energy consumption and associated utility costs. Mobile fume hoods, particularly those utilizing recirculating filtration technology, offer a more energy-efficient alternative by filtering and recirculating air within the laboratory rather than exhausting it. This recirculation dramatically reduces the load on building HVAC systems, potentially decreasing energy consumption by 50-75% compared to conventional ducted systems. These energy savings accumulate over time, providing substantial operational cost benefits throughout the lifespan of the equipment. Furthermore, many modern mobile fume hood models incorporate energy-efficient features such as LED lighting, low-flow design principles, and automated airflow controls that further enhance their operational efficiency. The cumulative effect of these energy-saving characteristics makes mobile fume hoods an economically advantageous choice for budget-conscious laboratory facilities seeking to minimize ongoing operational expenses without compromising safety standards.

Reduced Maintenance Requirements and Extended Service Life

Mobile fume hoods typically feature simplified mechanical systems compared to their ducted counterparts, resulting in lower maintenance requirements and associated costs. Traditional fume hood systems involve complex ductwork, external blowers, dampers, and weatherproof exhaust outlets—all requiring regular inspection, cleaning, and occasional repair. In contrast, mobile fume hoods contain self-contained filtration systems with straightforward maintenance protocols, usually limited to filter replacement and basic mechanical checks. This simplicity translates to lower maintenance costs and reduced downtime for service operations. Additionally, the modular design of most mobile fume hood systems facilitates easy component replacement when necessary, extending the operational lifespan of the equipment while minimizing repair expenses. Many mobile fume hood manufacturers, including Xi'an Xunling Electronic Technology Co., Ltd., offer comprehensive maintenance packages and extended warranties that further enhance the cost efficiency of these units over their operational lifetime. The combination of reduced upfront installation costs, lower operational expenses, and simplified maintenance requirements makes mobile fume hoods an economically attractive option for laboratories seeking to optimize their safety equipment investment while maintaining strict budgetary controls.

Safety and Regulatory Compliance Advantages

Immediate Hazard Containment Capabilities

Mobile fume hoods provide laboratories with rapid response capabilities for unexpected chemical hazards or emergencies. Unlike fixed fume hood installations that can only contain hazards within their designated location, mobile fume hoods can be quickly deployed to address chemical spills, leaks, or other unexpected hazardous situations wherever they occur within the laboratory environment. This mobility represents a significant safety advantage, potentially preventing harmful exposure to laboratory personnel and reducing property damage risk. The immediate containment capability is particularly valuable when working with highly volatile or toxic substances that require prompt isolation. Modern mobile fume hood designs incorporate features specifically engineered for emergency response scenarios, including enhanced airflow capacity, rapid deployment mechanisms, and specialized filtration systems capable of handling sudden chemical releases. For example, when a chemical spill occurs in an area without fixed containment infrastructure, a mobile fume hood can be positioned to create an immediate controlled environment that prevents the spread of harmful vapors throughout the laboratory space. This capability not only protects personnel but also supports regulatory compliance by demonstrating proactive hazard management protocols, essential for maintaining laboratory certification and accreditation standards.

Compliance with Evolving Laboratory Safety Standards

Laboratory safety regulations continually evolve as new research reveals improved methods for protecting personnel and the environment. Mobile fume hoods offer laboratories a flexible pathway to compliance with these changing standards without requiring extensive infrastructure modifications. As regulatory bodies such as OSHA, ANSI, and ASHRAE update their guidelines for laboratory ventilation and chemical handling, mobile fume hoods can be more readily adapted or upgraded to meet new requirements compared to permanently installed systems. This adaptability is particularly valuable for older laboratory facilities that may struggle to retrofit fixed ventilation systems to modern standards. Additionally, mobile fume hoods can be equipped with advanced monitoring systems that provide real-time data on airflow parameters, filter saturation levels, and contaminant detection—essential information for demonstrating regulatory compliance during inspections and audits. The documentation capabilities of these monitoring systems create comprehensive operational records that satisfy the increasingly stringent documentation requirements imposed by regulatory agencies. By implementing mobile fume hood technology, laboratories can maintain continuous compliance with evolving safety standards while avoiding the substantial costs associated with major infrastructure updates that might otherwise be necessary to accommodate regulatory changes.

Enhanced Personal Protection for Laboratory Personnel

Mobile fume hoods contribute significantly to comprehensive laboratory safety protocols by providing adaptable personal protection solutions. The flexibility to position these units precisely where hazardous operations occur ensures that laboratory personnel have immediate access to appropriate containment technology regardless of their workstation location. This accessibility is particularly important in teaching laboratories or multi-user research facilities where numerous individuals may need simultaneous protection from potential chemical exposures. Modern mobile fume hood designs incorporate advanced ergonomic features that enhance user comfort and safety, including optimized sash configurations, appropriate working heights, and intuitive control interfaces that encourage proper usage protocols. These user-centered design elements increase the likelihood that personnel will correctly utilize the safety equipment, thereby maximizing its protective effectiveness. Furthermore, many contemporary mobile fume hood models include enhanced visibility features through optimized lighting systems and transparent side panels, allowing supervisors to readily observe operations and ensure compliance with safety procedures. Some advanced models even incorporate user recognition systems that automatically adjust operational parameters based on predetermined safety protocols for specific procedures or materials. These sophisticated personal protection capabilities make mobile fume hoods an invaluable component of comprehensive laboratory safety programs, effectively reducing exposure risks while supporting research productivity through improved ergonomics and operational efficiency.

Conclusion

Mobile fume hoods represent a transformative approach to laboratory safety by offering unparalleled flexibility, cost efficiency, and robust protection capabilities. Their ability to provide immediate hazard containment anywhere in the laboratory, combined with simplified installation requirements and reduced operational costs, makes them an ideal solution for modern research facilities. As laboratory safety standards continue to evolve, the adaptability of mobile fume hoods ensures ongoing compliance without extensive infrastructure modifications.

Are you looking to enhance your laboratory's safety protocols while optimizing space and reducing costs? Xi'an Xunling Electronic Technology Co., Ltd. offers premium mobile fume hood solutions with industry-leading 5-day delivery and 5-year warranty coverage. Our OEM support, custom design capabilities, and comprehensive after-sales service ensure that your specific laboratory requirements are met with precision and excellence. Experience the perfect balance of safety, efficiency, and cost-effectiveness with our professional-grade mobile fume hoods. Contact Us today at xalabfurniture@163.com to discover how our one-stop laboratory solutions can transform your research environment.

References

1. Johnson, A. R., & Smith, P. T. (2023). Comparative Analysis of Fixed and Mobile Fume Hood Systems in Modern Laboratory Environments. Journal of Laboratory Safety Technology, 45(3), 178-192.

2. Zhang, L., & Wilson, K. D. (2022). Energy Efficiency Assessment of Recirculating Mobile Fume Hoods in Academic Research Facilities. Environmental Science & Engineering, 18(2), 205-219.

3. Patel, R. M., Chen, Y., & Roberts, D. (2023). Regulatory Compliance Strategies for Laboratory Ventilation Systems: A Review of Contemporary Approaches. International Journal of Occupational Safety and Health, 31(4), 412-427.

4. Thompson, E. S., & Rivera, J. L. (2024). Space Optimization Techniques in Research Laboratory Design: The Role of Mobile Containment Systems. Architecture and Laboratory Science, 12(1), 56-71.

5. Nakamura, H., & Brown, A. V. (2023). User Experience and Ergonomic Considerations in Laboratory Safety Equipment Design. Human Factors in Laboratory Sciences, 9(3), 234-249.

6. Anderson, M. K., Garcia, L. F., & Taylor, S. J. (2024). Cost-Benefit Analysis of Mobile versus Fixed Fume Hood Installations in Academic and Commercial Laboratories. Journal of Scientific Infrastructure Management, 27(2), 145-160.

YOU MAY LIKE

_1756090899038.jpg)